Method for preparing spherical silver powder

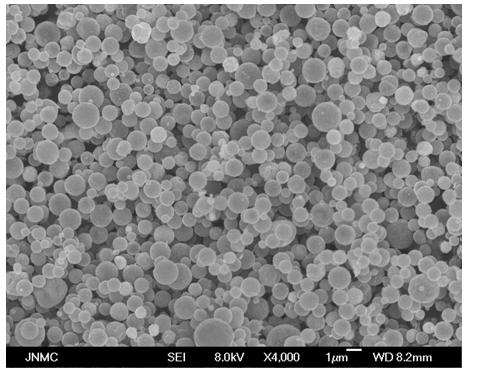

A silver powder, spherical technology, applied in the field of preparation of spherical silver powder, to achieve the effect of uniform particle size distribution, significant economic and social benefits, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

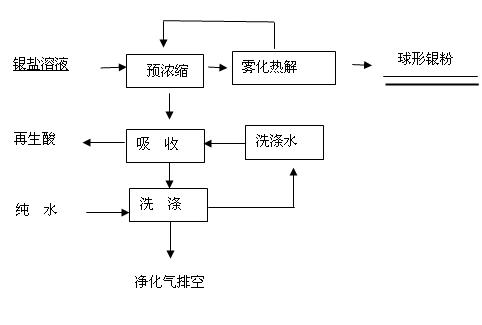

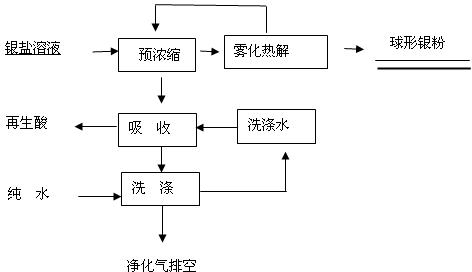

[0018] The invention discloses a preparation method of a spherical silver powder material. The preparation process is to atomize a silver nitrate solution and perform thermal decomposition at a high temperature to obtain a spherical silver powder material. The steps of the preparation process include:

[0019] 1) Ingredients: Silver nitrate solution is prepared according to the silver ion concentration of 10-400g / L.

[0020] 2) Atomization: Atomize the solution in ingredient 1) into droplets of 0.5-100 μm.

[0021] 3) Pyrolysis: pyrolyze the droplets obtained in 2) at 200-900°C under controlled atmosphere conditions (nitrogen, hydrogen, carbon monoxide) for 1-30 minutes.

Embodiment 1

[0023] Configure a silver nitrate solution with a silver ion concentration of 100g / L; atomize the solution through an atomizer; spray the atomized droplets into a heating furnace, and heat for 30 minutes at a temperature of 300°C and a hydrogen reducing atmosphere. The obtained spherical silver powder has complete crystal form, no impurity phase, uniform particle size distribution, D50 of 1 μm, and tap density of 1.42 g / cm 3 , Oxygen content 0.1%.

Embodiment 2

[0025] Prepare a silver nitrate solution with a silver ion concentration of 100g / L; atomize the solution through an atomizer; spray the atomized droplets into a heating furnace, and heat for 10 minutes at a temperature of 500°C and a carbon monoxide reducing atmosphere. The obtained spherical silver powder has complete crystal form, no impurity phase, uniform particle size distribution, D50 of 2 μm, and tap density of 2.45 g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com