Patents

Literature

66results about "Crystallization conditions screening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High throughput screening of crystallization of materials

InactiveUS7052545B2Sequential/parallel process reactionsFrom normal temperature solutionsHigh-Throughput Screening MethodsSize determination

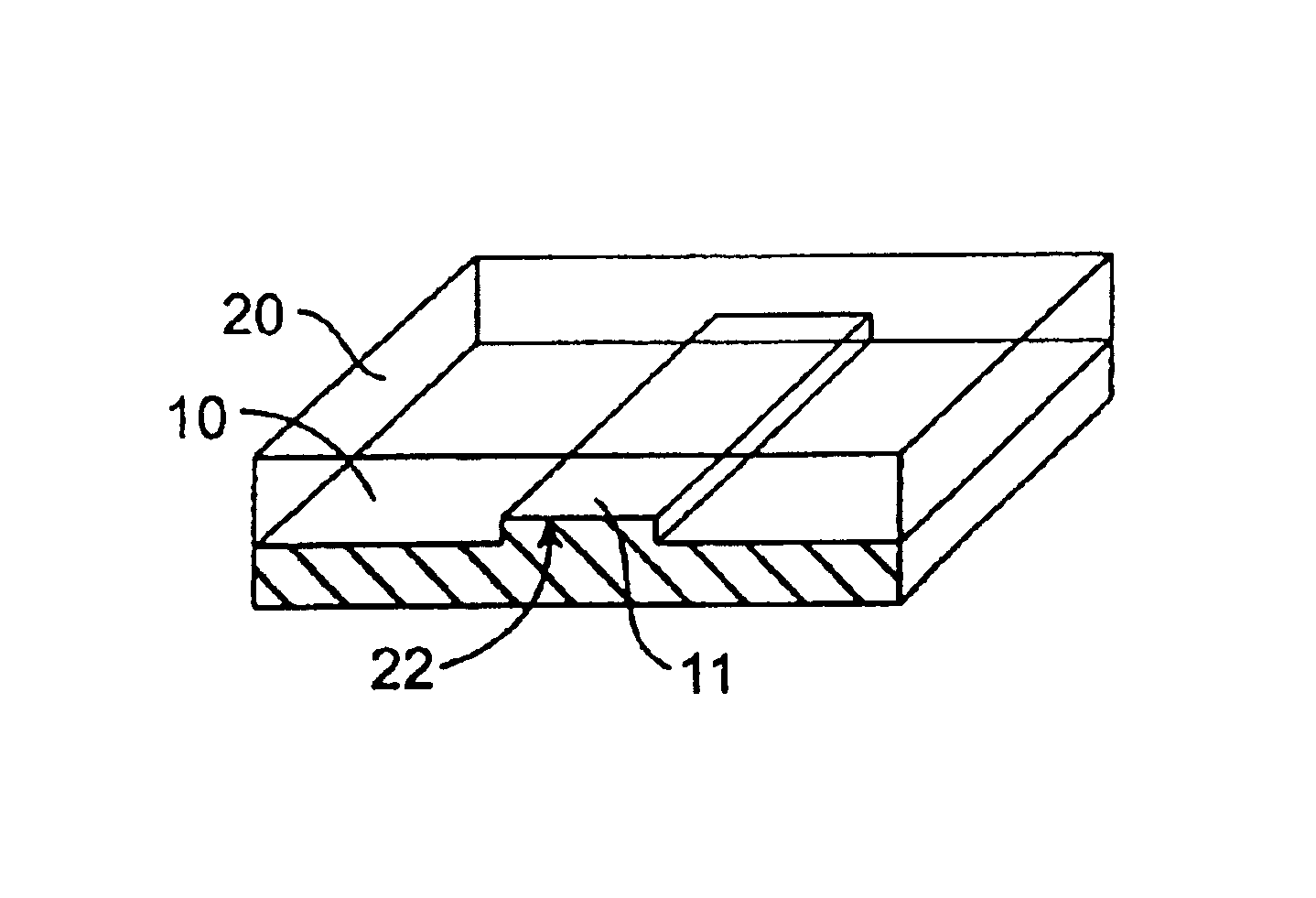

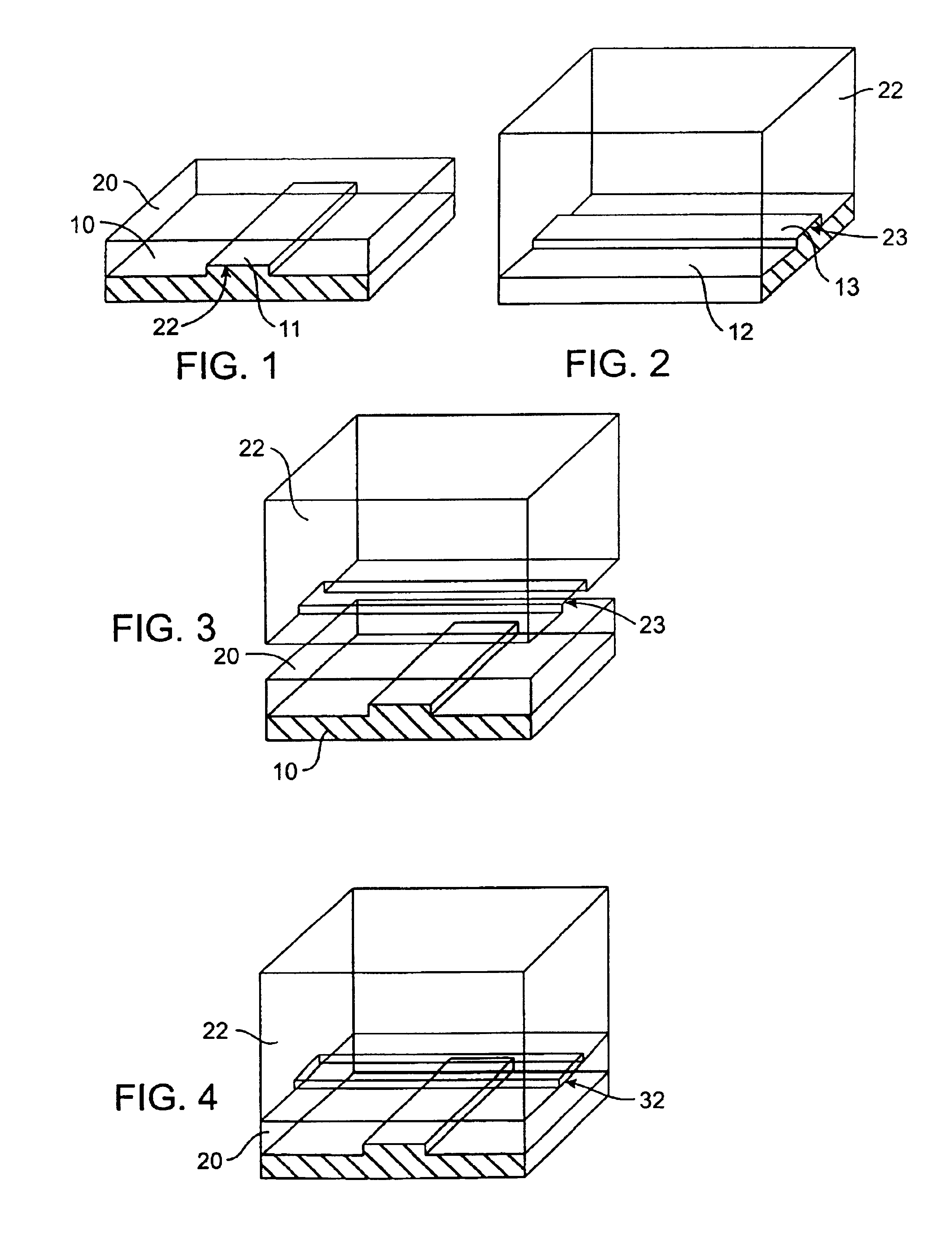

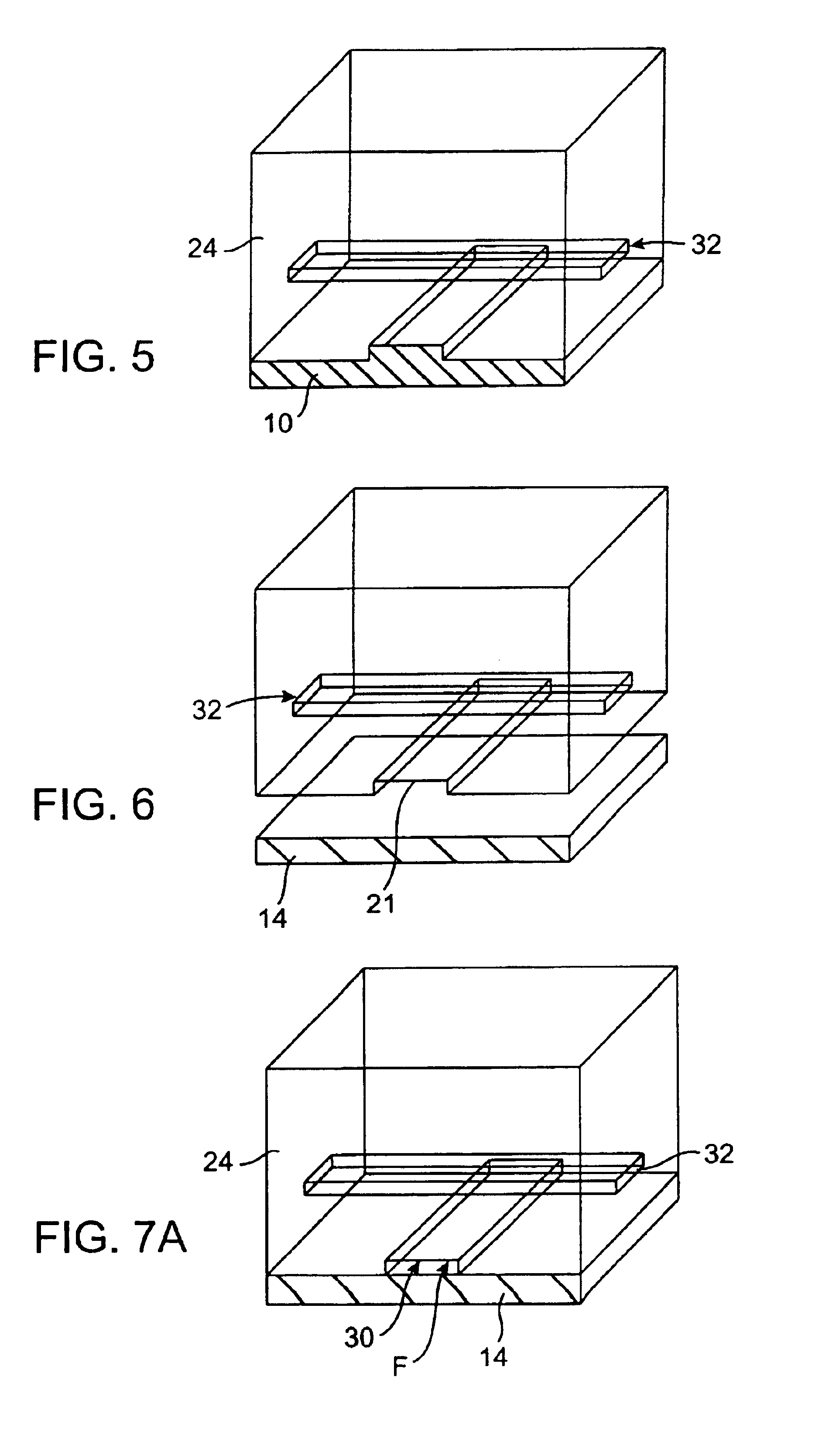

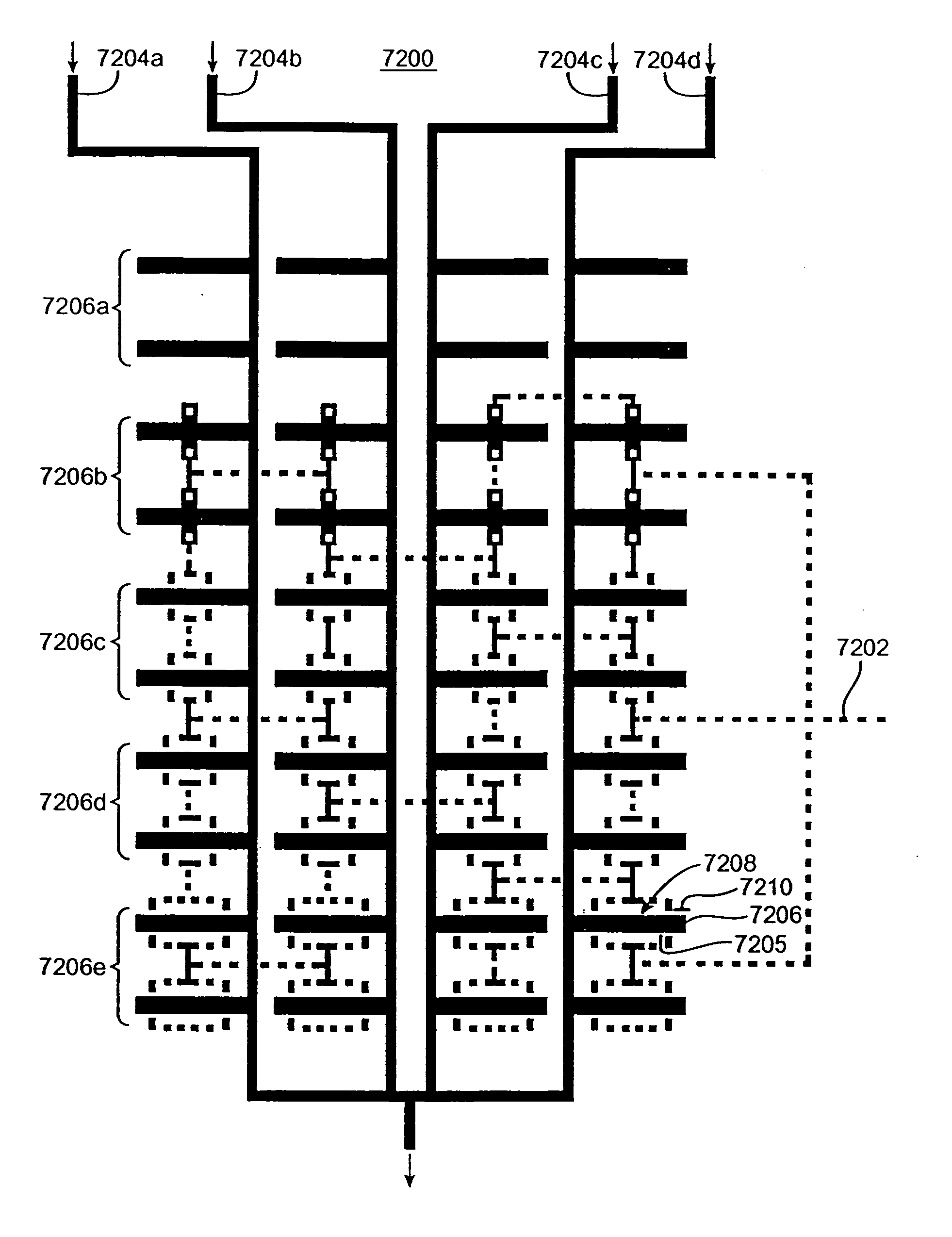

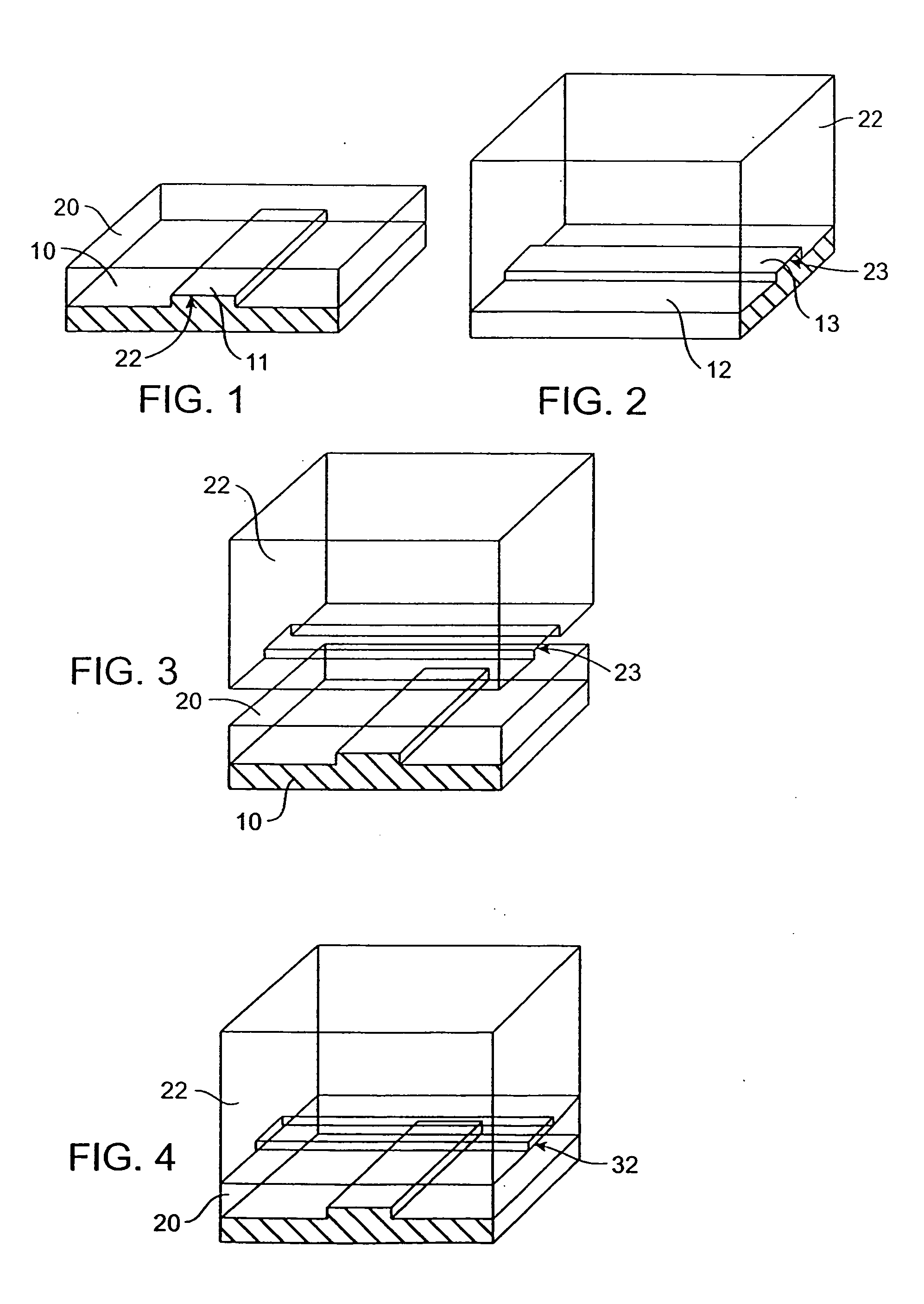

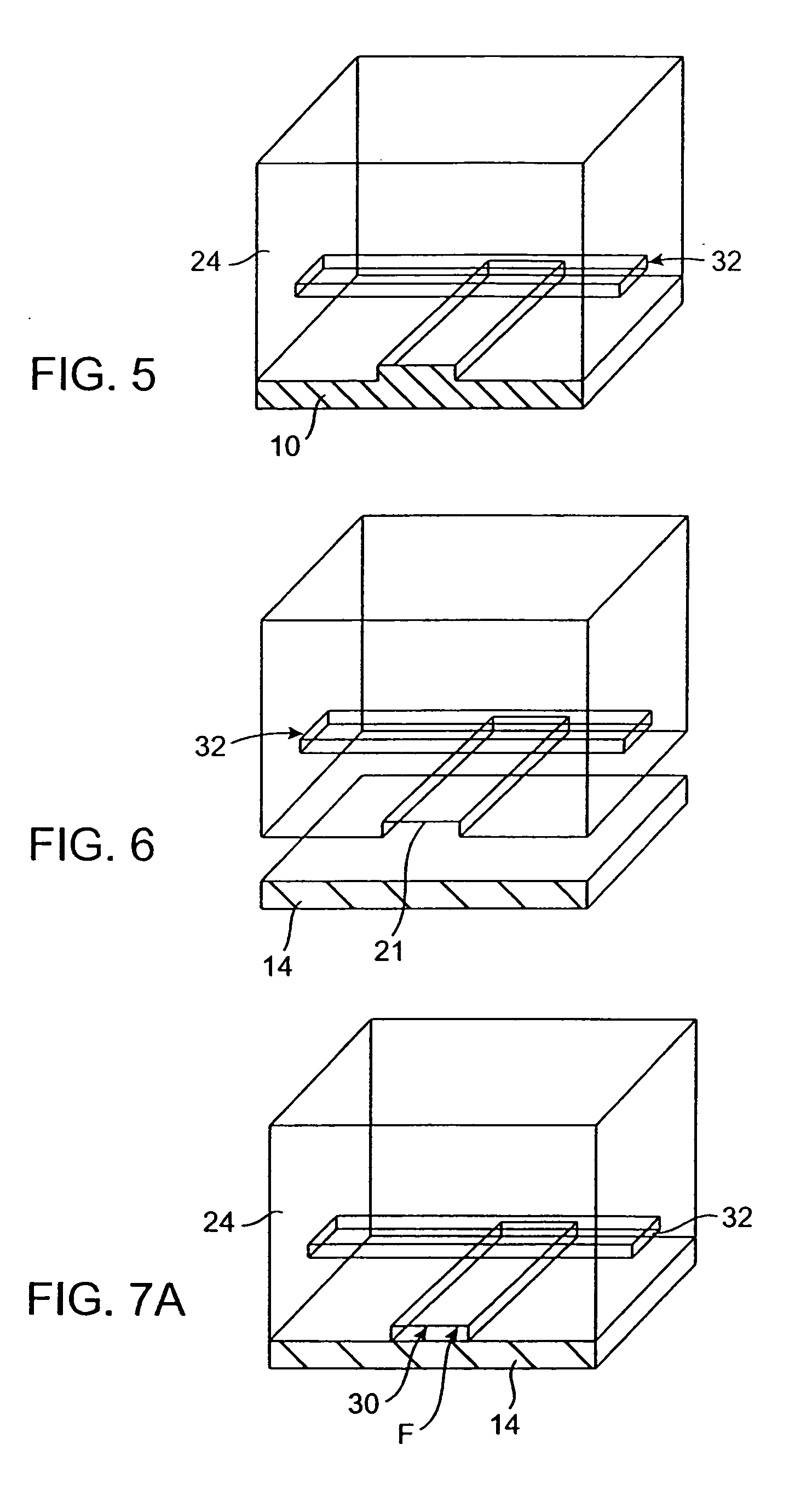

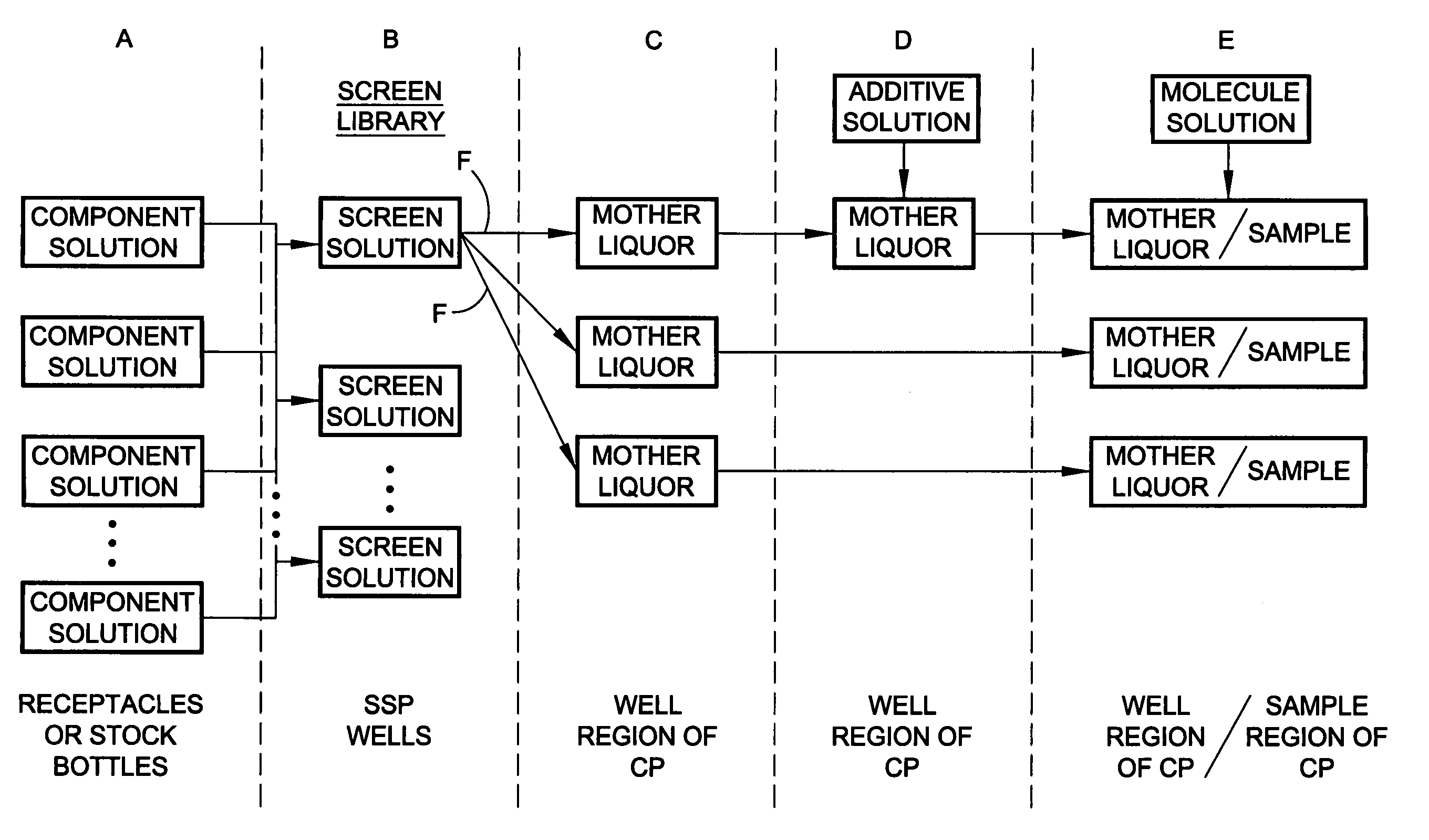

High throughput screening of crystallization of a target material is accomplished by simultaneously introducing a solution of the target material into a plurality of chambers of a microfabricated fluidic device. The microfabricated fluidic device is then manipulated to vary the solution condition in the chambers, thereby simultaneously providing a large number of crystallization environments. Control over changed solution conditions may result from a variety of techniques, including but not limited to metering volumes of crystallizing agent into the chamber by volume exclusion, by entrapment of volumes of crystallizing agent determined by the dimensions of the microfabricated structure, or by cross-channel injection of sample and crystallizing agent into an array of junctions defined by intersecting orthogonal flow channels.

Owner:RGT UNIV OF CALIFORNIA +1

High throughput screening of crystallization of materials

InactiveUS20050229839A1Sequential/parallel process reactionsFrom normal temperature solutionsHigh-Throughput Screening MethodsSize determination

High throughput screening of crystallization of a target material is accomplished by simultaneously introducing a solution of the target material into a plurality of chambers of a microfabricated fluidic device. The microfabricated fluidic device is then manipulated to vary the solution condition in the chambers, thereby simultaneously providing a large number of crystallization environments. Control over changed solution conditions may result from a variety of techniques, including but not limited to metering volumes of crystallizing agent into the chamber by volume exclusion, by entrapment of volumes of crystallizing agent determined by the dimensions of the microfabricated structure, or by cross-channel injection of sample and crystallizing agent into an array of junctions defined by intersecting orthogonal flow channels.

Owner:CALIFORNIA INST OF TECH +1

Screening for solid forms by ultrasound crystallization and cocrystallization using ultrasound

InactiveUS20110251426A1Raise the possibilitySignificant comprehensive benefitsCrystallization conditions screeningOrganic chemistryActive agentMedicine

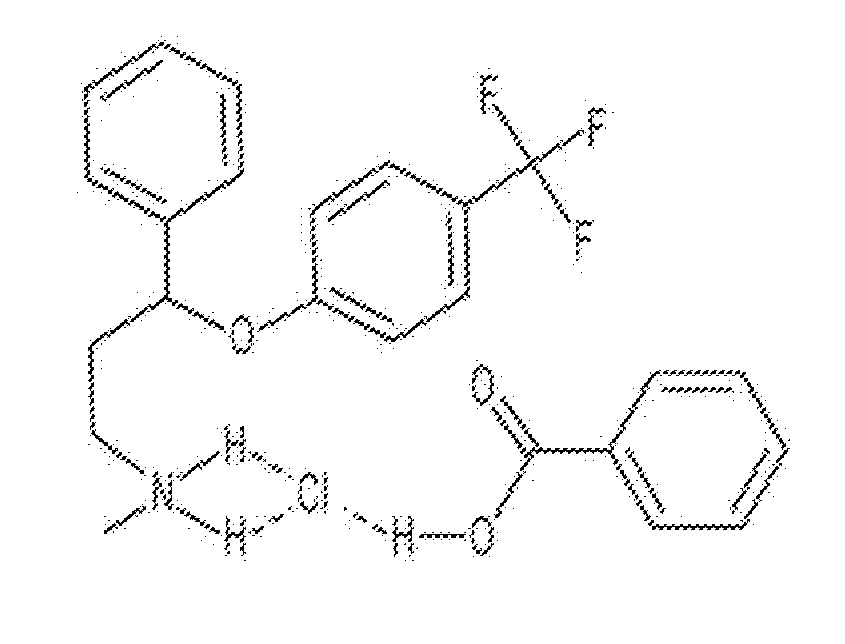

The present disclosure relates to crystallizing a chemical substance(s) using ultrasound. Methods are provided for screening a chemical substance according to its solid forms by using ultrasound to generate new or unusual solid forms. Methods are also provided for crystallizing a chemical substance by novel techniques that include sonication. The present disclosure also relates to cocrystallization using ultrasound. Methods are provided for preparing cocrystals of an active agent and a guest by sonicating and crystallizing. Methods are also provided for screening a sample according to solid state phases (such as cocrystals and salts) and include generating a cocrystal from the sample using ultrasound.

Owner:AMRI SSCI

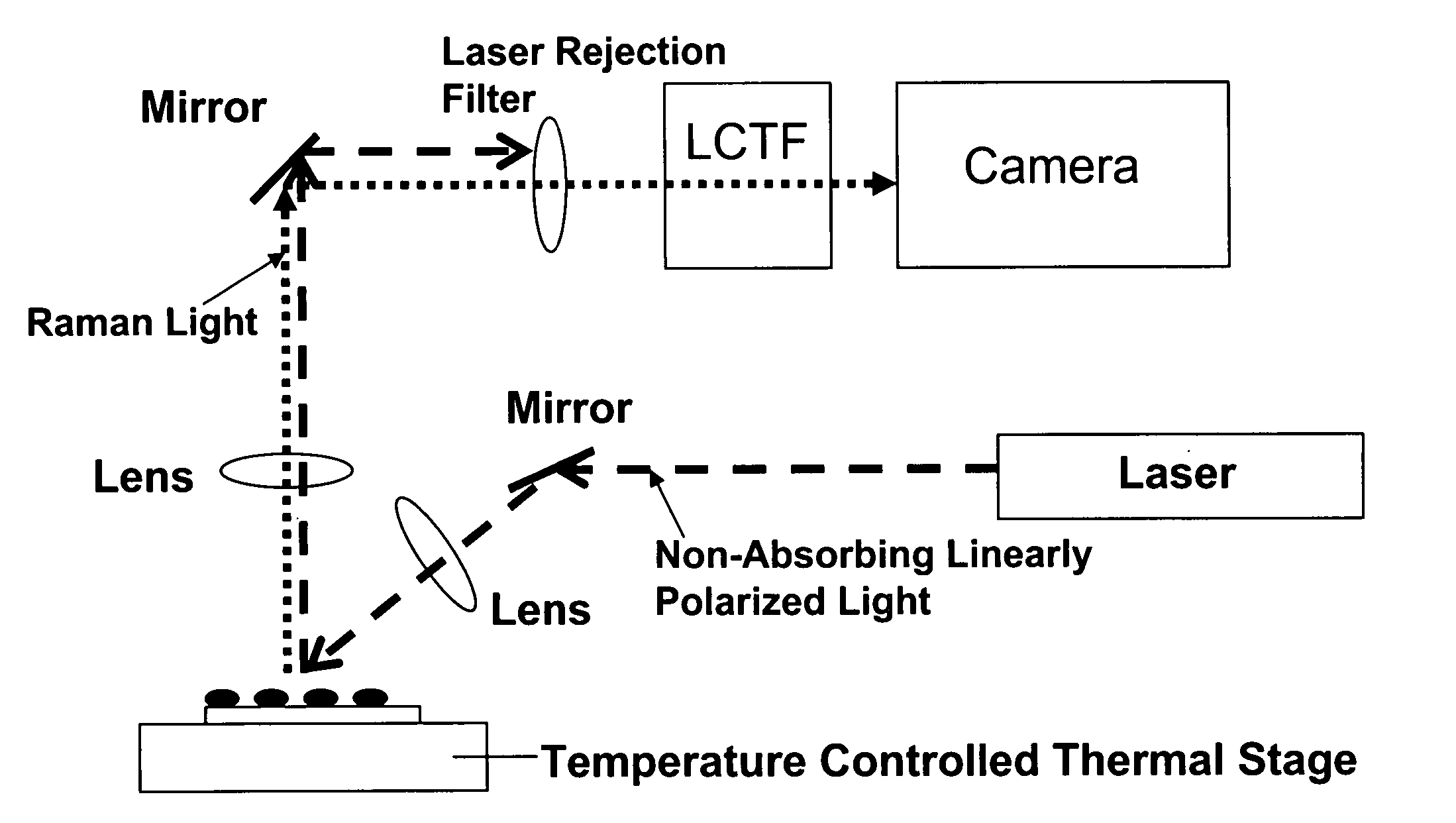

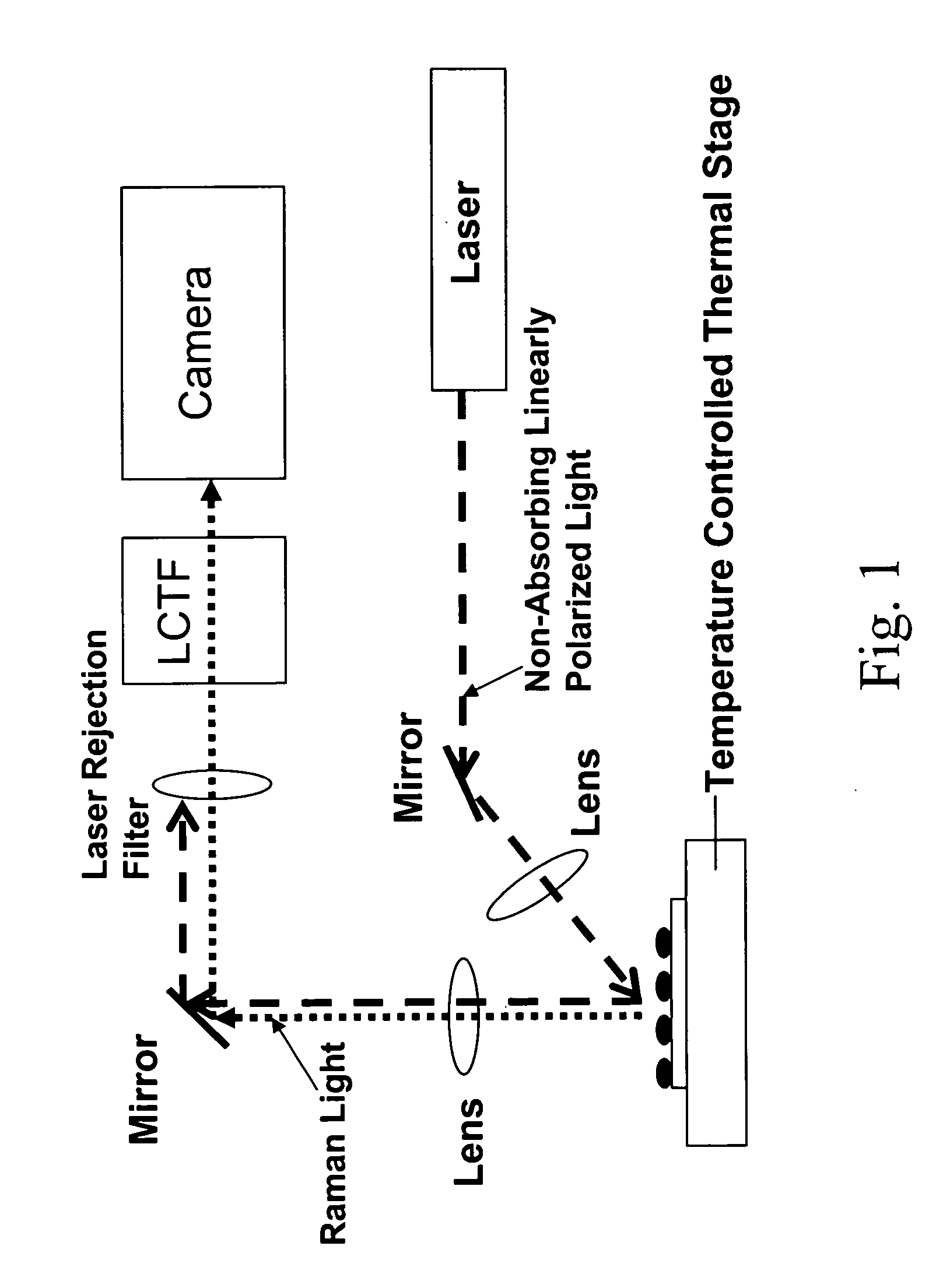

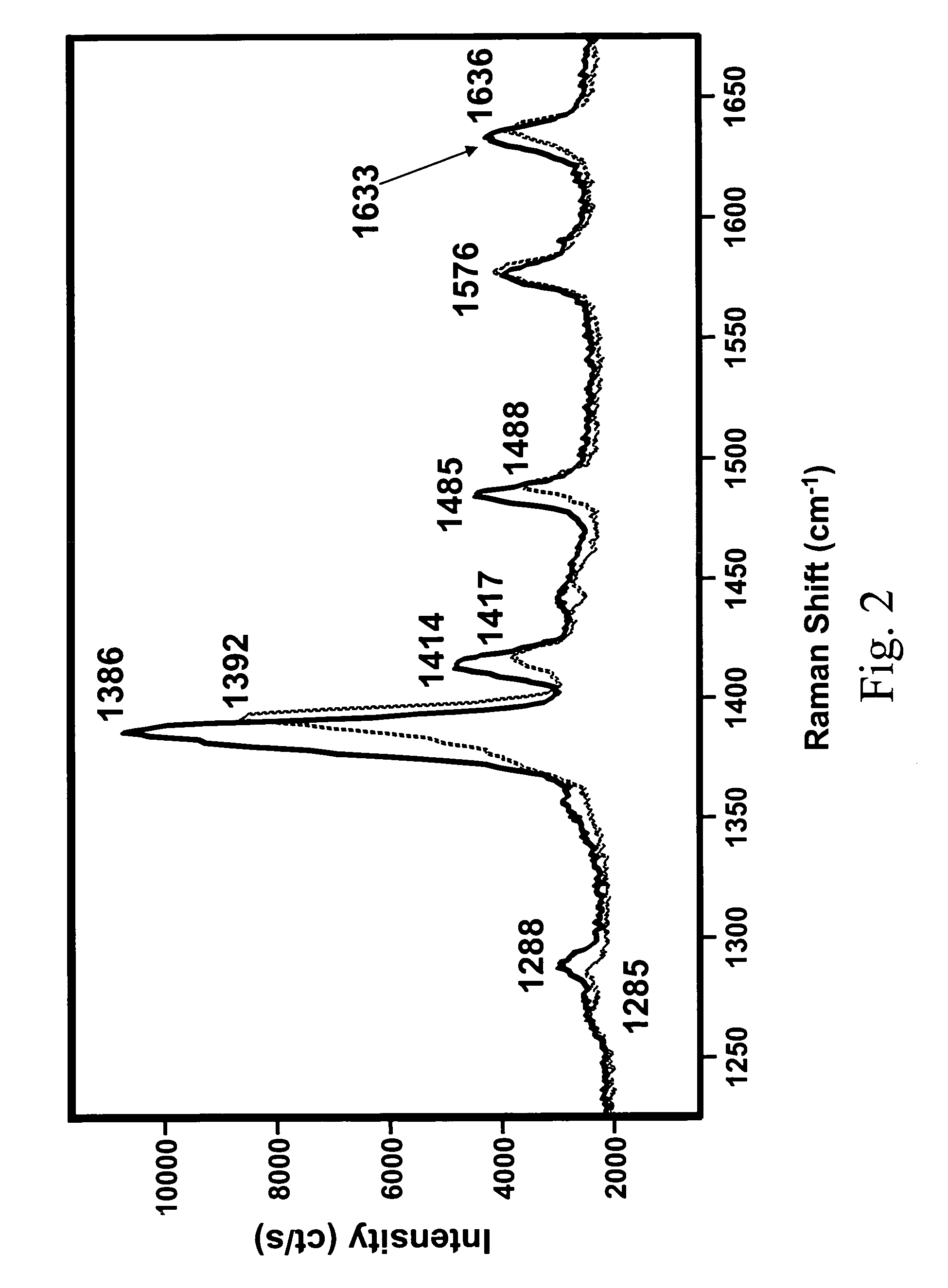

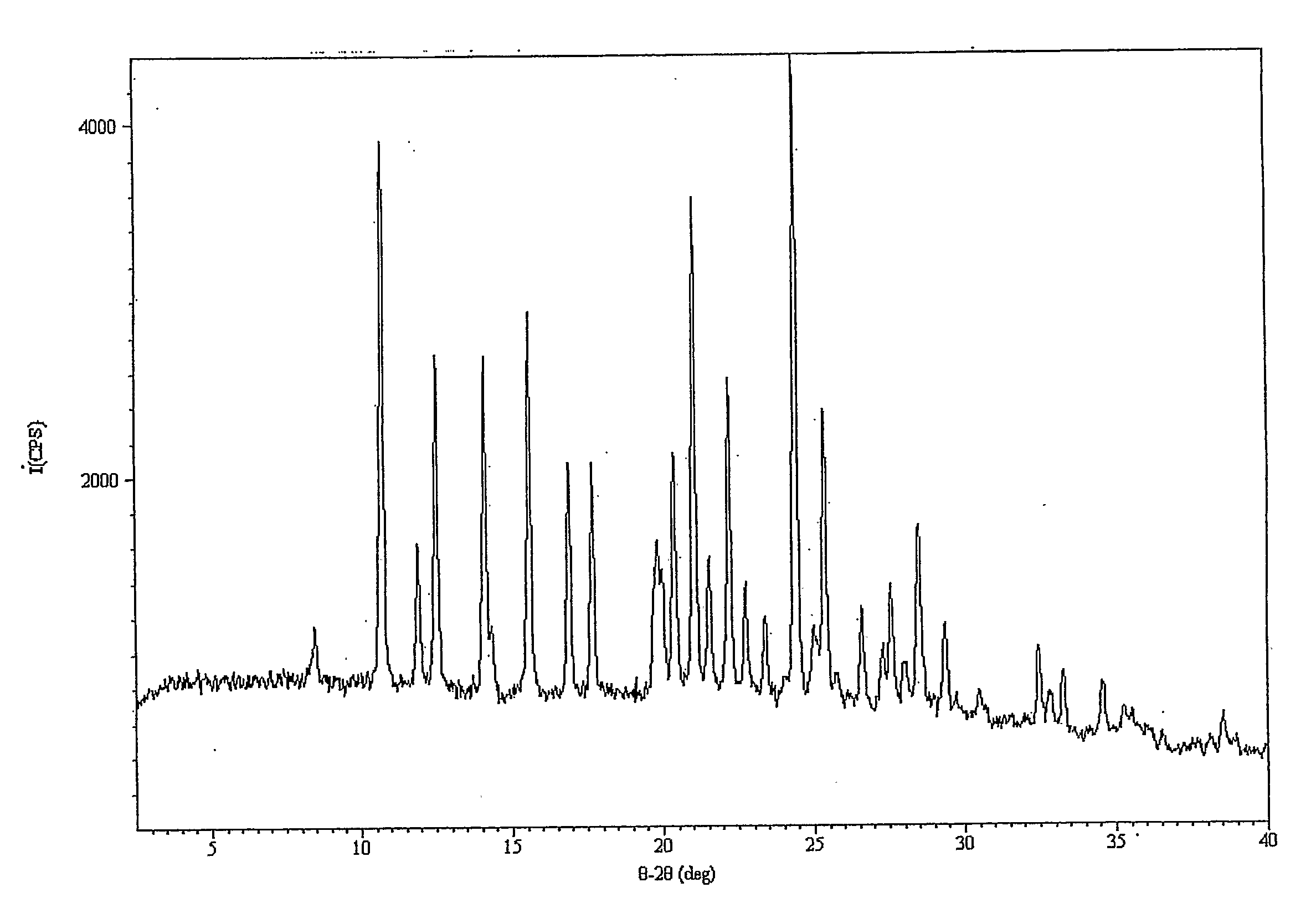

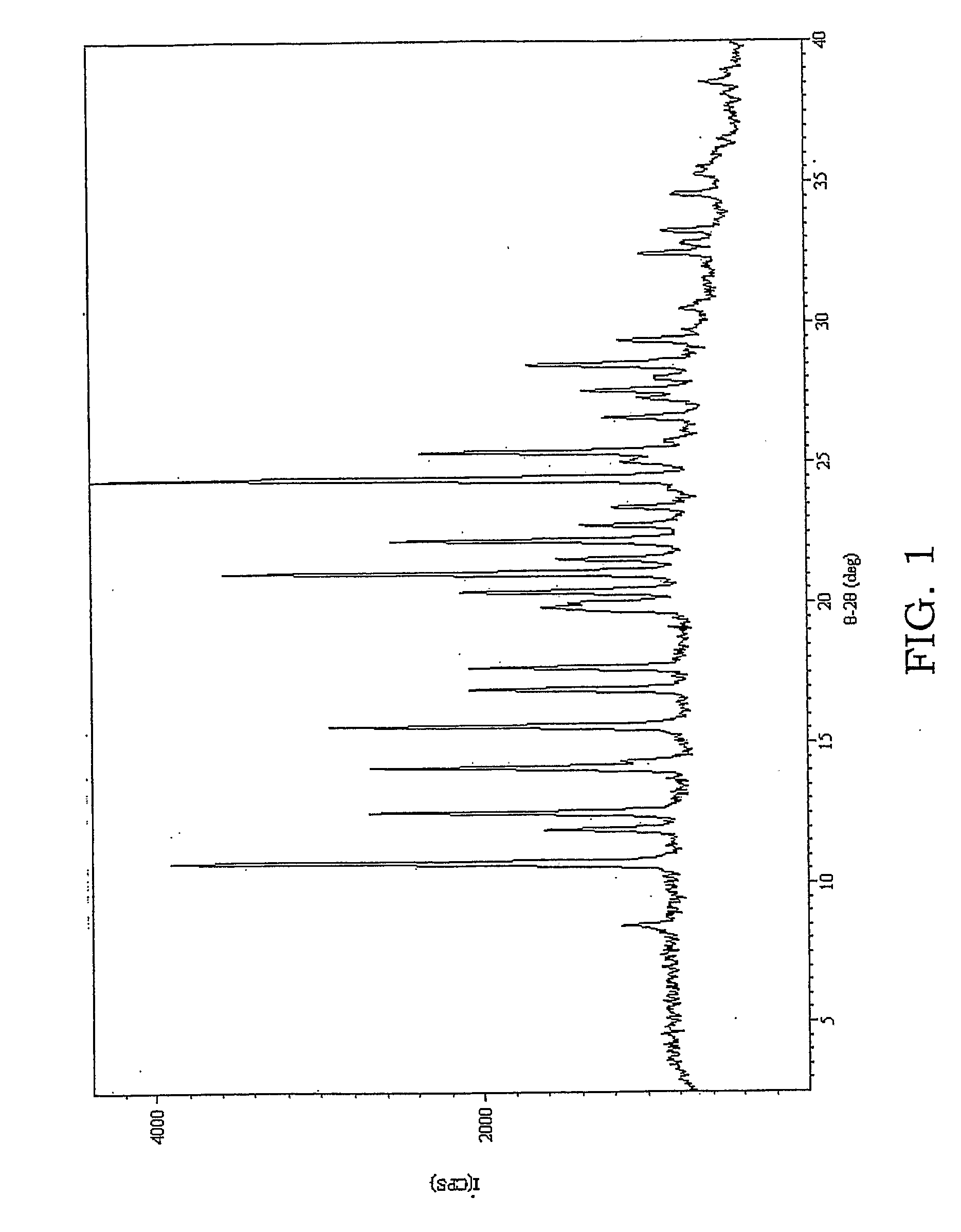

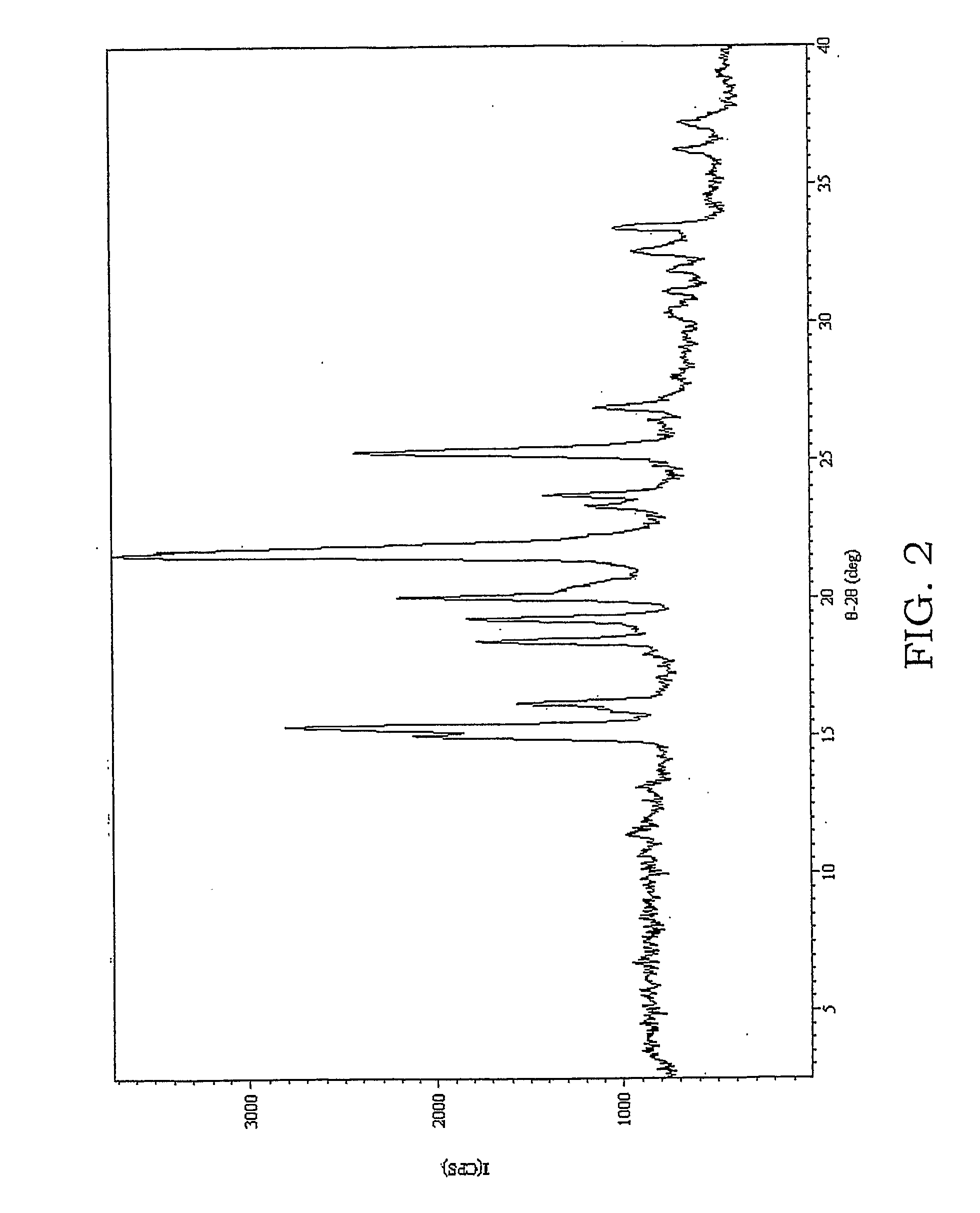

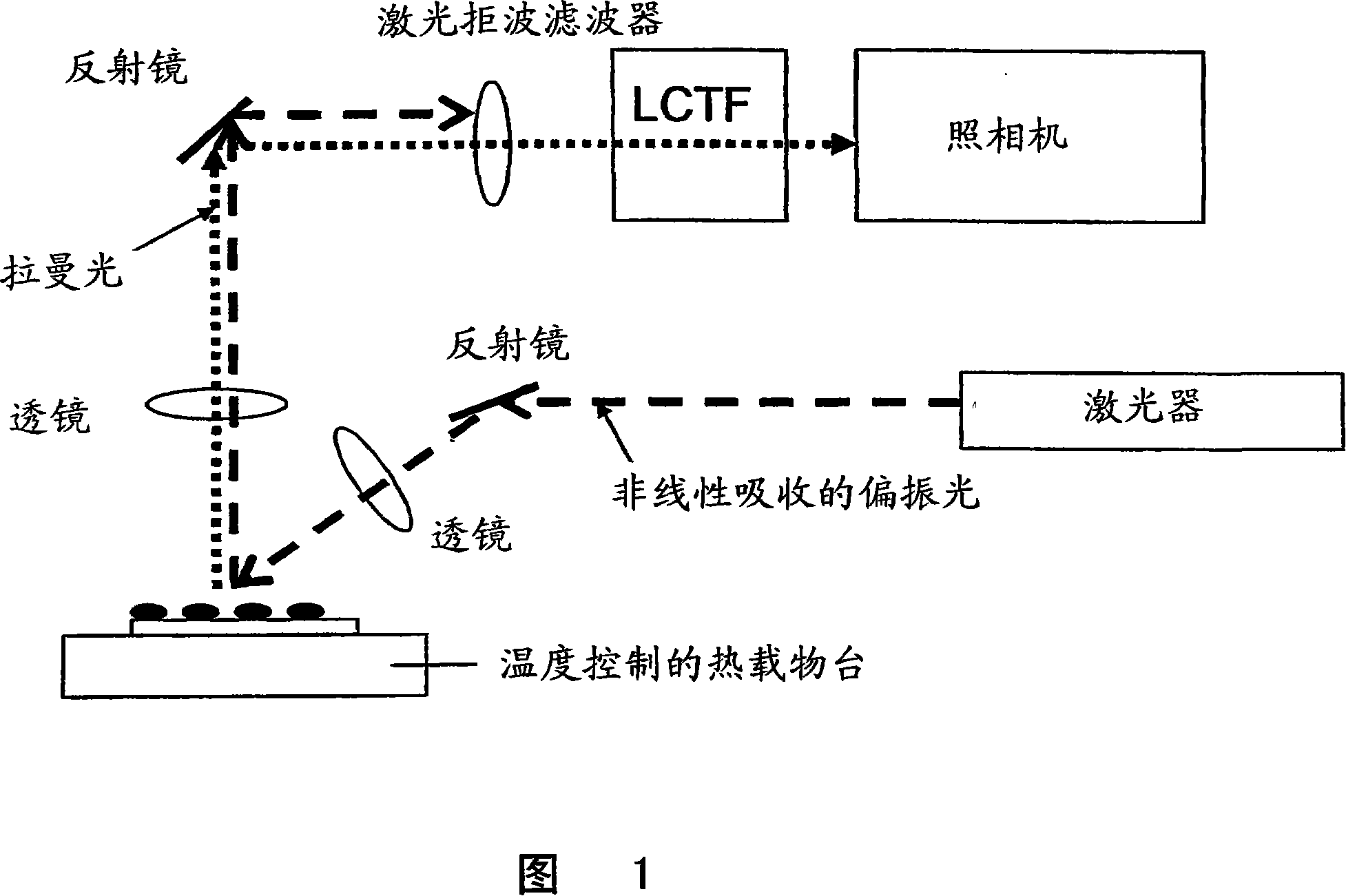

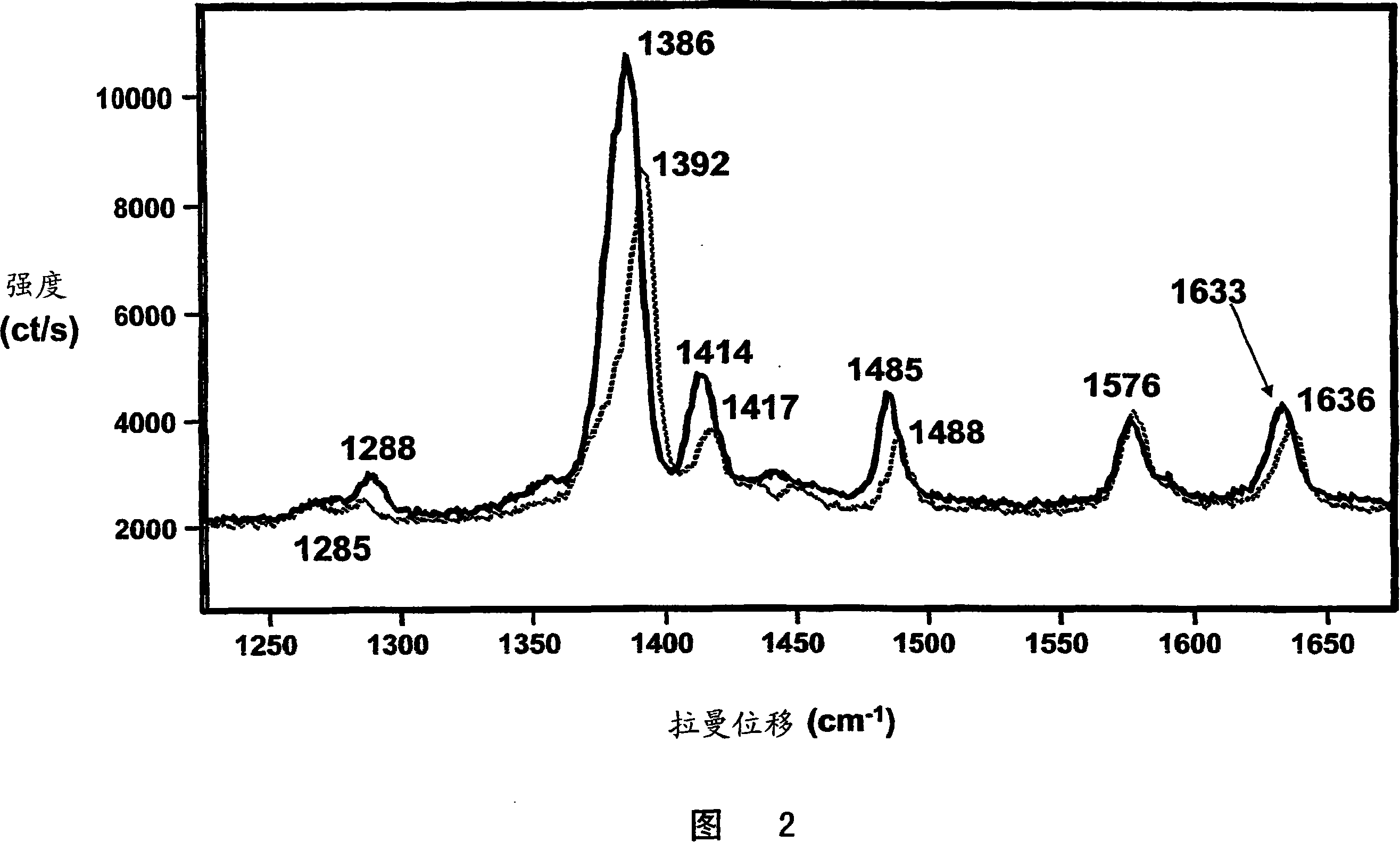

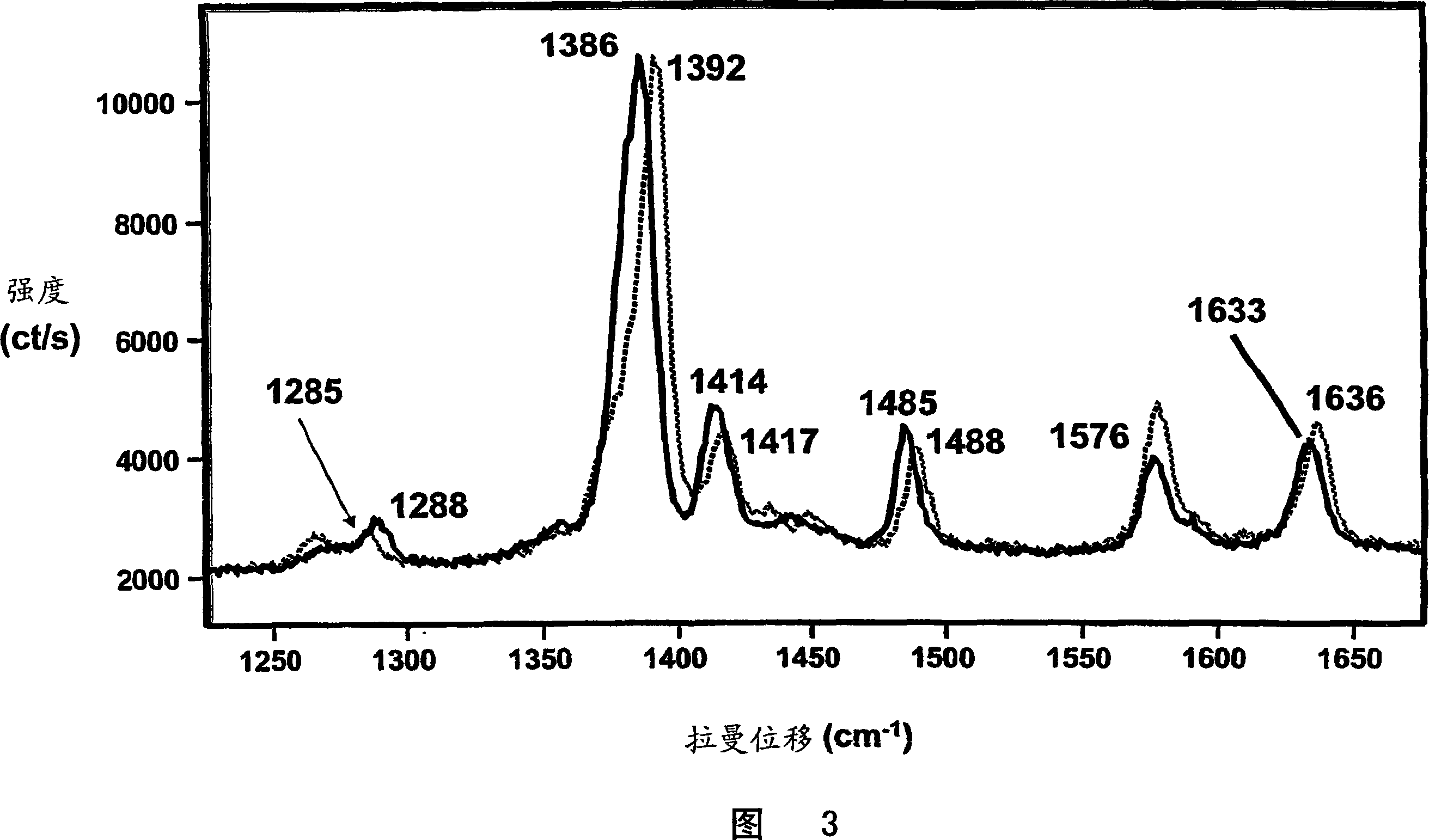

Control and monitoring of non-resonant radiation-induced nucleation, crystallization, and polymorph formation

InactiveUS20060124443A1Crystallization conditions screeningOrganic compound preparationOptical radiationEngineering

The invention relates to methods of assessing the polymorphic form of a substance by assessing Raman-shifted radiation scattered by a particle of the substance. The method is useful, for example, for assessing particle sizes and size distributions in mixtures containing both particles of the substance and other materials. The invention also relates to methods of selecting and controlling polymorph formation by illuminating a material with non-resonant (i.e., non-absorbed) laser radiation as it is thermally driven through a phase transition temperature.

Owner:CHEMIMAGE

Screening For Solid Forms By Ultrasound Crystallization And Cocrystallization Using Ultrasound

InactiveUS20070287194A1Significant comprehensive benefitsRaise the possibilityCrystallization conditions screeningOrganic chemistrySonificationActive agent

The present disclosure relates to crystallizing a chemical substance(s) using ultrasound. Methods are provided for screening a chemical substance according to its solid forms by using ultrasound to generate new or unusual solid forms. Methods are also provided for crystallizing a chemical substance by novel techniques that include sonication. The present disclosure also relates to cocrystallization using ultrasound. Methods are provided for preparing cocrystals of an active agent and a guest by sonicating and crystallizing. Methods are also provided for screening a sample according to solid state phases (such as cocrystals and salts) and include generating a cocrystal from the sample using ultrasound.

Owner:AMRI SSCI

Control and monitoring of non-resonant radiation-induced nucleation, crystallization, and polymorph formation

InactiveCN101084049ACrystallization conditions screeningOrganic chemistry methodsNucleationTransition temperature

The invention relates to methods of assessing the polymorphic form of a substance by assessing Raman-shifted radiation scattered by a particle of the substance. The method is useful, for example, for assessing particle sizes and size distributions in mixtures containing both particles of the substance and other materials. The invention also relates to methods of selecting and controlling polymorph formation by illuminating a material with non-resonant (i.e., non-absorbed) laser radiation as it is thermally driven through a phase transition temperature.

Owner:CHEMIMAGE CORP

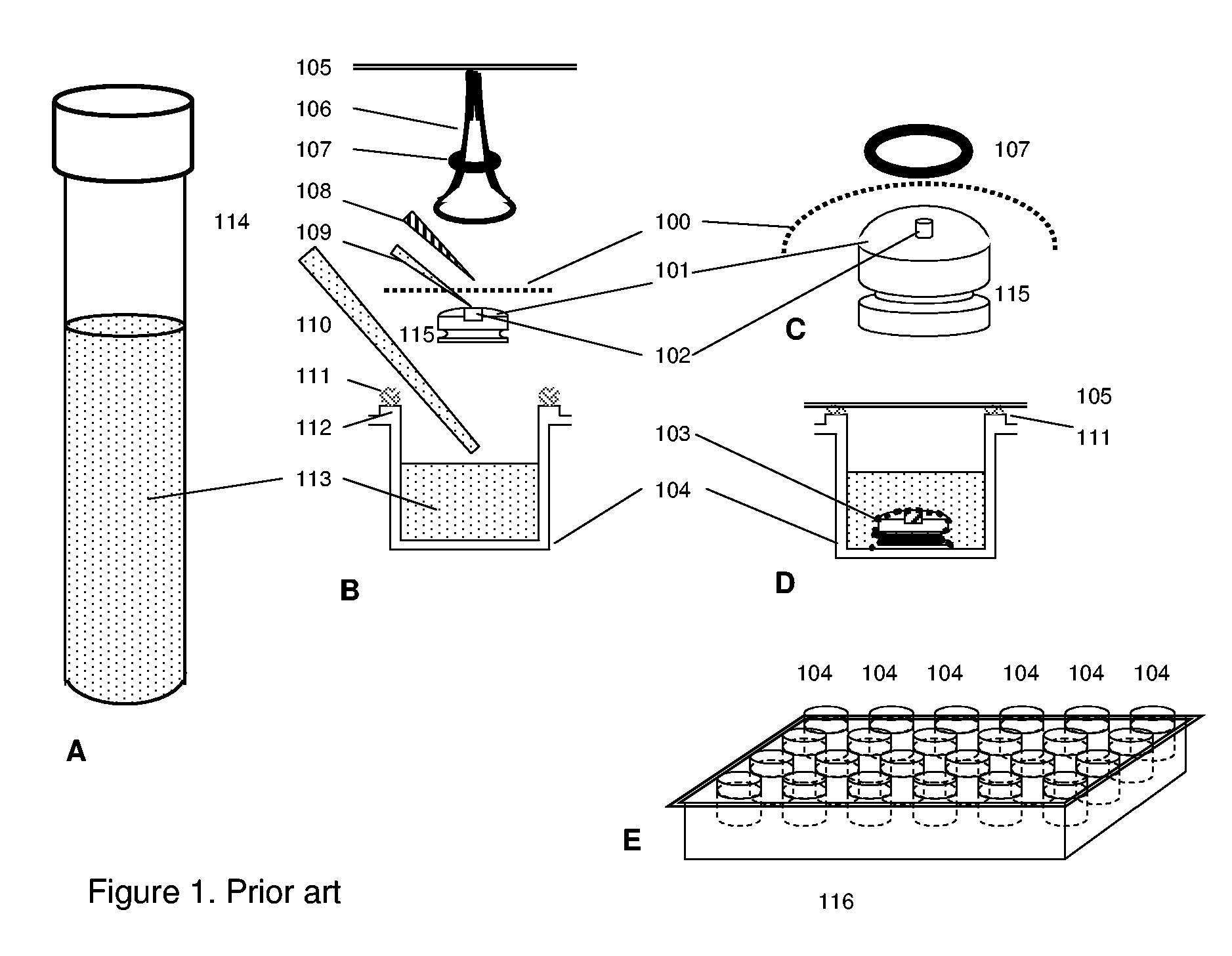

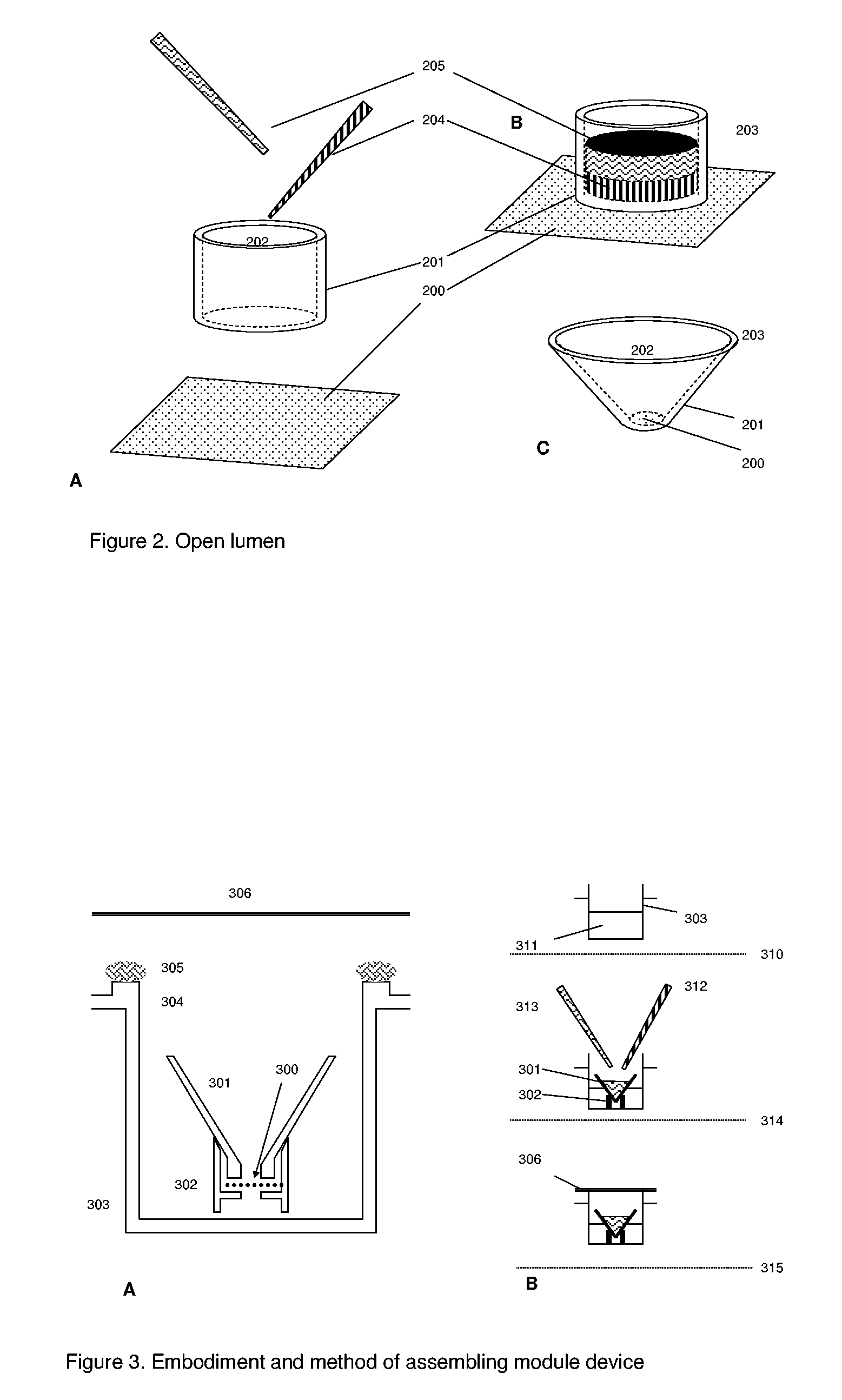

Protein crystallography dialysis chamber that enables off-site high throughput cocktail screen

InactiveUS20070025895A1Simple procedureImprove efficiencyPolycrystalline material growthCrystallization conditions screeningDialysis membranesProtein materials

A device that enables protein materials dialyses against crystal mother liquid and methods for fabricating and using the device to screen crystallization cocktail solution are described herein. The device includes an open lumen attached by dialysis membrane at one end, which is immersed in the cocktail pool. In operation, a layer of liquid inert oil covers the protein material and prevents it evaporated in the crystallization process. The protein material loaded in the dialysis chamber may grow crystals through dialysis crystallization process.

Owner:QIN ZUNSHE

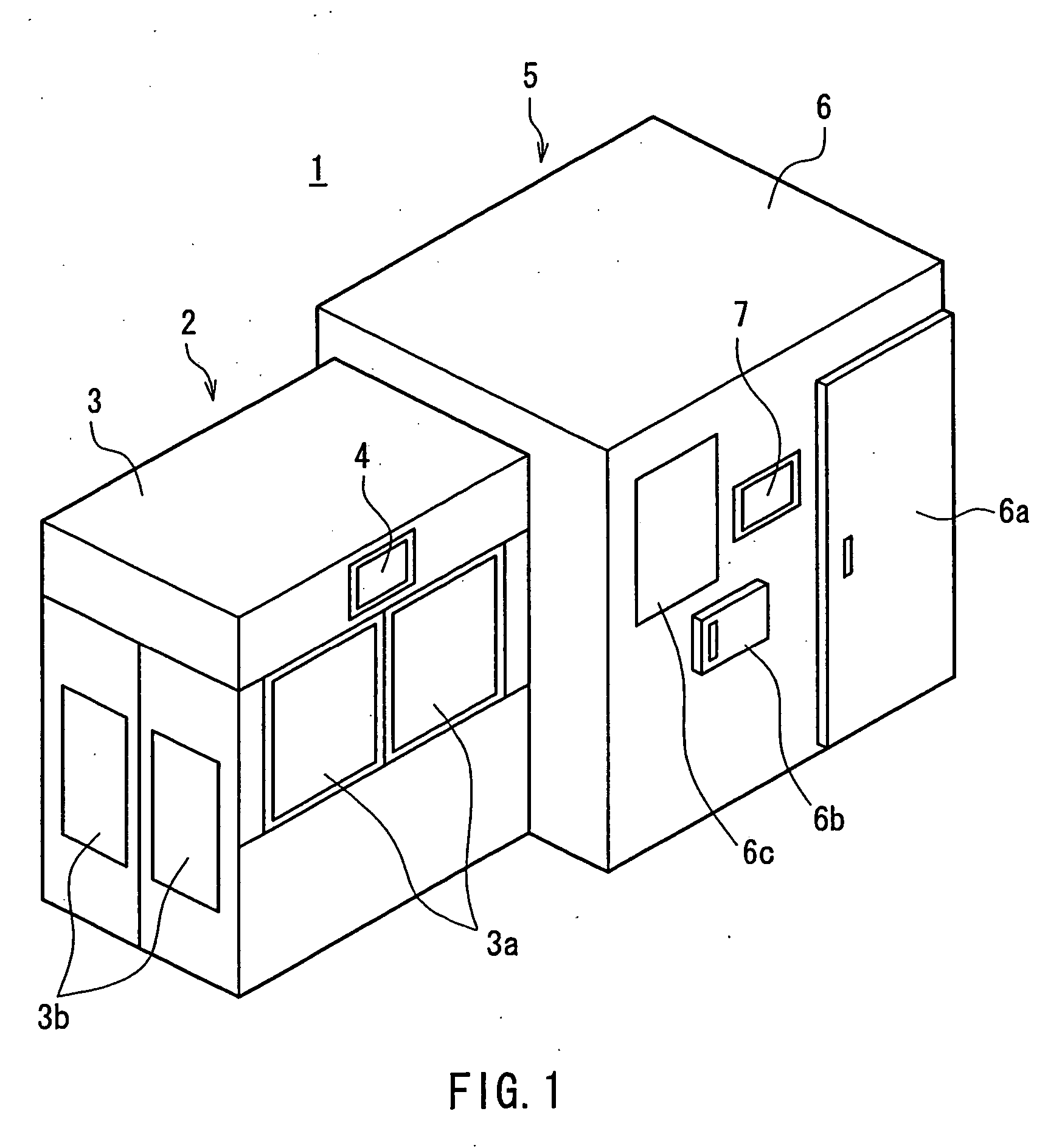

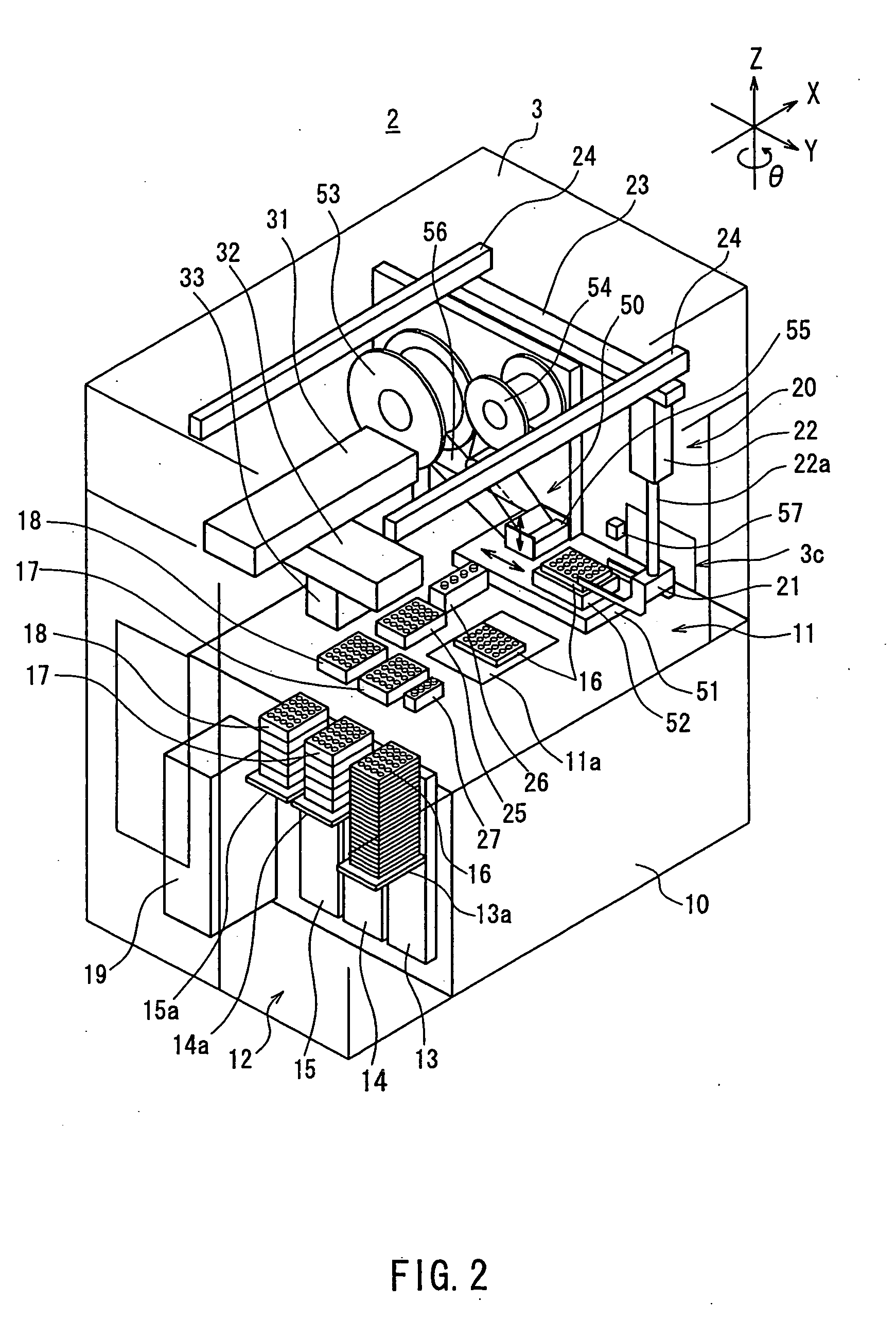

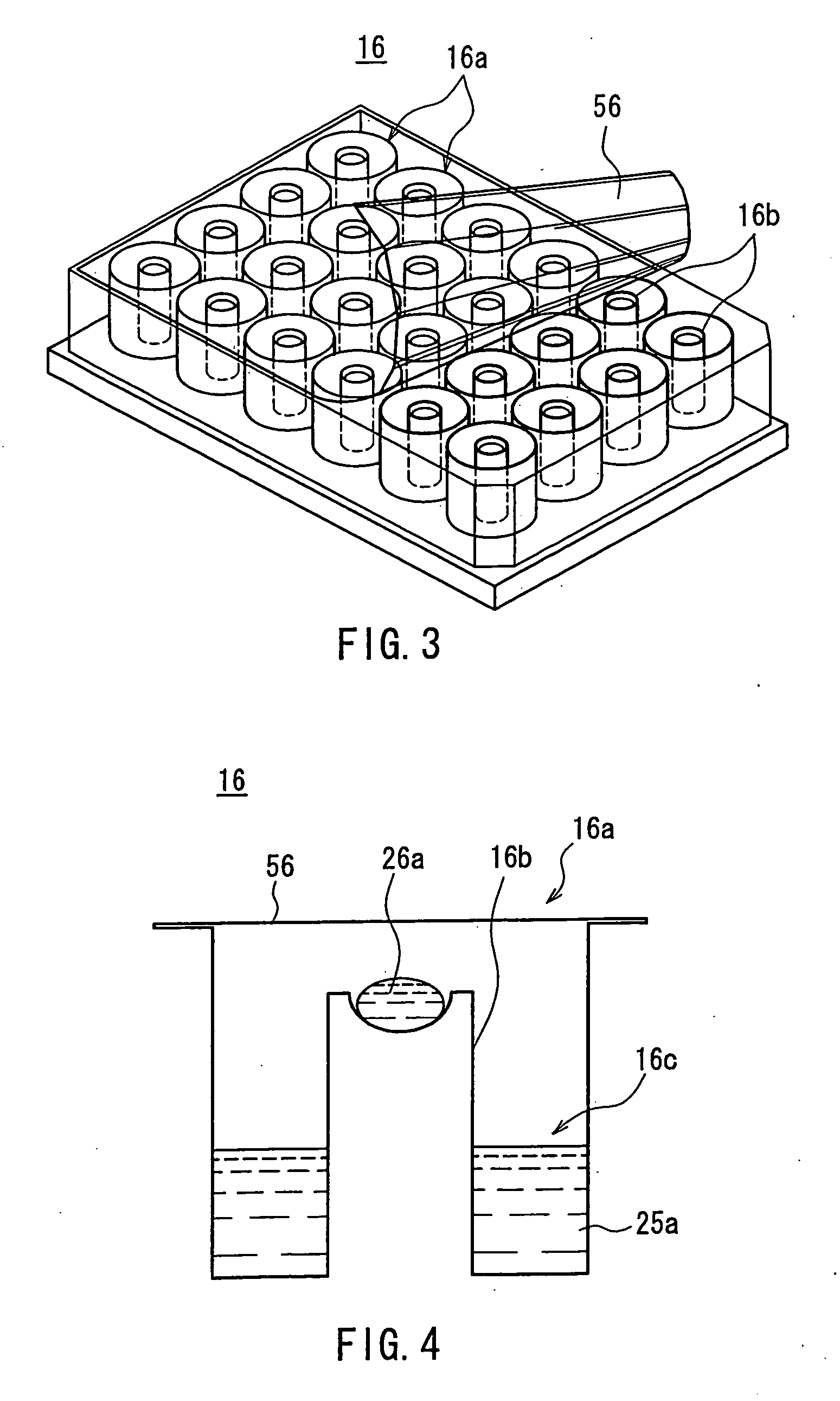

Apparatus for screening proptein crystallization conditions

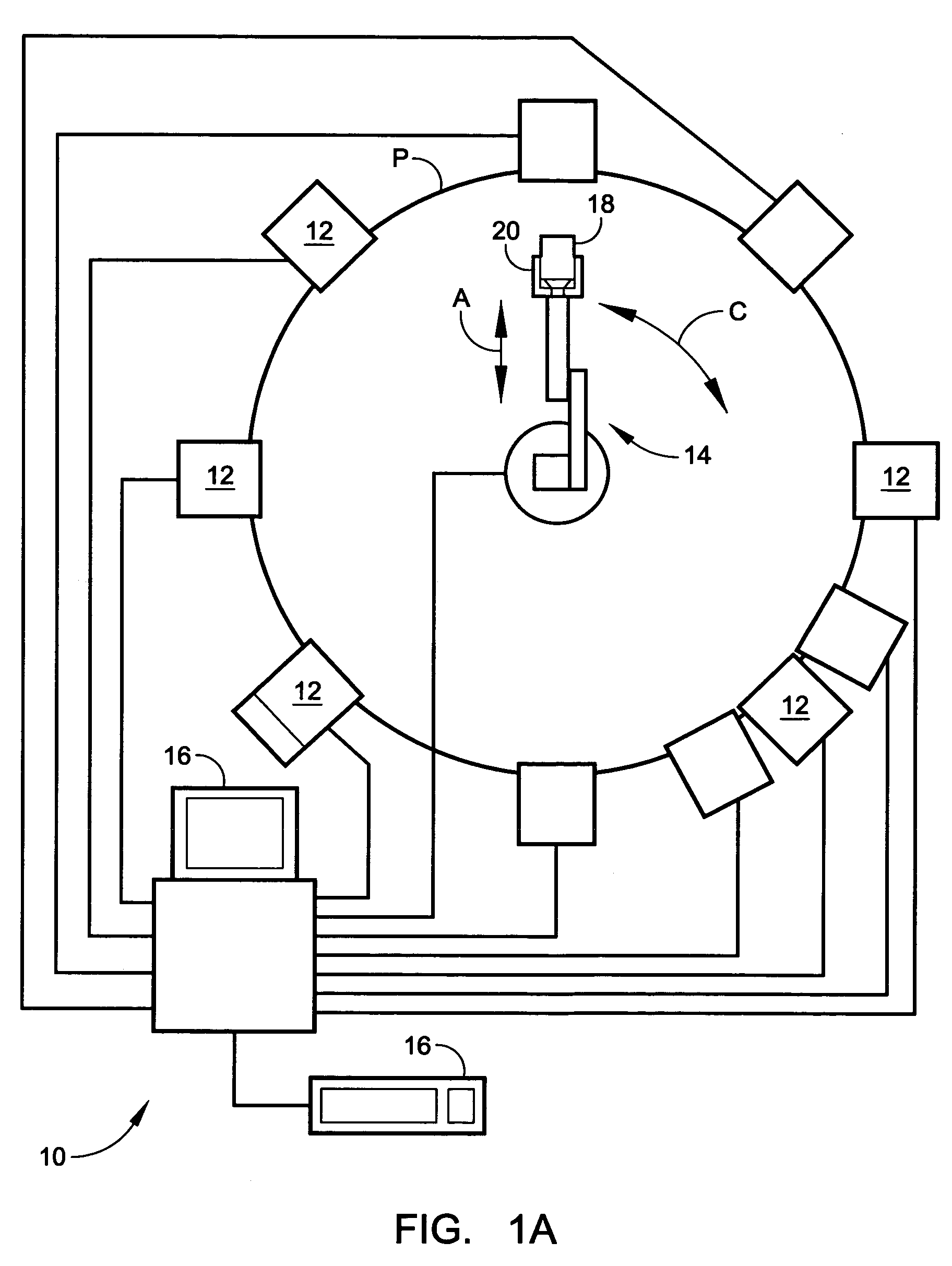

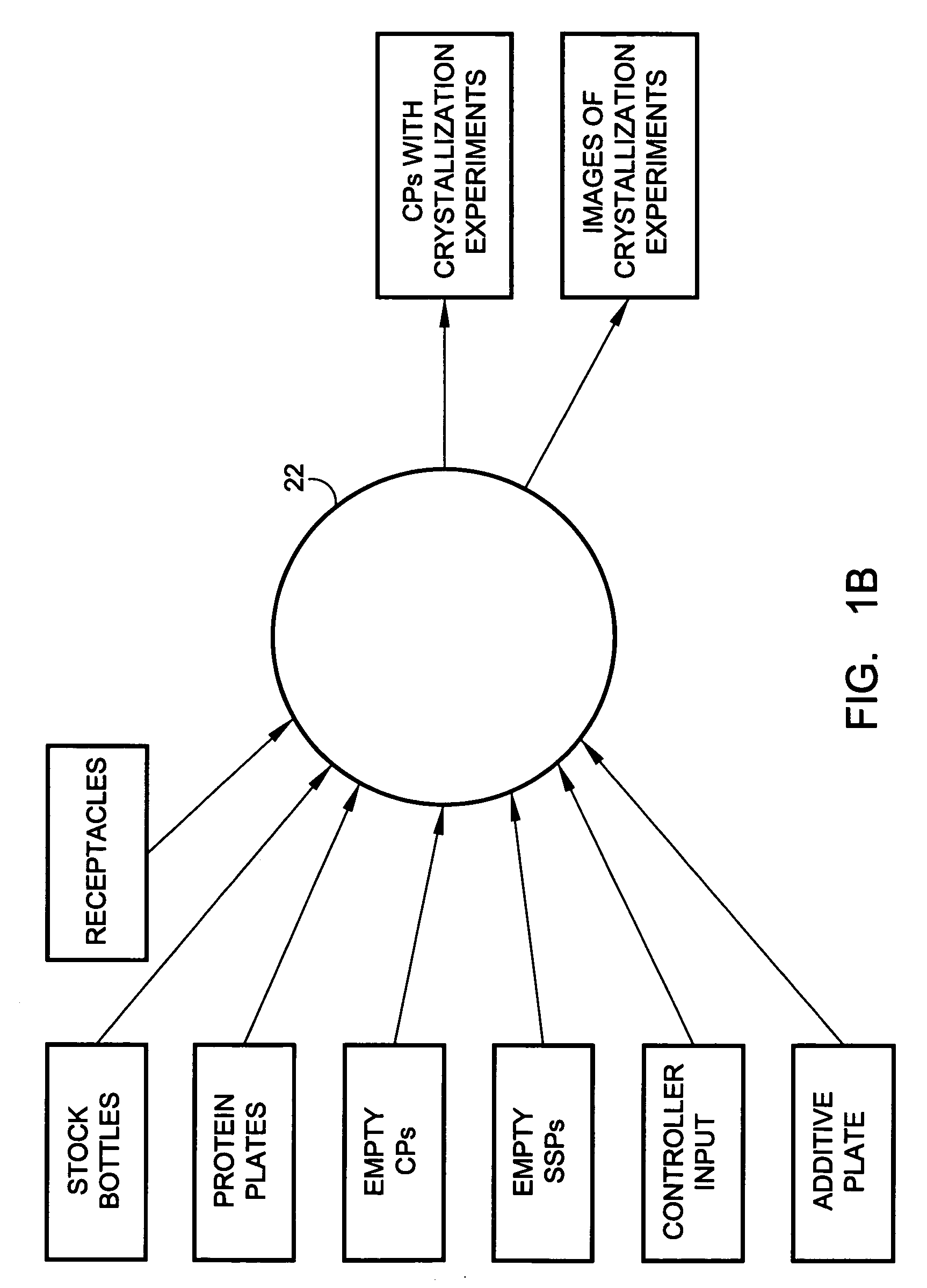

InactiveUS20070020748A1Efficient screeningBioreactor/fermenter combinationsFrom normal temperature solutionsDiffusion methodsProtein solution

The present invention is intended to provide an apparatus for screening protein crystallization conditions that can screen protein crystallization conditions efficiently by the vapor diffusion method using the sitting drop technique. In order to achieve the above-mentioned object, in an apparatus for screening protein crystallization conditions that screens protein crystallization conditions using the sitting drop technique that is one of the techniques of protein crystallization to be carried out by the vapor diffusion method, an apparatus 2 for preparing a crystallization plate that includes a dispensing means for dispensing a protein solution and a crystallization solution in wells of the crystallization plate and a seal attachment unit that seals the wells that have been subjected to dispensation is connected to a protein crystal detection apparatus 5 that detects protein crystals produced in the crystallization plate in a thermostatic chamber that stores the crystallization plate that has been subjected to the dispensing in a predetermined environment. Accordingly, the crystallization plate is transferred automatically and thus screening is carried out efficiently and automatically.

Owner:PANASONIC CORP

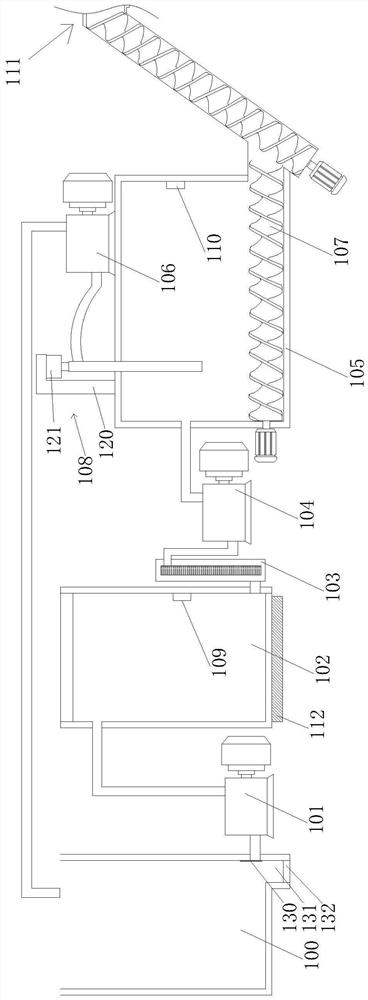

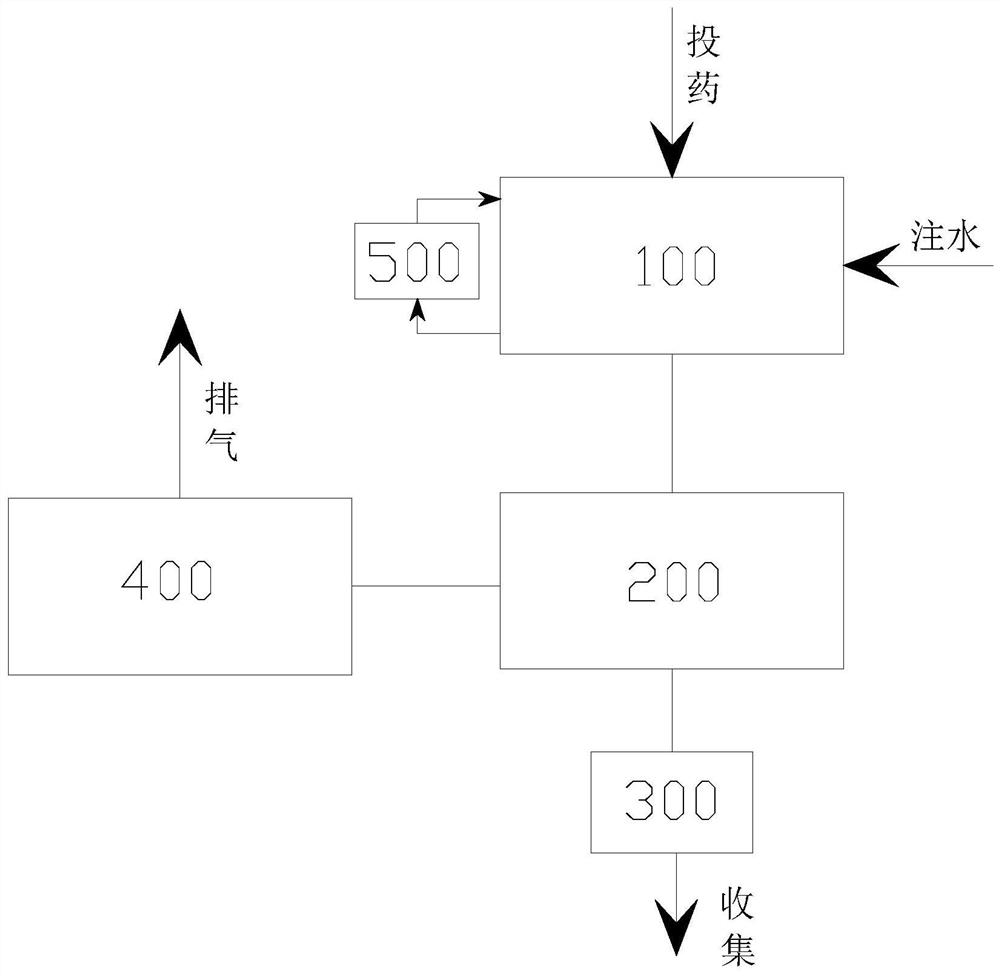

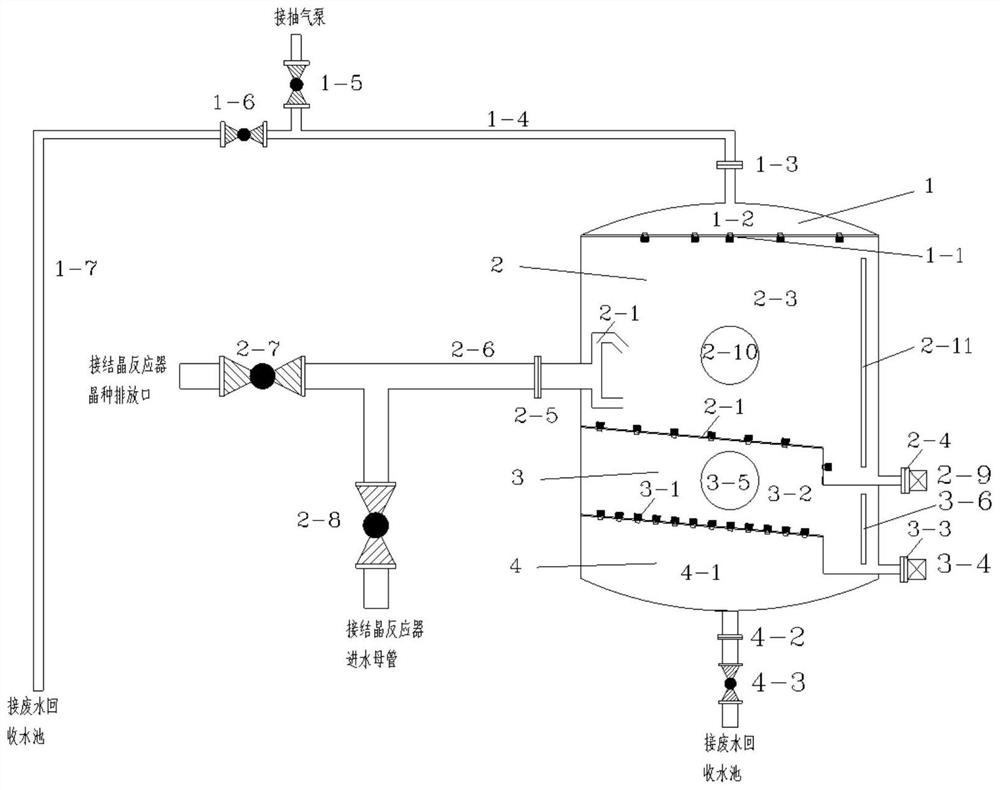

Preparation equipment and method for efficiently purifying ferrite for chemical reagent

ActiveCN111643923AAvoid compromising qualityImprove the heating effectCrystallization conditions screeningSolution crystallizationInfusion pumpAnalytical chemistry

The invention discloses preparation equipment and method for efficiently purifying ferrite for a chemical reagent. The invention belongs to the technical field of chemical equipment. The preparation equipment comprises a feeding cylinder, a first infusion pump, a reaction pot, a filter, a second infusion pump, a crystallizing tank, a third infusion pump, a conveying mechanism, an infusion liftingmechanism, a first temperature detector, a second temperature detector and a drum dryer, wherein the side wall of the bottom of the feeding cylinder is communicated with a liquid inlet pipe of a firstliquid pump; a liquid outlet pipe of the first liquid pump is connected to the upper portion of the side wall of the reaction pot, the first temperature detector is installed in the middle of the side wall of the reaction pot, a heater is arranged on the bottom face of the reaction pot, the side wall of the bottom of the reaction pot is communicated with the liquid inlet end of the filter, and the liquid outlet end of the filter is communicated with a liquid inlet pipe of the second liquid pump. The preparation equipment disclosed by the invention can avoid the influence of atmosphere on thecrystallization process and improve the product quality.

Owner:WENZHOU CHEM MATERIAL FACTORY

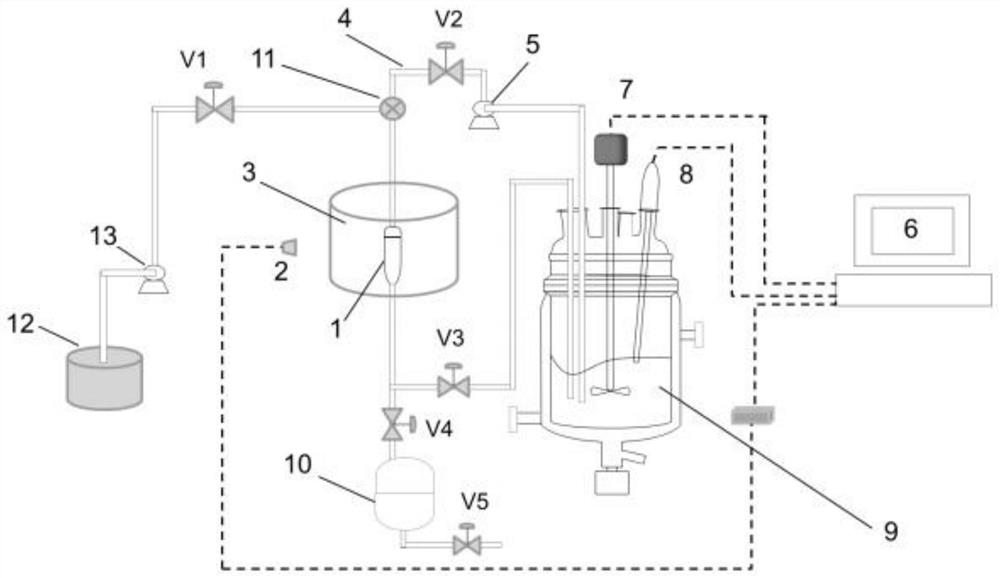

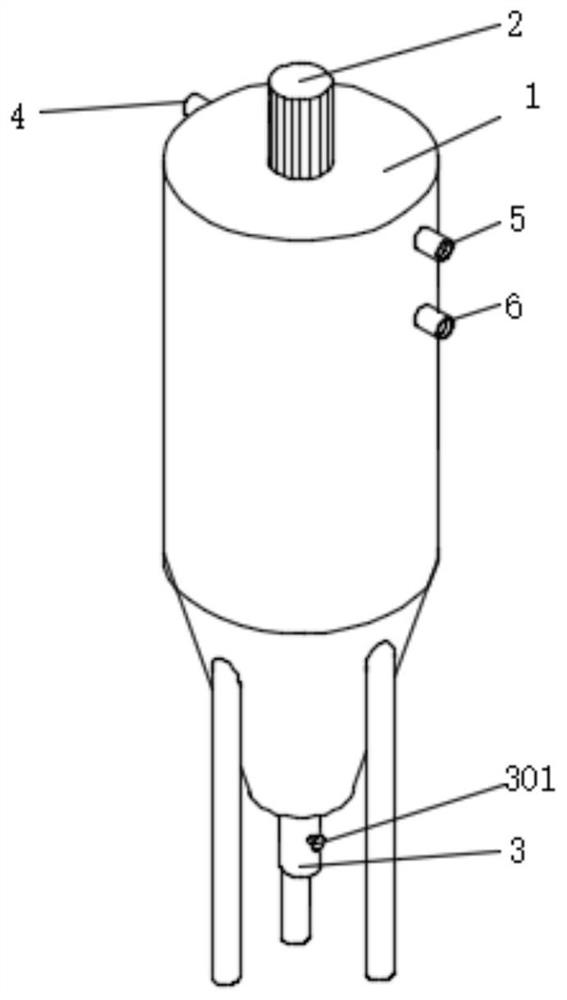

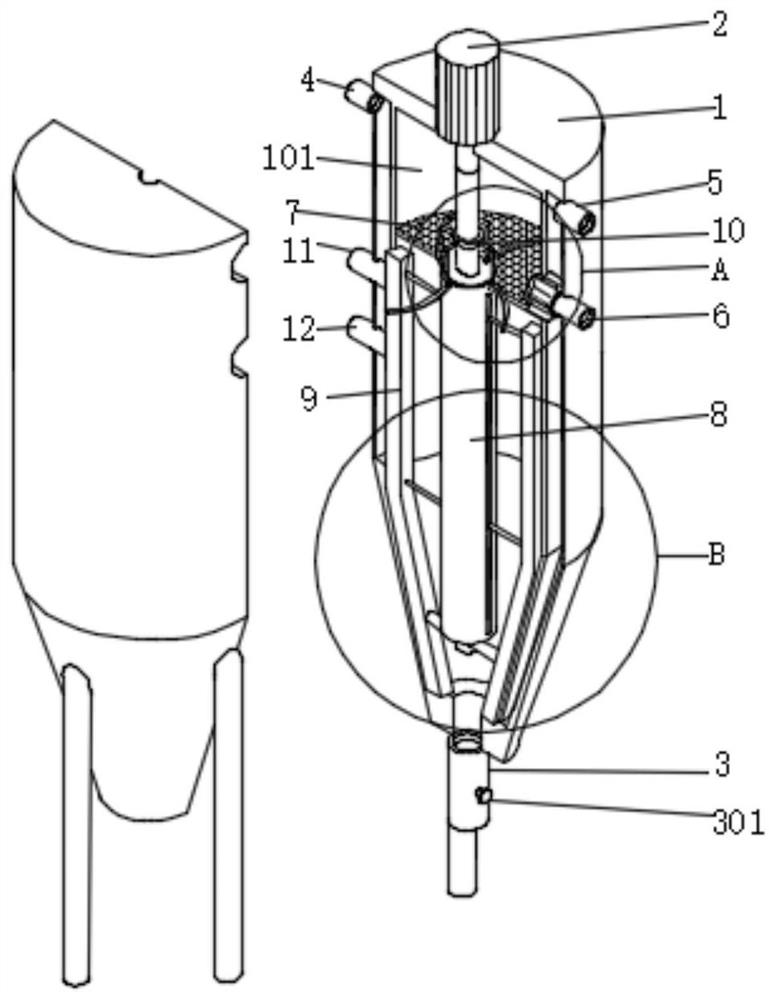

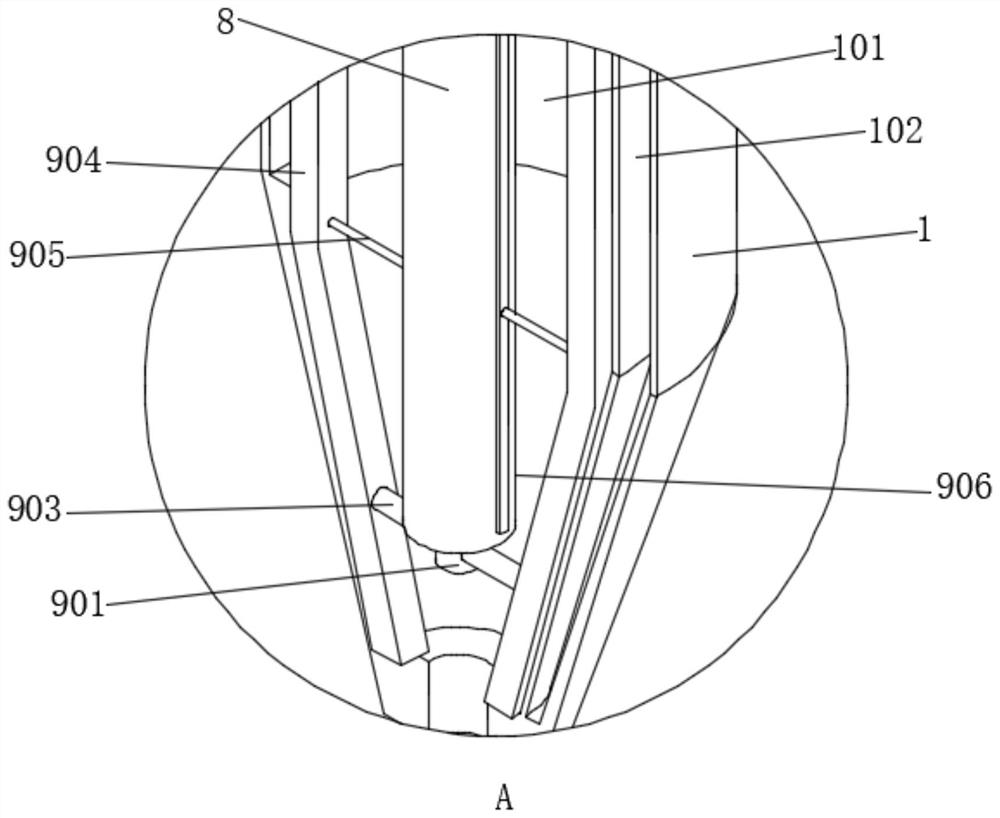

Online measurement device for crystal size and shape in high-solid-content crystallization process

ActiveCN112485165AAvoid pipe blockageReduce the impact of disturbanceInvestigating crystalsSolution crystallizationPhysicsMeasurement device

The invention discloses an online measurement device for the size and shape of a crystal in a high-solid-content crystallization process. The online measurement device comprises a solution amplifier,a measurement device, a peristaltic pump, a crystallization kettle, a dilution device and a liquid storage tank, a crystal-containing solution is arranged in the crystallization kettle; the inner wallof the solution amplifier is smooth, one end is an amplification end, and the other end is a contraction end; the contraction end of the solution amplifier is communicated with one end of the liquidstorage tank and one end of the crystallization kettle; the amplification end of the solution amplifier is respectively communicated with the dilution device and the peristaltic pump; the peristalticpump is communicated with the other end of the crystallization kettle; the solution amplifier, the peristaltic pump and the crystallization kettle form a complete passage through a pipeline; a measuring instrument of the measuring device is arranged in the outer side of the solution amplifier and focuses on the solution in the amplification end of the solution amplifier; and at least one stop valve is mounted on each branch of the pipeline. According to the invention, measurement of a crystalline solution with solid content higher than 10% is realized; and the pipeline heat preservation and constant-temperature tank is designed, so that the problems of solution crystallization on the pipe wall and pipeline blockage are avoided.

Owner:QINGDAO UNIV OF SCI & TECH

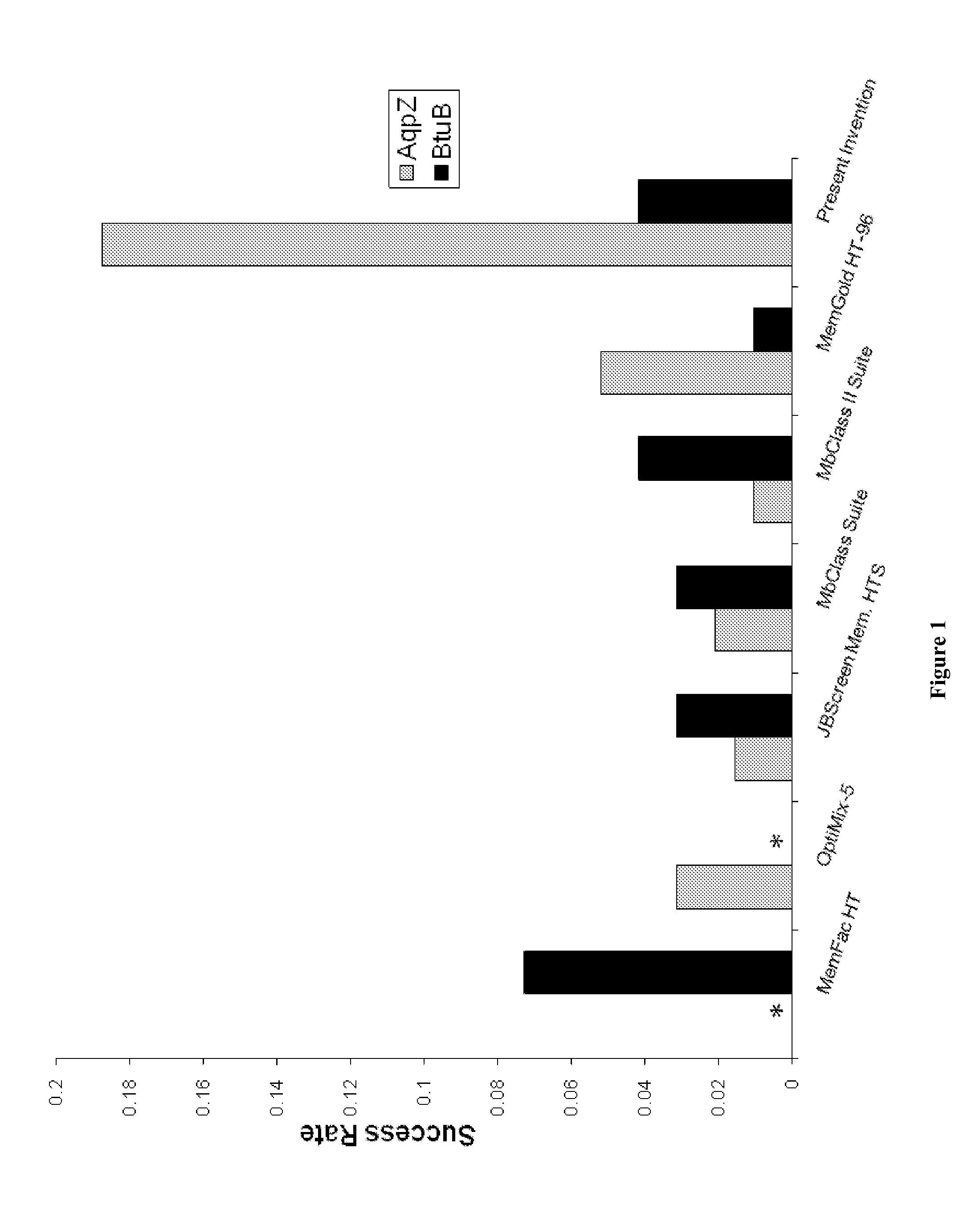

Compositions and methods for a membrane protein crystallization screening kit

InactiveUS20120065104A1Reduce in quantityOptimal protein concentrationCrystallization conditions screeningOther chemical processesSolubilityCell Membrane Proteins

The present invention comprises compositions and methods useful as a system for efficiently determining conditions that result in the formation of crystals of membrane proteins from solutions containing a membrane protein in a purified and soluble state. The system is comprised of two primary components, a solubility screen and a crystallization screen. Each component is a set of solutions. The present invention further provides a kit comprising solutions of the invention and an instructional material for the use thereof.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

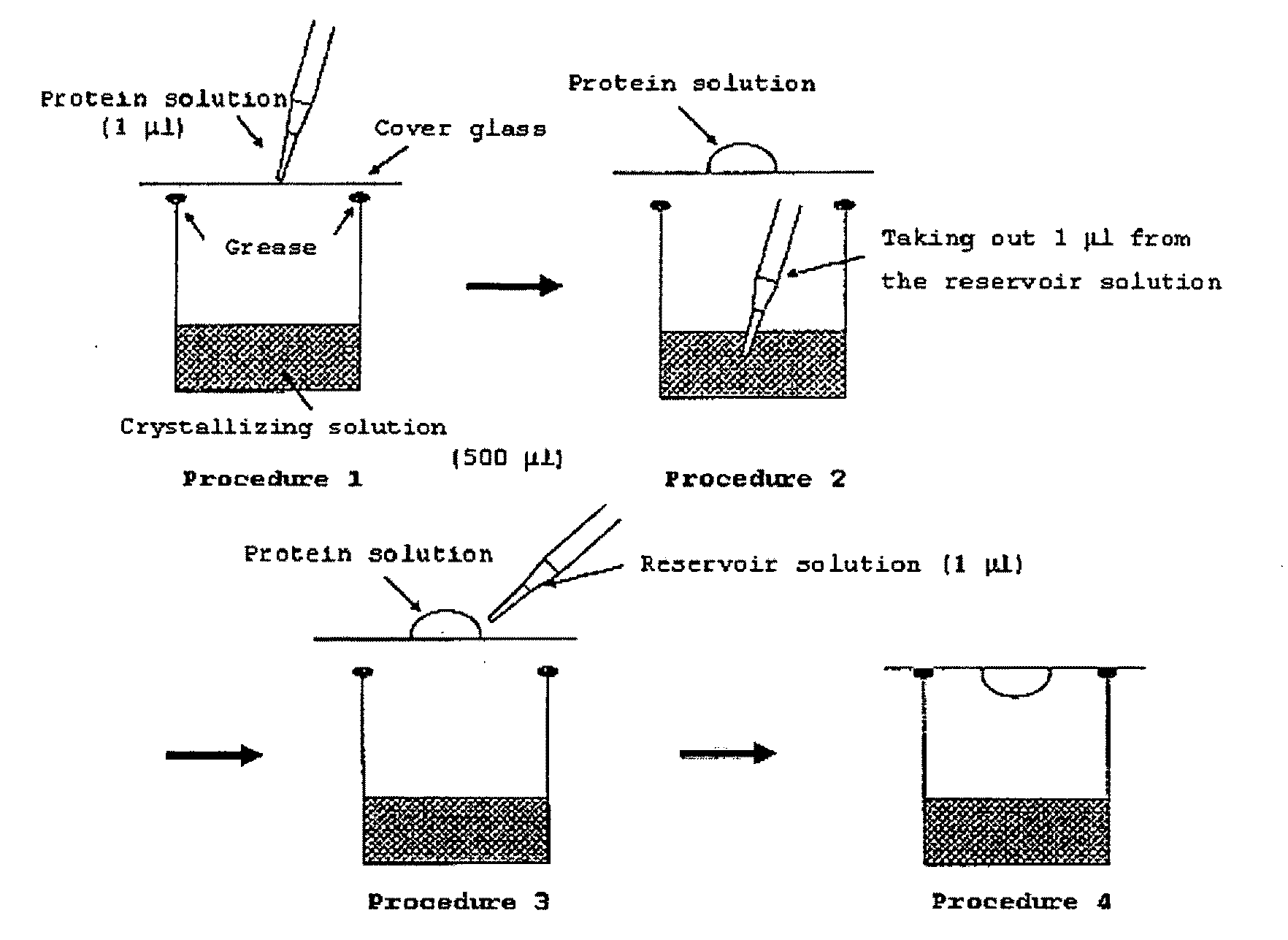

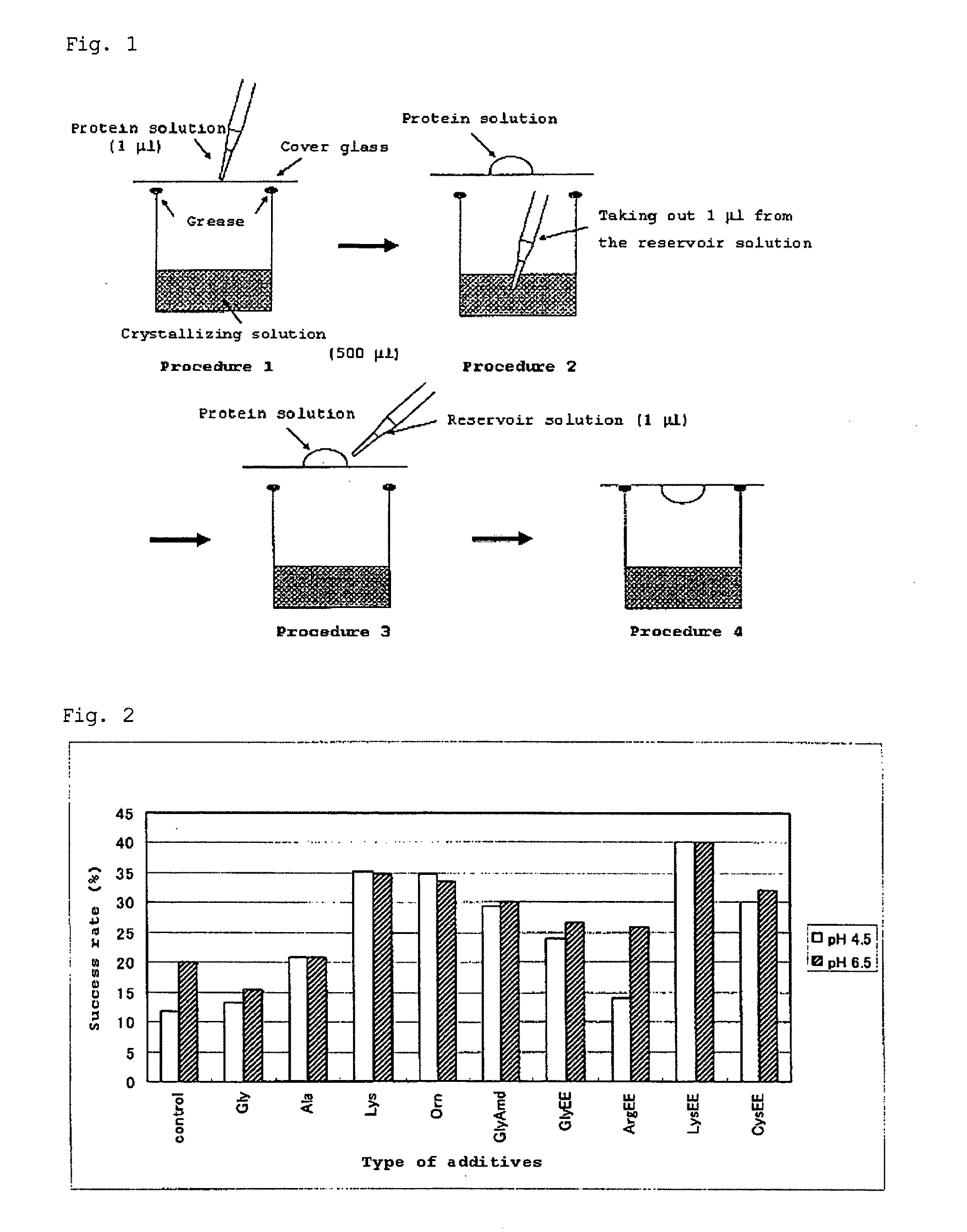

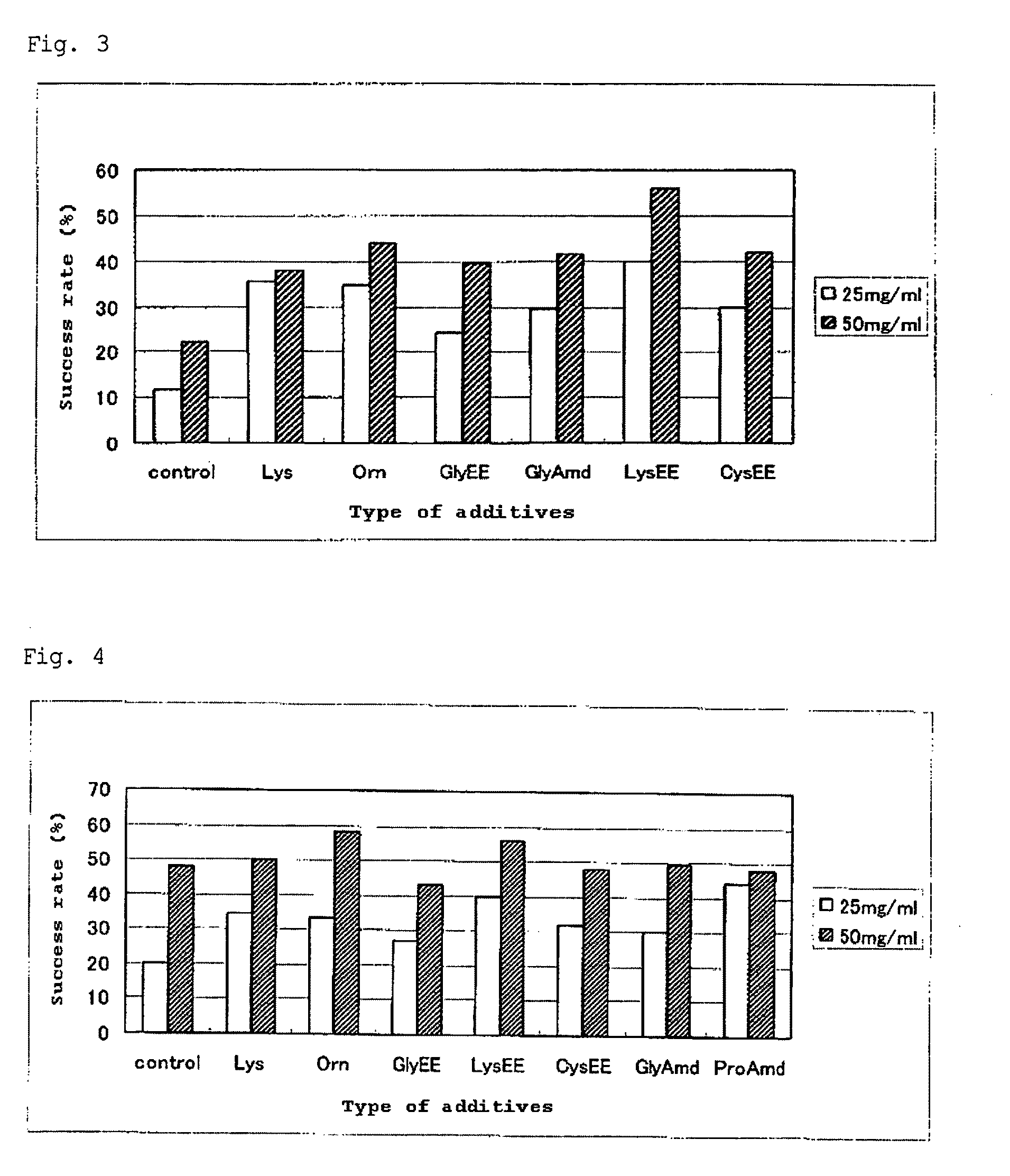

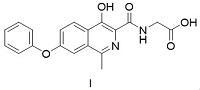

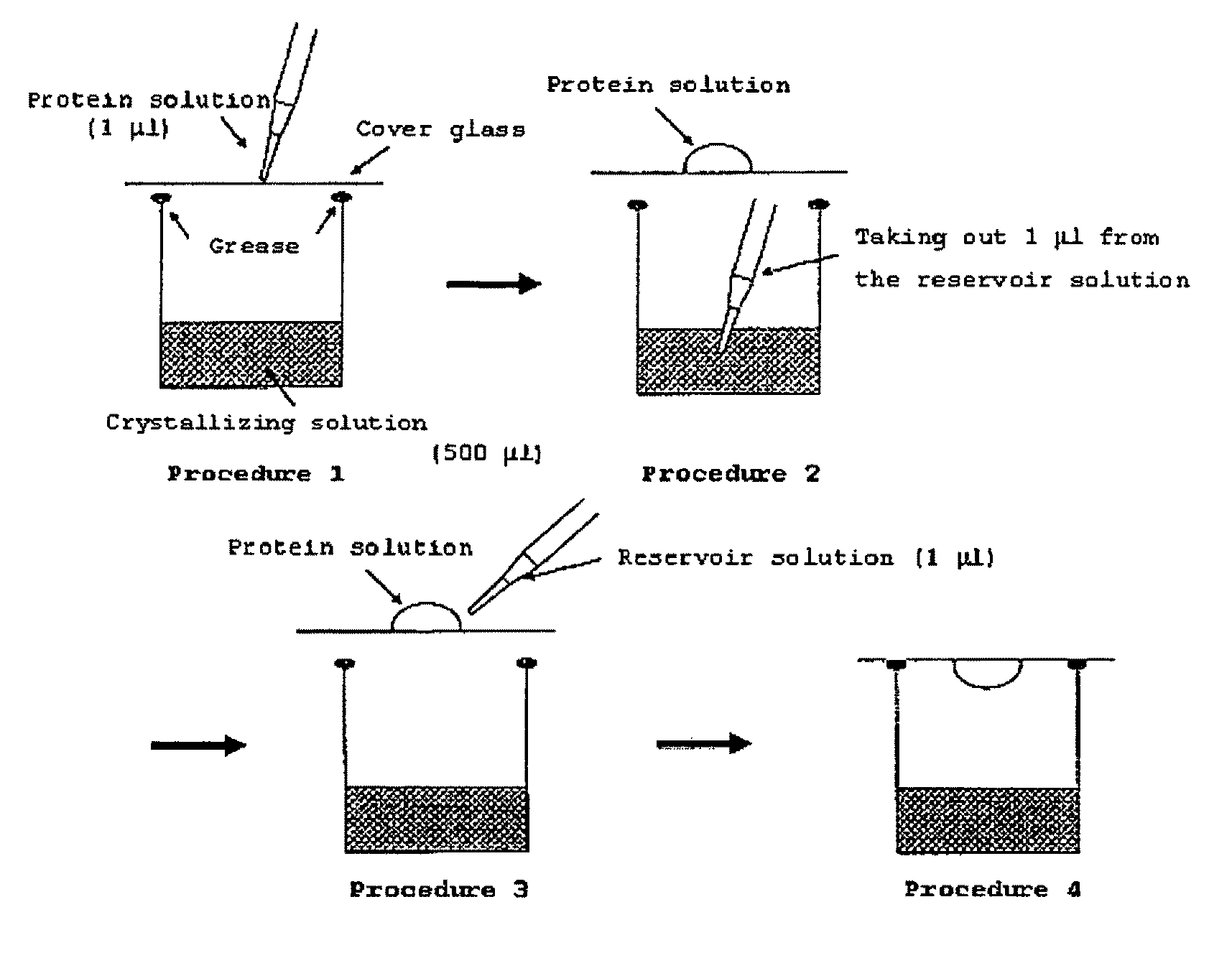

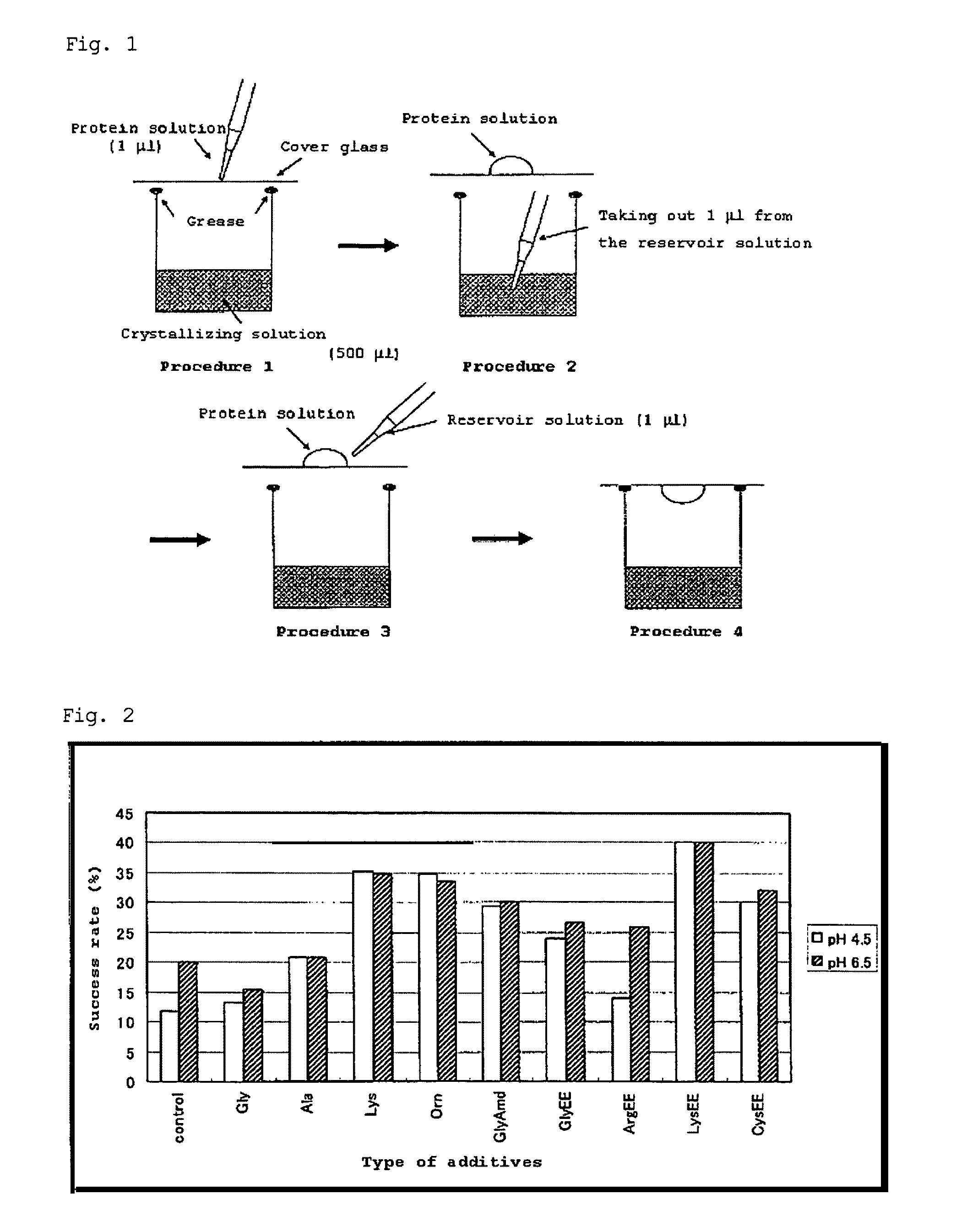

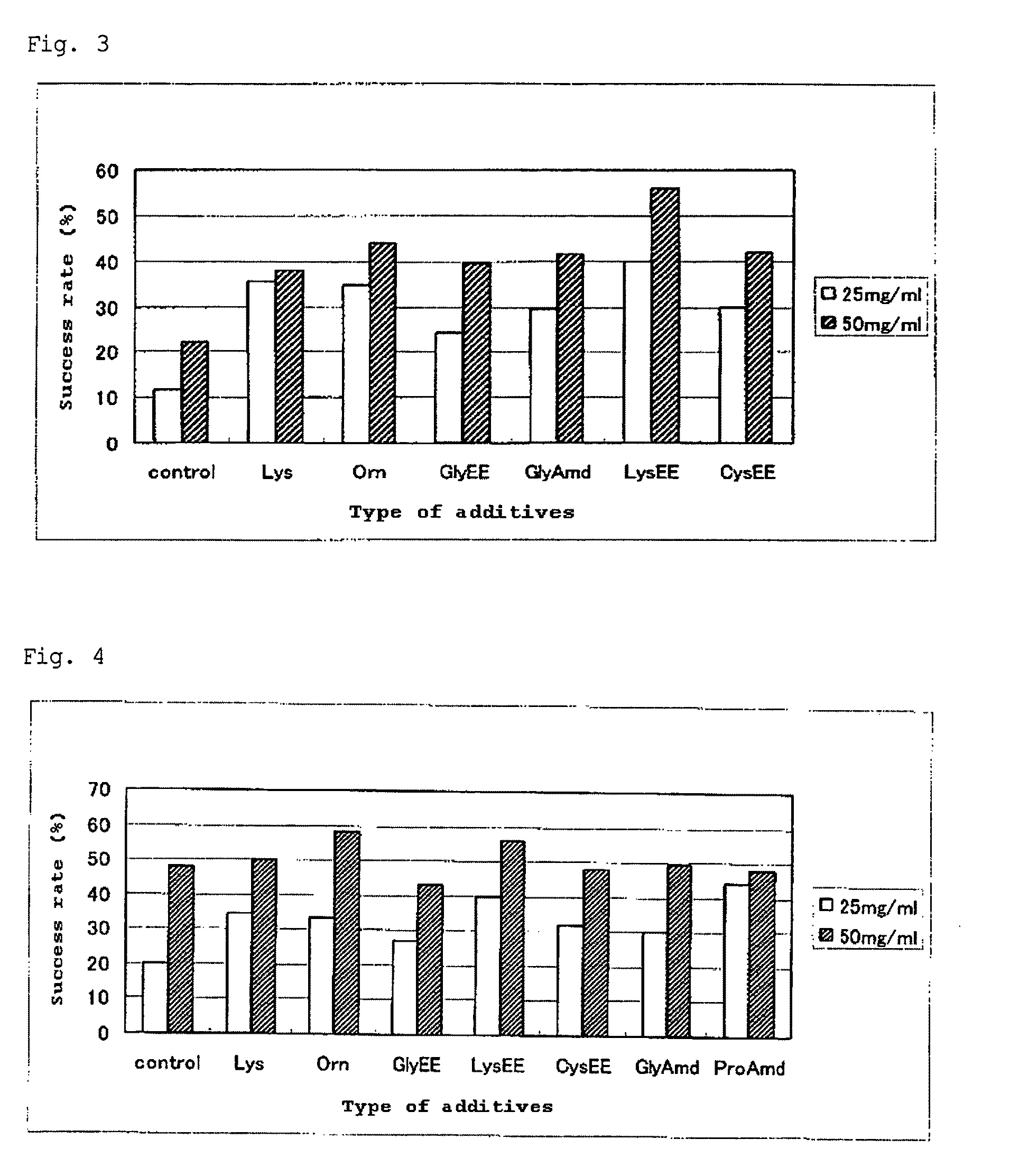

Protein crystallizing agent and method of crystallizing protein therewith

InactiveUS20100095749A1Easy to useImprove crystallizationUrea derivatives preparationFrom normal temperature solutionsCrystallographyHigh probability

The present invention provides a technique for crystallizing a desired protein at a high probability; namely, a protein crystallizing agent and a method of crystallizing protein. The present invention also provides a technique for determining the conditions for protein crystallization easily with high efficiency; namely, a method of screening the conditions for protein crystallization and a protein crystallization screening reagent. As the protein crystallizing agent, at least one compound selected from the group consisting of a basic amino acid, acidic amino acid, ester derivative of amino acid and amide derivative of amino acid is used, or at least one of these compounds is used in combination with another protein crystallizing agent.

Owner:KWANSEI GAKUIN EDUCATIONAL FOUND

Method for producing chiral drug

InactiveCN113769687AEasy to produceIncrease productivityCrystallization conditions screeningSolution crystallizationCombinatorial chemistryPharmaceutical Substances

The invention discloses a method for producing a chiral drug. The chiral drug is subjected to mixed reaction. According to the synthesis of the chiral drug, drug components for synthesizing the chiral drug are divided into a plurality of drug groups, each drug group is mixed, then mixing is performed among reaction kettles; after the mixed reaction is complete, crystallization and drying are carried out through a crystallization drying device, multiple procedures are completed in the same equipment; after drying is finished, along with discharging of crystals, the grain size of the crystals is controlled through a crystallization grinding and discharging device, and the crystals are collected; and due to the fact that discharged materials of the crystallization drying device are directly discharged into the crystallization grinding and discharging device, discharging and grinding directly act and are continuously carried out, and production procedures are reduced. The production process of the chiral drug is simplified, the production efficiency of the chiral drug is improved, and the investment of funds and personnel is reduced. The method of the invention is suitable for the technical field of chiral drug production equipment.

Owner:HEBEI CHEM & PHARMA COLLEGE

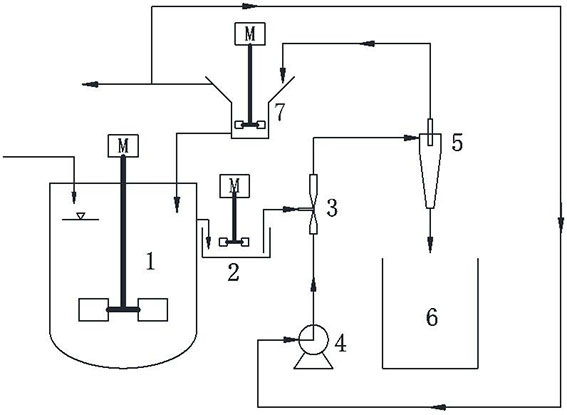

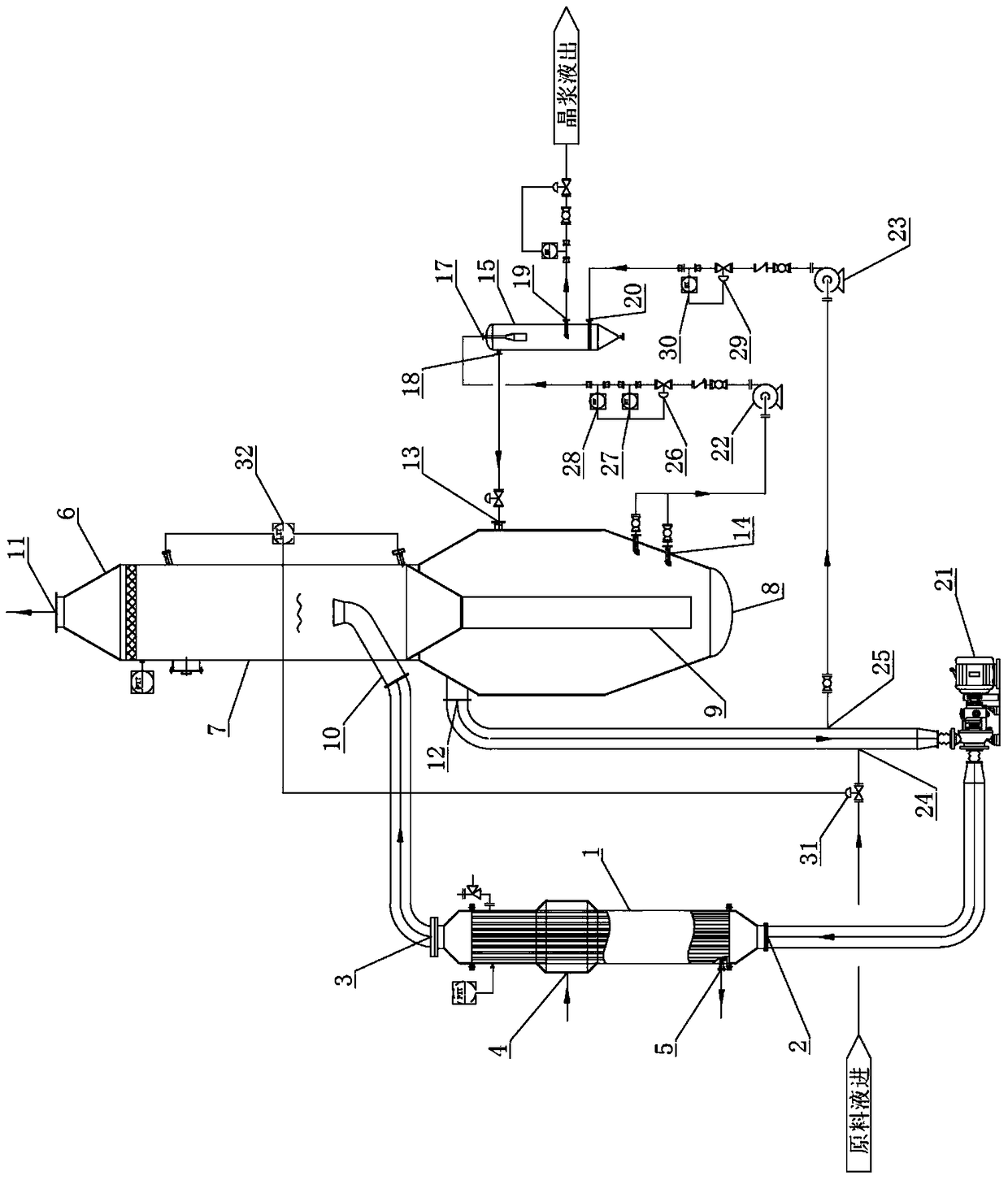

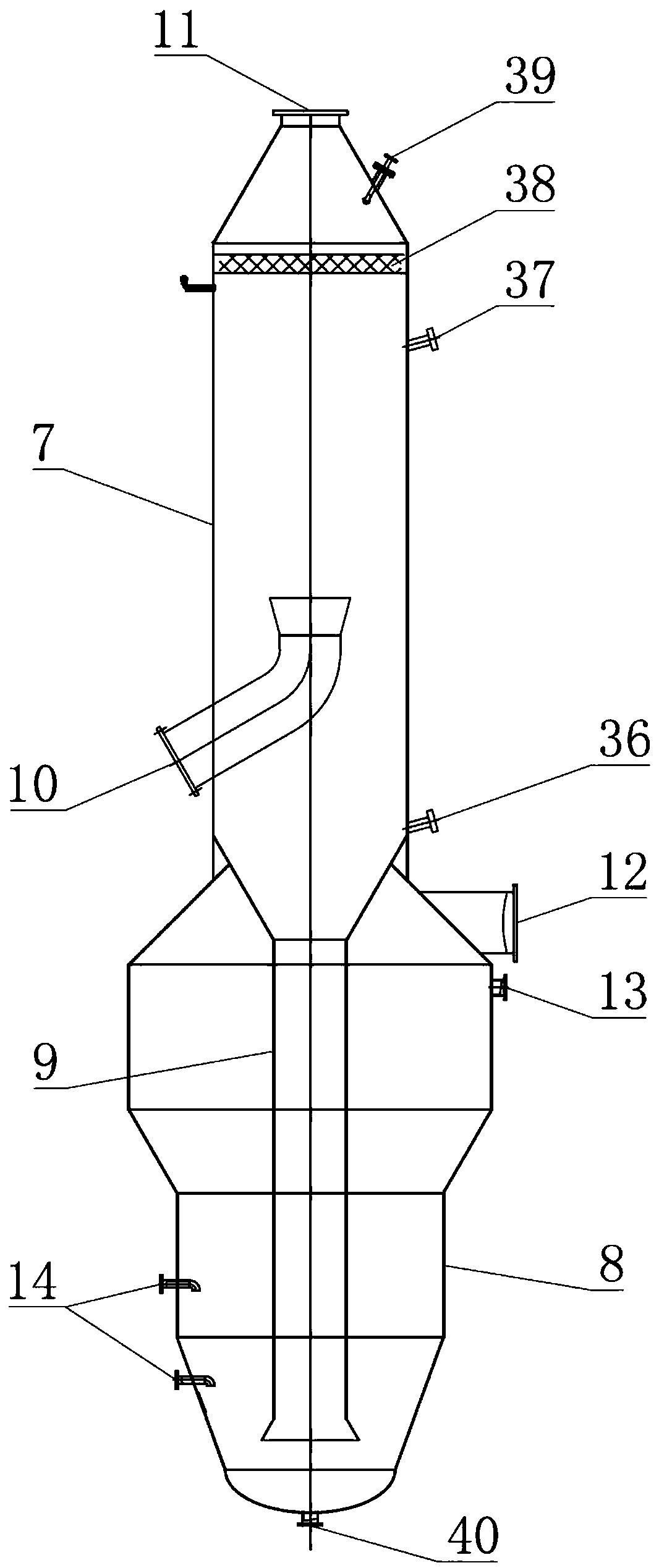

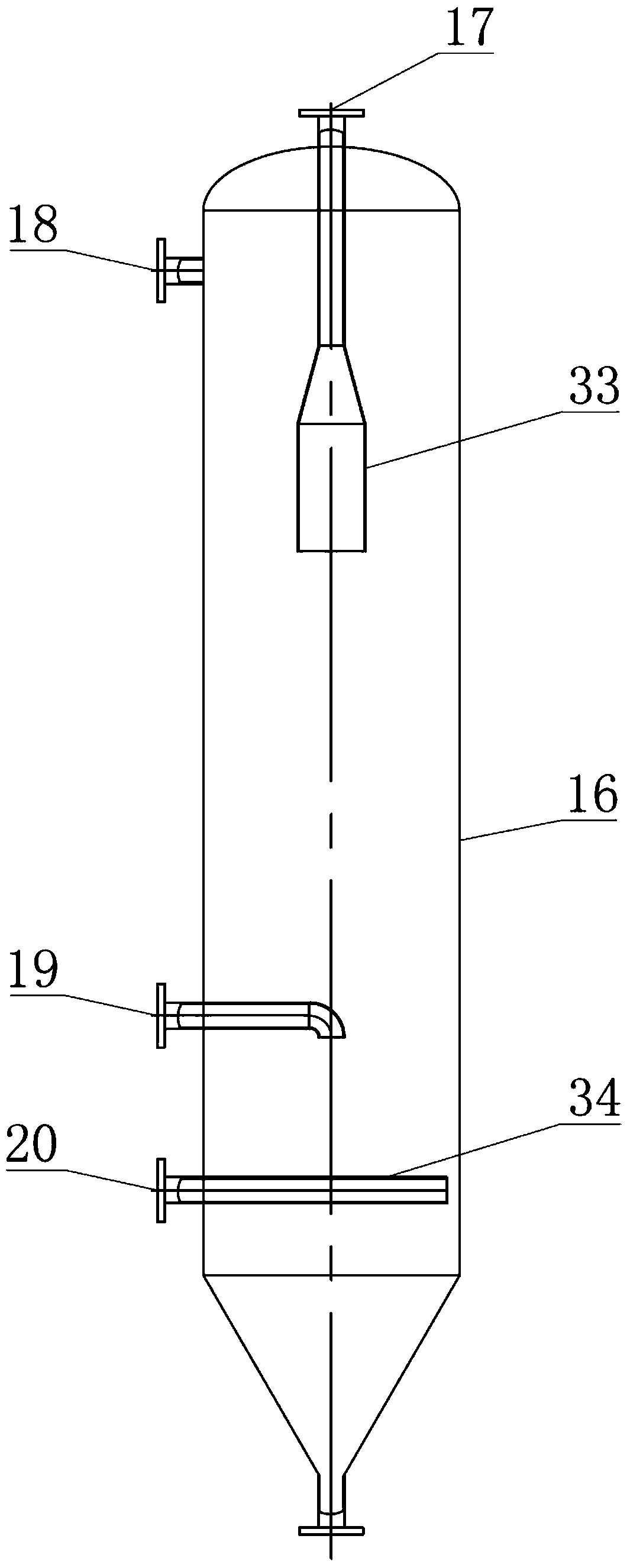

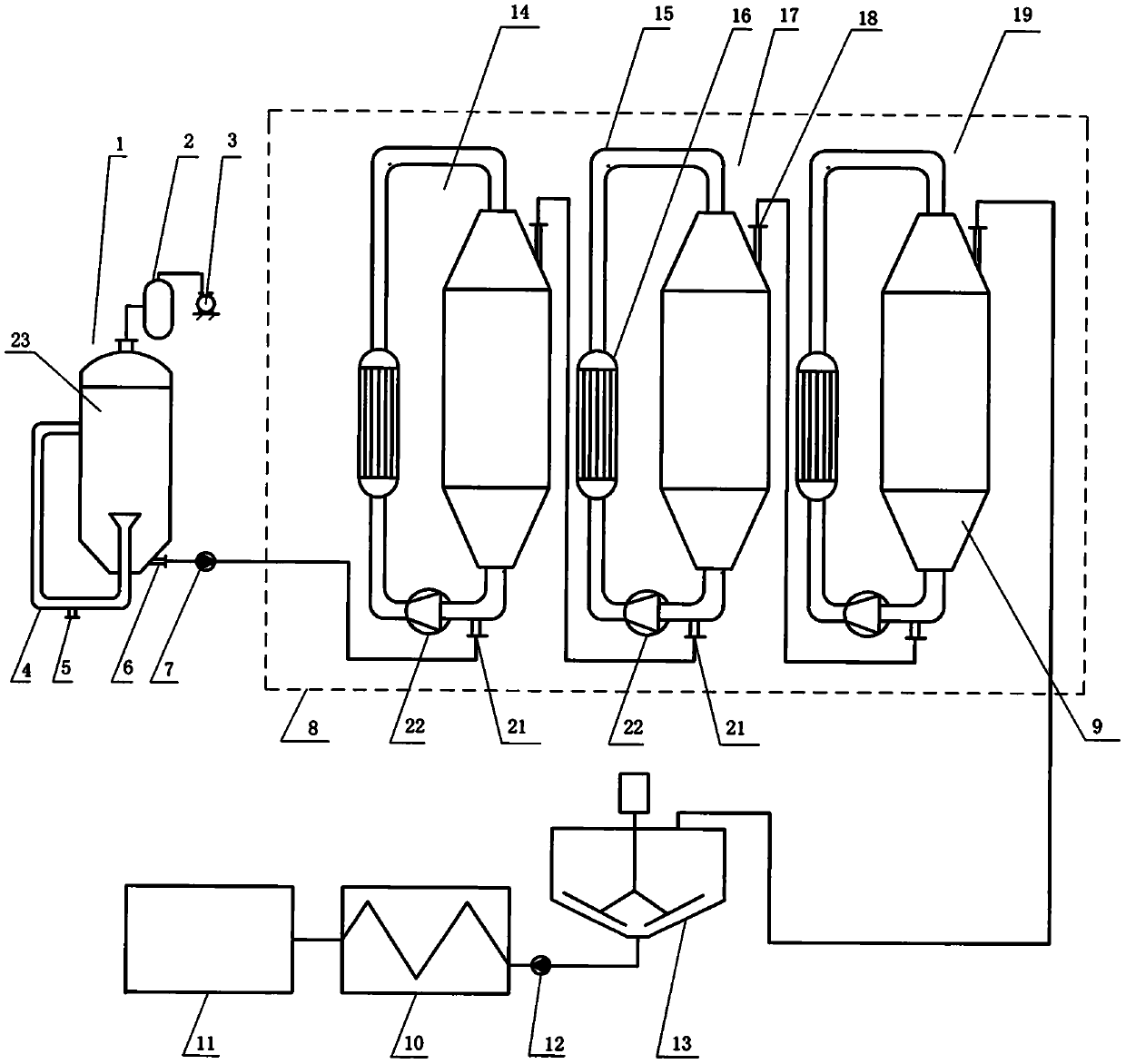

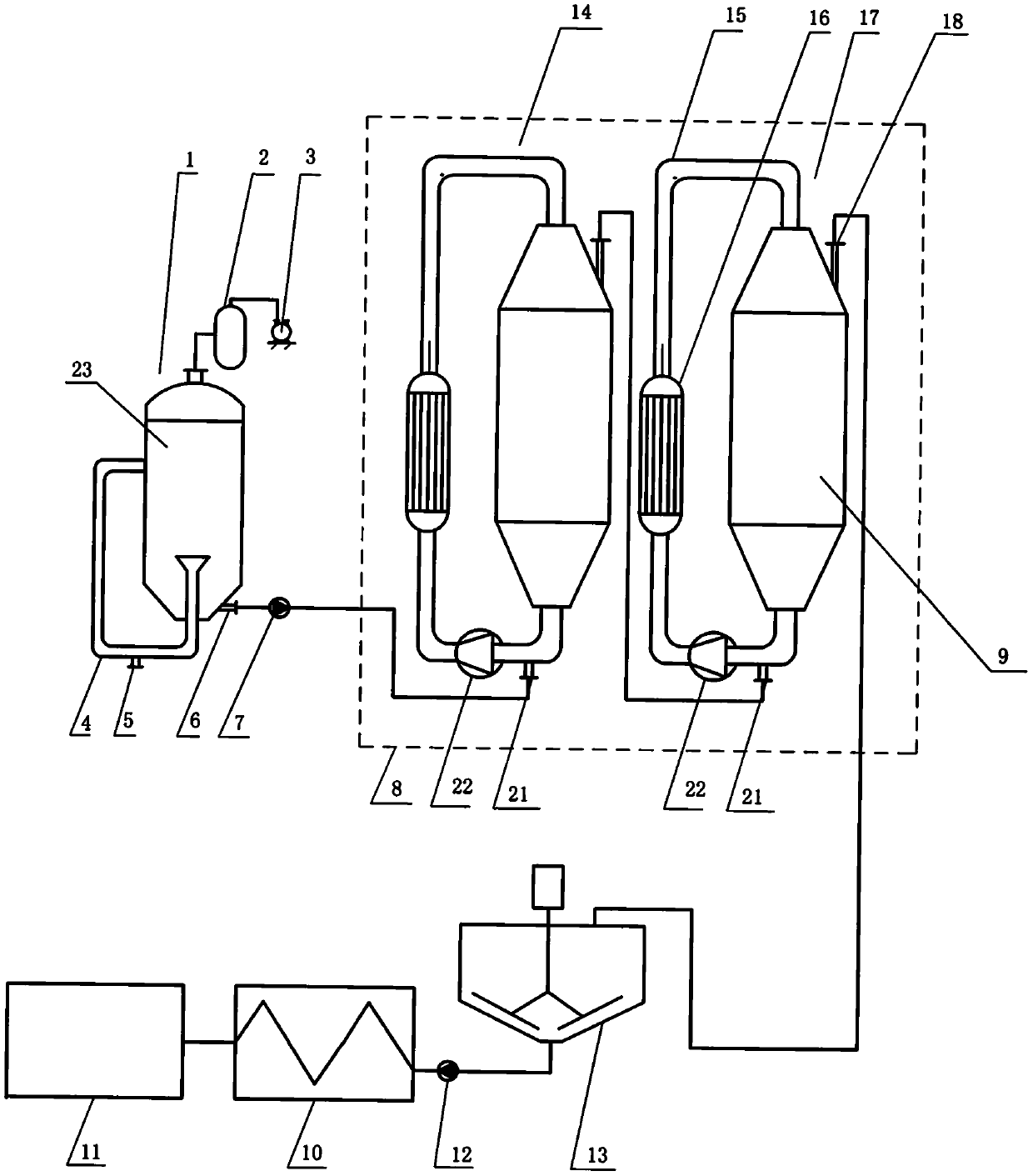

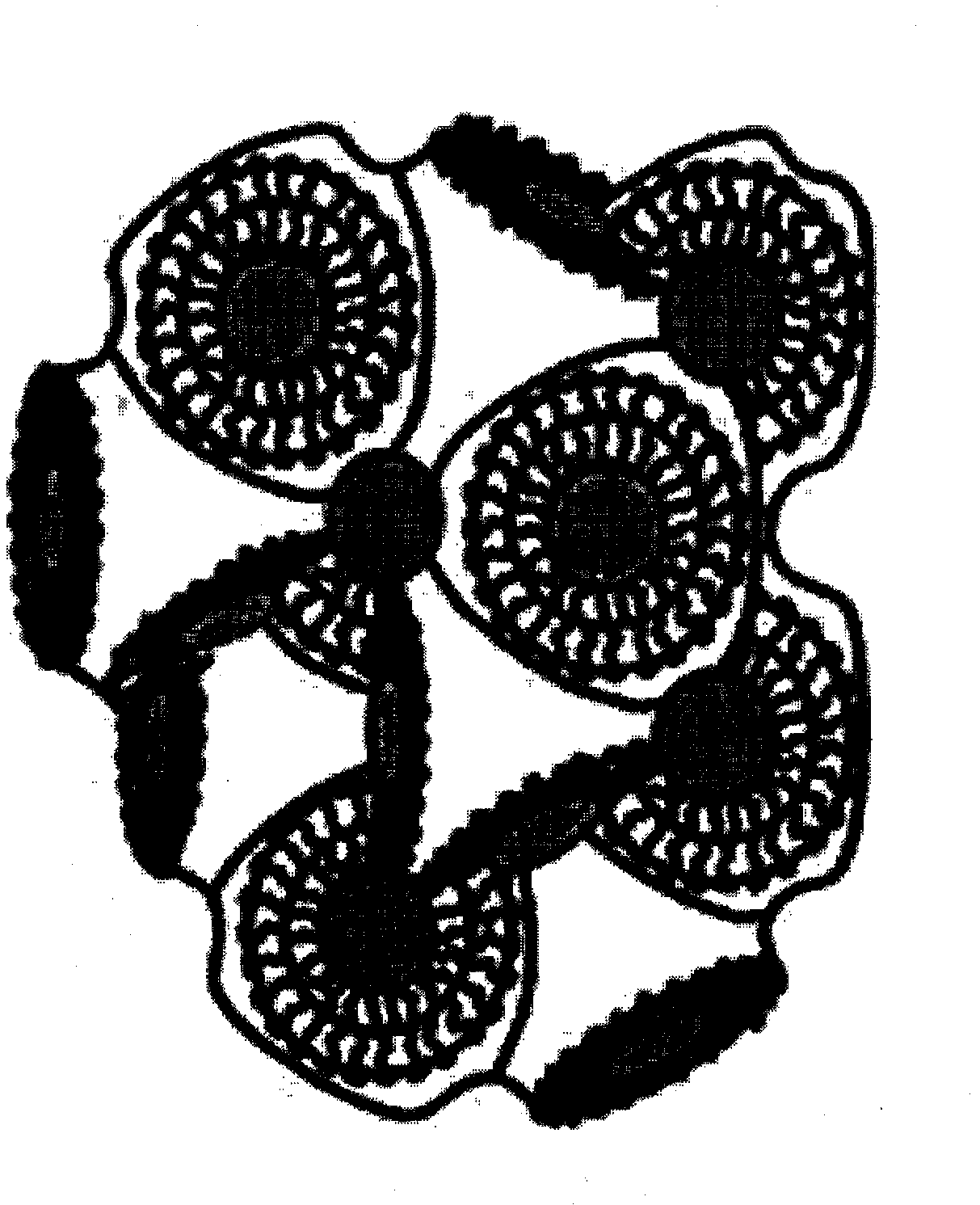

A method for returning small crystal particles in the slurry discharged from a reaction crystallizer

ActiveCN111054294BAvoid fragmentationAvoid wastingCrystallization conditions screeningSolution crystallizationCirculator pumpSlurry

The invention discloses a method for returning small crystal particles in the slurry discharged from a reaction crystallizer. The method includes the following steps: (1) The slurry discharged from the reaction crystallizer first enters a slurry storage tank, and then is sucked out by a venturi tube and fed from The clear liquid of the clear liquid circulation pump is mixed and diluted; (2) The diluted slurry enters the hydrocyclone for continuous separation of large and small crystal particles, and the large particles and a small part of the clear liquid are taken out as underflow and enter the product storage tank, and the small particles and Most of the clear liquid is discharged into the settling reflux tank as the top flow; (3) In the settling reflux tank, small crystal particles settle down and return to the reaction crystallizer to continue to grow; (4) Most of the supernatant in the settling reflux tank The liquid is pumped out by the clear liquid circulating pump as carrier fluid and diluent, and a small part goes to the water treatment unit. The method has low equipment investment, is easy to realize continuous operation, can effectively improve the particle size distribution of the product, and can simultaneously improve the utilization efficiency of the raw material liquid and avoid environmental pollution.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +1

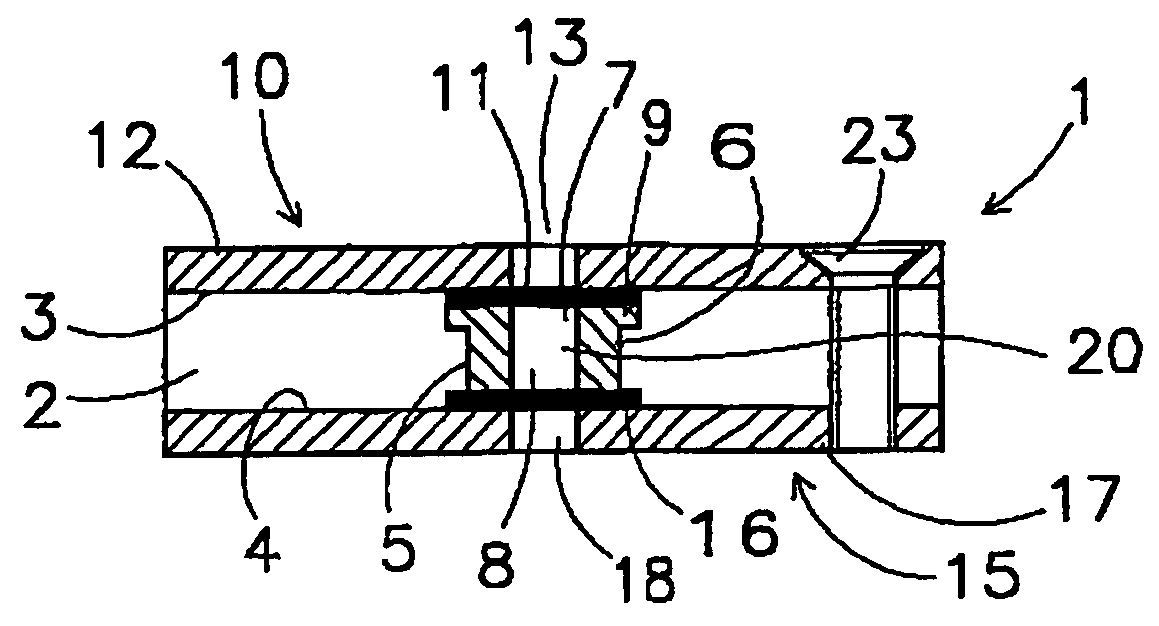

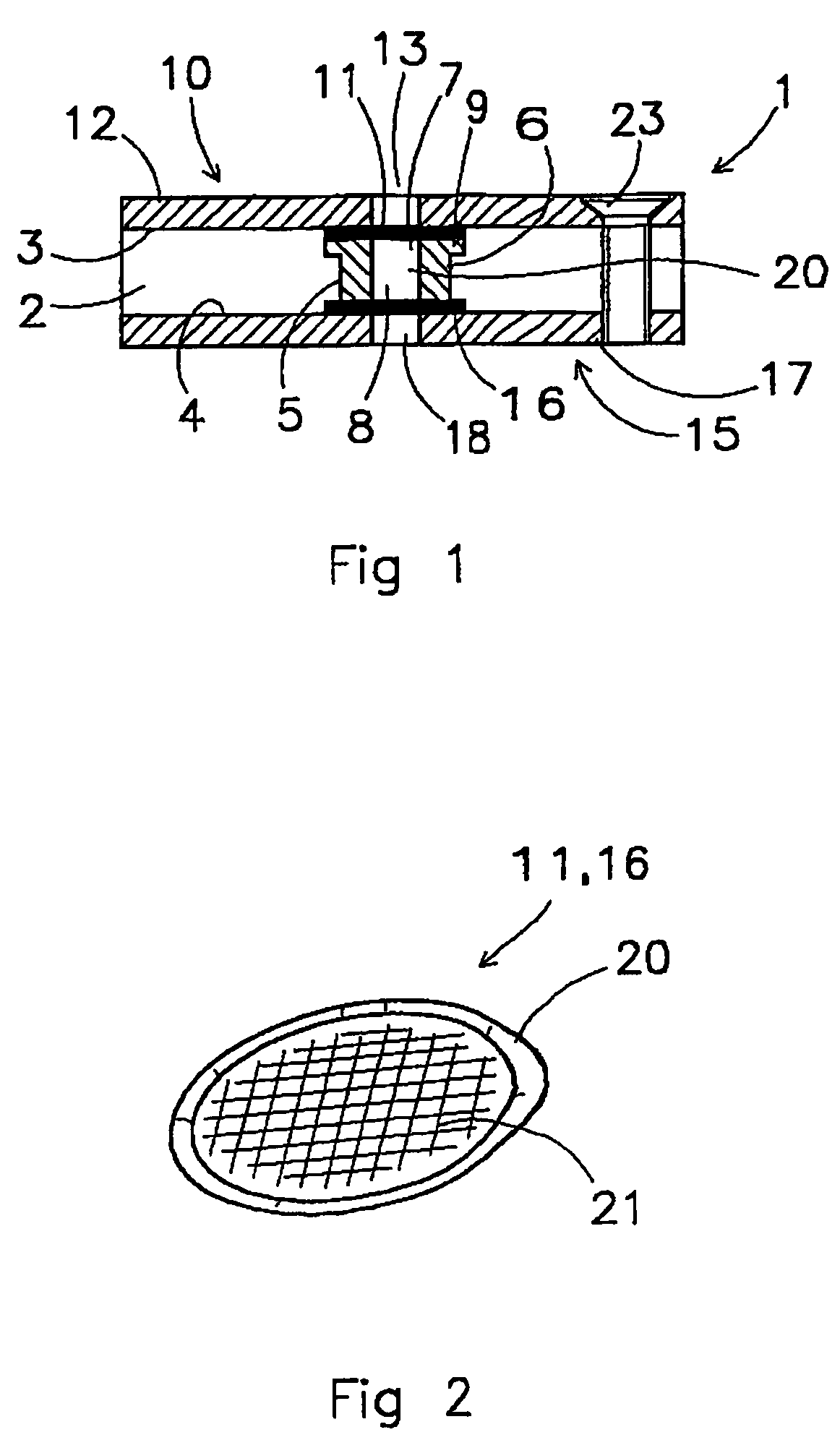

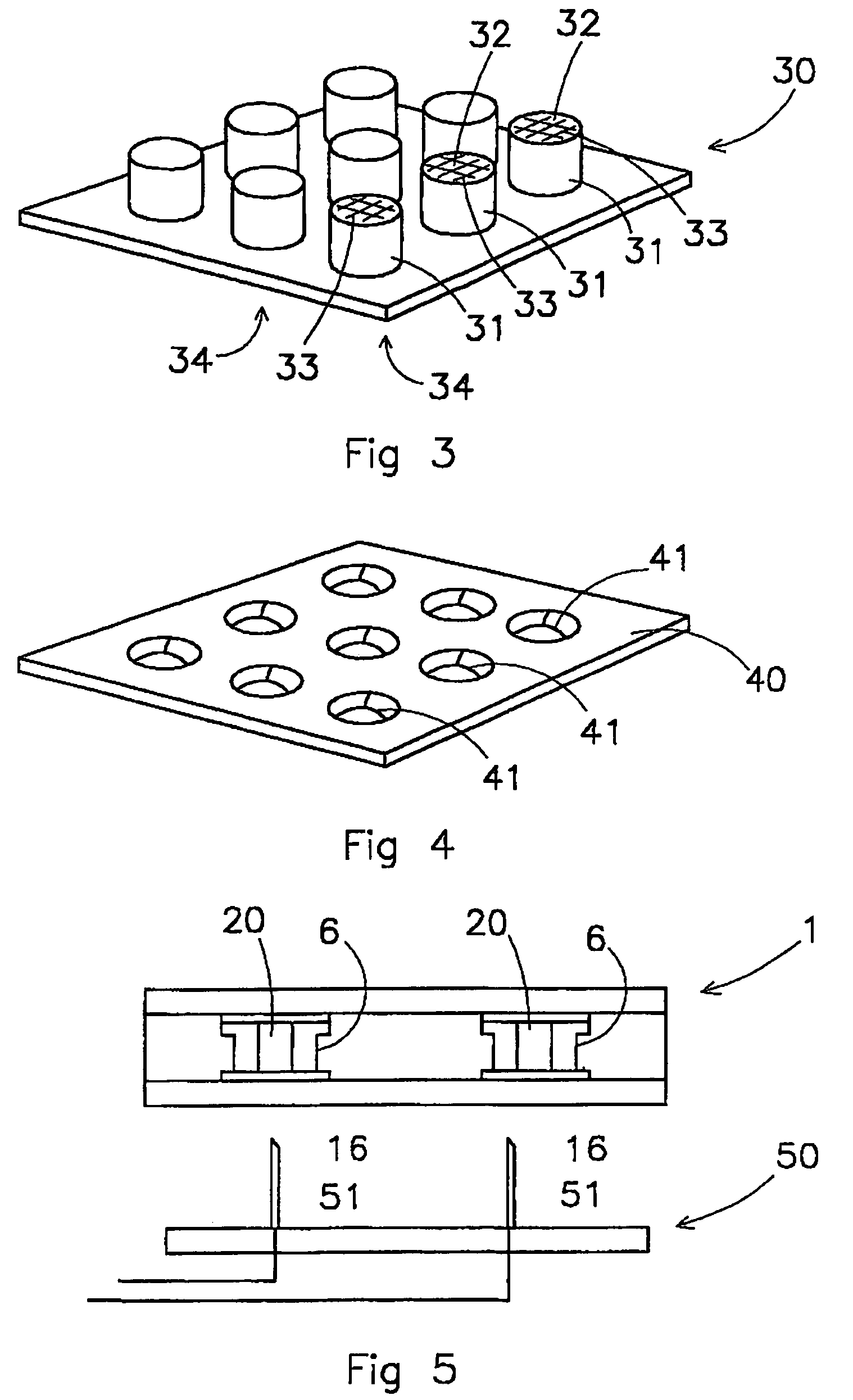

Assembly and method for performing parallel chemical experiments, in particular crystallisation experiments

InactiveUS7608222B2Easy to manufactureEasy to cleanCrystallization conditions screeningSequential/parallel process reactionsCompound (substance)Engineering

An assembly and method for performing parallel chemical experiments, in particular crystallisation experiments. The assembly has a main body having a first and a second face on opposite sides thereof. Multiple bores extend through said main body between said first and second face. Tubular liners are provided having openings at opposite ends thereof, each liner removably fitting in a bore in the main body. First closure means close the openings of the liners at the first face of the main body. Second closure means close the openings of the liners at the second face of the main body. The first and second closure means are fastenable to said main body, so that an experimentation chamber is defined within each liner.

Owner:AVANTIUM INT

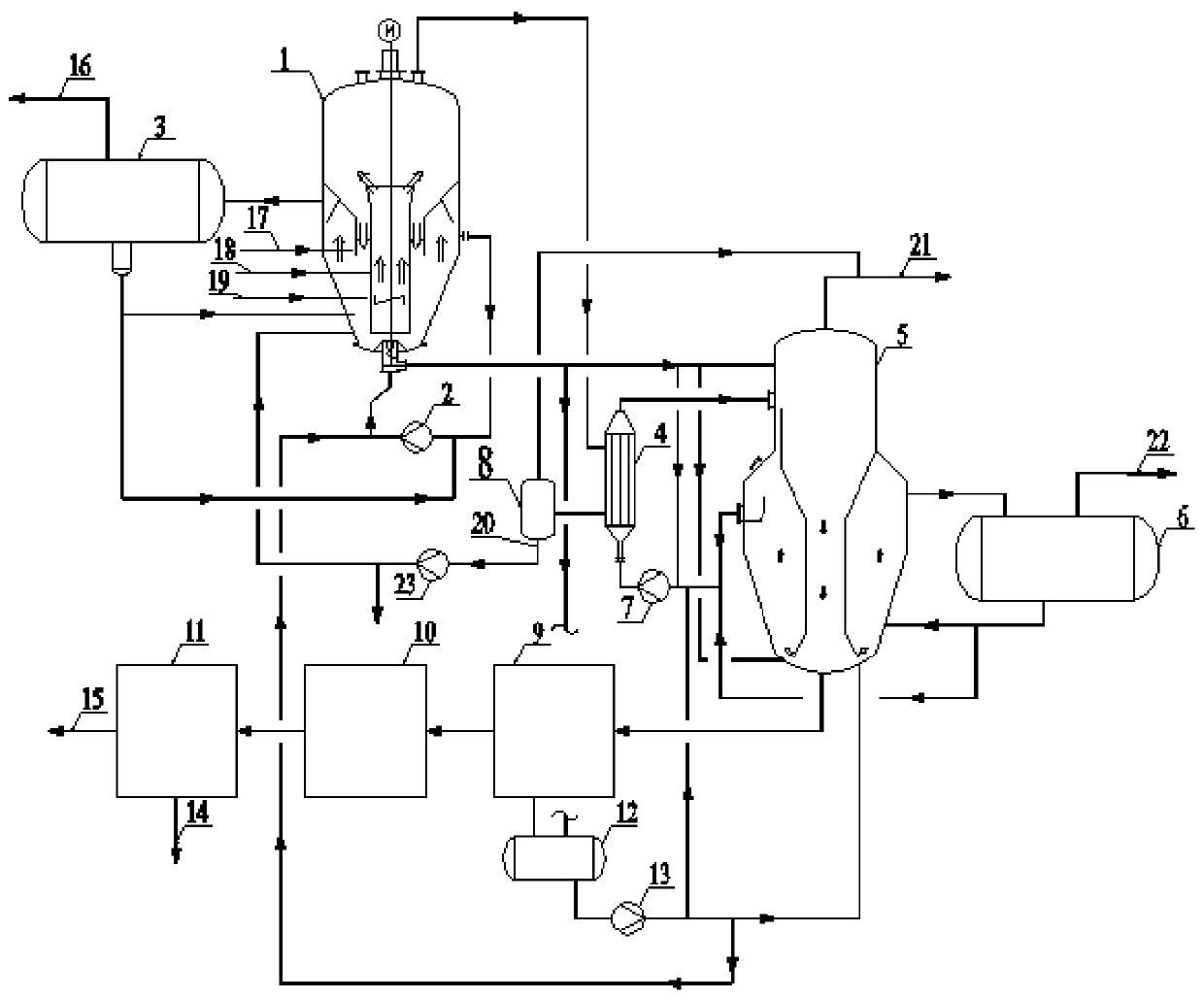

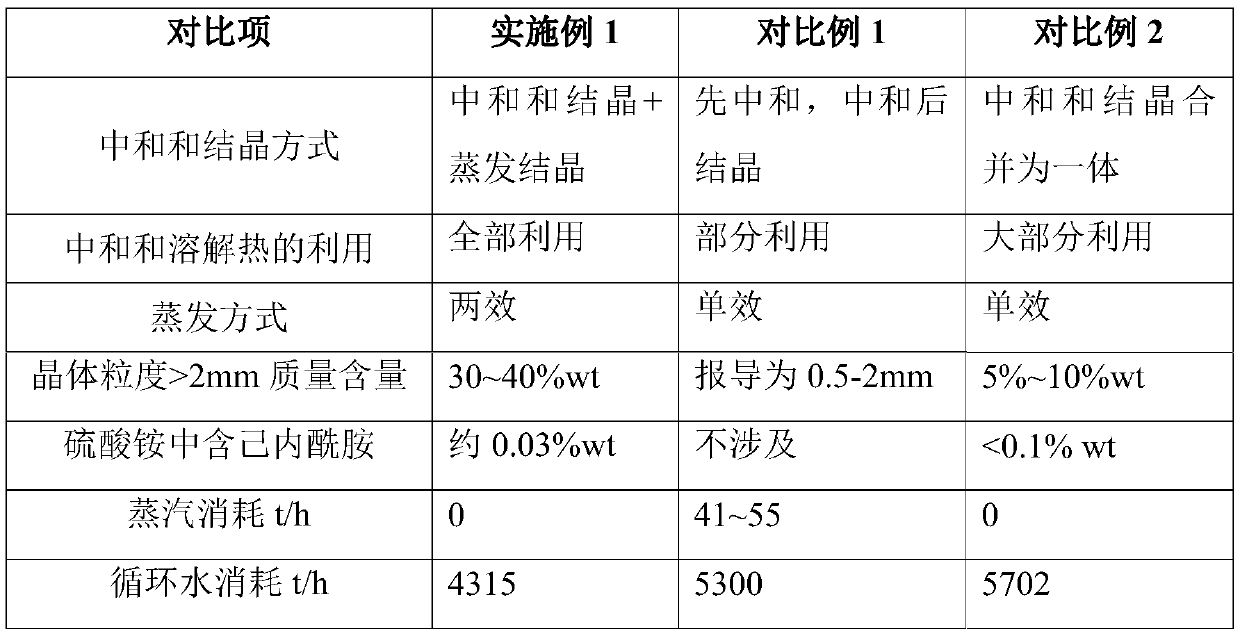

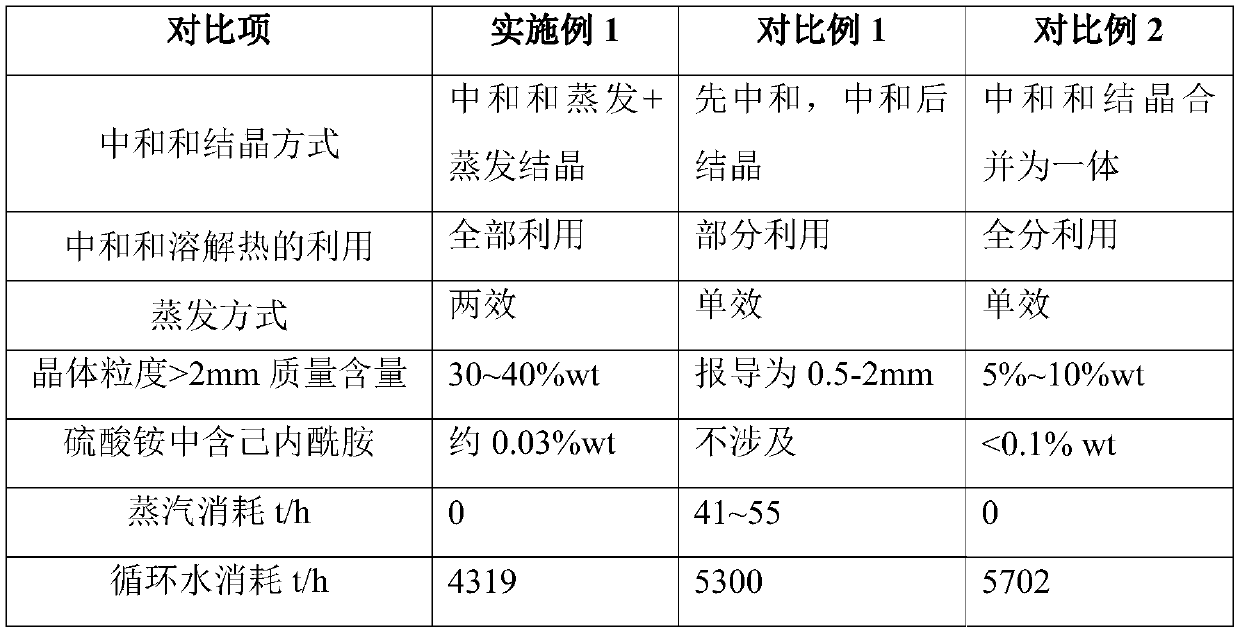

Ammonium sulfate crystallization method and device

ActiveCN111408157AReduce consumptionRaise the ratioCrystallization conditions screeningSolution crystallizationPhysical chemistrySlurry

The invention discloses an ammonium sulfate crystallization method and device, and belongs to the field of chemical engineering. According to the device, two crystallizers connected in series are used, a two-effect vacuum crystallization process is adopted, the first effect is neutralization crystallization, and the second effect is evaporation crystallization. The first effect is slurry which isgenerated by neutralization and crystallization and contains fine crystal particles in a large proportion, and the second effect is an evaporation and crystallization system to obtain ammonium sulfatewith a large-particle ammonium sulfate proportion. According to the device, gas ammonia dissolution heat and neutralization heat of sulfuric acid and ammonia neutralization reaction are fully utilized, and secondary steam of the neutralization crystallizer is used as a heat source, so that the consumption of circulating water is reduced, the proportion of large-particle ammonium sulfate is increased, and meanwhile, the coating loss of caprolactam is reduced.

Owner:SINOPEC NANJING ENG & CONSTR +1

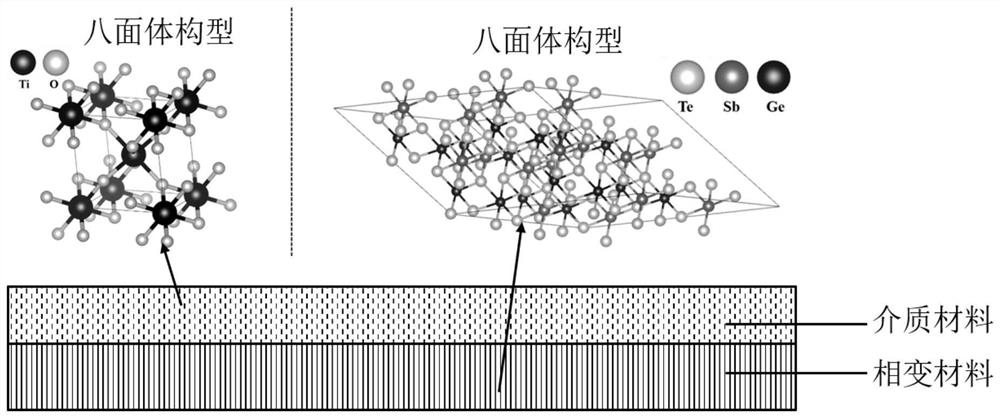

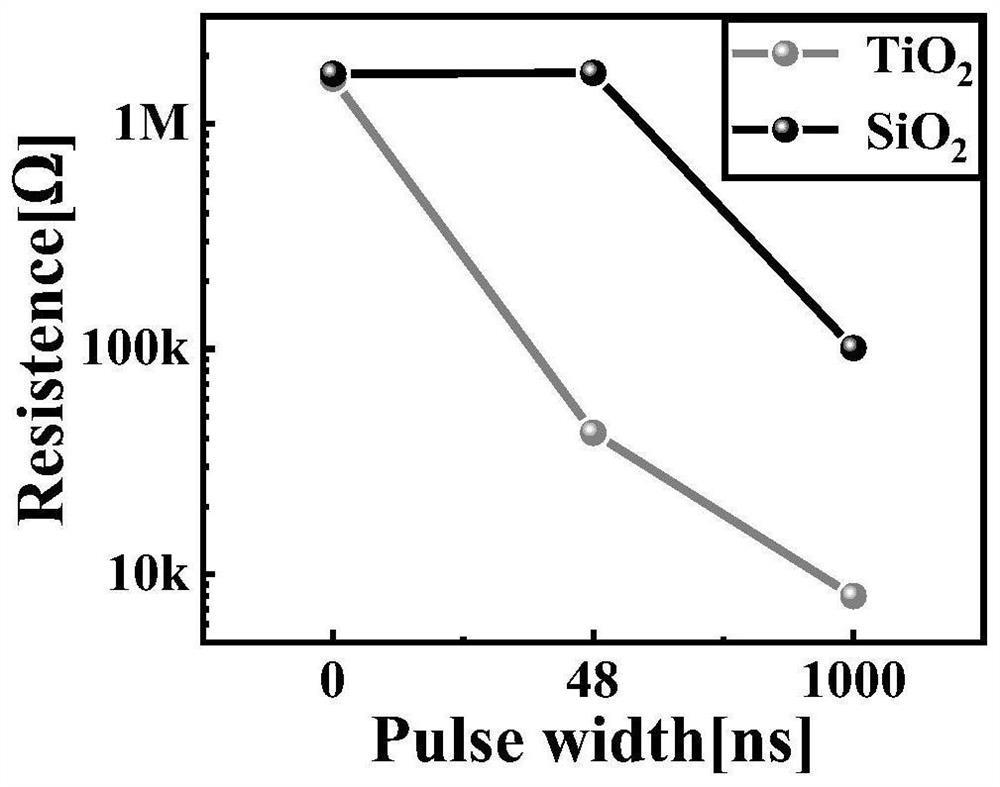

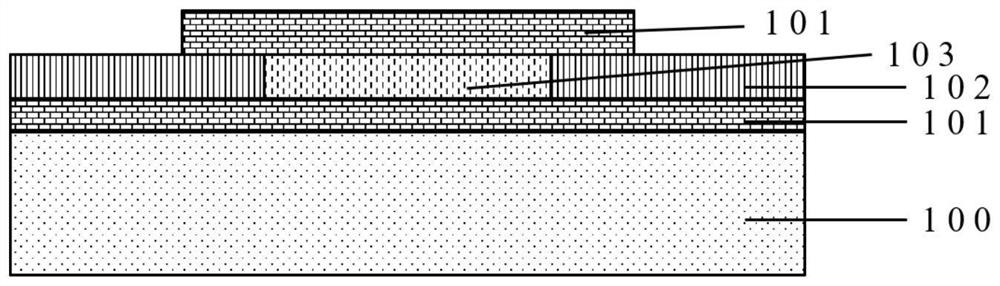

Method for inducing crystallization of chalcogenide phase change material and application thereof

ActiveCN113241405AFast crystallizationPromote crystallizationCrystallization conditions screeningElectrical apparatusOctahedronPhase-change memory

The invention belongs to the field of microelectronics, and particularly relates to a method for inducing crystallization of a chalcogenide phase change material and application thereof, wherein specifically, a dielectric material is in interface contact with a chalcogenide phase change material, and the dielectric material is of an octahedral structure, and provides a crystal nucleus growth center for crystallization of the chalcogenide phase change material at the contact interface of the dielectric material and the chalcogenide phase-change material so as to induce accelerated crystallization of the phase-change material. The method is further applied to an existing phase change memory unit, so that the dielectric material structure of at least one dielectric material layer in all dielectric material layers in contact with the chalcogenide phase change material layer is of an octahedral structure. According to the invention, the dielectric material with an octahedral structure is in contact with the interface of the phase change material layer, the contact interface is inherent to a memory unit device and does not need to be additionally introduced, the influence on the whole semiconductor process is reduced to the minimum, and the phase change material is not optimized and modified in the design of the phase change memory unit, so that a series of other problems caused by optimization of the phase change material are avoided.

Owner:HUAZHONG UNIV OF SCI & TECH

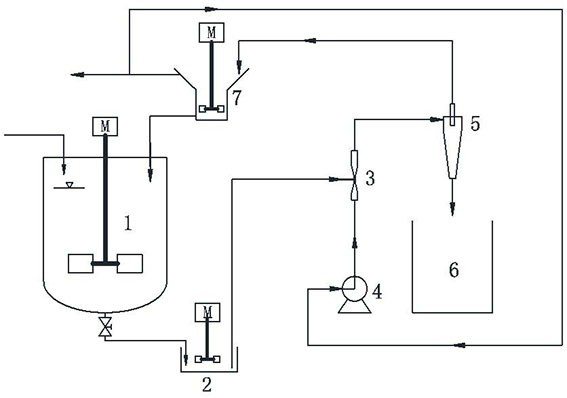

MVR crystallization salification grain control system and control method

PendingCN109481952AQuality assuranceCrystallization conditions screeningSolution crystallizationControl systemEngineering

The invention provides an MVR crystallization salification grain control system and a control method. The system comprises a forced circulation pump, a crystallizer discharging pump, an elutriation circulating pump, a control system, a forced circulation heat exchanger, an Oslo crystallizer and an elutriation separator, wherein a circulating liquid outlet is connected with a heat exchange inlet, aheat exchange outlet is connected with a circulating liquid inlet, a crystallization material liquid outlet is connected with a crystallization material liquid inlet through the crystallizer discharging pump, an elutriation clear liquid outlet is connected with a elutriation clear liquid inlet, a mother solution outlet is further connected to a connecting pipeline of a circulating liquid outlet and the forced circulation pump and is connected with a mother solution inlet through the elutriation circulating pump, and the control system is connected with the forced circulation pump, the crystallizer discharging pump and the elutriation circulating pump, respectively. The crystallizer is of an Oslo structure, the elutriation separator is additionally arranged, and the grains are primarily screened in the crystallizer and are further elutriated and screened by virtue of the elutriation separator, so that the quality of the product is guaranteed.

Owner:JIANGSU RUISHENGHUA ENERGY TECH CO LTD

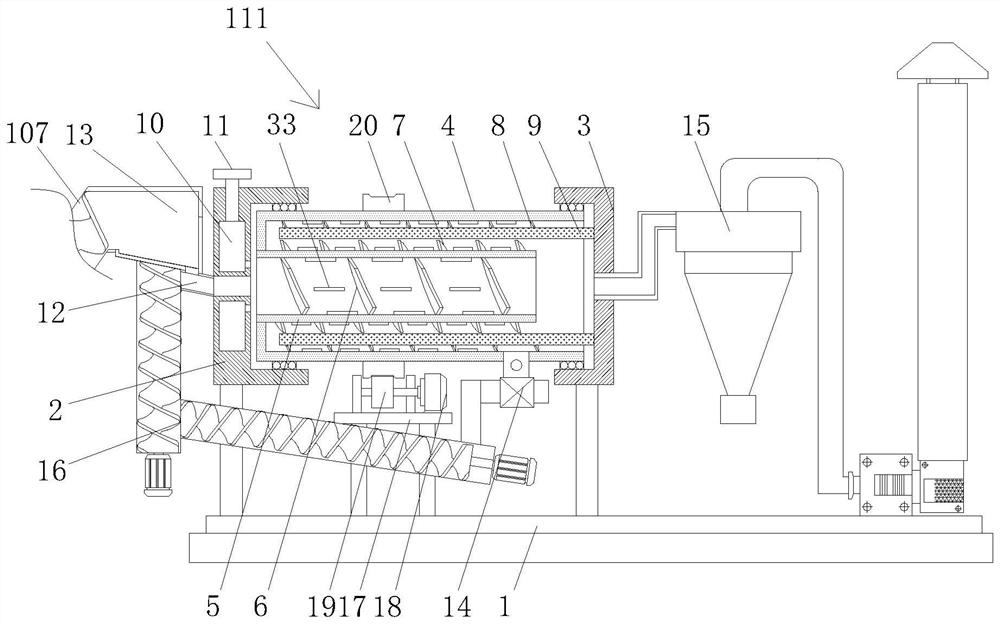

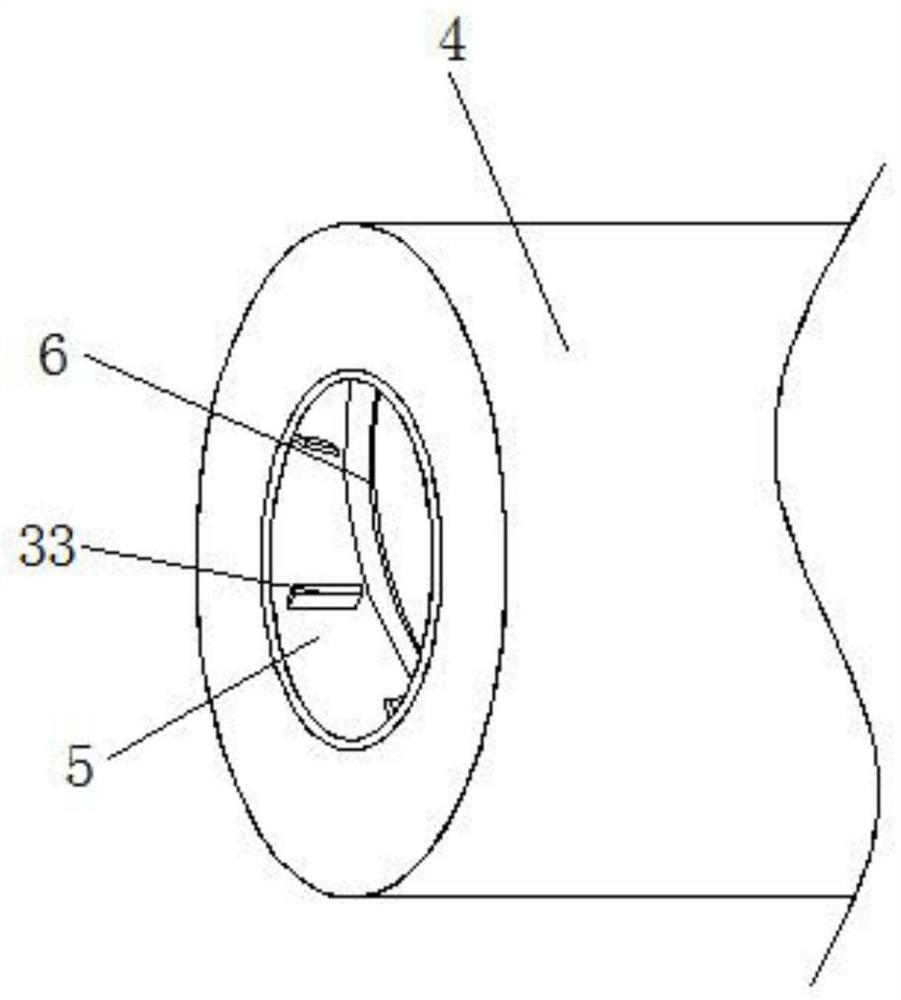

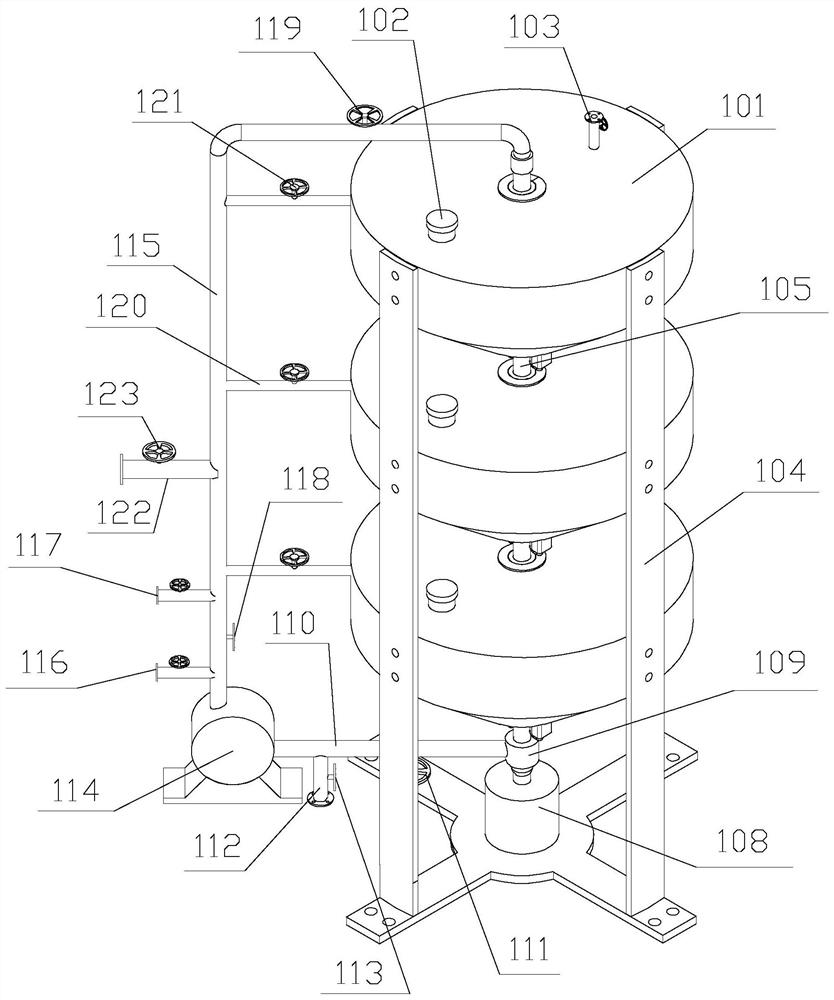

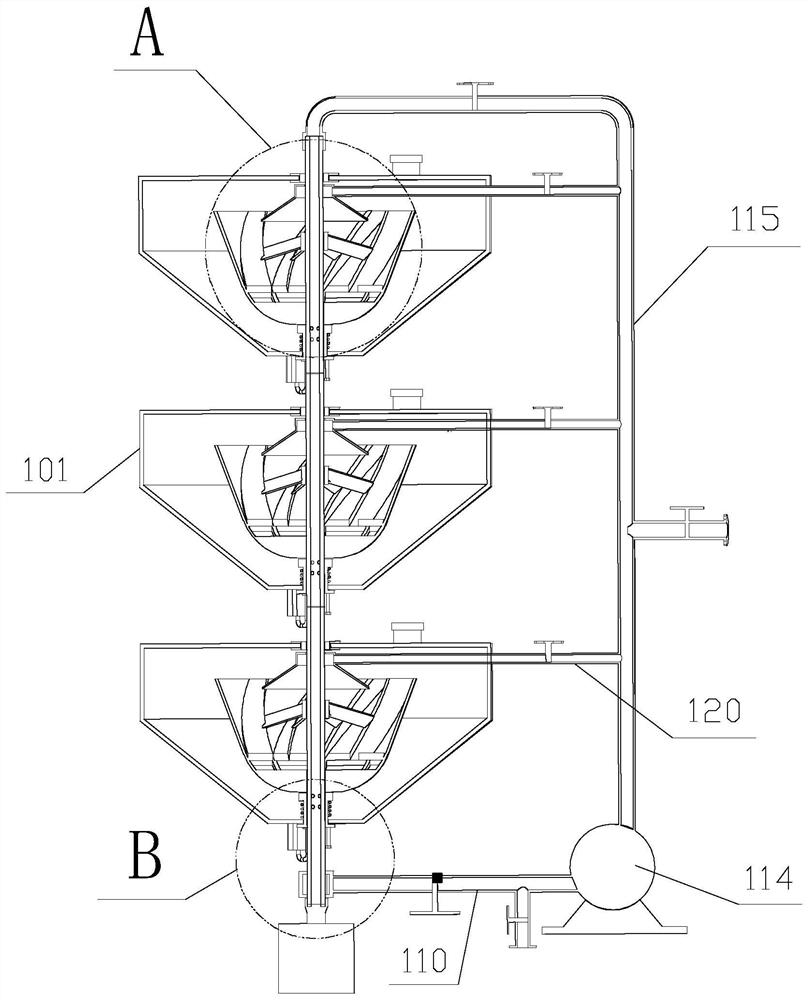

Granulation and crystallization device used in sodium metasilicate preparation process

ActiveCN113058284AEasy to separateAvoid stickingCrystallization conditions screeningAlkali metal silicatesSodium metasilicateSpiral blade

The invention discloses a granulation and crystallization device used in a sodium metasilicate preparation process, and relates to the technical field of sodium metasilicate production equipment.The granulation and crystallization device comprises a crystallization tank, a discharging mechanism, a granulation and crystallization mechanism and a wall scraping mechanism, a motor is arranged at the top end of the crystallization tank, and a slag discharging pipe is arranged at the bottom end of the crystallization tank; a slag discharging valve is arranged on one side of the outer wall of the slag discharging pipe, and a cooling liquid inlet pipe, a stock solution feeding pipe and a seed crystal feeding pipe are arranged on one side of the outer wall of the crystallizing tank. By arranging the crystallizing tank, the crystallizing bin, the motor, the filter plate, the water suction cylinder, the water suction groove hole, the rotating shaft, the spiral blade, the first connecting rod, the stirring rod, the second connecting rod, the vertical scraper, the stock solution feeding pipe and the seed crystal feeding pipe, quick separation of crystallized particles can be achieved, and the working efficiency of sodium metasilicate crystallization is effectively improved.

Owner:高安市环瓷达釉料有限公司

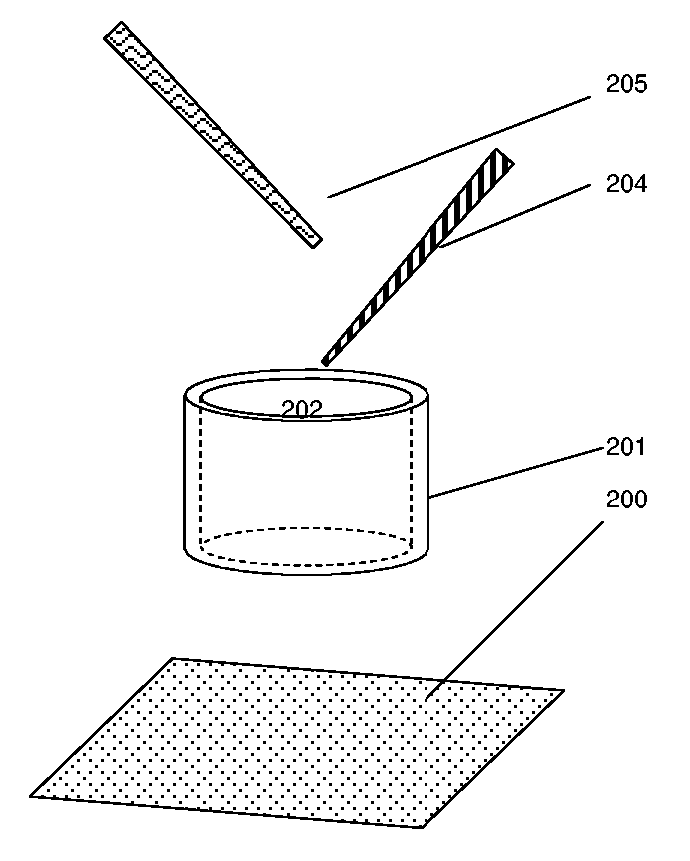

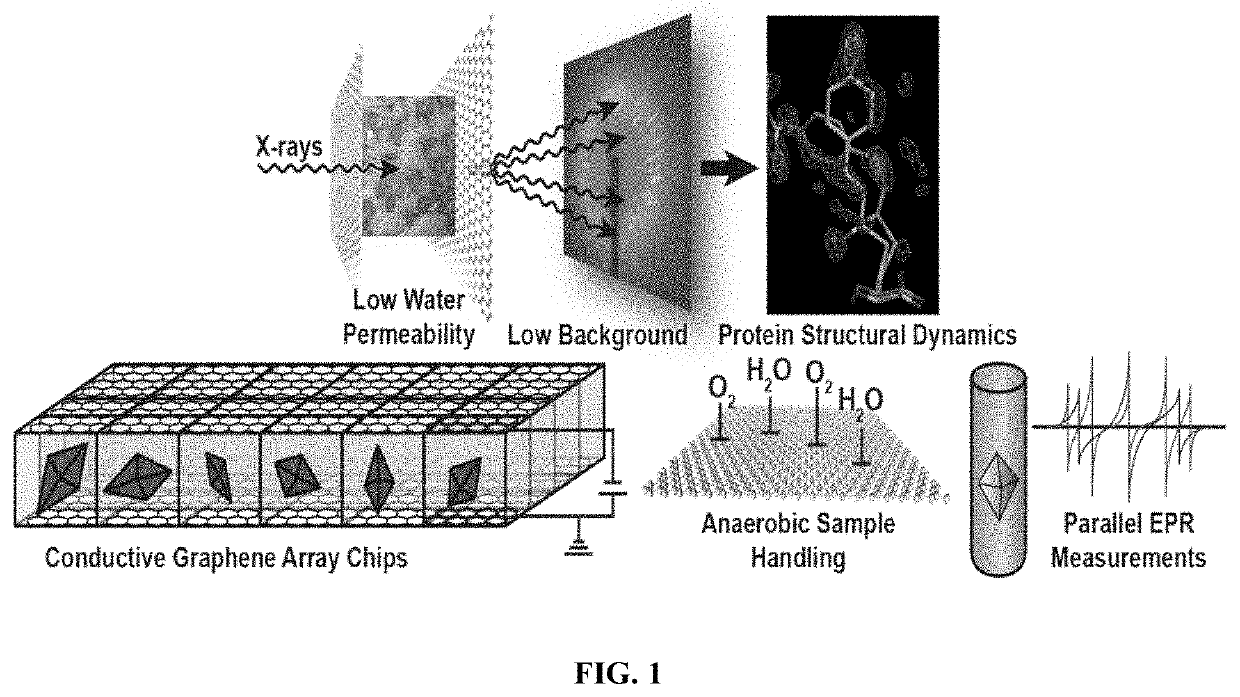

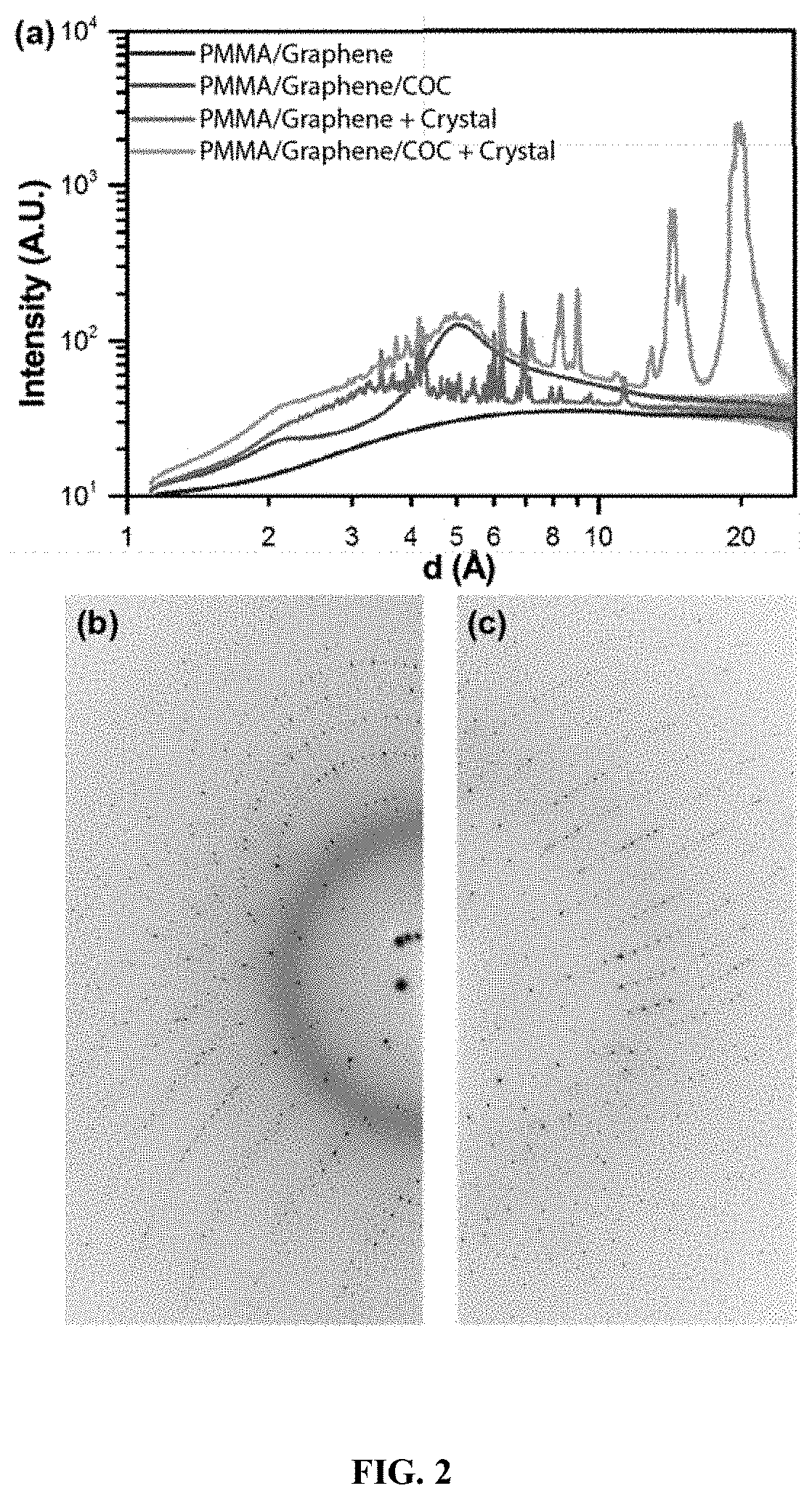

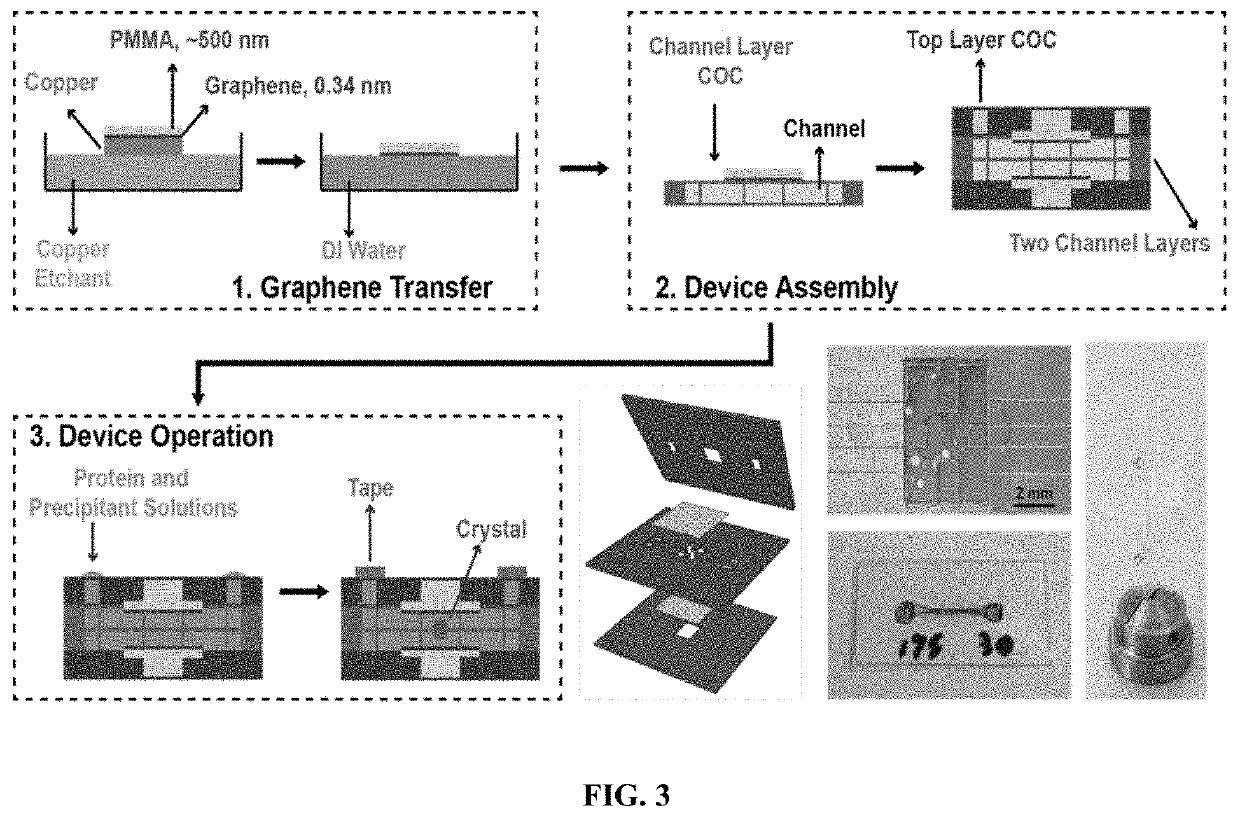

Graphene-based electro-microfluidic devices and methods for protein structural analysis

ActiveUS20190383764A1Fast crystal growthFast nucleationCrystallization conditions screeningPolycrystalline material growthX-rayStructural analysis

The invention provides a novel microfluidic platform for use in electro-crystallization and electro-crystallography experiments. The manufacturing and use of graphene as X-ray compatible electrodes allows the application of electric fields on-chip, during X-ray analysis. The presence of such electric fields can be used to modulate the structure of protein (or other) molecules in crystalline (for X-ray diffraction) or solution form (for X-ray scattering). Additionally, the presence of an electric field can be used to extend the lifetime of fragile samples by expediting the removal of reactive secondary radiation damage species.

Owner:UNIV OF MASSACHUSETTS

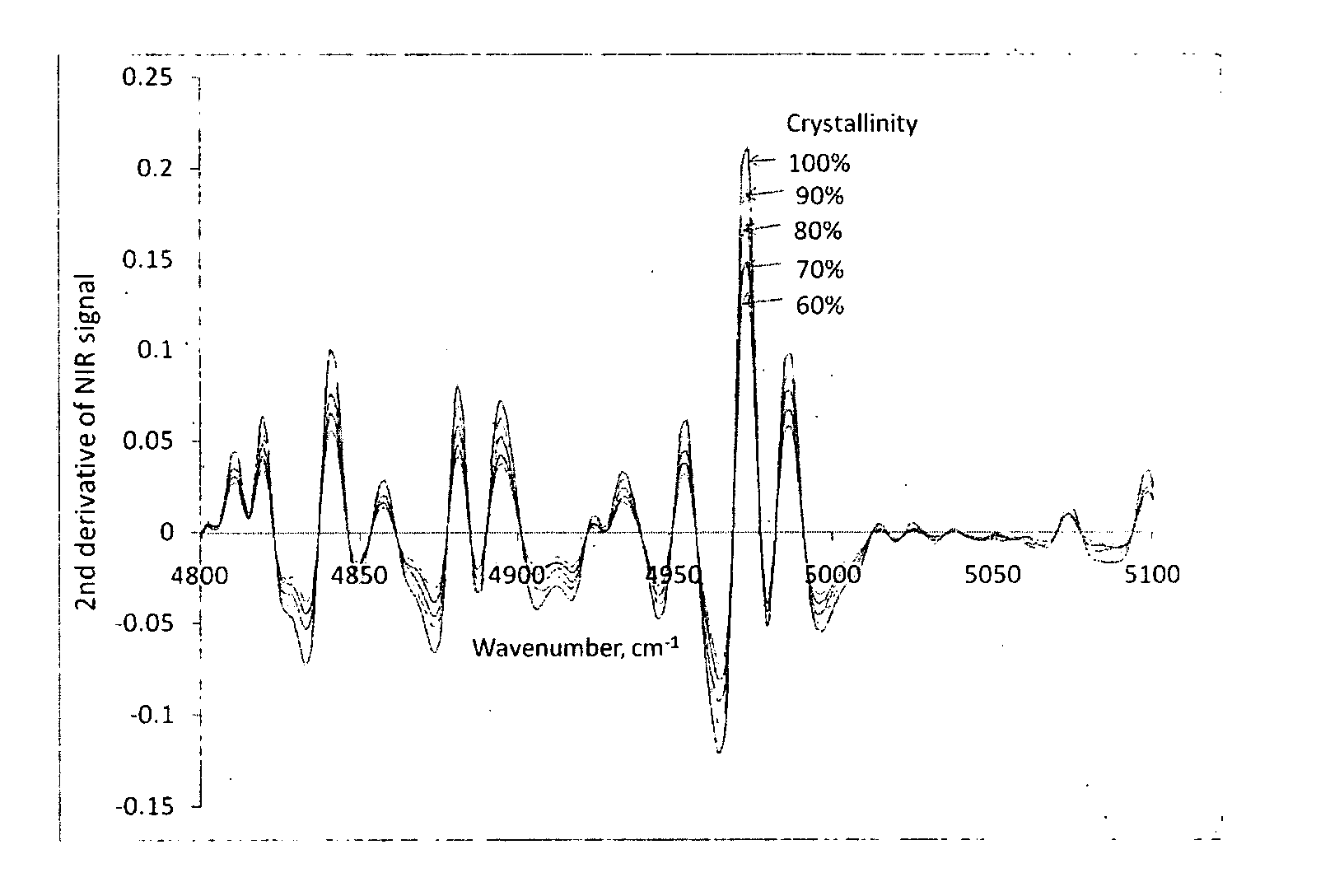

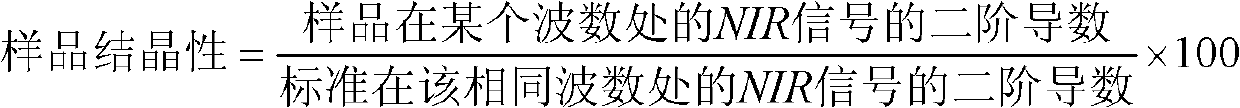

Method for Determination of Sirolimus Stability and Process for Preparing Its Stable Form

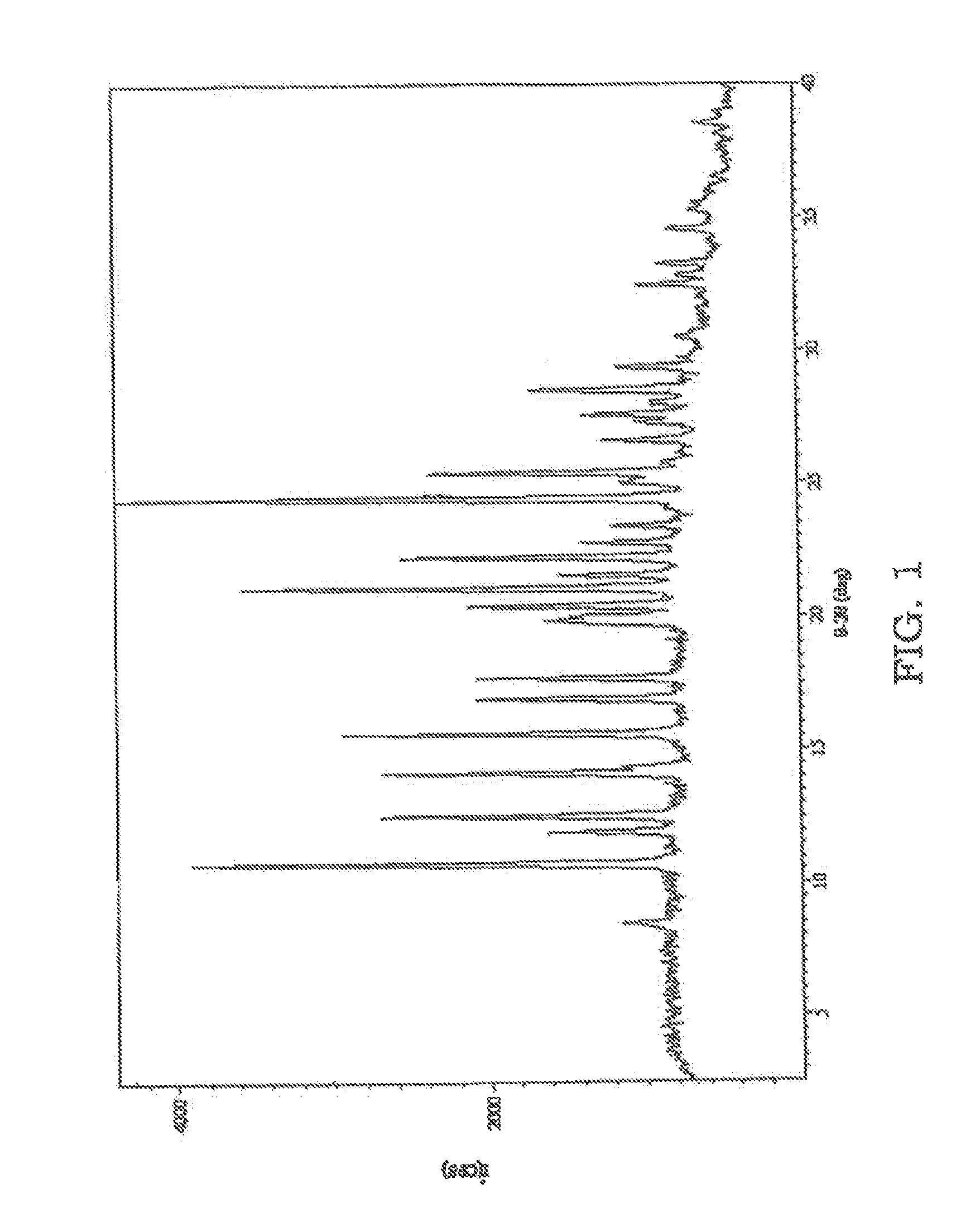

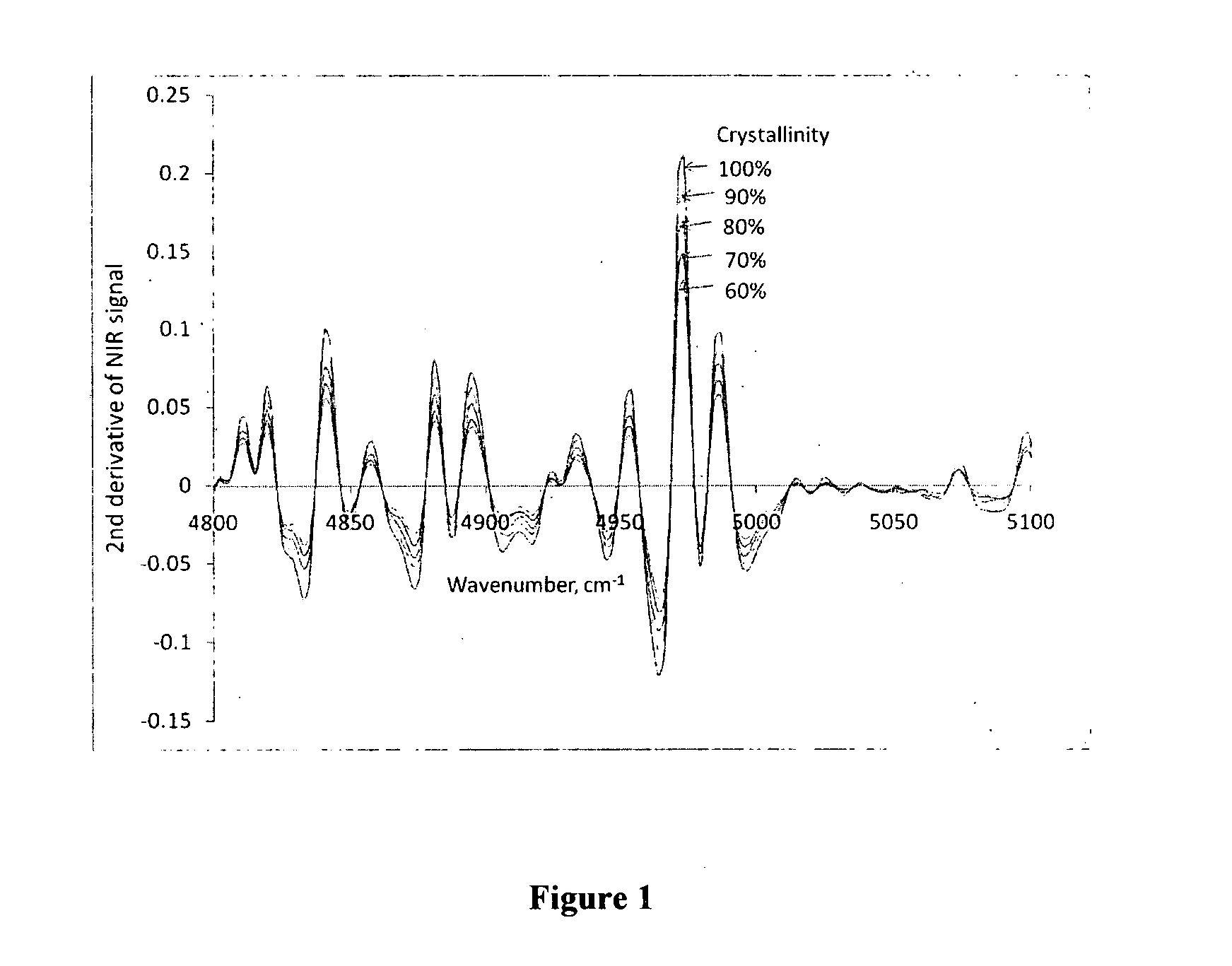

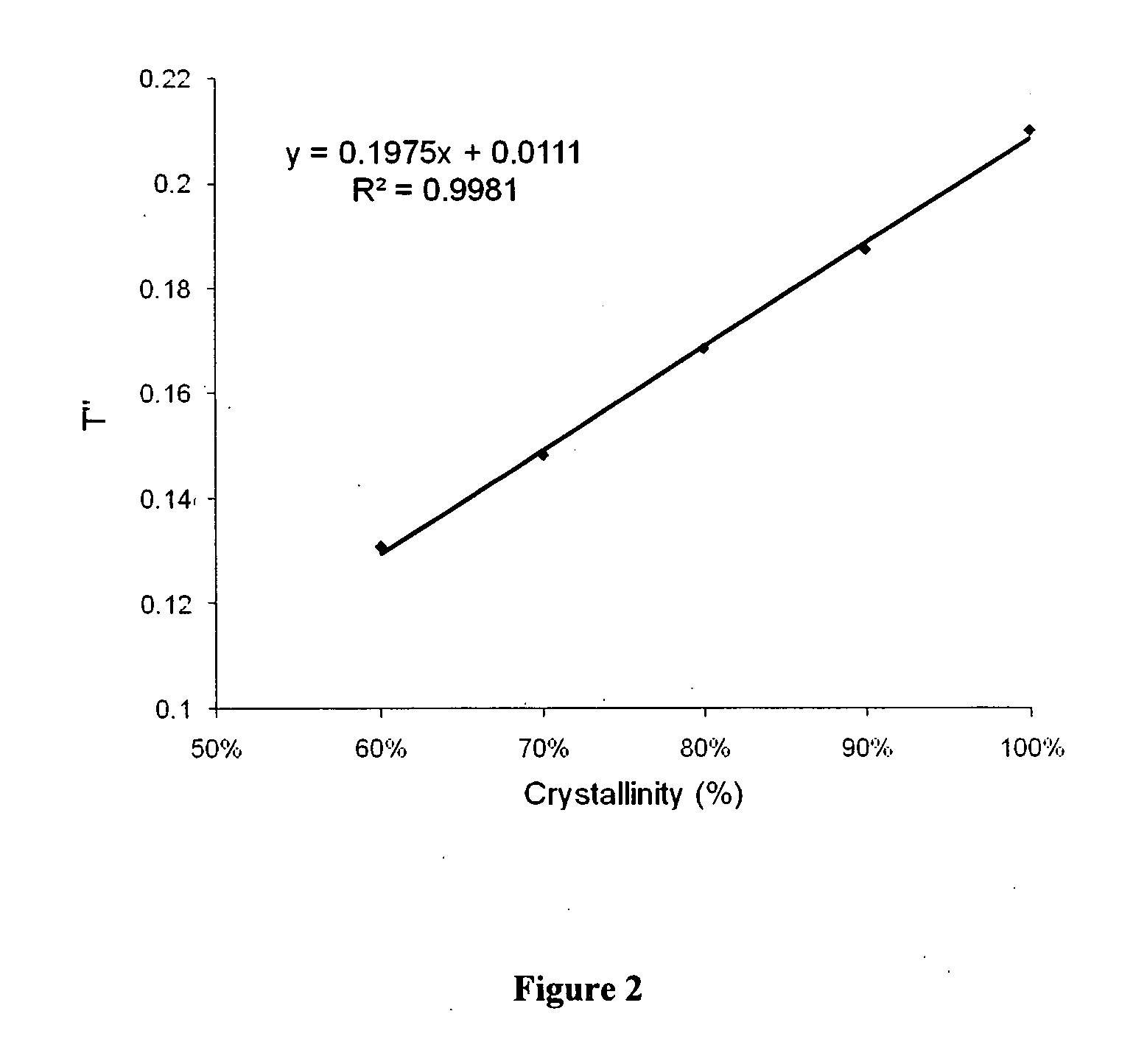

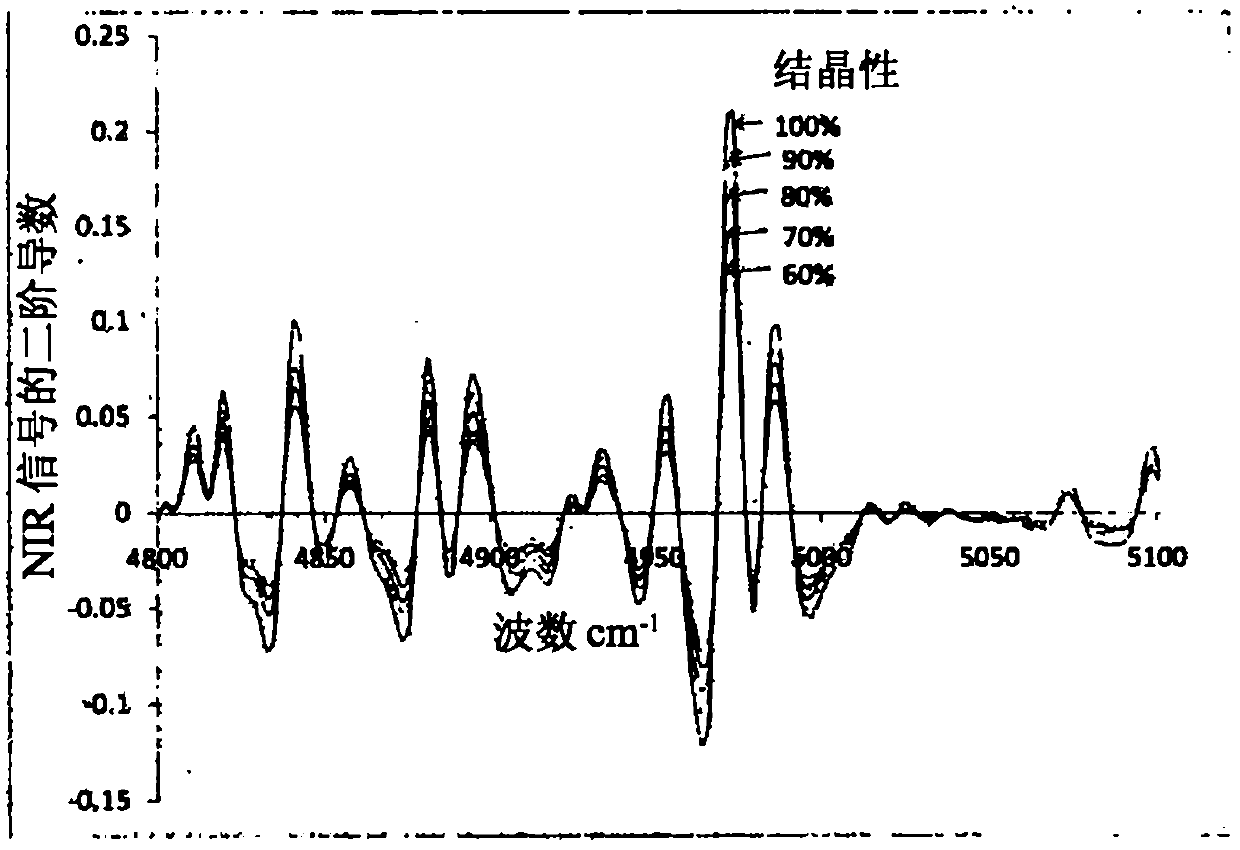

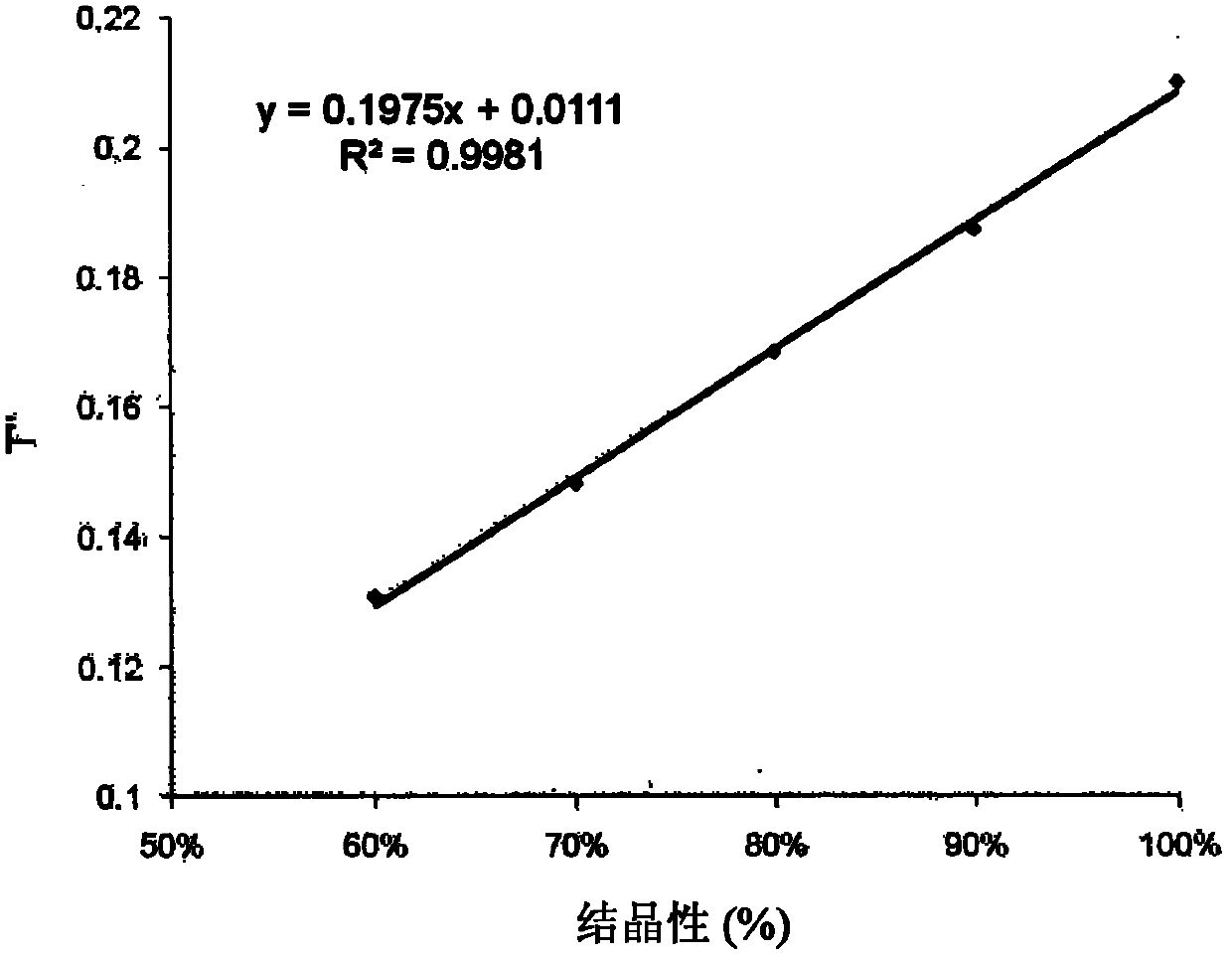

InactiveUS20110275798A1Crystallization conditions screeningRadiation pyrometrySpectroscopyCrystallinity

The present disclosure provides solution to the problems involved in determining the crystallinity of sirolimus. More particularly, the instant disclosure is successful in providing a method to determine crystallinity of sirolimus or its analogues using Near-Infrared [NIR] spectroscopy. Also, the instant disclosure provides a method for crystallization of sirolimus or its analogues.

Owner:BIOCON LTD

Method for determining the stability of sirolimus and process for preparing stable forms thereof

The present disclosure provides solution to the problems involved in determining the crystallinity of sirolimus. More particularly, the instant disclosure is successful in providing a method to determine crystallinity of sirolimus or its analogues using Near-Infrared [NIR] spectroscopy. Also, the instant disclosure provides a method for crystallization of sirolimus or its analogues.

Owner:BIOCON LTD

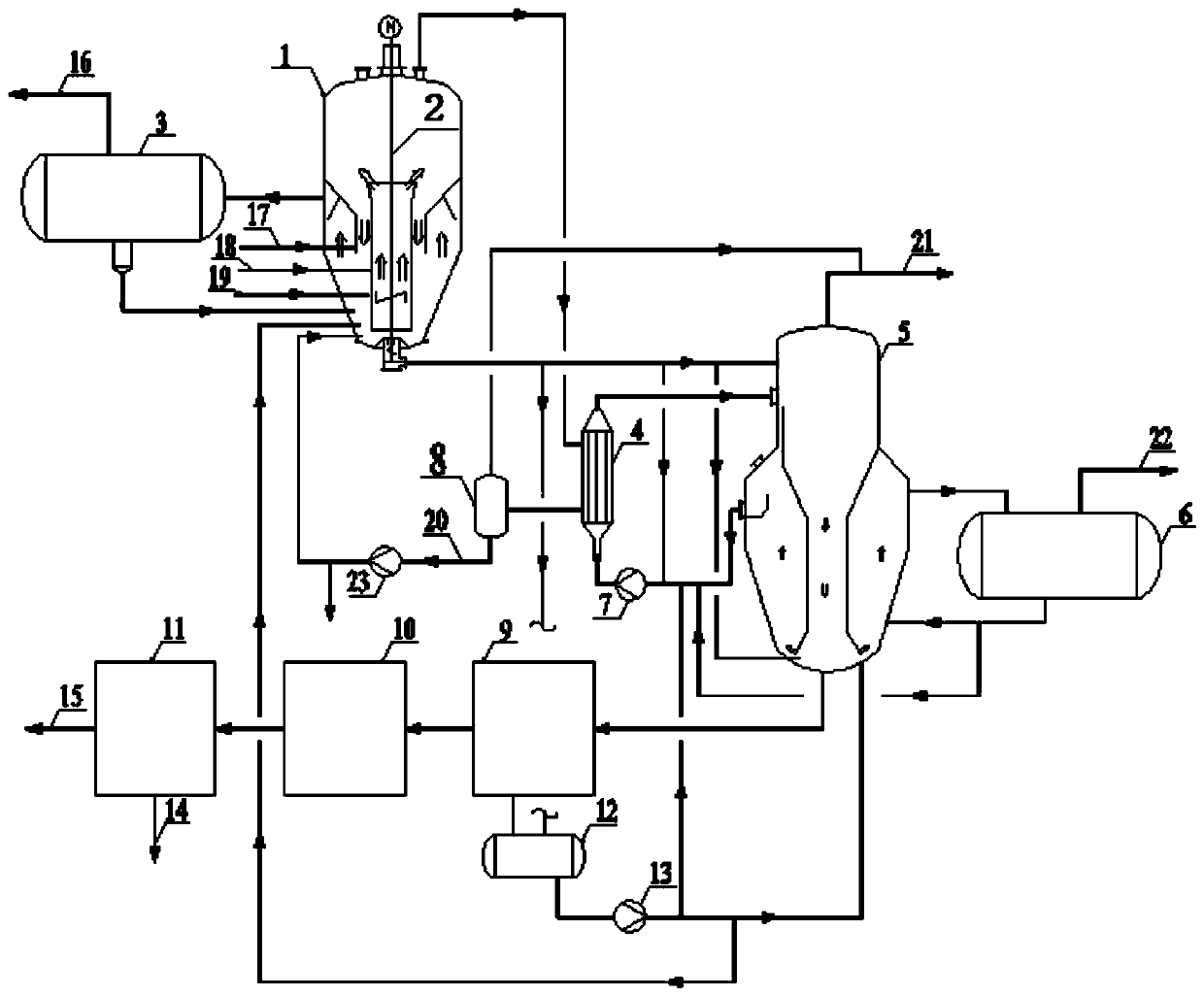

Tandem ammonium sulfate crystallization method and device

ActiveCN111530119AReduce consumptionRaise the ratioCrystallization conditions screeningLactams preparationPhysical chemistryAmmonia

The invention discloses a tandem ammonium sulfate crystallization method and device, and belongs to the field of chemical engineering. According to the device, two crystallizers connected in series are used, a two-effect vacuum crystallization process is adopted, the first effect is neutralization evaporation, and the second effect is evaporation crystallization. An ammonium sulfate solution withthe concentration of about 40% neutralized and evaporated is fed into the second effect section of an evaporative crystallization system so that ammonium sulfate with a large-particle ammonium sulfateproportion is obtained. According to the device, gas ammonia dissolution heat and neutralization heat of sulfuric acid and ammonia neutralization reaction are fully utilized, and secondary steam of the neutralization evaporator is used as a heat source, so that the consumption of circulating water is reduced, the proportion of large-particle ammonium sulfate is increased, and meanwhile, the coating loss of caprolactam is reduced.

Owner:SINOPEC NANJING ENG & CONSTR +1

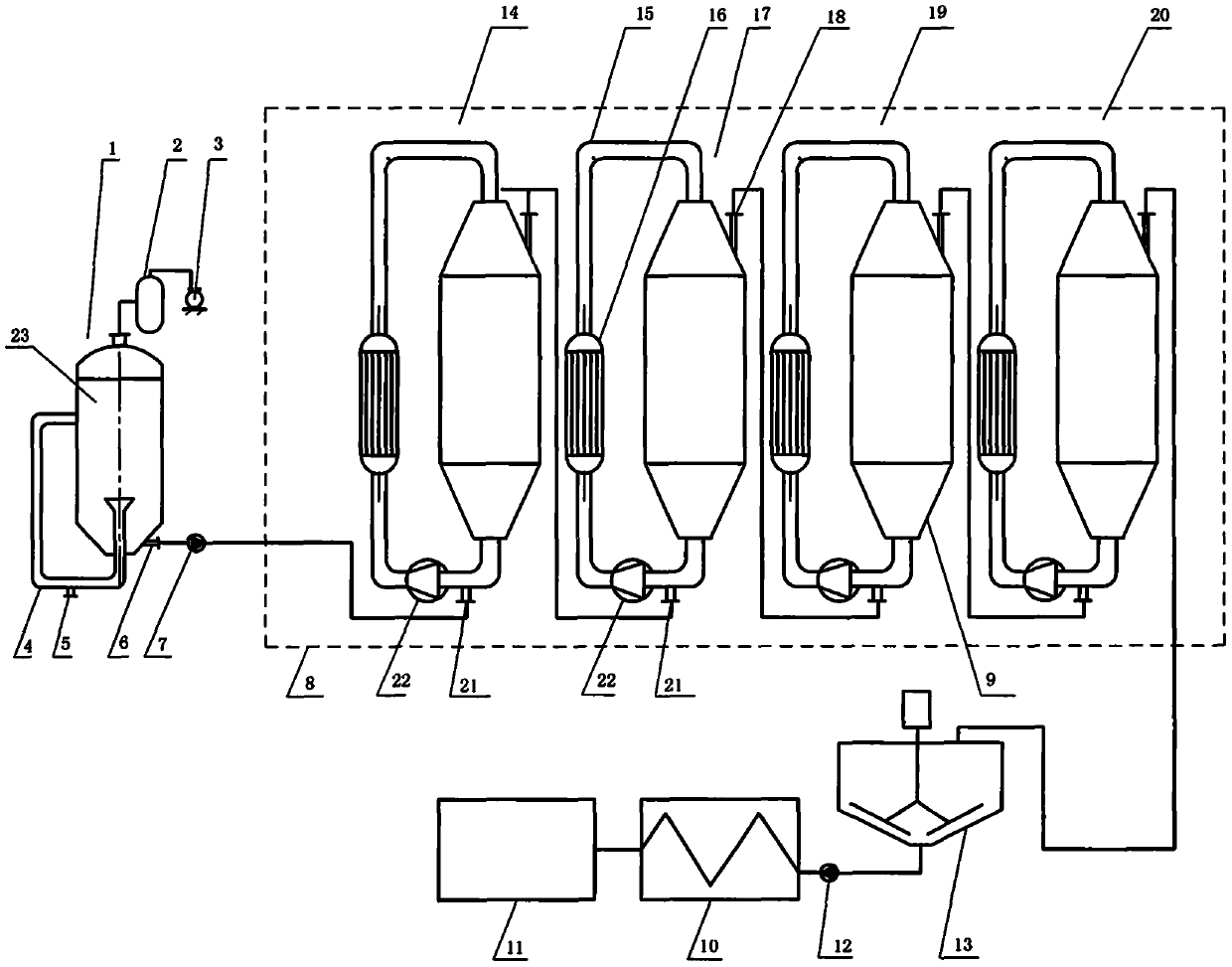

Equipment and method for producing inorganic salt with solubility changing along with temperature through cooling crystallization

PendingCN110860105AGranularity controllableUniform particle sizeCrystallization conditions screeningFrom normal temperature solutionsInorganic saltsEngineering

The invention discloses equipment for producing an inorganic salt with solubility changing along with temperature through cooling crystallization. The equipment comprises a nucleation controller, a first delivery pump, a crystal growth device, a heat preservation settler, a second delivery pump, a centrifugal machine and a vibration drying bed which are sequentially connected. The nucleation controller comprises a nucleation tank, a first circulating pipe, a condenser and a vacuum pump, wherein one end of the first circulating pipe is connected with the side wall of the nucleation tank; the other end of the first circulating pipe extends into the nucleation tank from the bottom end of the nucleation tank and is horn-mouth-shaped; one end of the first circulating pipe is higher than the other end; a feeding pipe is arranged at the lower end of the first circulating pipe outside the nucleation tank; the sectional area of the first circulating pipe is 3-7 times the sectional area of the feeding pipe; a discharging pipe is installed at the position close to the bottom end of the nucleation tank and connected with the crystal growth device through the first delivery pump; the top end ofthe nucleation tank is sequentially connected with the condenser and the vacuum pump; and the crystal growth device comprises at least two crystallizers which are sequentially connected.

Owner:尹博闻

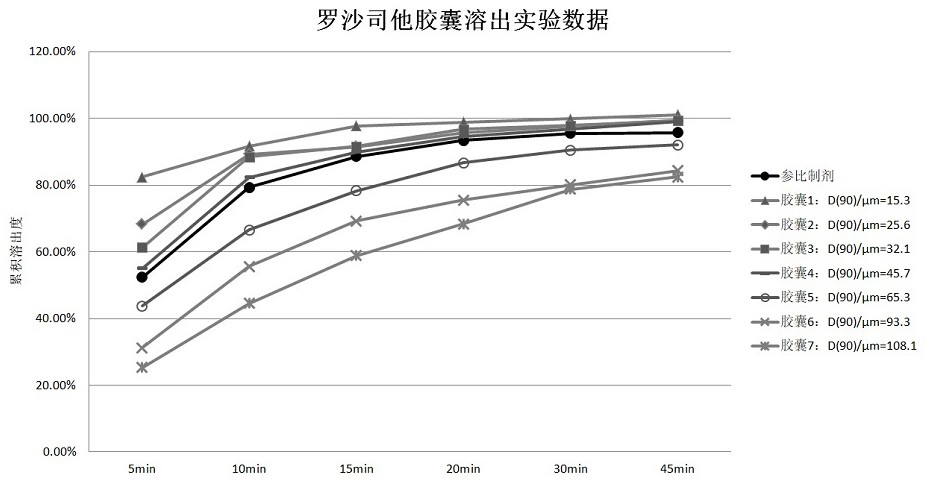

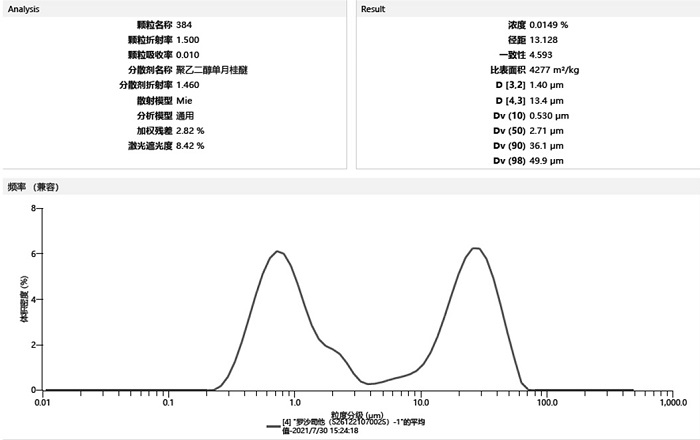

Crystallization process of Roxadustat bulk drug with controlled particle size

PendingCN113956200ASafe and simple crystallization processHigh yieldCrystallization conditions screeningOrganic chemistry methodsAcetic acidMedicine

The invention relates to a crystallization process of a Roxadustat bulk drug with a controlled particle size. The process comprises the steps of salifying the Roxadustat (I) with alkali, filtering, heating, adding a first part of an acetic acid aqueous solution to adjust the pH value to 6.4-6.7, adding a Roxadustat seed crystal and a second part of the acetic acid aqueous solution, crystallizing, centrifuging, and drying to obtain the Roxadustat bulk drug with a controlled particle size. The particle size D (90) of the Roxadustat bulk drug prepared by the process method is 25-45 [mu] m, and the Roxadustat bulk drug meets the requirements of preparations and is suitable for industrial production.

Owner:NANJING VCARE PHARMATECH CO LTD

Protein crystallizing agent and method of crystallizing protein therewith

InactiveUS8367412B2Easy to useImprove crystallizationUrea derivatives preparationFrom normal temperature solutionsCrystallographyHigh probability

The present invention provides a technique for crystallizing a desired protein at a high probability; namely, a protein crystallizing agent and a method of crystallizing protein. The present invention also provides a technique for determining the conditions for protein crystallization easily with high efficiency; namely, a method of screening the conditions for protein crystallization and a protein crystallization screening reagent. As the protein crystallizing agent, at least one compound selected from the group consisting of a basic amino acid, acidic amino acid, ester derivative of amino acid and amide derivative of amino acid is used, or at least one of these compounds is used in combination with another protein crystallizing agent.

Owner:KWANSEI GAKUIN EDUCTIONAL FOUND

Efficient seed crystal grading and separating device

ActiveCN114130637AAvoid wastingImprove utilization efficiencySievingCrystallization conditions screeningPhysical chemistryBiology

A # 0 separation plate, a # 1 separation plate and a # 2 separation plate are sequentially arranged in a shell from top to bottom, and the interior of the shell is divided into a drainage chamber, a # 1 seed crystal chamber, a # 2 seed crystal chamber and a clear water chamber which are sequentially distributed from top to bottom through the # 0 separation plate, the # 1 separation plate and the # 2 separation plate; the top of the drainage chamber is provided with a top connector, the top connector is connected with one end of a top main pipe, and the other end of the top main pipe is connected with a sucking pump through a sucking valve; a water inlet device is arranged in the # 1 seed crystal chamber; a # 1 seed crystal discharge interface is formed in the side surface of the bottom of the # 1 seed crystal chamber; a water inlet of the water inlet device is connected with one end of the water inlet main pipe through a water inlet connector, and the other end of the water inlet main pipe is connected with a crystal seed discharging port of the crystallization reactor through a water inlet valve. And immature seed crystals are not recycled.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION +1

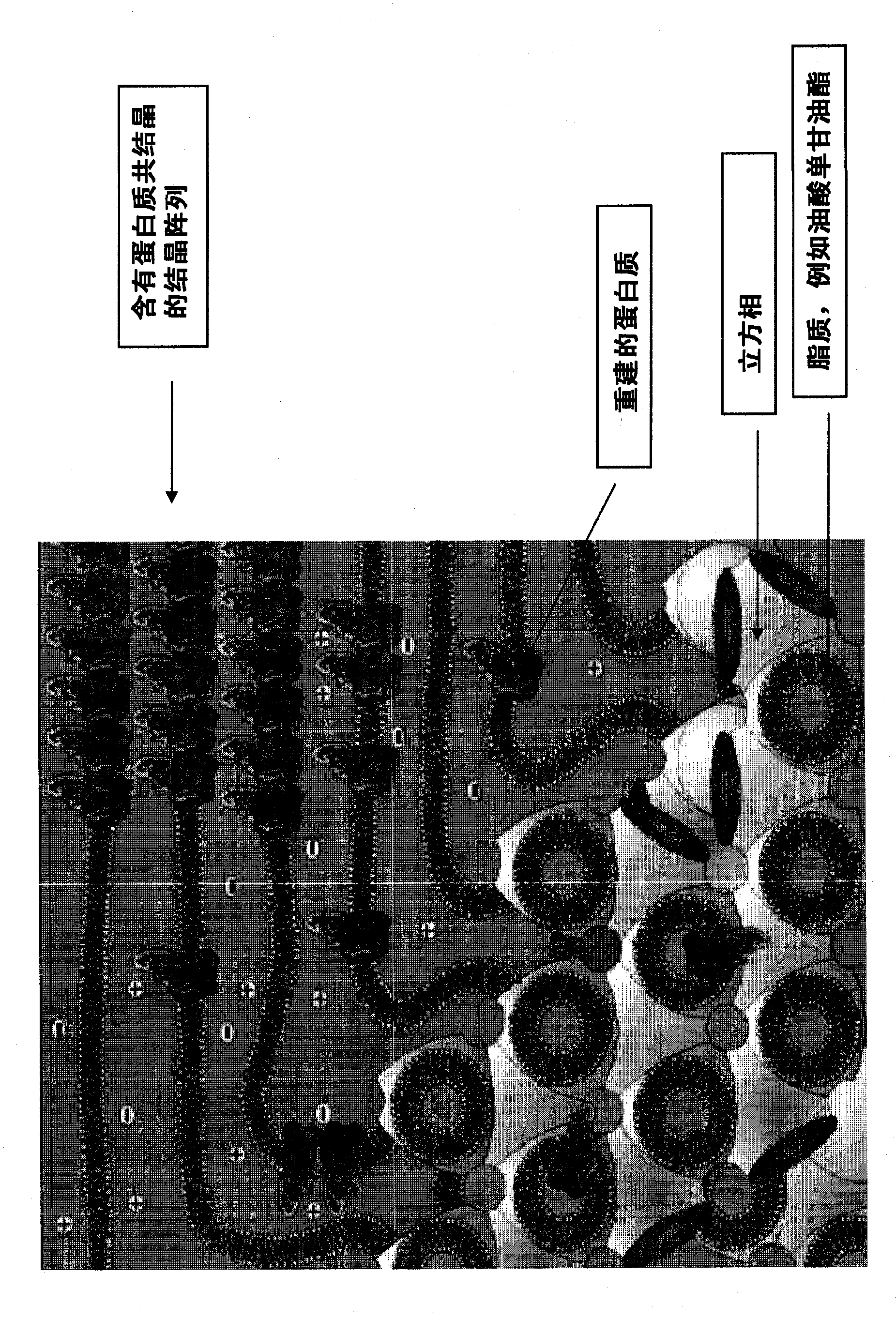

Method of loading a crystallization device

ActiveCN102170946APrevent evaporationPolycrystalline material growthCrystallization conditions screeningWAS PROTEINMembrane protein crystallization

The present invention pertains to a method for loading a crystallization device and for manufacturing a crystallization device comprising multiple receptacles with a pre-defined amount of at least one matrix-forming compound capable of forming a crystallization matrix for a membrane protein, said method comprising the following steps: a) modifying the state of aggregation of said at least one matrix-forming compound to a fluidic state which allows dispensing said at least one matrix-forming compound, and b) dispensing a defined amount of said at least one matrix-forming compound into at least one receptacle of the crystallization device, wherein said dispensed matrix-forming compound solidifies within said receptacle. Thereby, prefilled crystallization devices are obtained which can be used as consumables in particular in automated crystallization processes. Also provided are protein crystallization methods using respectively prepared crystallization devices.

Owner:QIAGEN GMBH +1

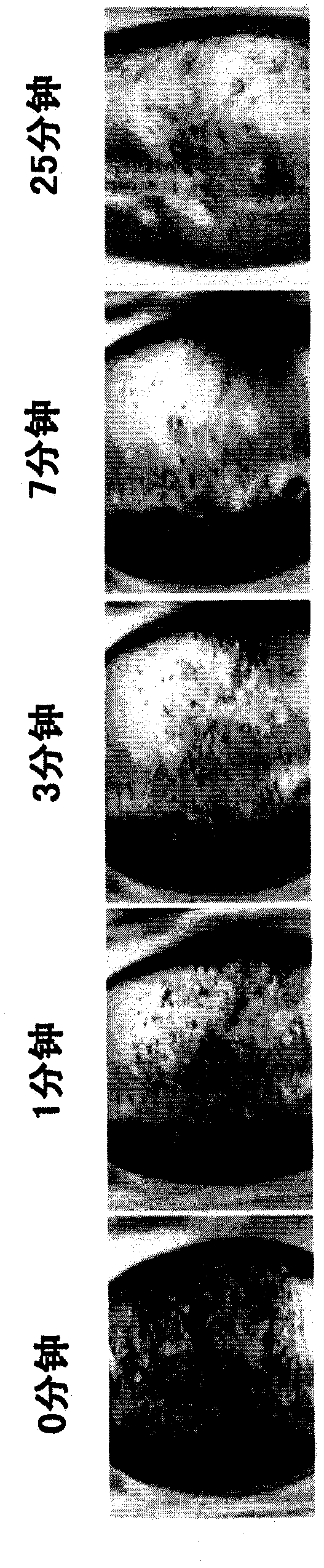

Method for performing crystallization trials

InactiveUS7416709B1Improve accuracyReduce needAfter-treatment apparatusPolycrystalline material growthPhysical chemistryOrganic chemistry

A method is provided that comprises having a trial generation station generate crystallization trials in a crystallization plate transporting the crystallization plate to an imaging station; and having the imaging station take images of the crystallization trials within 30 minutes of the formation of the crystallization trials; wherein the method is performed in a single automated system.

Owner:TAKEDA SAN DIEGO

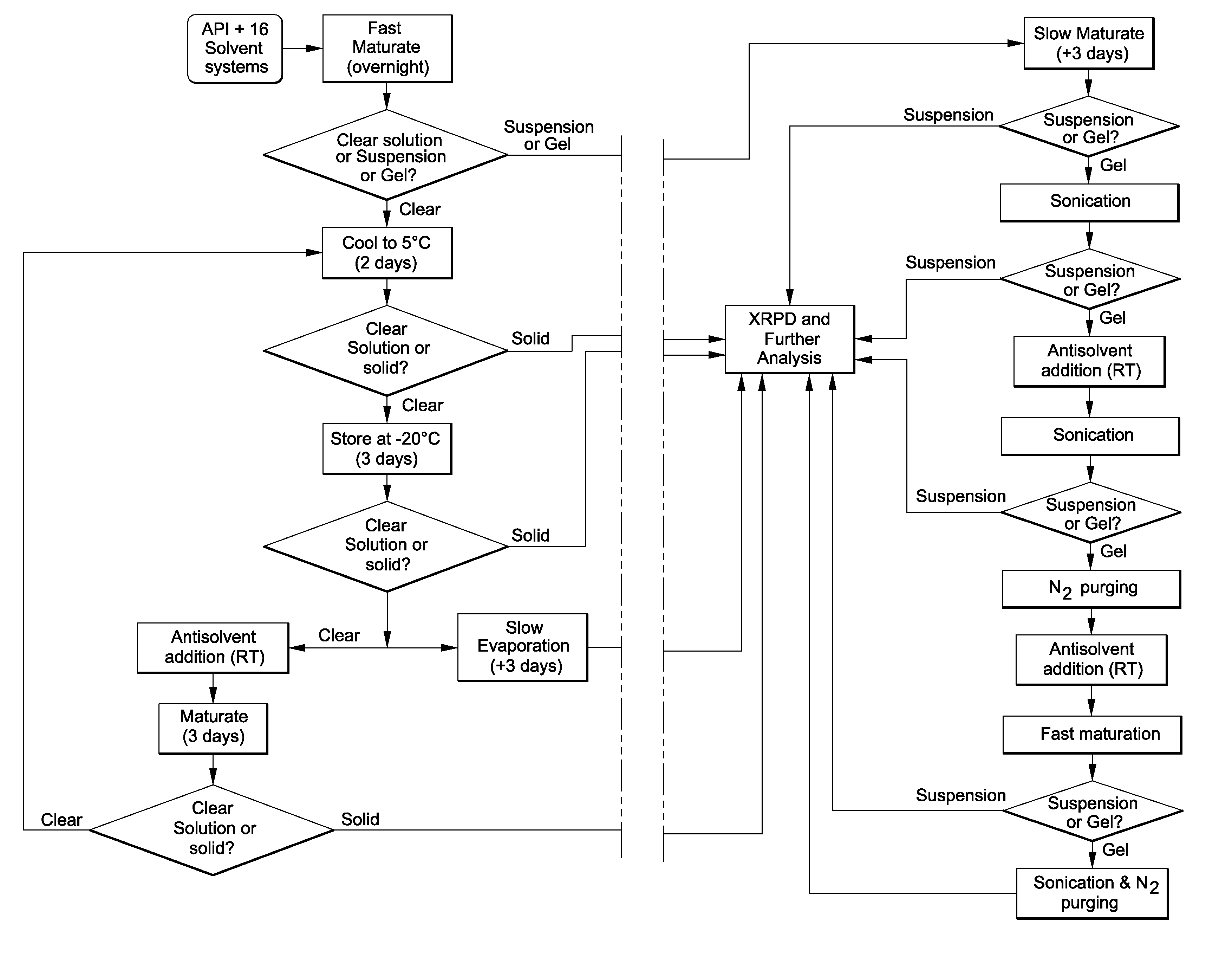

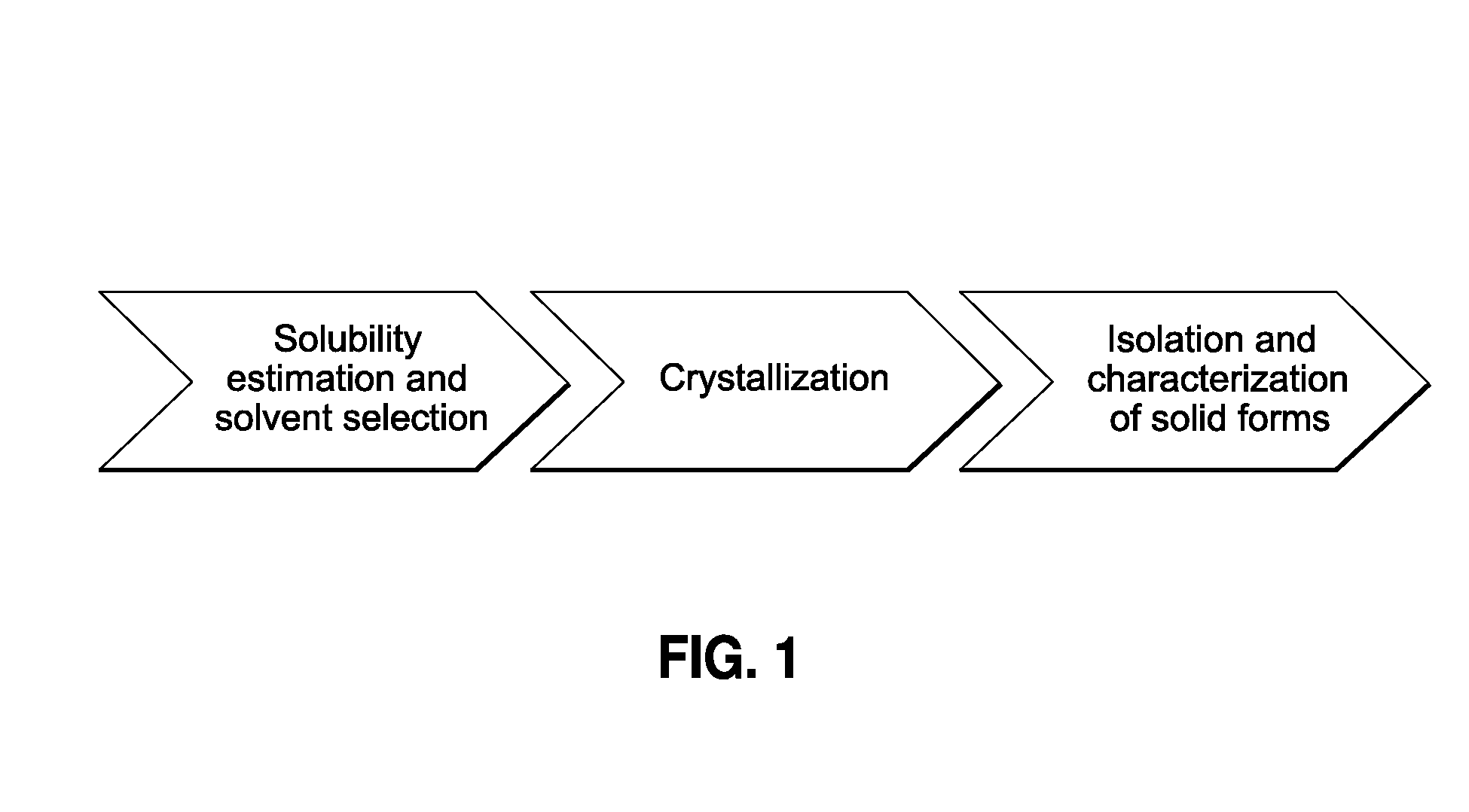

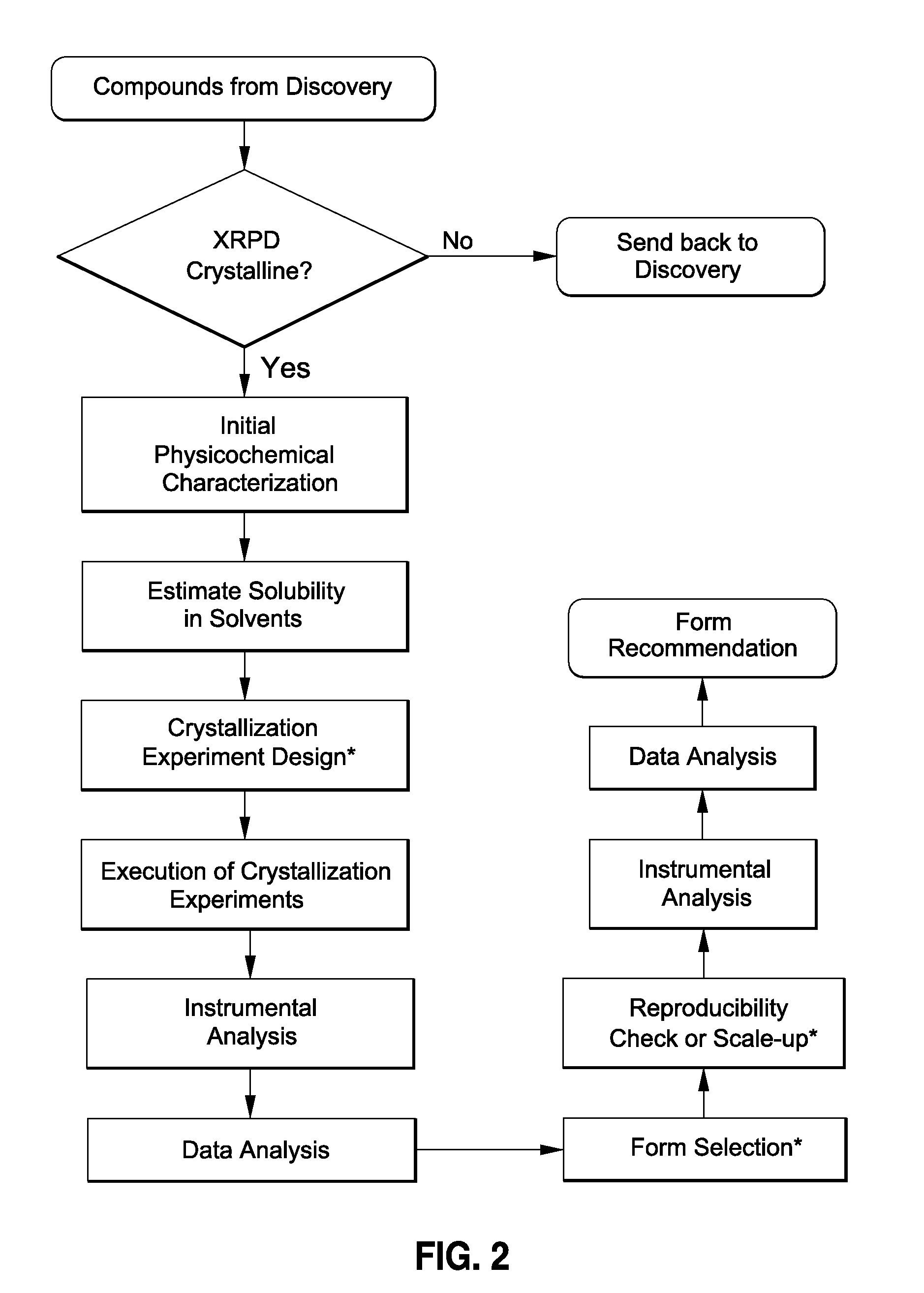

Process for rapid identification and preparation of crystalline forms

ActiveUS9321717B2Facilitate decision-makingPolycrystalline material growthCrystallization conditions screeningSolvent evaporationRapid identification

Owner:ALLERGAN INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com