Ammonium sulfate crystallization method and device

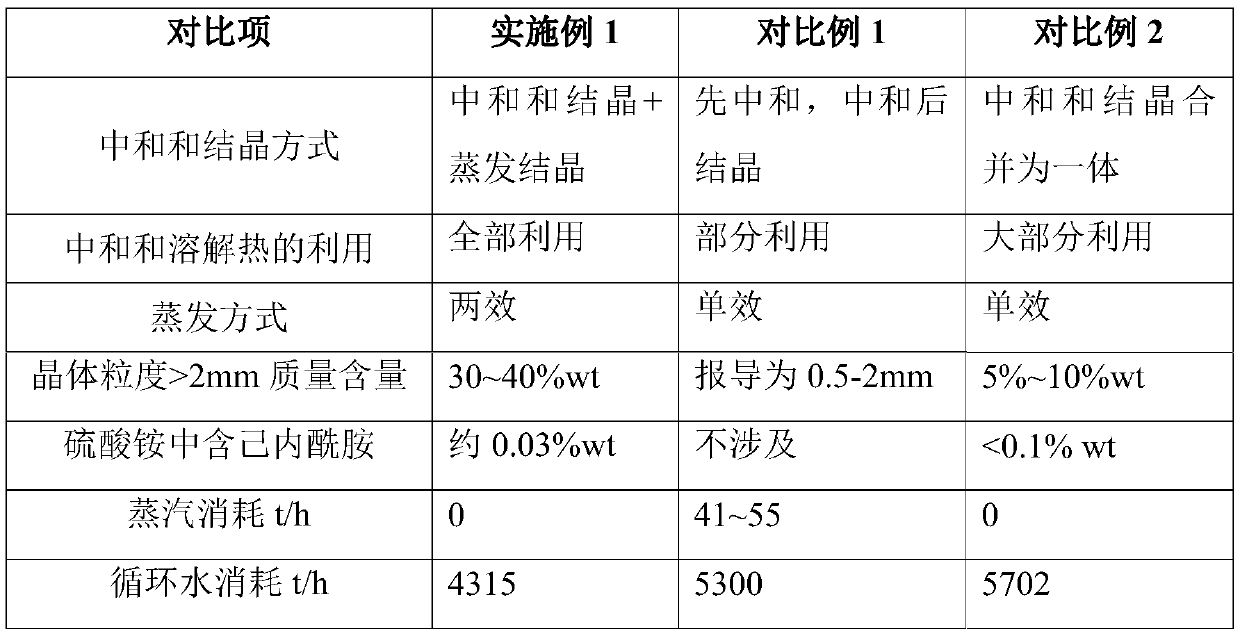

A crystallization device and ammonium sulfate technology, applied in the field of chemical plants, can solve the problems of unreasonable utilization of energy, large cooling water consumption, loss of caprolactam, etc., and achieve the effect of reducing circulating water consumption and saving heat source consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

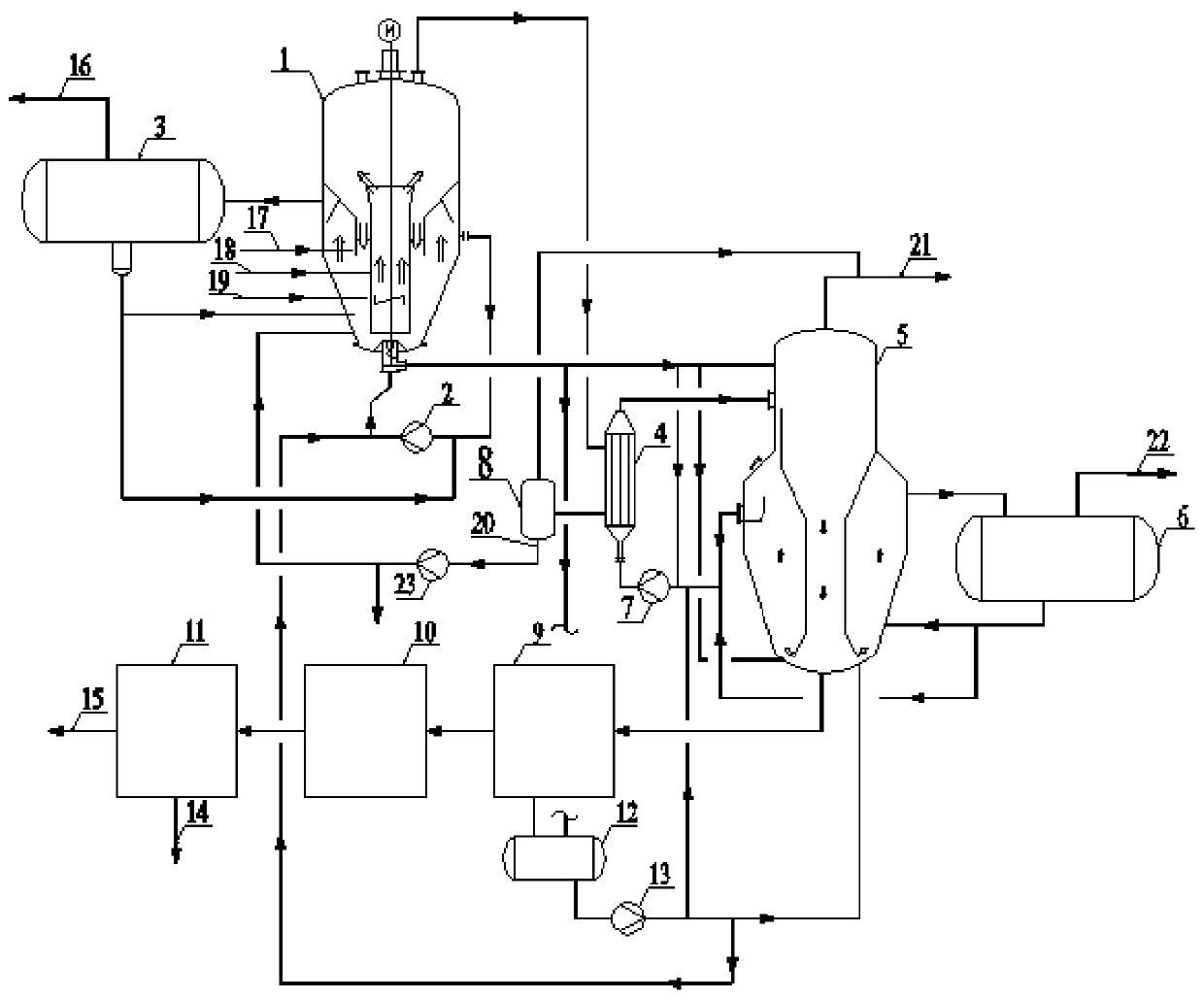

Image

Examples

Embodiment 1

[0074] The production capacity of ammonium sulfate is 300,000 tons / year of the neutralization crystallization device, and each ton of caprolactam is calculated as 1.56251 tons of by-product ammonium sulfate.

[0075] 1) About 51.86t / h of the rearrangement liquid from the rearrangement system of the caprolactam plant, which contains about 24t / h of caprolactam, about 26t / h of sulfuric acid, about 1.86t / h of sulfur trioxide, at a temperature of 105°C, passed through a single-effect DTB type The nozzle on the distributor in the neutralization crystallizer 1 enters the crystallizer guide tube, and about 10t / h of normal temperature gas ammonia 19 outside the boundary area is sent to the lower part of the first-effect DTB neutralization crystallizer guide tube, and the rearrangement liquid The sulfuric acid neutralizes at a pressure of 19.5-20.5kPa (absolute pressure) and a temperature of 65°C: H 2 SO 4 +2NH 3 =(NH 4 )2SO 4+Q, the ammonium sulfate solution in the diversion barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com