Improved diffusion technology of polycrystalline solar cell

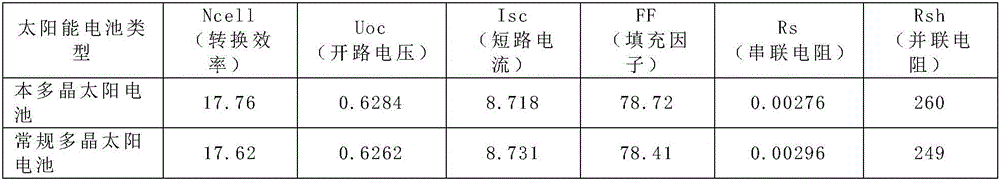

A solar cell and diffusion process technology, applied in the field of solar cells, can solve the problems of low conversion efficiency of solar cells, and achieve the effects of high conversion efficiency, low packaging loss and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

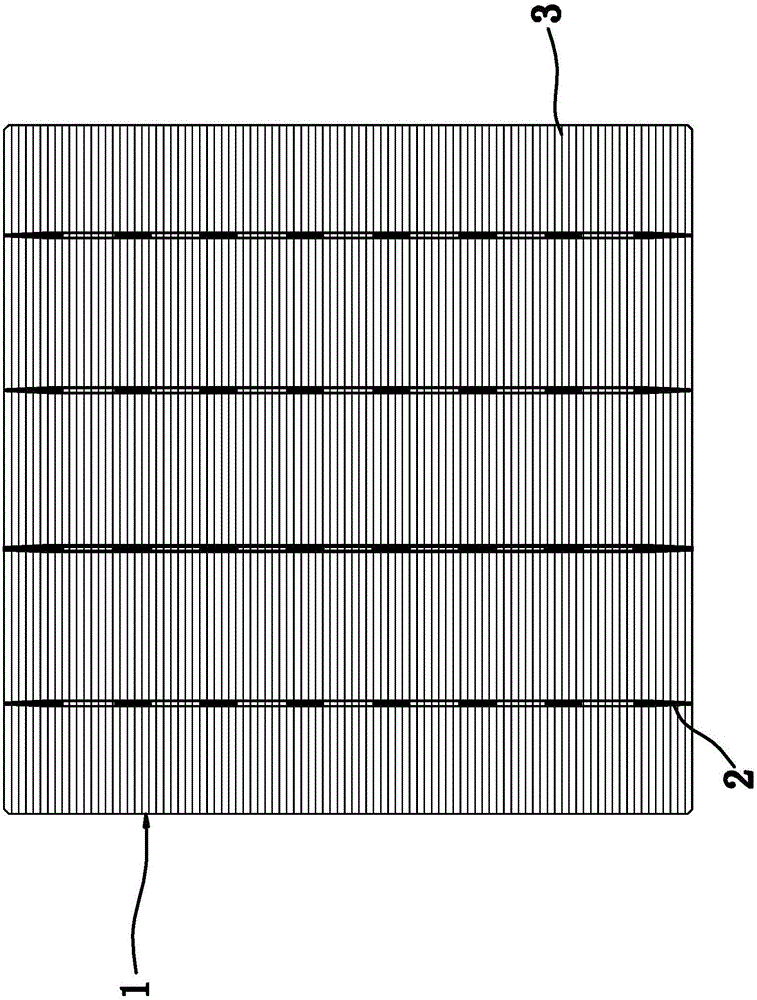

[0033] Such as figure 1 As shown, the polycrystalline solar cell includes a plate-shaped body 1, one side of the body 1 is a positive electrode, the other side of the body 1 is a negative electrode, and four main grids 2 and 90 fine grids are evenly distributed on the positive electrode. 3. The main grid 2 and the fine grid 3 are vertically arranged and they are electrically connected. The distance between each main grid 2 is 35 mm, the width of the main grid 2 is 0.8 mm, and the spacing of the fine grid 3 is 1.4 mm. The width is 0.035 mm.

[0034] Such as figure 1 As shown, the main grid 2 is arranged longitudinally and uniformly by several main grid segments; the length of each main grid segment is 7 mm; the length of the fine grid 3 is 152 mm.

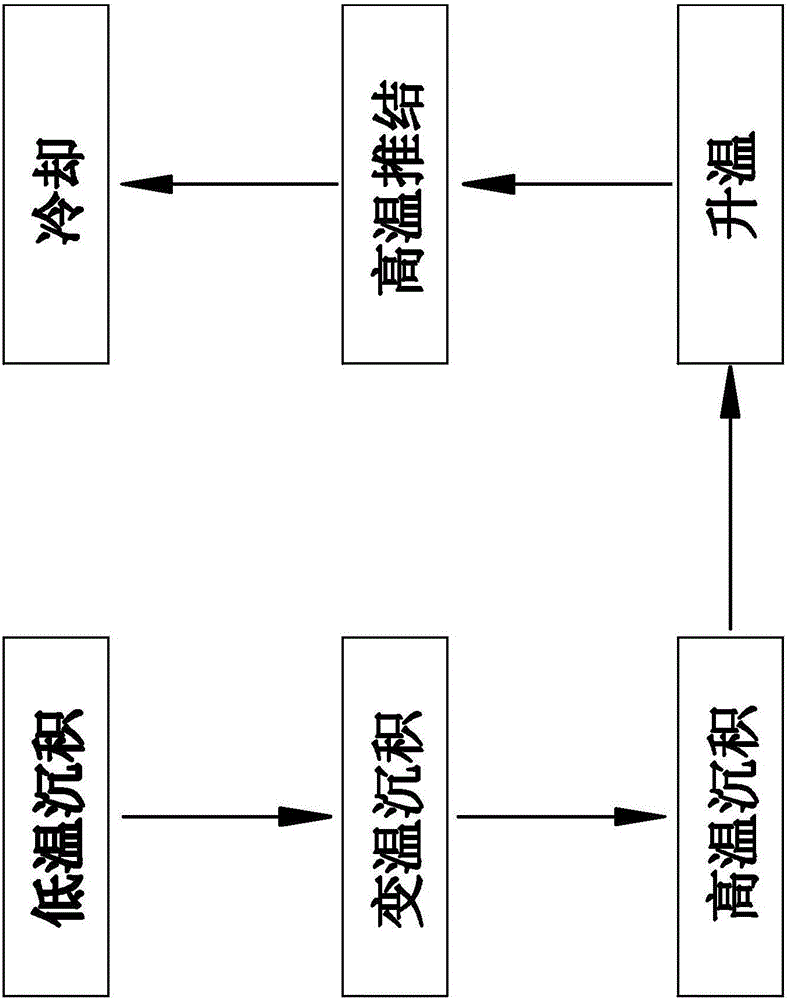

[0035] Such as figure 2 Shown, the diffusion process of this improved polycrystalline solar cell, this process comprises the following steps:

[0036] A. Low-temperature deposition: Put the body into an ordinary diffusion furna...

Embodiment 2

[0048] Such as figure 1 As shown, the polycrystalline solar cell includes a plate-shaped body 1, one side of the body 1 is a positive electrode, the other side of the body 1 is a negative electrode, and four main grids 2 and 90 fine grids are evenly distributed on the positive electrode. 3. The main grid 2 and the fine grid 3 are vertically arranged and they are electrically connected. The distance between each main grid 2 is 42 mm, the width of the main grid 2 is 1.2 mm, and the spacing of the fine grid 3 is 2.0 mm. The width is 0.045 mm.

[0049] Such as figure 1 As shown, the main grid 2 is arranged longitudinally and uniformly by several main grid segments; the length of each main grid segment is 11 mm; the length of the fine grid 3 is 158 mm.

[0050] Such as figure 2 Shown, the diffusion process of this improved polycrystalline solar cell, this process comprises the following steps:

[0051] A. Low-temperature deposition: Put the body into an ordinary diffusion furn...

Embodiment 3

[0062] Such as figure 1 As shown, the polycrystalline solar cell includes a plate-shaped body 1, one side of the body 1 is a positive electrode, the other side of the body 1 is a negative electrode, and four main grids 2 and 90 fine grids are evenly distributed on the positive electrode. 3. The main grid 2 and the fine grid 3 are vertically arranged and they are electrically connected. The distance between each main grid 2 is 38 mm, the width of the main grid 2 is 1.0 mm, and the spacing of the fine grid 3 is 1.7 mm. The width is 0.04 mm.

[0063] Such as figure 1 As shown, the main grid 2 is arranged longitudinally and uniformly by several main grid segments; the length of each main grid segment is 9 mm; the length of the fine grid 3 is 155 mm.

[0064] Such as figure 2 Shown, the diffusion process of this improved polycrystalline solar cell, this process comprises the following steps:

[0065] A. Low-temperature deposition: Put the body into an ordinary diffusion furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com