Valve tappet device of engine

A technology of engine valve and rod device, which is applied in the direction of engine components, machines/engines, valve devices, etc. It can solve the problems of flexibility and rotation direction, affecting the service life of the tappet body, increasing the stress on the edge of the pin, etc., to achieve contact Good and transmission, convenient assembly, and the effect of reducing contact stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

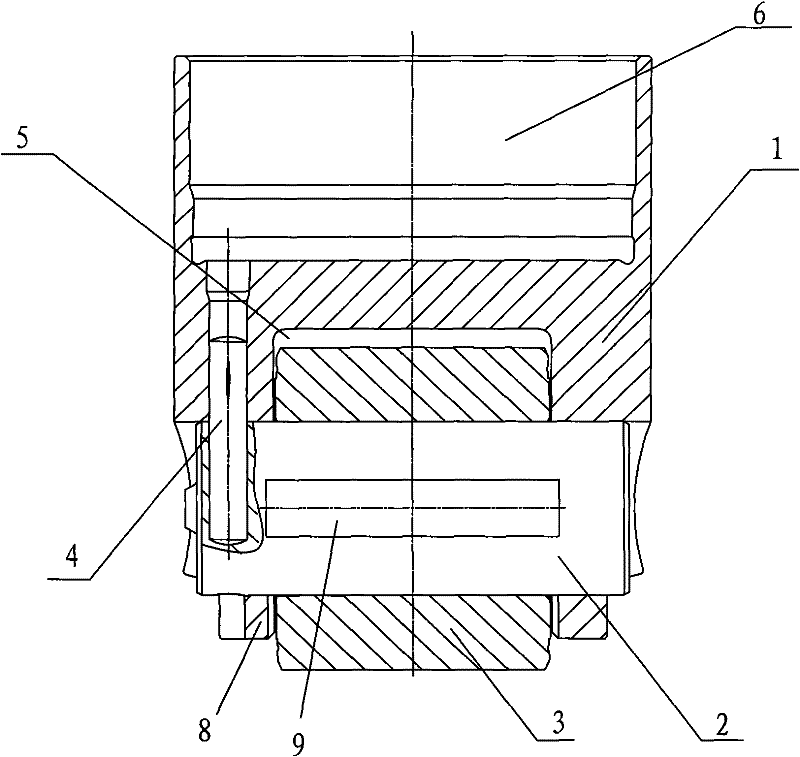

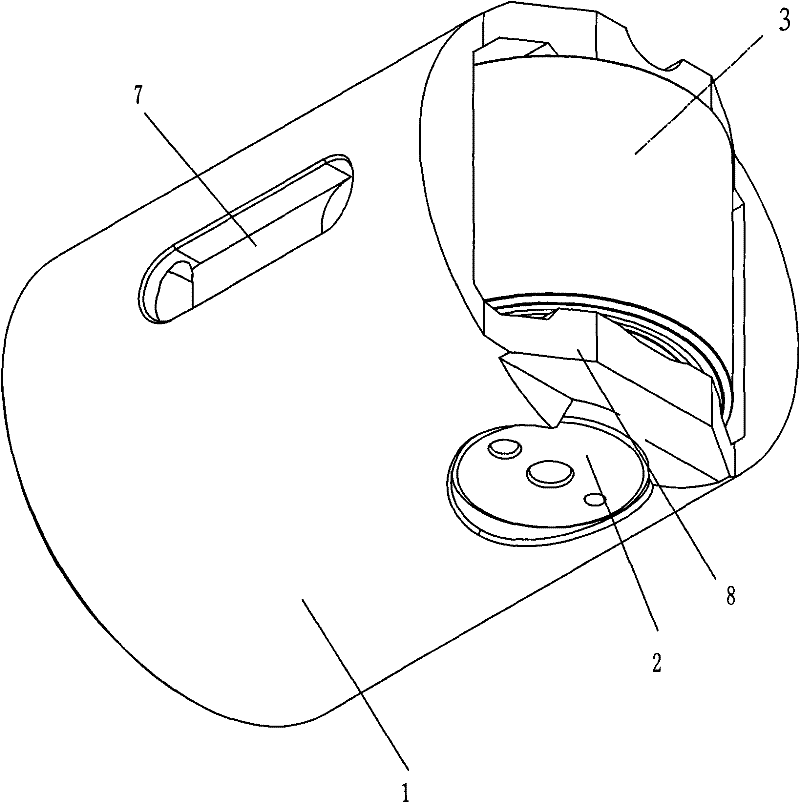

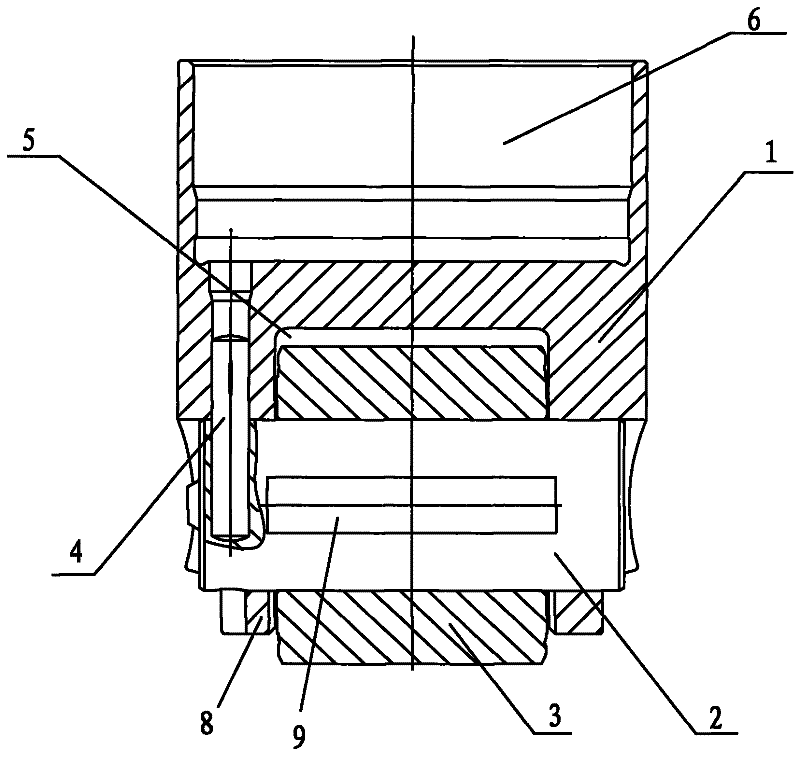

[0009] Such as figure 1 As shown: the side axial U-shaped positioning groove 7 of the tappet body 1, the two side wings of the tappet body are provided with through holes that are concentric and perpendicular to the axis of the tappet body 1; the two sides of the roller pin 2 The ends are respectively located in the through holes of the two side wings; the roller pin 2 is provided with a roller 3, and the roller 3 is located in the roller groove opened by the tappet body. The roller pin 2 and the tappet body 1 are fixed by a positioning pin 4 . The roller pin 2 and the tappet body 1 are clearance fit, and the positioning pin 4 limits the axial movement of the roller pin 2, thus ensuring the reliability of the roller pin 2 in use. Described roller 3 is installed on the roller pin 2, and roller 3 can rotate in the positioning groove 5 of tappet body 1, and roller 3 and roller pin 2 are clearance fit, and roller 3 can slide on roller pin 2. The positioning pin 4 is located at o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com