Preparation method of size controllable grapheme

A graphene and dimension technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problem that the electrical conductivity cannot be greatly improved, and achieve the effects of easy operation, low cost, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A method for preparing graphene with controllable size, the steps are as follows:

[0058] (1) Add 50ml of concentrated nitric acid to a mixed solution of 5g flake graphite and 150ml of concentrated sulfuric acid, stir at room temperature for 24 hours, wash with deionized water for 3 times, and dry at 60°C to obtain graphite intercalation compound;

[0059] (2) Rapidly expand the graphite interlayer compound obtained above for 30s at 1050°C to obtain expanded graphite;

[0060] (3) Slowly add 3g of potassium permanganate to the mixture of 0.3g of expanded graphite obtained above and 60ml of concentrated sulfuric acid, stir at 60°C for 24h, add 60ml of deionized water and 15ml of peroxide in an ice bath Hydrogen, the mixture is washed to neutrality to obtain graphene oxide;

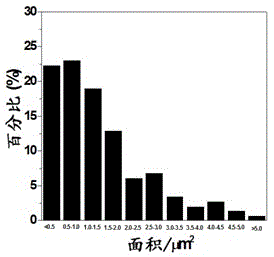

[0061] (4), disperse the graphene oxide obtained above in water, and separate the graphene oxide by centrifugation;

[0062] ①. Centrifuge at 8000rmp and 40min at a rotating speed and time respect...

Embodiment 2

[0077] A method for preparing graphene with controllable size, the steps are as follows:

[0078] (1) Add 50ml of concentrated nitric acid to a mixed solution of 5g flake graphite and 150ml of concentrated sulfuric acid, stir at room temperature for 24 hours, wash with deionized water for 3 times, and dry at 60°C to obtain graphite intercalation compound;

[0079] (2) Rapidly expand the graphite interlayer compound for 30s at 1050°C to obtain expanded graphite;

[0080] (3) Slowly add 3g of potassium permanganate into the mixture of 0.3g of expanded graphite and 60ml of concentrated sulfuric acid, stir at 60°C for 24h, add 60ml of deionized water and 15ml of hydrogen peroxide in an ice bath, and The mixture is washed with water to neutrality to obtain graphene oxide;

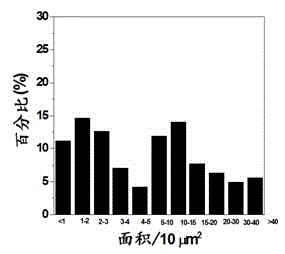

[0081] (4) Disperse graphene oxide in water, and separate graphene oxide by centrifugation;

[0082] ①. Centrifuge at 8000rmp and 40min at a rotating speed and time respectively to obtain supernatant 1 and sed...

Embodiment 3

[0088] A method for preparing graphene with controllable size, the steps are as follows:

[0089] (1) Add 50ml of concentrated nitric acid to a mixed solution of 5g flake graphite and 150ml of concentrated sulfuric acid, stir at room temperature for 24 hours, wash with deionized water for 3 times, and dry at 60°C to obtain graphite intercalation compound;

[0090] (2) Rapidly expand the graphite interlayer compound for 30s at 1050°C to obtain expanded graphite;

[0091] (3) Slowly add 3g of potassium permanganate into the mixture of 0.3g of expanded graphite and 60ml of concentrated sulfuric acid, stir at 60°C for 24h, add 60ml of deionized water and 15ml of hydrogen peroxide in an ice bath, and The mixture is washed with water to neutrality to obtain graphene oxide;

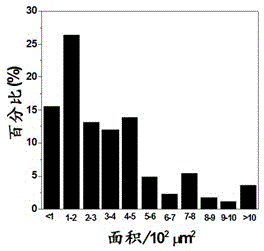

[0092] (4) Disperse graphene oxide in water, and separate graphene oxide by centrifugation;

[0093] ①. Centrifuge at 8000rmp and 40min at a rotating speed and time respectively to obtain supernatant 1 and sed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com