Preparation method for high open-circuit voltage polycrystalline solar cells

A technology of solar cells and open circuit voltage, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high doping concentration, increase the recombination loss of minority carriers, reduce the lifetime of minority carriers, etc., and achieve high open circuit The effect of voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

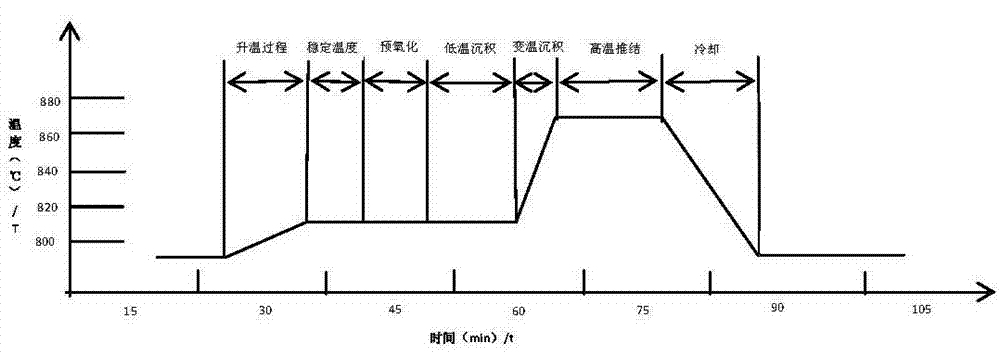

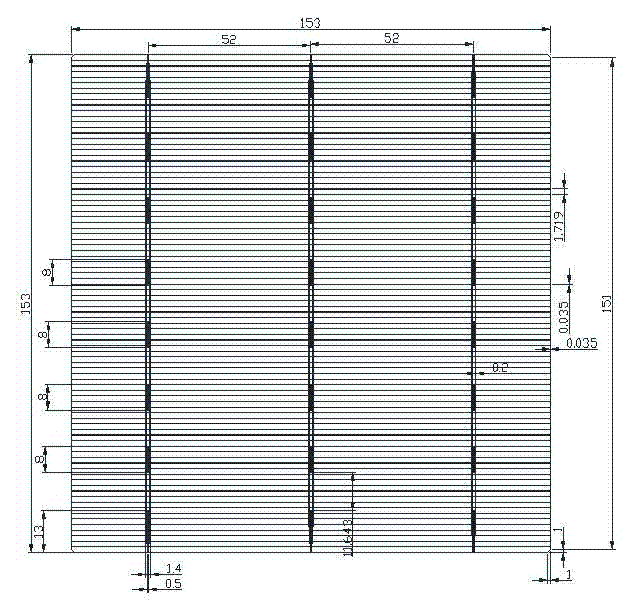

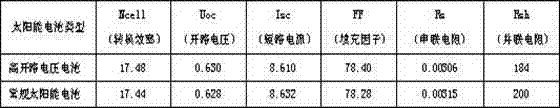

[0022] A preparation method of high open-circuit voltage polycrystalline solar cells, including texturing, diffusion, wet etching, PE coating, drying, printing back field, drying, printing back electrode, printing positive electrode, sintering and test sorting. The diffusion process adopts variable temperature deposition and high-temperature push junction technology, and the positive electrode printing pattern in the positive electrode printing process adopts a dense grid design of 90 fine grids. Other processes are the same as conventional methods.

[0023] The specific steps of the diffusion process are as follows:

[0024] (1) Pre-oxidation: Pre-oxidize the silicon wafer at 800°C for 13 minutes, O 2 The ratio is 10% by volume;

[0025] (2) Low-temperature deposition: Low-temperature deposition is performed on silicon wafers at 800°C for 10-20 minutes, and large N 2 , O 2 and small N 2 mixed gas, small N 2 The ratio is 7% in volume percentage;

[0026] (3) Variable te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com