A method for returning small crystal particles in the slurry discharged from a reaction crystallizer

A technology of reaction crystallization and crystallization, applied in chemical instruments and methods, chemical/physical/physicochemical fixed reactors, crystallization and separation, etc., can solve the problems of difficult continuous operation, increase of pre-order operation load and cost, and increase of fine powder content To achieve the effect of ensuring product purity, avoiding crushing, and reducing fine powder content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

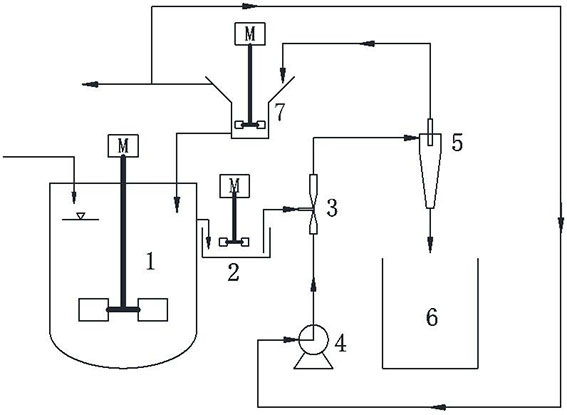

[0018] Attached below figure 1 The inventive method is described further:

[0019] see figure 1 , the reaction crystallizer 1 is continuously fed and discharged, the slurry in it enters the slurry storage tank 2 through overflow, and the good liquid-solid mixing in the slurry storage tank 2 can be maintained by proper mechanical stirring, and the crystal particles will not significantly settle. The clear liquid circulation pump 4 extracts most of the supernatant liquid in the settling reflux tank 7 and sends it into the Venturi tube 3 as the carrier fluid. Under the action of negative pressure, the slurry in the slurry storage tank 2 will be sucked into the Venturi tube 3, and mixed and diluted with the clear liquid from the clear liquid circulation pump 4. The diluted slurry flowing out of the Venturi tube 3 enters the hydrocyclone 5, where the continuous separation of larger crystal particles and smaller crystal particles is realized, and the larger crystal particles and a...

Embodiment approach 2

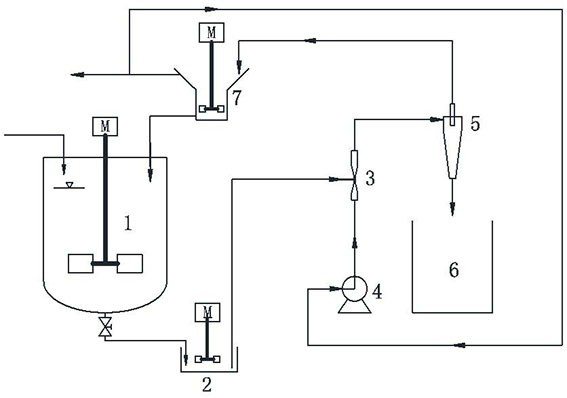

[0021] Attached below figure 2 The inventive method is described further:

[0022] see figure 2 , the reaction crystallizer 1 is continuously fed and intermittently discharged, and the slurry is discharged intermittently through the discharge valve at the bottom and enters the slurry storage tank 2. Good liquid-solid mixing in the slurry storage tank 2 can be maintained by proper mechanical stirring, and the crystal Particles do not settle significantly. The clear liquid circulation pump 4 extracts most of the supernatant liquid in the settling reflux tank 7 and sends it into the Venturi tube 3 as the carrier fluid. Under the action of negative pressure, the slurry in the slurry storage tank 2 will be automatically sucked into the Venturi tube 3, mixed with the clear liquid from the clear liquid circulation pump 4, and diluted. The diluted slurry flowing out of the Venturi tube 3 enters the hydrocyclone 5, where the continuous separation of larger crystal particles and sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com