Battery string in N-type IBC (Interdigitated Back Contact) solar cell spliced connection, preparation method of battery string, assembly and system

A solar cell, N-type technology, applied in the field of solar cells, can solve problems such as the large number of emitter and base electrodes, difficulty in battery alignment and welding, and environmental pollution caused by waste, so as to improve fill factor and reduce lateral transmission loss , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

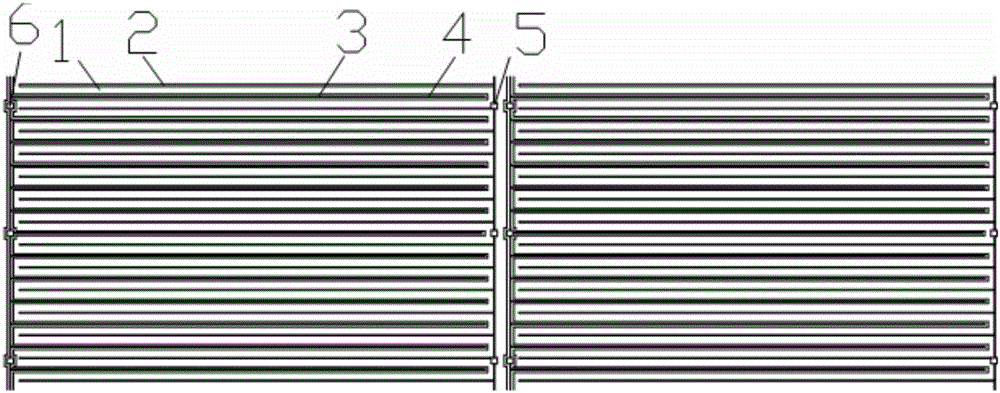

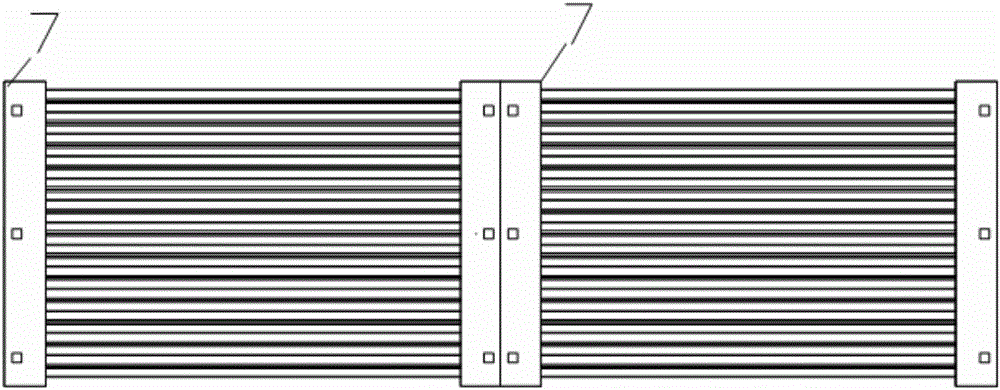

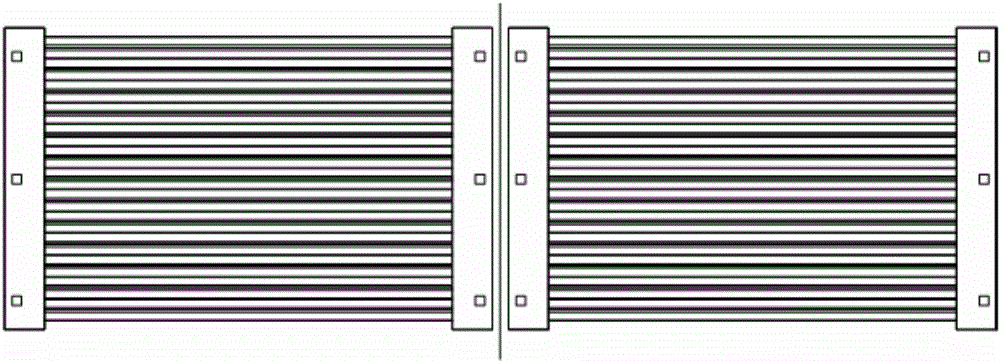

[0033] see Figure 1-5 As shown, a battery string connected by N-type IBC solar cells provided in this embodiment includes narrow N-type IBC solar cells and conductive members for ohmic connection between the narrow N-type IBC solar cells, The back surface of the narrow N-type IBC solar cell includes emitter p+ regions 1 and base n+ regions 3 arranged alternately, the emitter p+ region 1 is provided with a p+ emitter contact electrode 2, and the base n+ The area 3 is provided with an n+ base contact electrode 4, and also includes a p+ electrode confluence point 5 arranged on the p+ emitter contact electrode 2 and an n+ electrode confluence point 6 arranged on the n+ base contact electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com