Vibration reducer for automobile noise reduction

A shock absorber and noise reduction technology, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems affecting the quiet effect of cars, reduce comfort, and loud noise, and achieve noise reduction, prevent The effect of unstable movement and improved noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

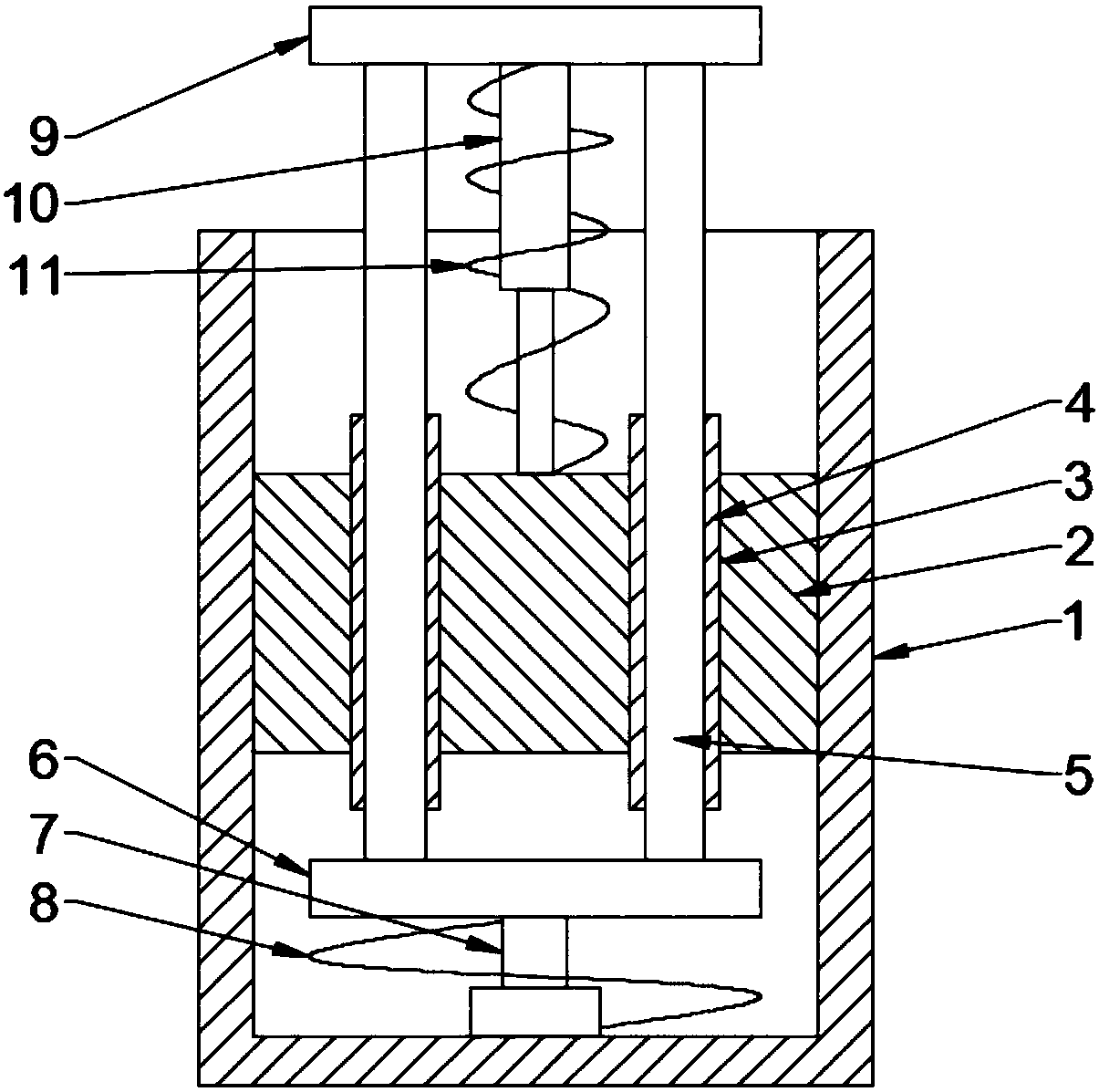

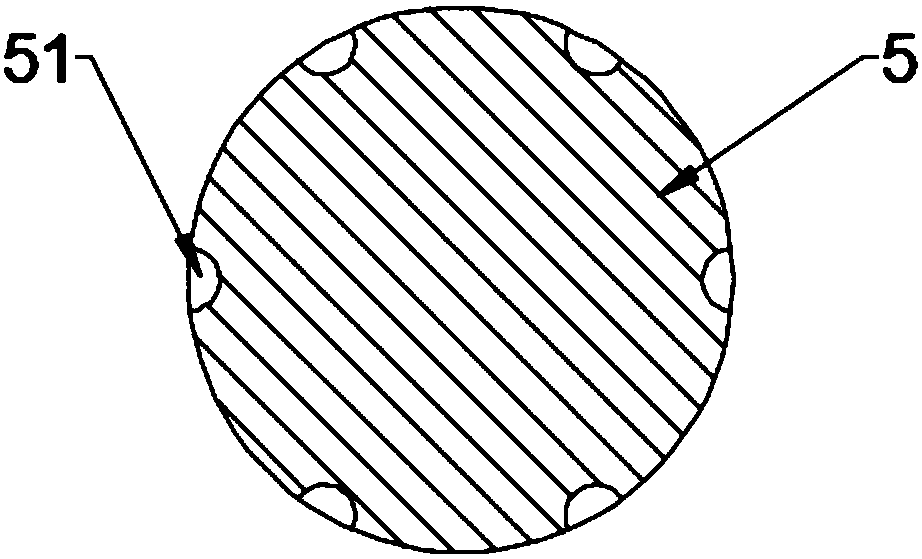

[0024] see Figure 1~4 , a shock absorber for automobile noise reduction, comprising a cylinder body 1 and a stabilizing plate 2, the cylinder body 1 is a cylindrical structure with an open top, a stabilizing plate 2 is provided in the middle of the inner cavity of the cylinder body 1, and the stabilizing plate 2 is The middle part of the board 2 is provided with a number of lifting holes 3 in a circular array. The lifting holes 3 are provided with a lifting sleeve 4, and the lifting sleeve 4 is provided with a lifting rod 5. There is a slide between the lifting sleeve 4 and the lifting rod 5. connected, the outer circular surface of the lifting rod 5 is in a circular array and is provided with a number of oil grooves 51 matched with the lifting sleeve 4, and the bottom ends of all the lifting rods 5 are fixedly connected to the lower pressing plate 6, and the bottom end of the lower pressing plate 6 Fixedly connected to the second telescopic rod 7, the other end of the first ...

Embodiment 2

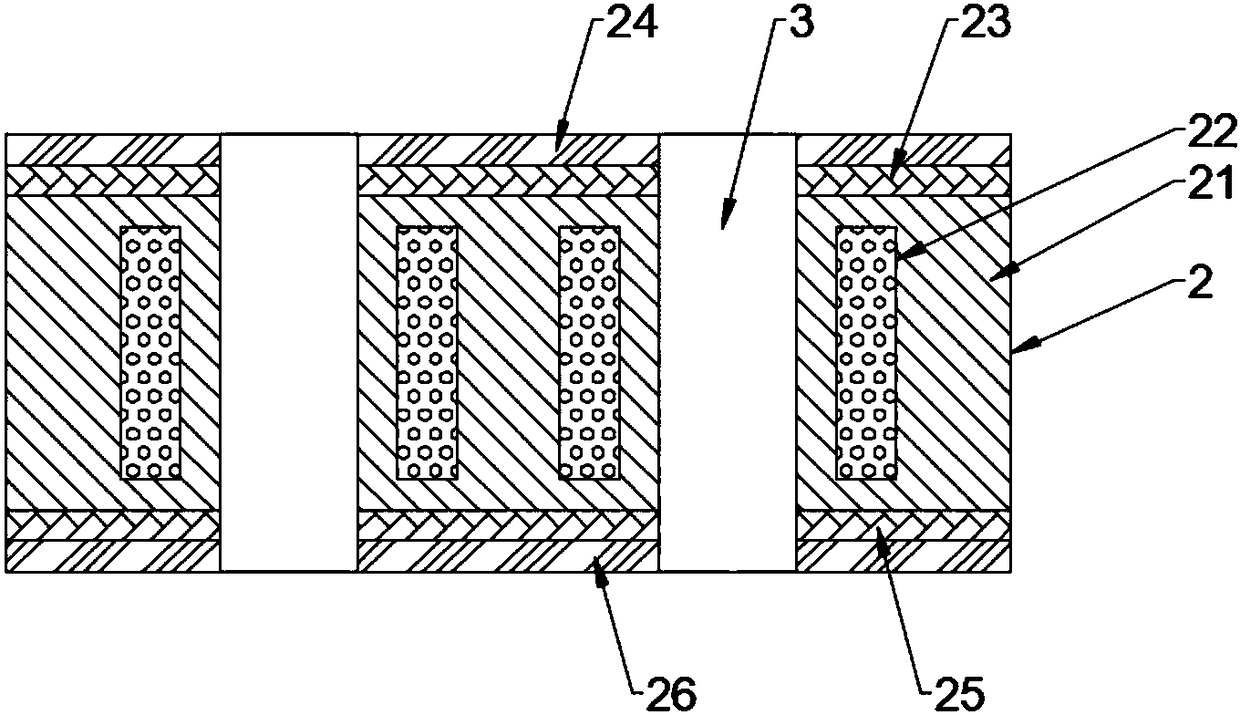

[0027] This embodiment is a further elaboration on the basis of Embodiment 1. The stable plate 2 includes a base plate 21, an upper sound-insulating layer 23, an upper protective layer 24, a lower sound-insulating layer 25, and a lower protective layer 26. There is a sound-absorbing cover 22 matched with the lifting hole 3. The sound-absorbing cover 22 is set on the outside of the lifting hole 3. The sound-absorbing cover 22 is made of suction sponge. The top of the base plate 21 is provided with an upper sound-insulating layer 23. The bottom of the substrate 21 is provided with a lower sound-insulating layer 25, the upper sound-insulating layer 23 and the lower sound-insulating layer 25 are all made of sound-insulating panels, the top of the upper sound-insulating layer 23 is provided with an upper protective layer 24, and the lower The bottom of the sound-insulating layer 25 is provided with a lower protective layer 26. By setting the sound-absorbing sleeve 22, the upper soun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com