PECVD film coating method

A conventional, gas flow technology, applied in the direction of gaseous chemical plating, coating, electrical components, etc., can solve the problems of the decrease of the minority carrier life of the silicon wafer, the deterioration of the surface passivation effect, and the easy fracture, so as to reduce the electrical loss, Effect of increasing production cost and reducing package loss of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

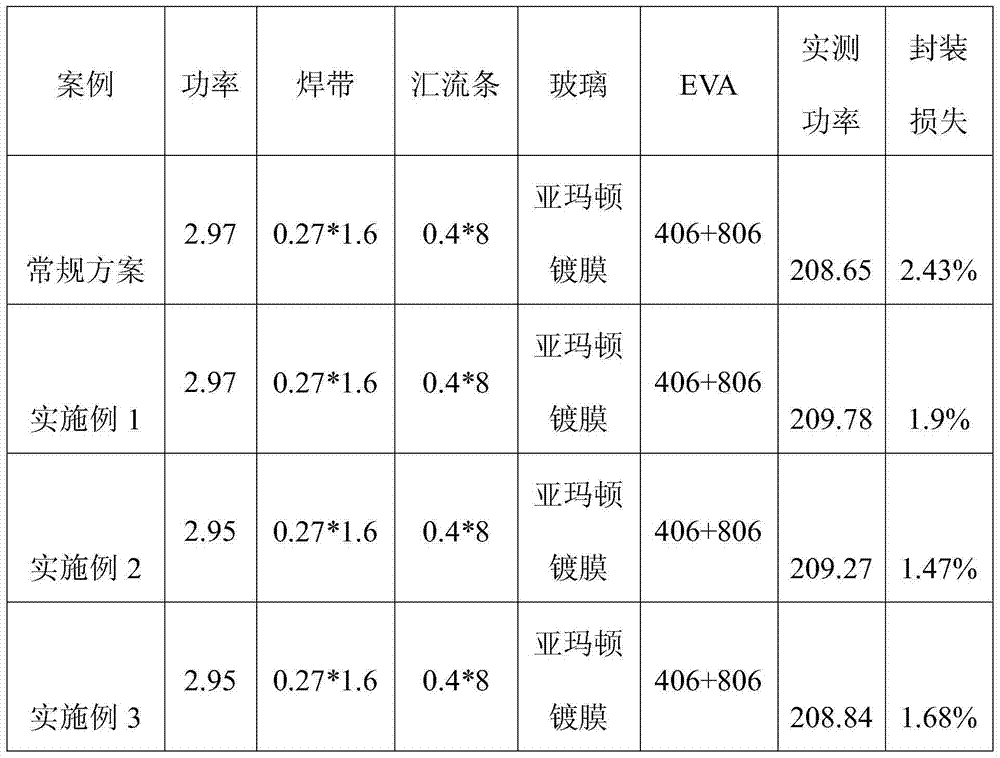

[0017] 125mm×125mm single crystal silicon wafer, using conventional process for texturing, diffusion and etching to remove phospho-silicate glass, anti-reflection coating using SiO 2 +SiNx coating process: deposit SiO first 2 Layer: deposition time 50s, SiH 4 Flow 300sccm, NH 3 Flow 2500sccm, N 2 O flow 2500sccm, pressure 1500mtor, power 3000W; re-deposit the first layer of SiNx: deposition time 170s, SiH 4 Flow 700sccm, NH 3 Flow rate 4300sccm, pressure 1700mtor, power 3000W; deposit the second layer of SiNx: deposition time 600s, SiH 4 Flow 450sccm, NH 3 The flow rate is 4500sccm, the pressure is 1700mtor, and the power is 4000W. After the coating is completed, the electrodes are printed and the electrical properties are tested, and cells of the same color and grade are selected to be packaged into components to test the electrical properties. The encapsulation loss of the cell assembly is shown in Table 1.

Embodiment 2

[0019] 125mm×125mm single crystal silicon wafer, using conventional process for texturing, diffusion and etching to remove phospho-silicate glass, anti-reflection coating using SiO 2 +SiNx coating process: deposit SiO first 2 Layer: deposition time 80s, SiH 4 Flow 300sccm, NH 3 Flow 2500sccm, N 2 O flow 2500sccm, pressure 1500mtor, power 3000W; re-deposit the first layer of SiNx: deposition time 170s, SiH 4 Flow 700sccm, NH 3 The flow rate is 4300sccm, the pressure is 1700sccm, and the power is 3000W; the second layer of SiNx is deposited: the deposition time is 540s, the flow rate of SiH4 is 450sccm, NH 3 The flow rate is 4500sccm, the pressure is 1700mtor, and the power is 4000W. After the coating is completed, the electrodes are printed and the electrical properties are tested, and cells of the same color and grade are selected to be packaged into components to test the electrical properties. The encapsulation loss of the cell assembly is shown in Table 1.

Embodiment 3

[0021] 125mm×125mm monocrystalline silicon wafer, using normal process for texturing, diffusion and etching to remove phospho-silicate glass, anti-reflection coating using SiO 2 +SiNx coating process: deposit SiO first 2 Layer: Deposition time 110s, SiH 4 Flow 200sccm, NH 3 Flow 3500sccm, N 2 O flow 2500sccm, pressure 1500mtor, power 3000W; re-deposit the first layer of SiNx: deposition time 170s, SiH 4 Flow 700sccm, NH 3 Flow rate 4300sccm, pressure 1700mtor, power 3000W; deposit the second layer of SiNx: deposition time 600s, SiH 4 Flow 450sccm, NH 3 The flow rate is 4500sccm, the pressure is 1700mtor, and the power is 4000W. After the coating is completed, the electrodes are printed and the electrical properties are tested, and cells of the same color and grade are selected to be packaged into components to test the electrical properties. The encapsulation loss of the cell assembly is shown in Table 1.

[0022] Table 1

[0023]

[0024] As shown in Table 1, by com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com