Short-wave ultraviolet pre-crosslinking adhesive film and preparation method thereof

An ultraviolet light and pre-crosslinking technology, which is applied in the field of solar cells, can solve the problems of reducing white film overflow and wrinkling, incomplete absorption, and easy generation of bubbles, etc., to achieve high photoelectric conversion rate and packaging formability, control Convenience and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

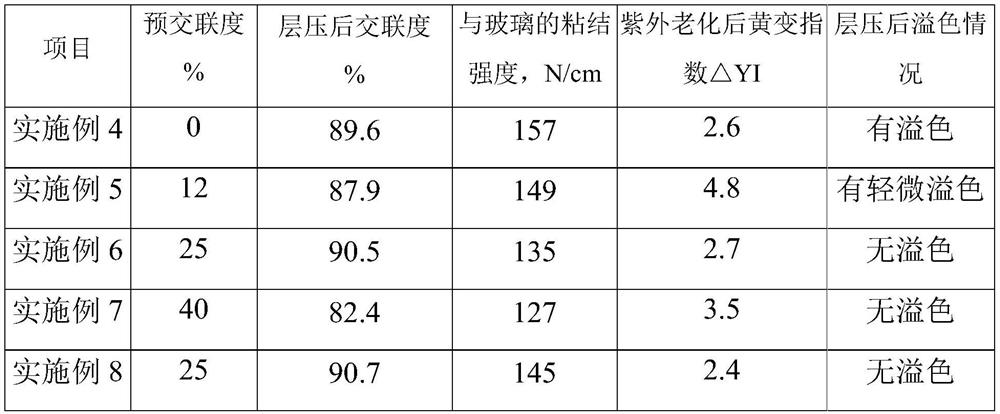

Examples

Embodiment 1

[0023] A short-wave ultraviolet light pre-crosslinked adhesive film, comprising the following raw materials in parts by weight: 90 parts of polymer resin, 0.2 part of short-wave ultraviolet light initiator, 0.2 part of thermal initiator, 0.5 part of cross-linking assistant, and 0.1 part of coupling agent , 0.01 part of light stabilizer, 0.01 part of ultraviolet absorption auxiliary, 0.001 part of antioxidant and 10 parts of color masterbatch.

[0024] The polymer resin is EVA resin; the antioxidant is 3,5-di-tert-butyl-4-hydroxybenzylphosphonic acid.

[0025] The short-wave ultraviolet light initiator is 4-methylbenzophenone. The thermal initiator is tert-butyl peroxy-2-ethylhexyl carbonate.

[0026] The crosslinking assistant is triallyl isocyanurate; the color masterbatch is white masterbatch. The coupling agent is a vinyl silane coupling agent.

[0027] The light stabilizer is composed of bis-2,2,6,6-tetramethylpiperidinol sebacate, N,N'-bis-(2,2,6,6-tetramethyl-4- pipe...

Embodiment 2

[0033] A short-wave ultraviolet light pre-crosslinked adhesive film, comprising the following raw materials in parts by weight: 100 parts of polymer resin, 1.1 parts of short-wave ultraviolet light initiator, 1.1 parts of thermal initiator, 3 parts of cross-linking assistant, and 0.6 part of coupling agent , 0.3 parts of light stabilizer, 0.3 parts of ultraviolet absorption auxiliary, 0.3 parts of antioxidant and 15 parts of color masterbatch.

[0034] The polymer resin is EVA resin; the antioxidant is tris(2,4-di-tert-butylphenyl) phosphite.

[0035] The short-wave ultraviolet light initiator is methyl o-benzoyl benzoate. The thermal initiator is ethyl 3,3-di(tert-butylperoxy)butyrate.

[0036] The cross-linking assistant is triallyl cyanurate; the color masterbatch is white masterbatch. The coupling agent is an aminohydrocarbyl silane coupling agent.

[0037] The light stabilizer is composed of bis-2,2,6,6-tetramethylpiperidinol sebacate, N,N'-bis-(2,2,6,6-tetramethyl-4- ...

Embodiment 3

[0043] A short-wave ultraviolet light pre-crosslinked adhesive film, comprising the following raw materials by weight: 110 parts of polymer resin, 2 parts of short-wave ultraviolet light initiator, 2 parts of thermal initiator, 5 parts of cross-linking assistant, and 1 part of coupling agent , 0.5 part of light stabilizer, 0.5 part of ultraviolet absorption auxiliary, 0.5 part of antioxidant and 20 parts of color masterbatch.

[0044] The polymer resin is EVA resin; the antioxidant is 3,5-di-tert-butyl-4-hydroxybenzylphosphonic acid.

[0045] The short-wave ultraviolet light initiator is 1-hydroxycyclohexyl phenyl ketone; the thermal initiator is 1,1-di(tert-butylperoxy)cyclohexane.

[0046] The crosslinking assistant is trimethylolpropane triacrylate; the color masterbatch is white masterbatch. The coupling agent is a vinyl silane coupling agent.

[0047] The light stabilizer is composed of bis-2,2,6,6-tetramethylpiperidinol sebacate, N,N'-bis-(2,2,6,6-tetramethyl-4- piper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com