Injection moulding die used for automotive sealing strip

A technology for automobile sealing strips and injection molds, which is applied to household appliances, other household appliances, applications, etc., can solve the problems of high yield and low yield, and achieve the effect of low cost, small error, and solving accumulated tolerances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

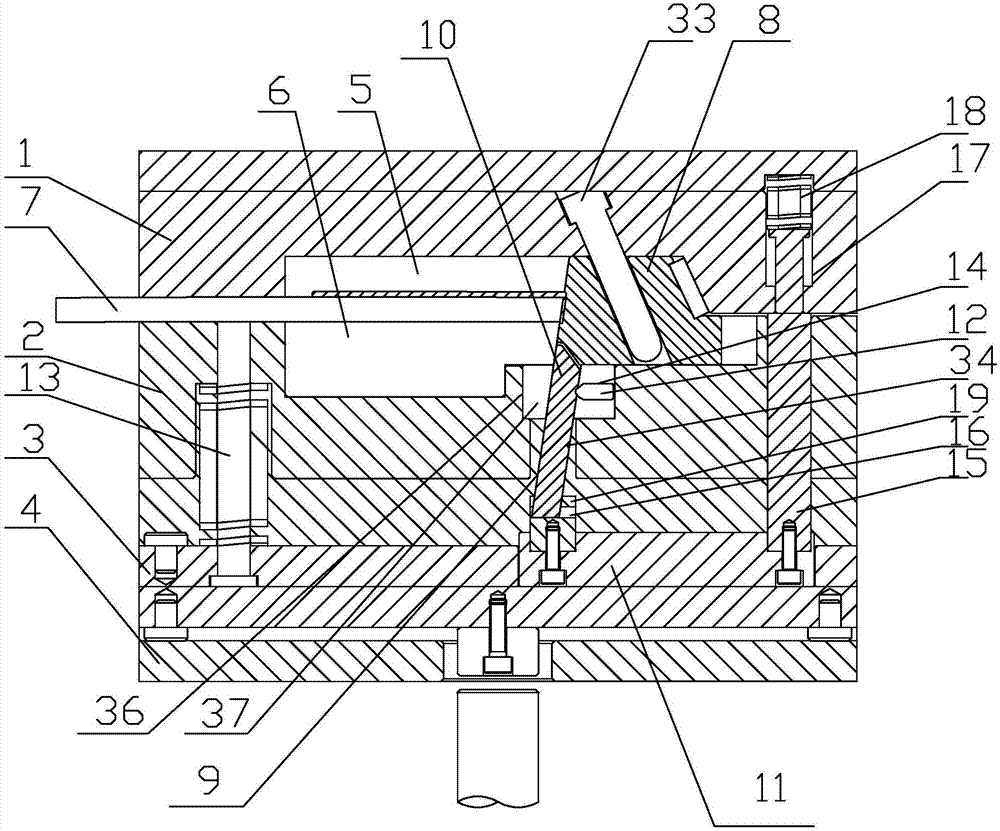

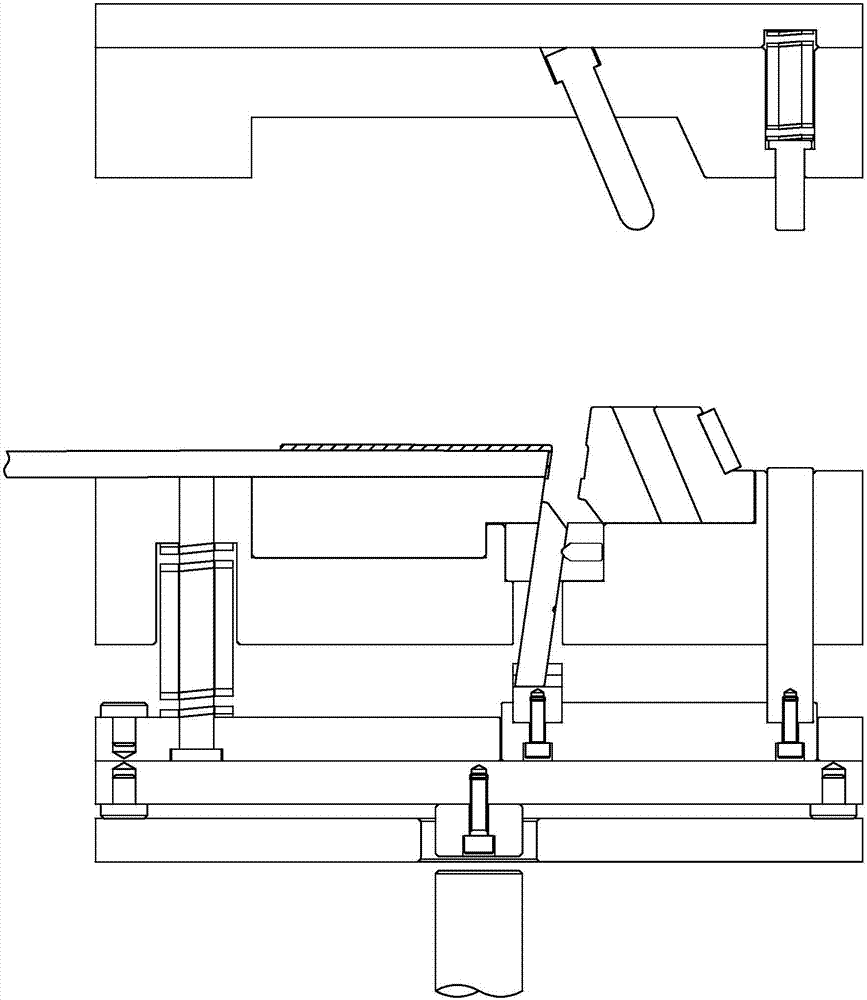

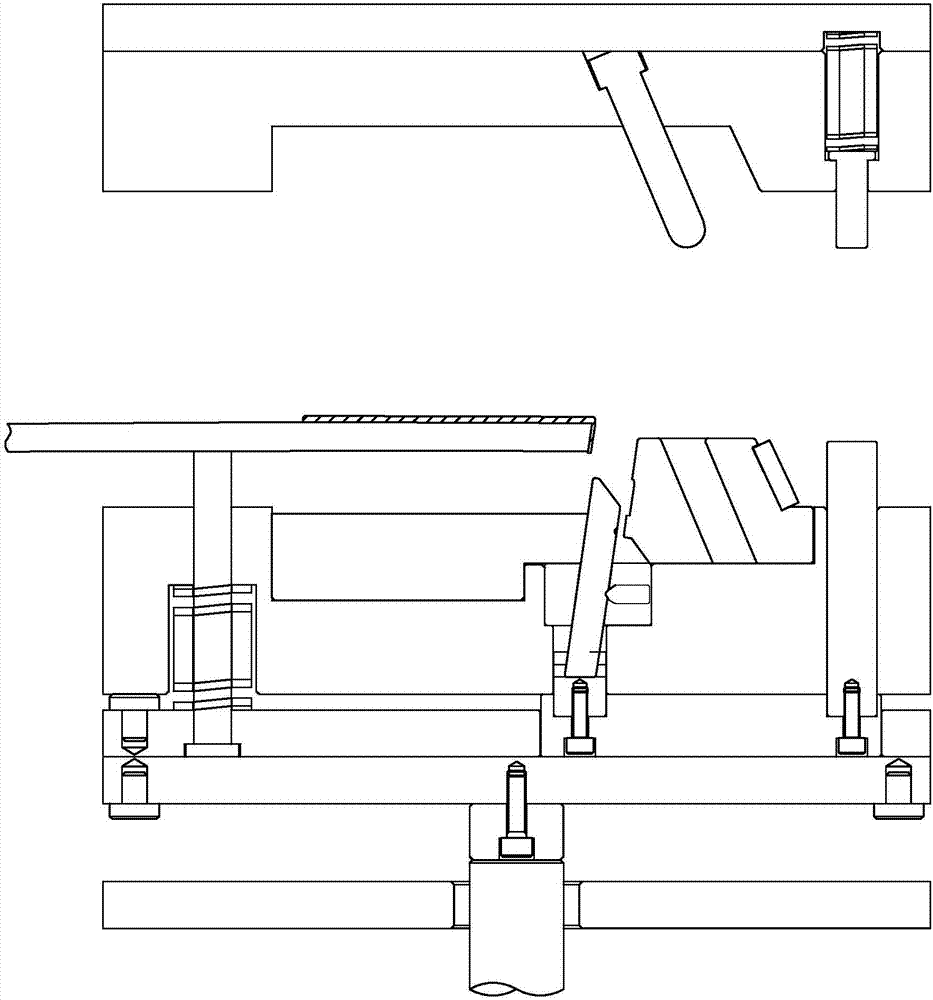

[0028]As shown in the figure, the present invention provides an injection mold for automotive weather strips, including an upper template 1, a lower template 2, a push plate 3, a base plate 4 and a seal 7, and the push plate 3 is located on the base plate 4 Above, the lower template 2 is located between the upper template 1 and the push plate 3, the upper mold core 5 is arranged below the upper template 1, and the lower mold core 6 is arranged above the lower template 2, and the The lower template 2 is provided with an oblique slider 8 for forming the front end of the sealing strip 7 and a slider 22 for forming the inner side of the front end of the sealing strip 7. The upper template 1 is provided with an oblique slide The oblique guide column 33 that slides and fits with the block 8, and the type that wraps the inner surface and the front end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com