Take-up device for power construction

A wire take-up device and electric construction technology, which is applied in the directions of transportation and packaging, thin material handling, and filamentary material transportation, etc., can solve the problems of large cable usage, increased use cost, and a lot of manpower and material resources, and reduce labor intensity. , Improve work efficiency, improve the effect of winding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

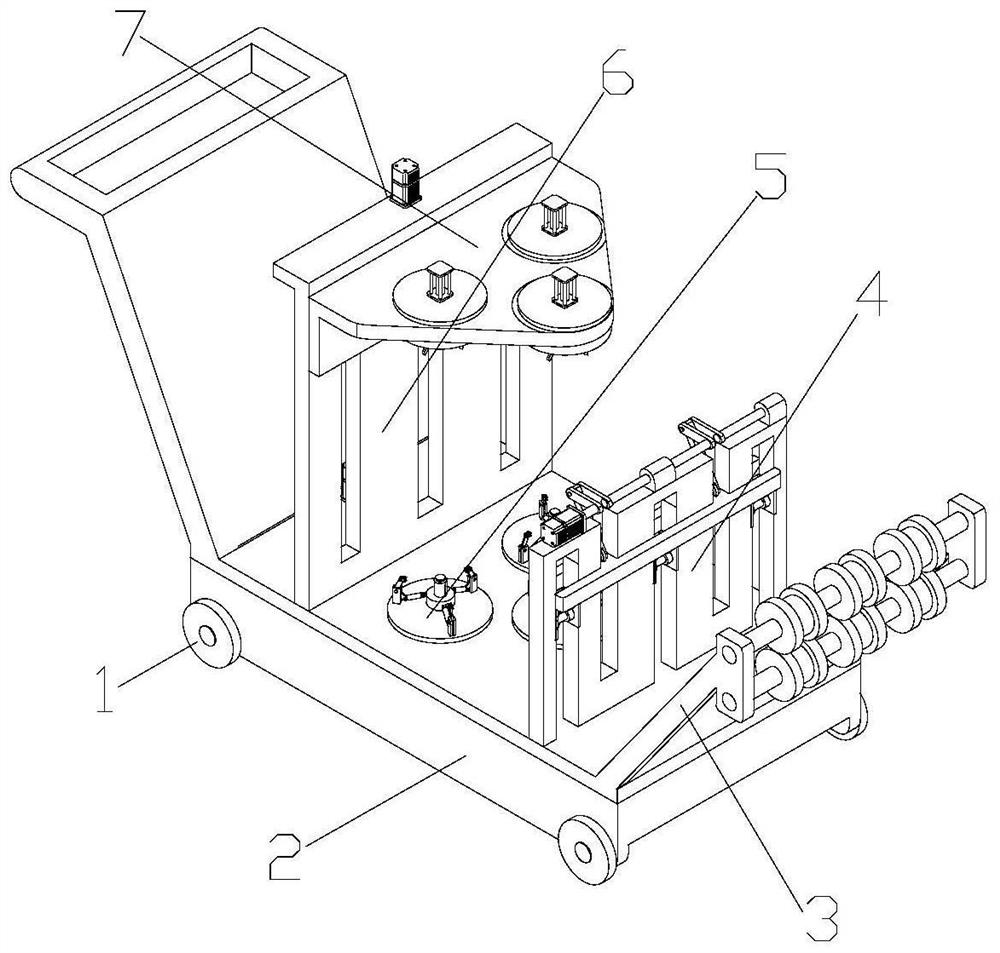

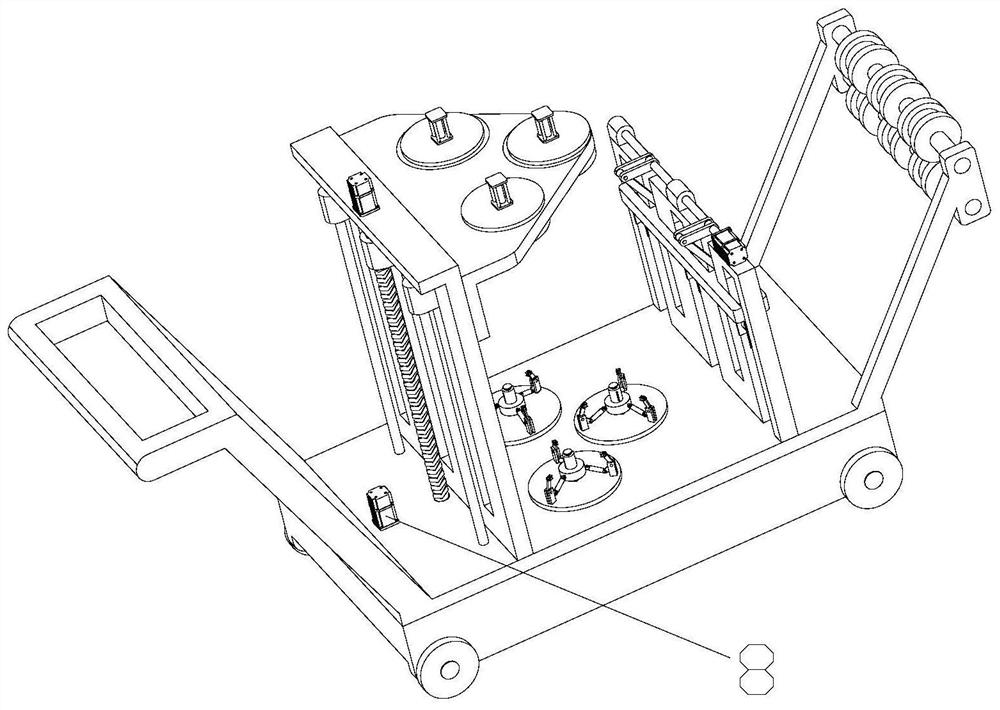

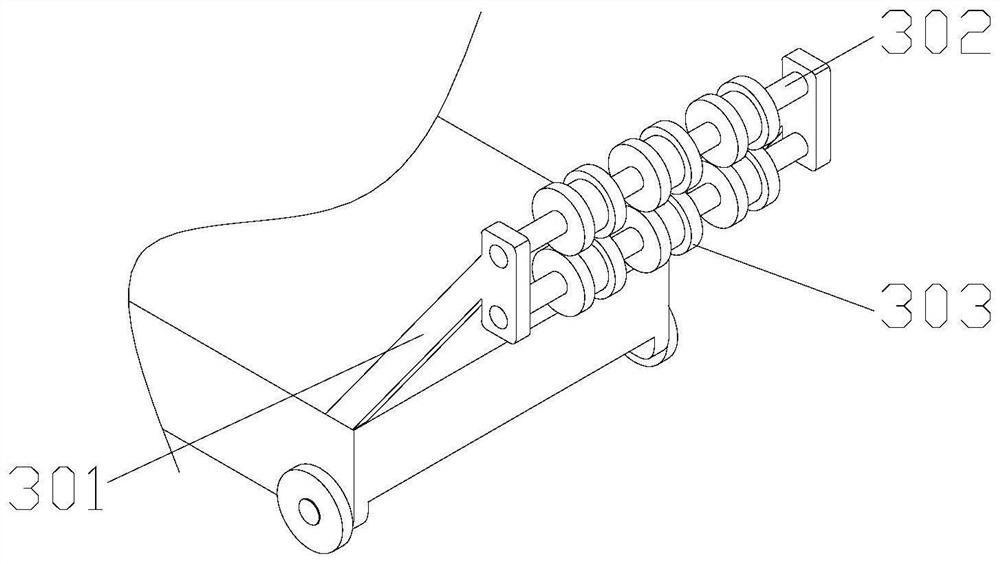

[0044] Such as Figure 1-6 , a wire take-up device for electric power construction, comprising a support plate 2, a moving wheel 1 with brake pads is installed at the bottom of the support plate 2, the support plate 2 is a cavity structure, and a The driving mechanism 8 is equipped with a rotating mechanism 5 and a guide mechanism 3 on the support plate 2. The guide mechanism 3 is installed on one end of the support plate 2. The guide mechanism 3 includes a bracket 301, a connecting shaft 302, and a guide roller 303. The bracket 301 is obliquely installed on the support plate 2, the connecting shaft 302 is provided with two, and the connecting shaft 302 is installed on the bracket 301, the guide roller 303 is provided with a plurality, and the plurality of guide rollers 303 are evenly installed on the two sides. On the two connecting shafts 302, the guide rollers 303 on the two connecting shafts 302 correspond one by one and cooperate with each other. The rotating mechanism 5 ...

Embodiment 2

[0050] Such as Figure 7-10 , the difference from Embodiment 1 is that it also includes a lifting mechanism 6, and the lifting mechanism 6 includes a first support vertical plate 602, a support frame 606, a threaded rod 603, a motor 601, and a guide rod 604. There are three chute 605 on the plate 602, and three fixed blocks 607 are installed on the support frame 606, and the three fixed blocks 607 are arranged in the three chute 605 and extend to the outside of the chute 605, and the threaded rod 603 One end of which is installed on the middle fixed block 607 and extends to the top of the fixed block 607, the other end is installed on the support plate 2, the motor 601 is installed on the top of the first support book board, and the output shaft of the motor 601 is connected with the screw thread The rods 603 are connected, and the guide rod 604 is symmetrically installed on both sides of the threaded rod 603, and one end of the guide rod 604 is installed on the fixed block 60...

Embodiment 3

[0054] Such as Figure 11-13 , The difference from Embodiment 1 and Embodiment 2 is that it also includes a forward adjustment mechanism 4, which includes a second support vertical plate 401, a fixed frame 403, a motor 404, a connecting rod 406, and a connecting piece 405 , the fixed shaft 407, a first strip-shaped through hole 402 and a second strip-shaped through-hole 408 are provided on the second support vertical plate 401, and the first strip-shaped through-hole 402 and the second strip-shaped through-hole 408 are intersected, so The fixing frame 403 is installed in the first strip-shaped through hole 402 and the second strip-shaped through hole 408, the first strip-shaped through hole 402 is provided with a guide, and the guide is installed on the fixing frame 403. The second strip-shaped through hole 408 is provided with a mounting block 4014, the motor 404 is installed on the top end of the second support vertical plate 401, the fixed shaft 407 is installed on the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com