Equipment and method for producing inorganic salt with solubility changing along with temperature through cooling crystallization

A technology of cooling crystallization and inorganic salts, applied in the direction of heat exchange cooling crystallization, chemical instruments and methods, selection of crystallization auxiliary conditions, etc., can solve the problems of small and uneven crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

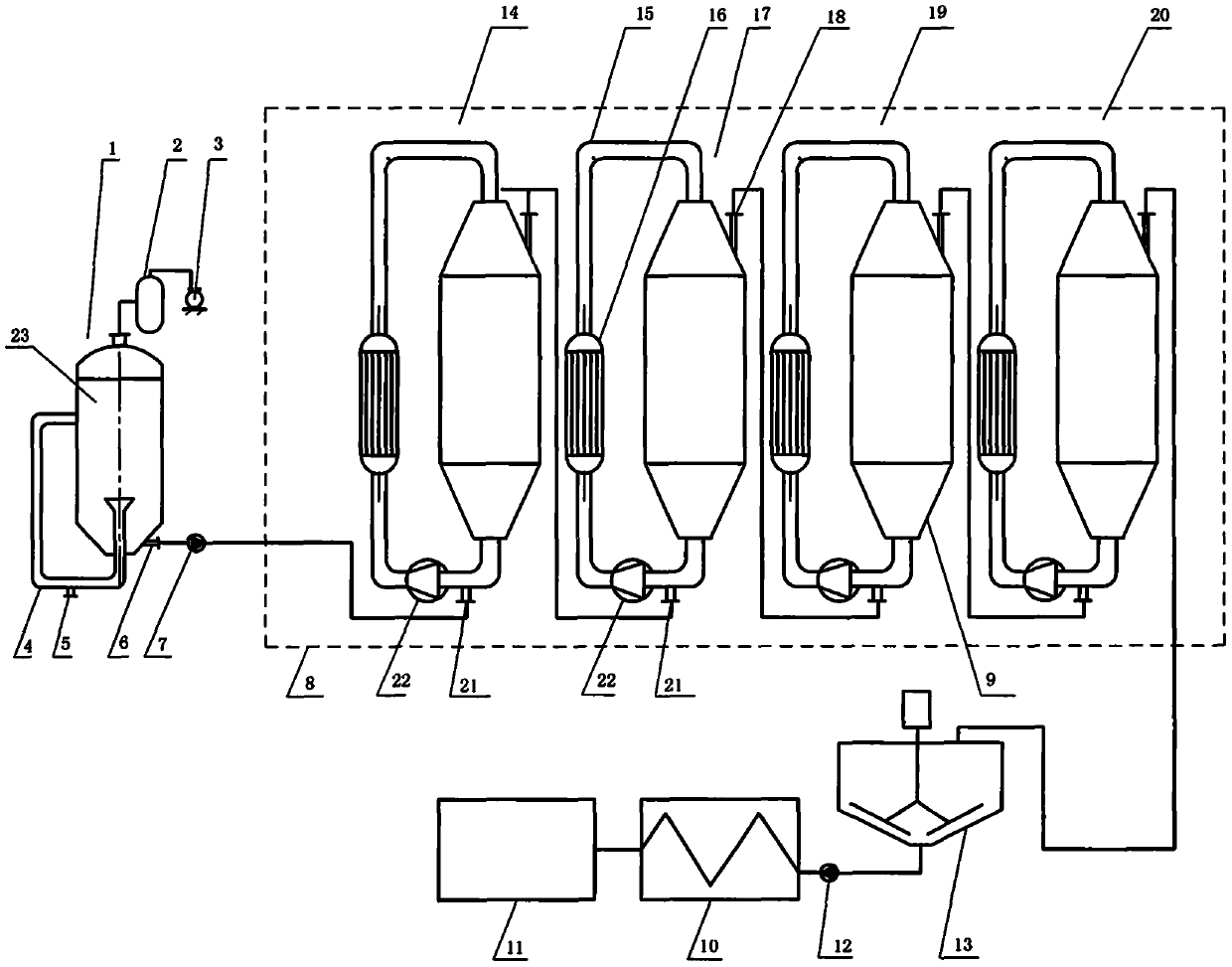

[0043] Such as figure 1 As shown, the equipment for producing inorganic salts whose solubility varies with temperature by cooling crystallization according to the present invention includes: a crystal nucleation controller 1, a first delivery pump 7, a crystal grower 8, a heat preservation settler 13, and a second delivery pump connected in sequence 12, centrifuge 10 and vibrating drying bed 11, crystal nucleus generation controller 1 comprises: crystal nucleus generation tank 23, the first circulation pipe 4, condenser 2 and vacuum pump 3, one end of the first circulation pipe 4 and crystal nucleus generation tank The side walls of 23 are connected, and the other end of the first circulation pipe 4 stretches into the crystal nucleus generation tank 23 from the bottom end of the crystal nucleus generation tank 23, and stretches into the other end of the first circulation pipe 4 in the crystal nucleus generation tank 23 In the shape of a bell mouth, the height of one end of the...

Embodiment 2

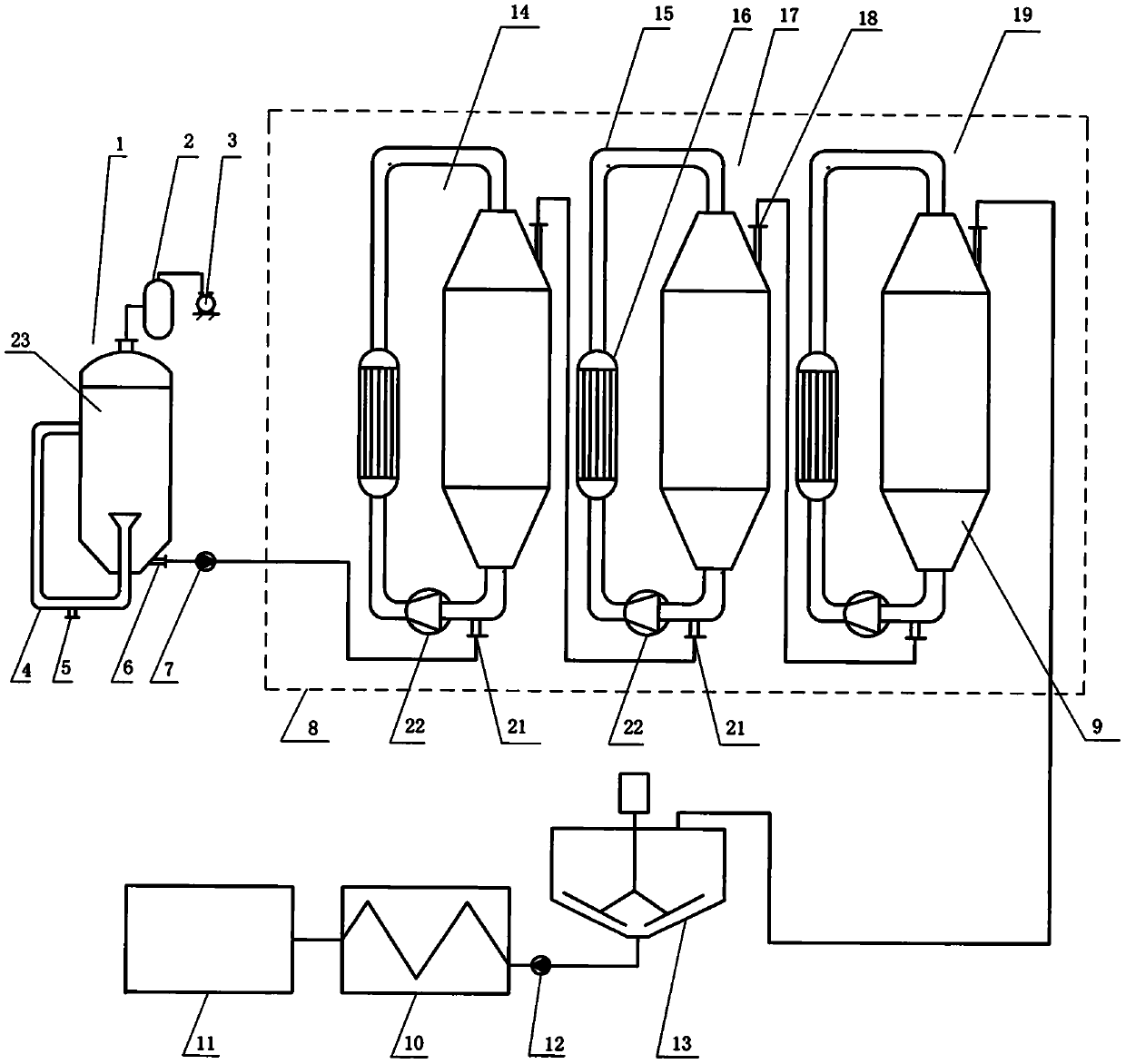

[0053] Embodiment 2 is basically the same as Embodiment 1, and the same part is no longer repeated, and the difference is: as figure 2 Shown, crystal grower 8 comprises the first crystallizer 14, the second crystallizer 17 and the 3rd crystallizer 19 that are connected successively, and the first crystallizer 14, the second crystallizer 17 and the 3rd crystallizer 19 comprise: crystallization tank 9, heat exchanger 16, second circulation pipe 15 and circulation pump 22, the lower end of crystallization tank 9 is connected with the lower end of heat exchanger 16 through second circulation pipe 15 and circulation pump 22, and the upper end of heat exchanger 16 is passed through second The circulation pipe 15 is connected to the upper end of the crystallization tank 9, and a feed port 21 is opened on the second circulation pipe 15 between the circulation pump 22 and the crystallization tank 9, and the discharge pipe 6 passes through the first delivery pump 7 and the first crystal...

Embodiment 3

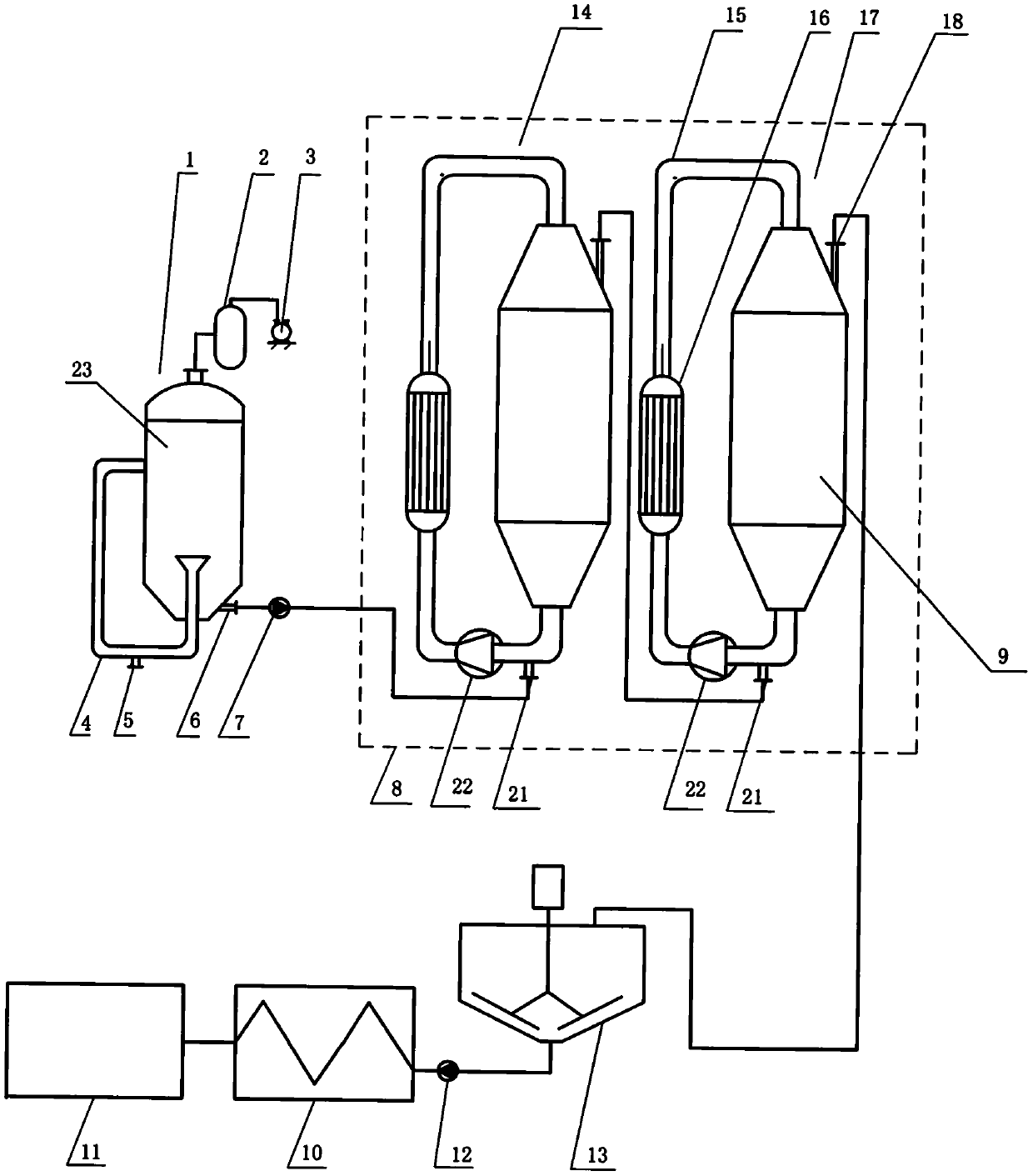

[0060] Embodiment 3 is basically the same as Embodiment 1, and the same part is no longer repeated, and the difference is: as image 3 Shown, crystal grower 8 comprises: the first crystallizer 14 and the second crystallizer 17 that are connected successively, and the first crystallizer 14 and the second crystallizer 17 comprise: crystallization tank 9, heat exchanger 16, the second circulation pipe 15 and circulation pump 22, the lower end of crystallization tank 9 links to each other with the lower end of heat exchanger 16 by second circulation pipe 15 and circulation pump 22, and the upper end of heat exchanger 16 links to each other with above-mentioned crystallization tank 9 upper ends by second circulation pipe 15, On the second circulation pipe 15 between circulation pump 22 and crystallization tank 9, have feed inlet 21, discharge pipe 6 links to each other with the feed inlet 21 of the first crystallizer 14 by the first transfer pump 7, crystallization tank 9 The upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com