Patents

Literature

64results about How to "Symmetrical force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

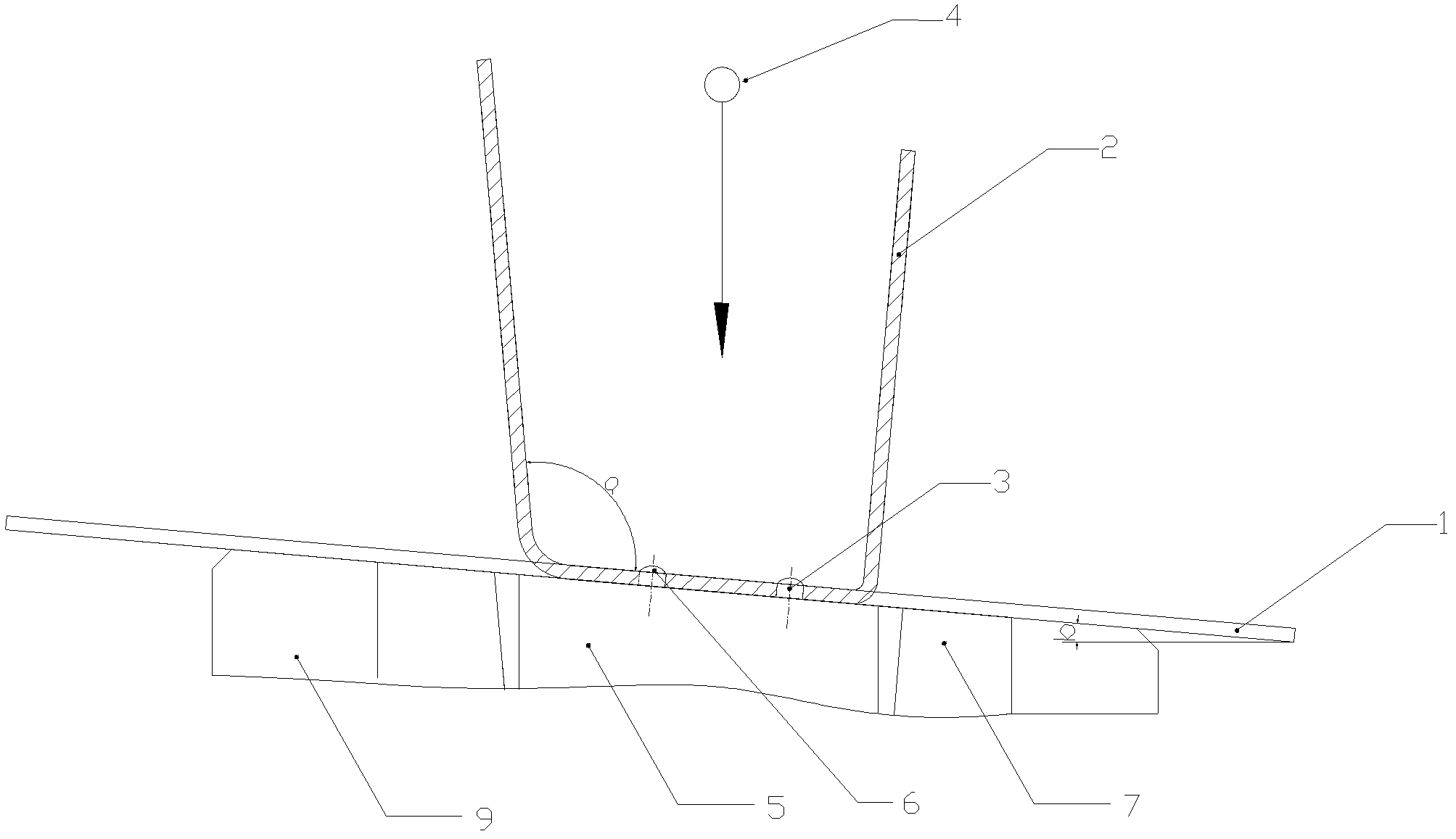

New rock II-type fracture toughness test method

InactiveCN104833590AEnables Mode II Fracture Toughness TestingIncrease the tensile stressPreparing sample for investigationMaterial strength using steady shearing forcesType fractureRock sample

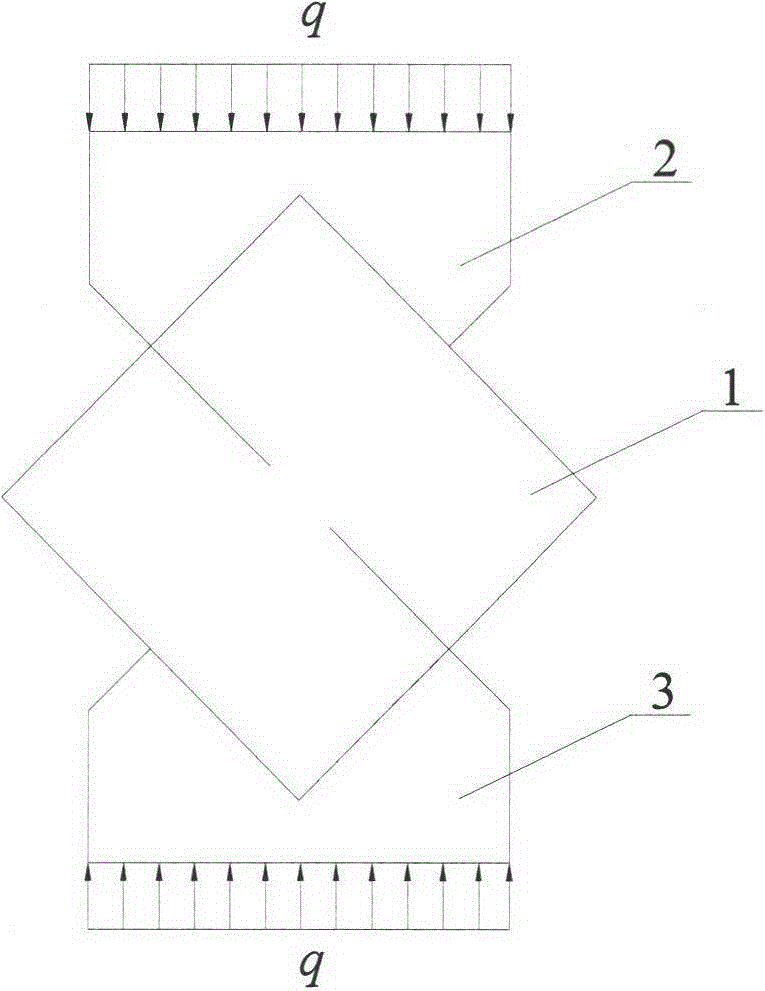

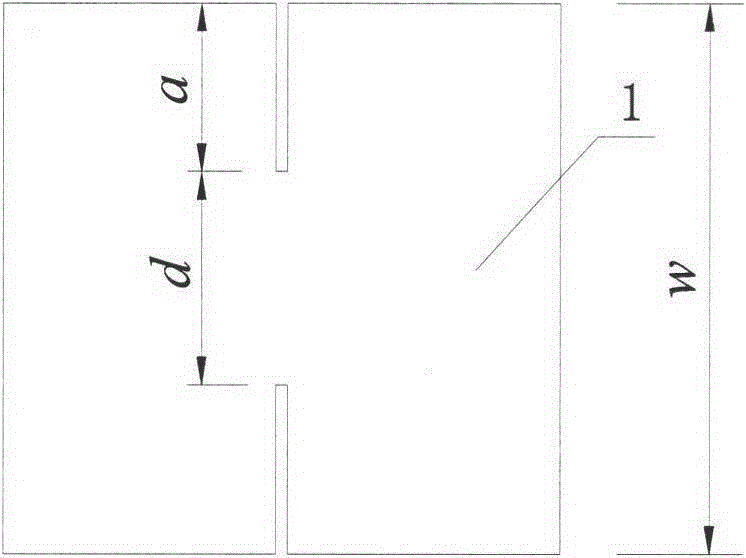

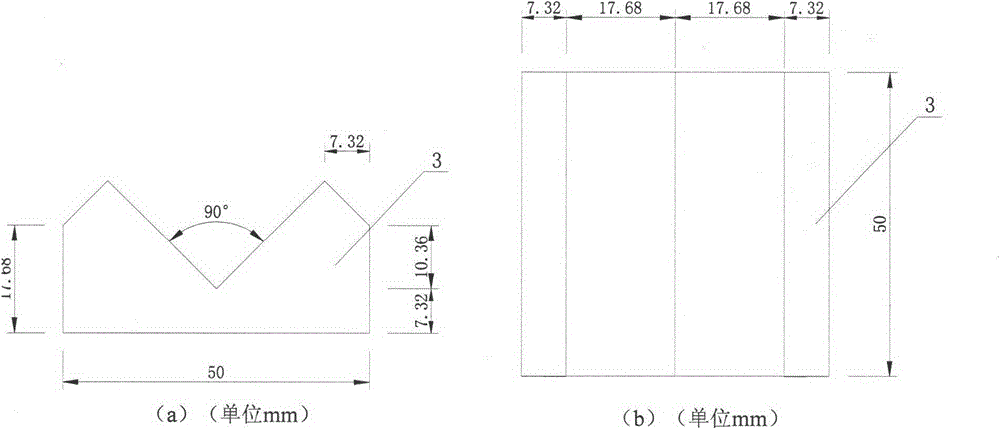

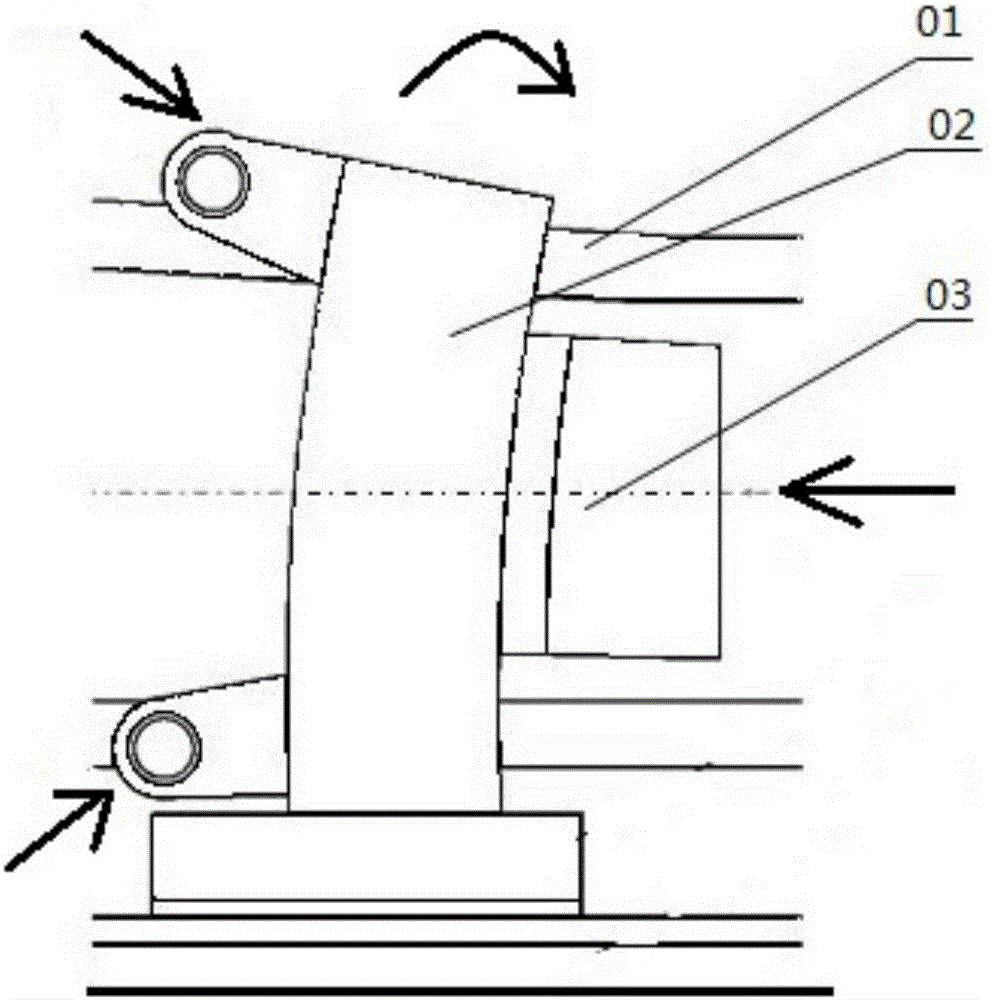

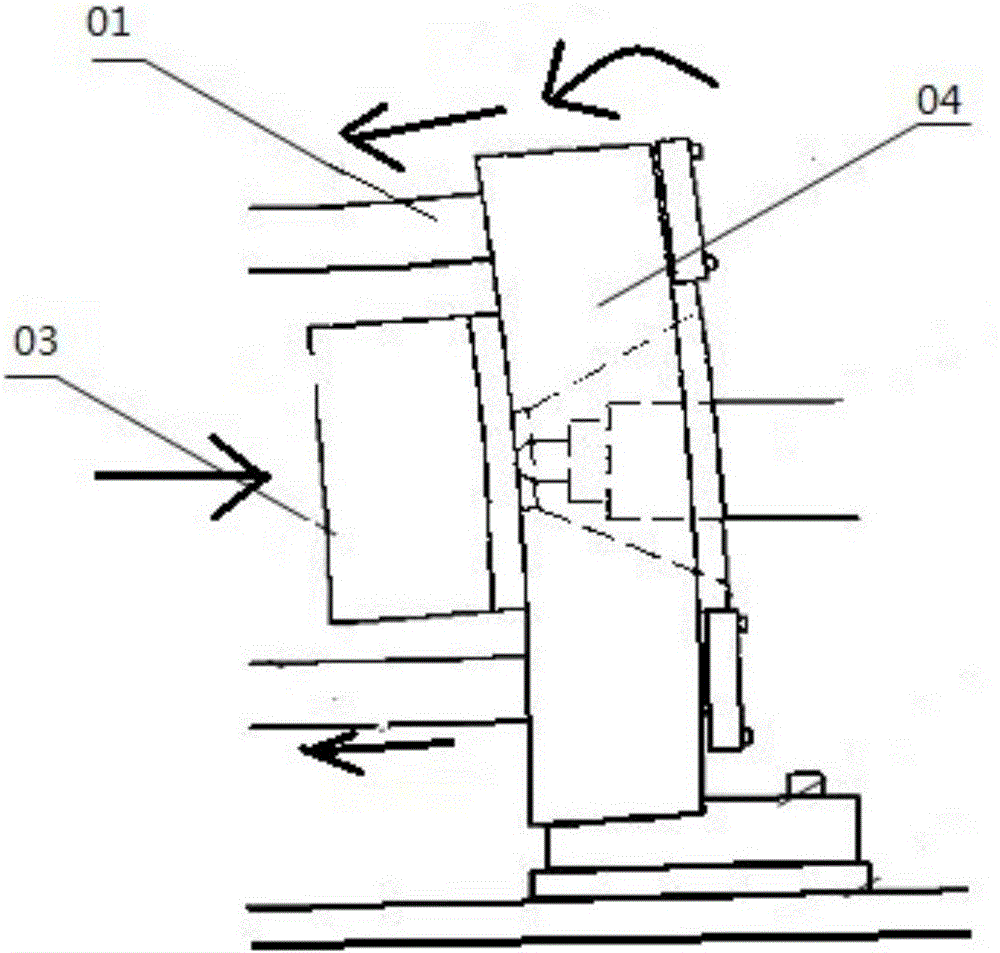

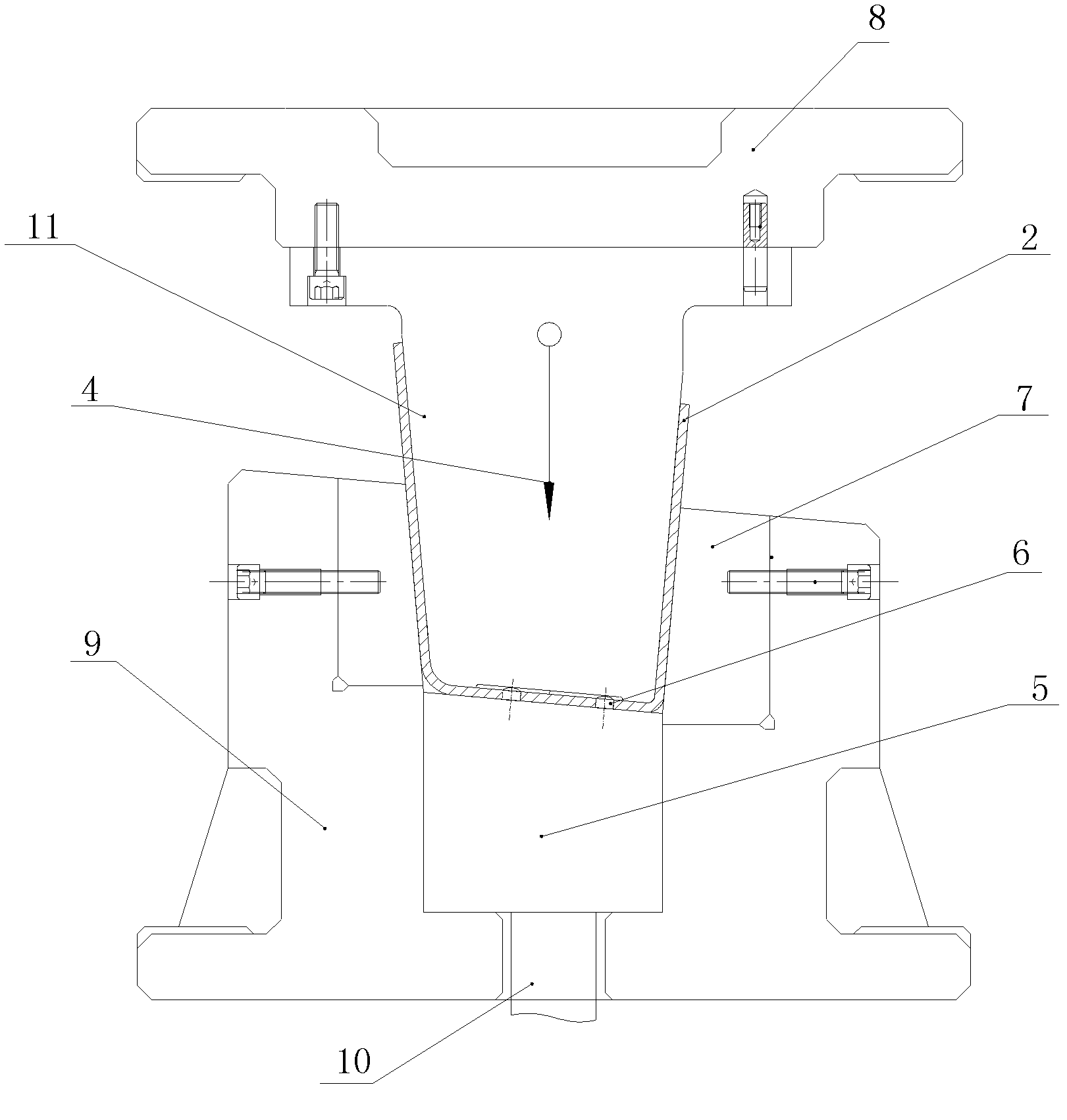

The invention relates to a new rock II-type fracture toughness test method. According to the invention, on the basis of an original shear box test, by means of adjustments of the stress state of a loaded mould and arrangement of a sample to eliminate rotation tendency of the sample, generation of an excessive tensile stress on a crack tip is inhibited, thereby achieving rock II-type fracture toughness test. A test model includes a square rock sample and two steel loading moulds. Straight cracks are pre-formed on the middle parts of the two sides of the square rock sample, wherein the lengths and the widths of the two straight cracks are equal to each other. The two straight cracks are arranged symmetrically. The loading moulds can achieve 45-degree loading of the sample with a loading end surface being flat and smooth. The widths of two contact surfaces between the loading moulds and the square rock sample are both half of the side length of the sample. An upper end and a lower end of the whole system are subjected to a uniform load. The method enables processing of the rock sample and the loading moulds to be more convenient, is simplified in test process, ensures accuracy of test data, is suitable for the II-type fracture toughness test of various rocks, and provides basis for researching the II-type fracture of rocks and a problem of composite fracture mainly comprising II-type fracture.

Owner:吴礼舟

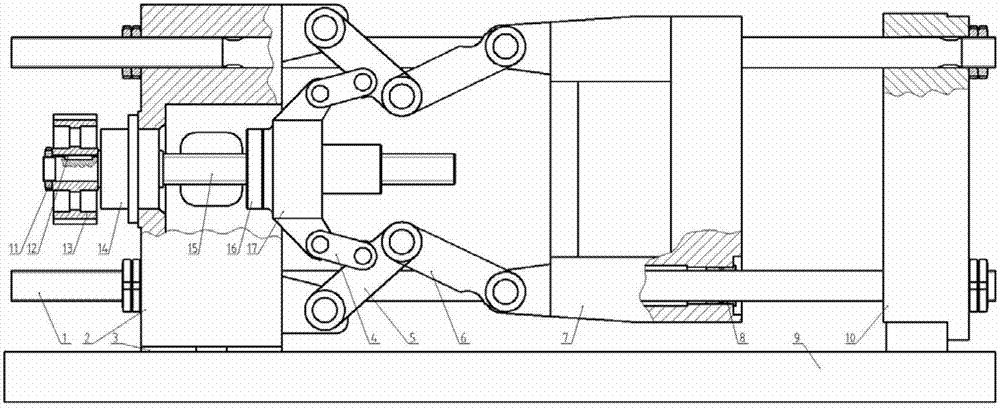

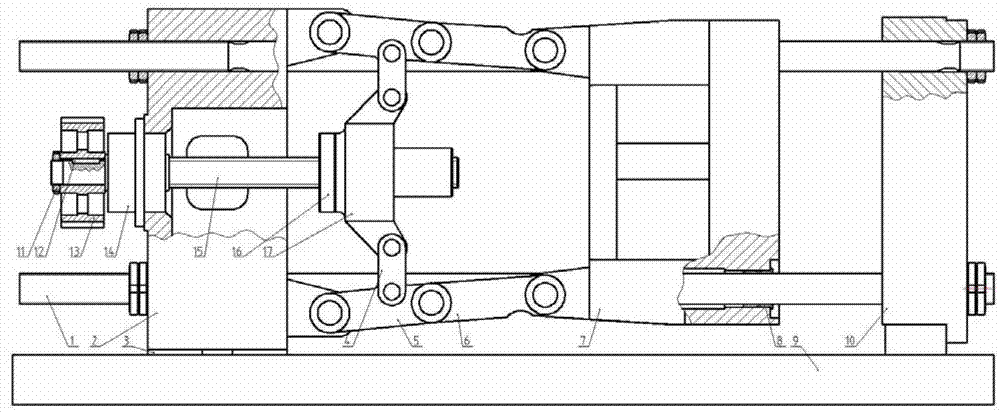

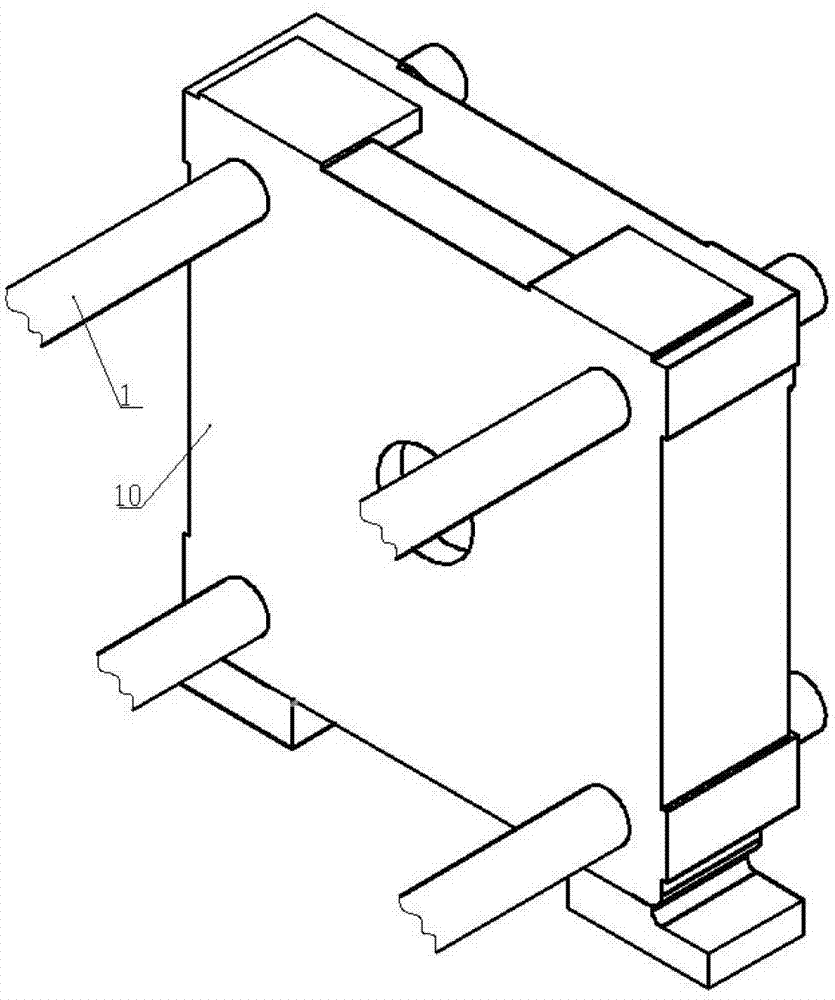

Ball screw pair-driven clamping mechanism

The invention discloses a ball screw pair-driven clamping mechanism. The ball screw pair-driven clamping mechanism comprises four pull rods, a tail plate, two toggle mechanisms, a movable mould plate, a head plate, a synchronous pulley, a screw bearing base, a ball screw, a ball nut and a thrust block, wherein the four pull rods fix the distance between the head plate and the tail plate and are used for guiding movement of the movable mould plate. The ball screw pair-driven clamping mechanism is driven by a servo motor; and through a toothed synchronous belt and a ball screw pair, rotation of the motor is converted into back-and-front movement of the thrust block to drive a toggle link mechanism so as to open and close the movable mould plate.

Owner:ZHEJIANG UNIV

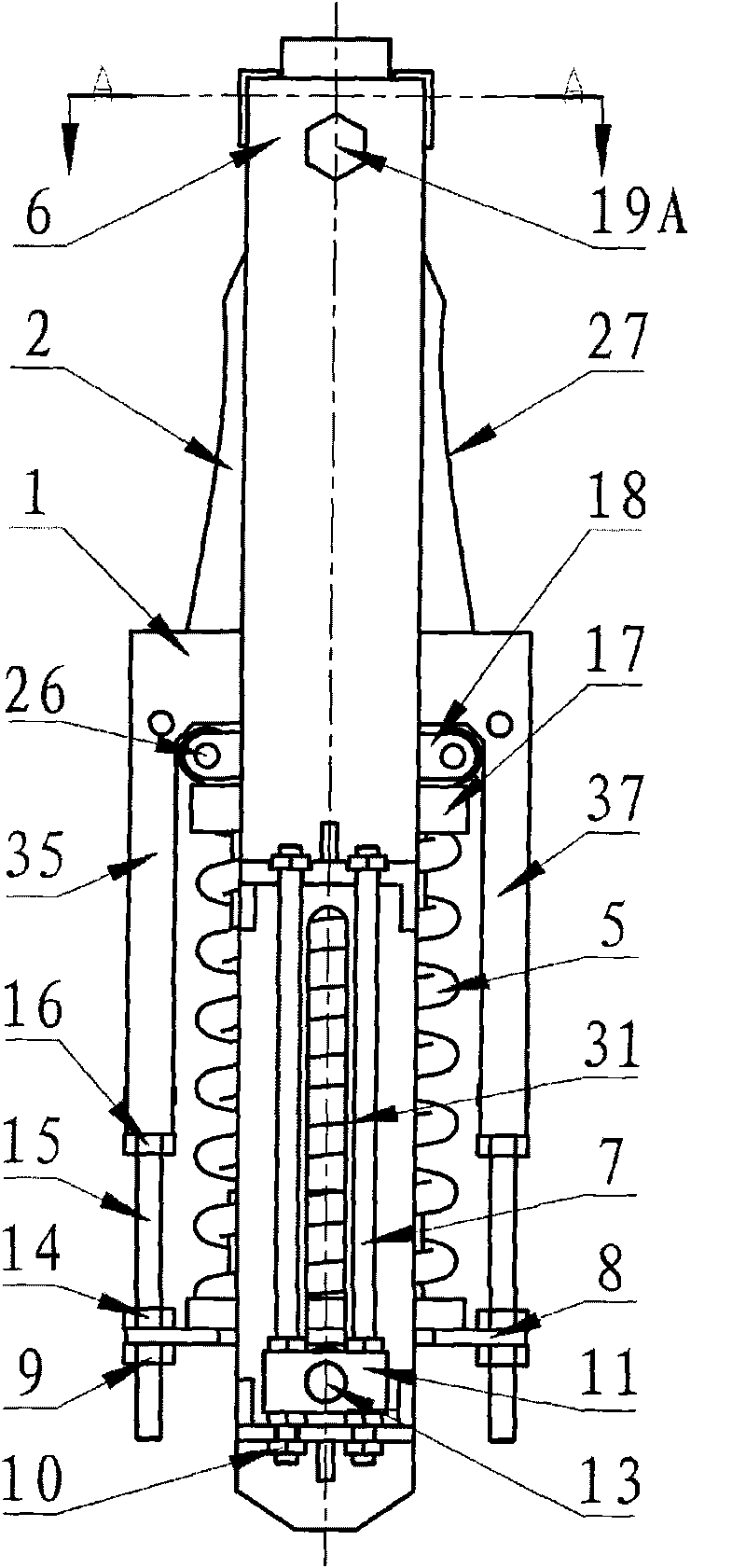

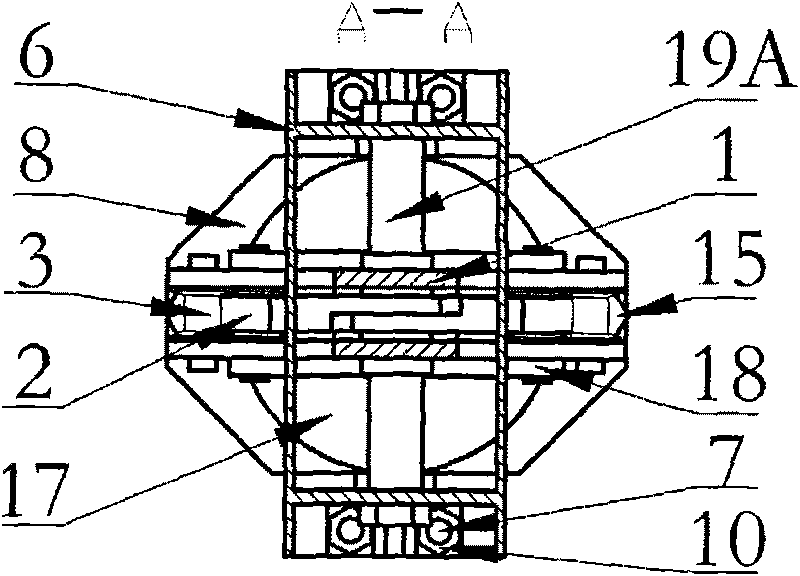

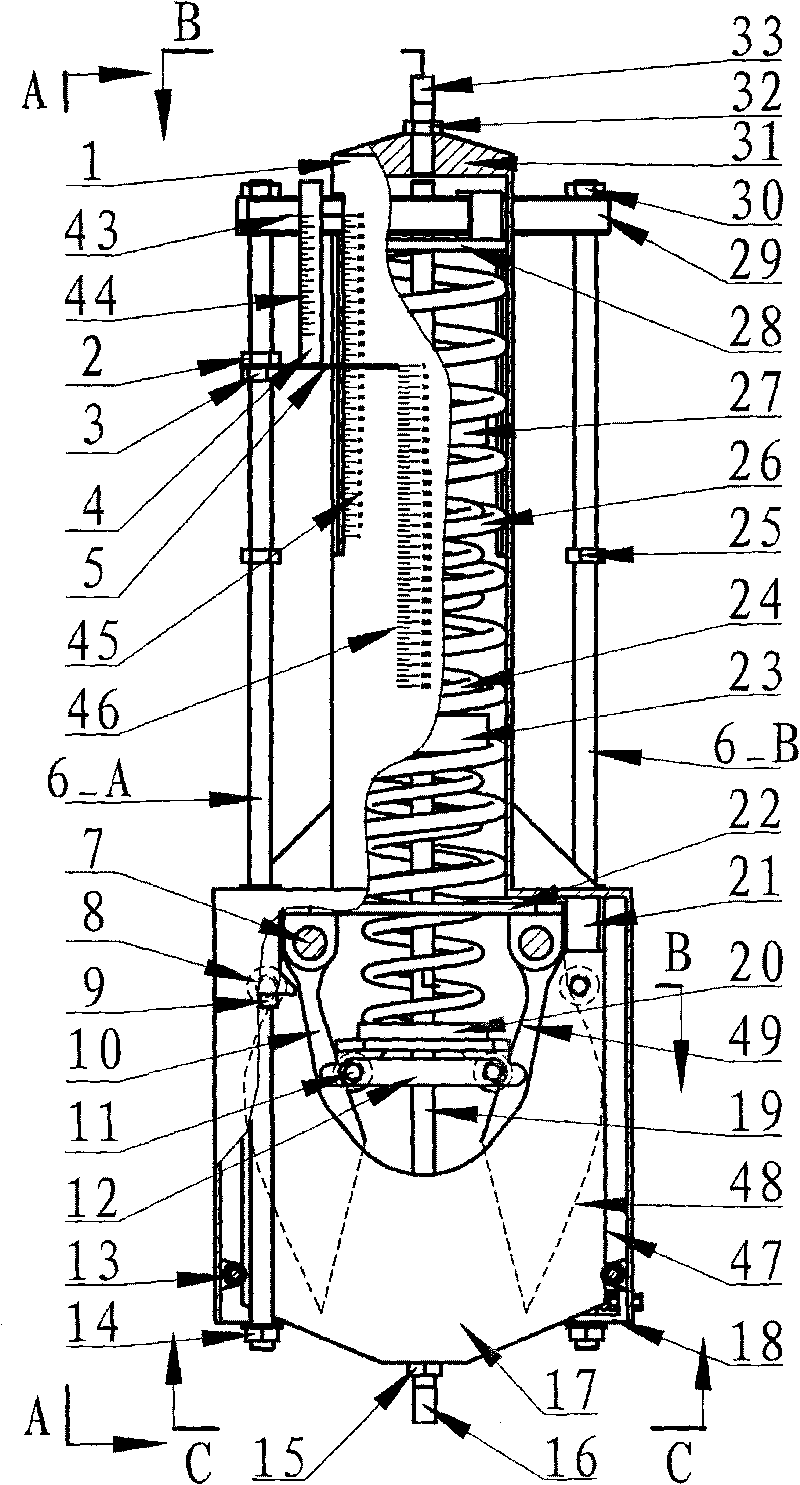

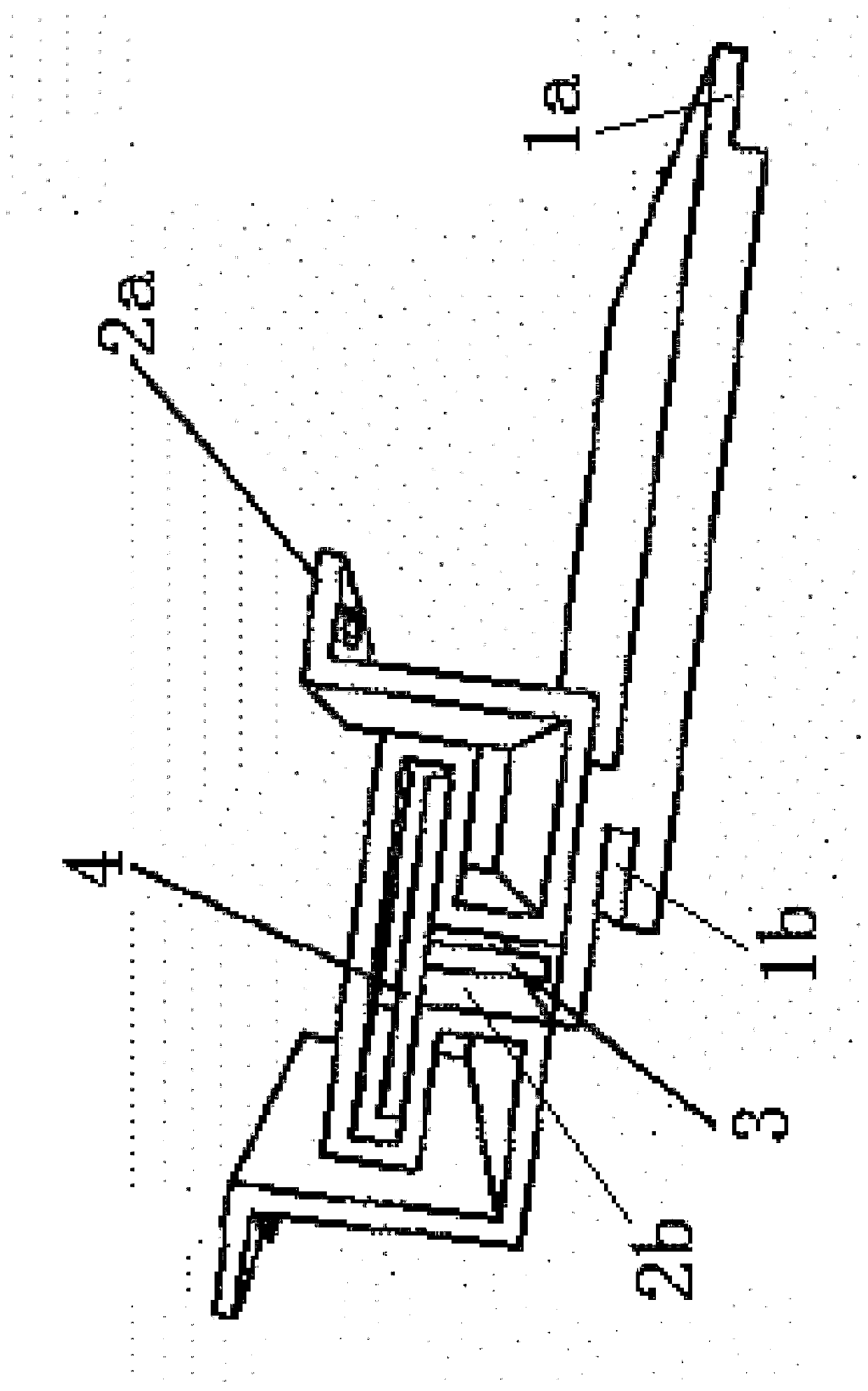

Self-compensating constant-force spring hanger

The invention relates to a self-compensating constant-force spring hanger, which mainly comprises a static frame, a dynamic frame, a cam, a spring, upper and lower spring end covers and static and dynamic idler wheels. The cam hinged on the dynamic frame by a cam shaft is provided with two inner and outer working curves which ensure a supporting and hanging force constant and are matched with the dynamic and static idler wheels arranged on the upper spring end cover and the static frame respectively. The spring and the upper and lower spring end covers are sleeved on a middle arm of the static frame. The lower spring end cover is connected with the static frame by an adjusting nut and an adjusting screw. The dynamic frame is provided with a locking support plate which can lock an indicating pin fixedly connected on the static frame after being matched with a locking device. The self-compensating constant-force spring hanger can be used for supporting and hanging pipelines with cold and thermal displacement in the industries, such as the power industry, the petrochemical industry and the like, and also can be used in the occasions that contact lines and the like of electrified railways needs the constant tensile force.

Owner:高永峰

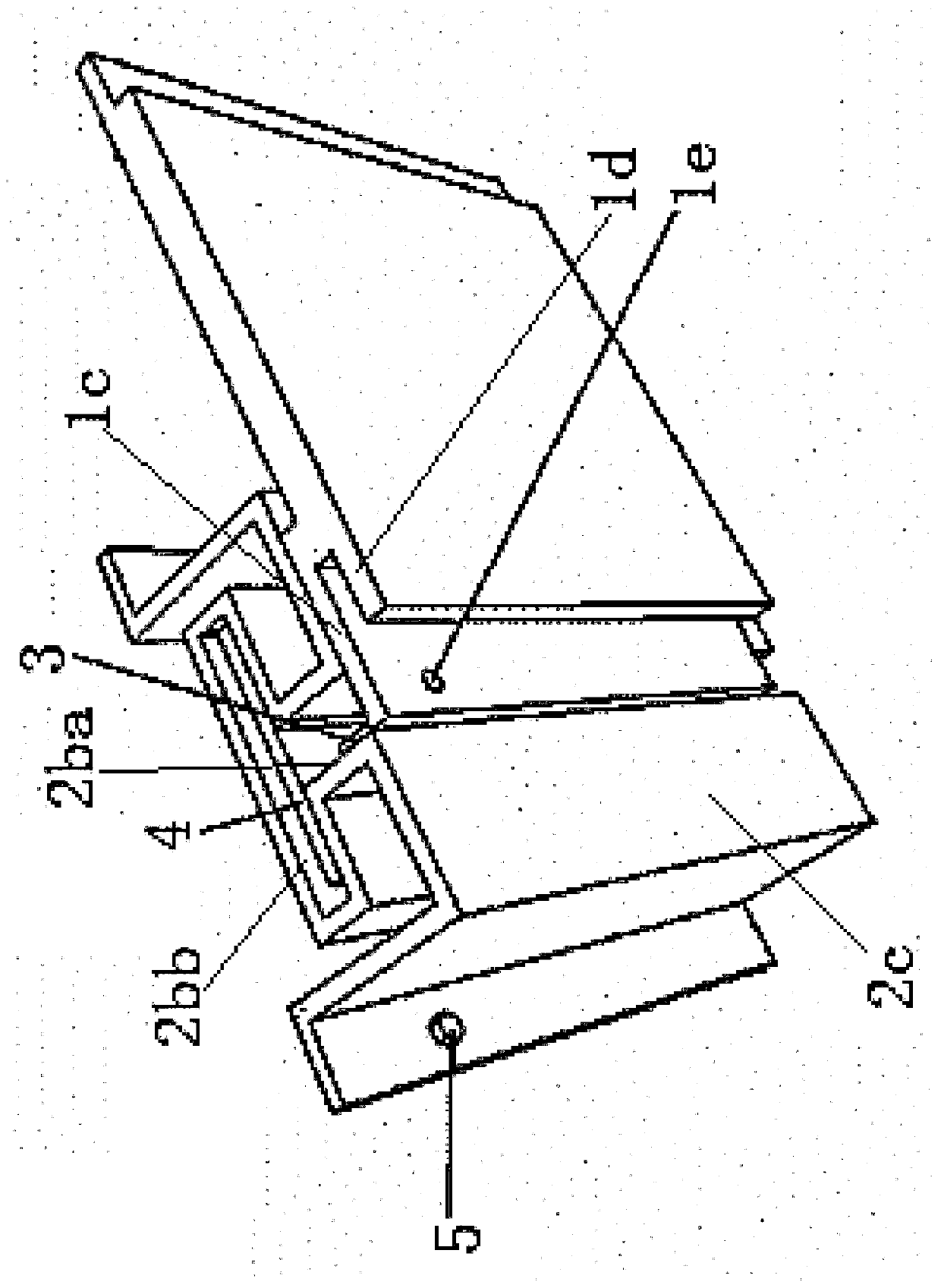

Coaxial constant force spring support hanger

The invention relates to a coaxial constant force spring support hanger which mainly comprises a shell, an inner frame, cams, an inner spring, an outer spring, a spring end cover, a threaded rod and inner and outer roller wheels, wherein the inner and outer springs and a pull rod fixedly connected on the inner frame are coaxial; the respective upper end cover of the inner and outer springs is fixedly connected with the inner frame; and the lower end cover of the outer spring is fixedly connected with the shell. The two cams are symmetrically articulated on the shell, and the working curves of the inner and outer cams are respectively matched with the inner and outer roller wheels arranged on the inner frame and the lower end cover of the inner spring. The threaded rod fixedly connected on the inner frame is provided with an adjusting, locking and indicating device. The invention can be used for hangers of pipelines with cold and thermal walking in power industry, petrochemical industry and the like and occasions of contact screen wires and the like of electrified railways, needing constant tensile force.

Owner:高永峰

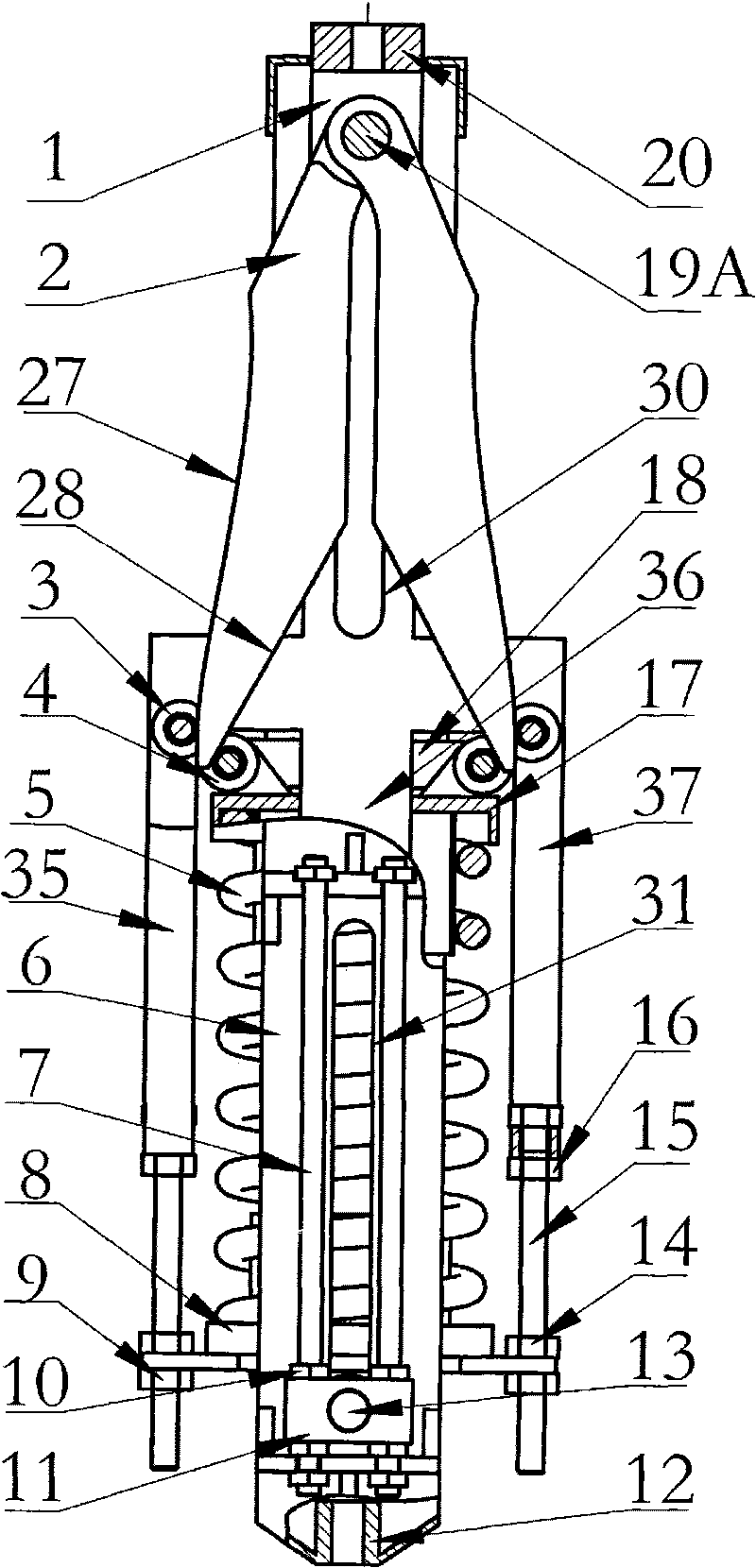

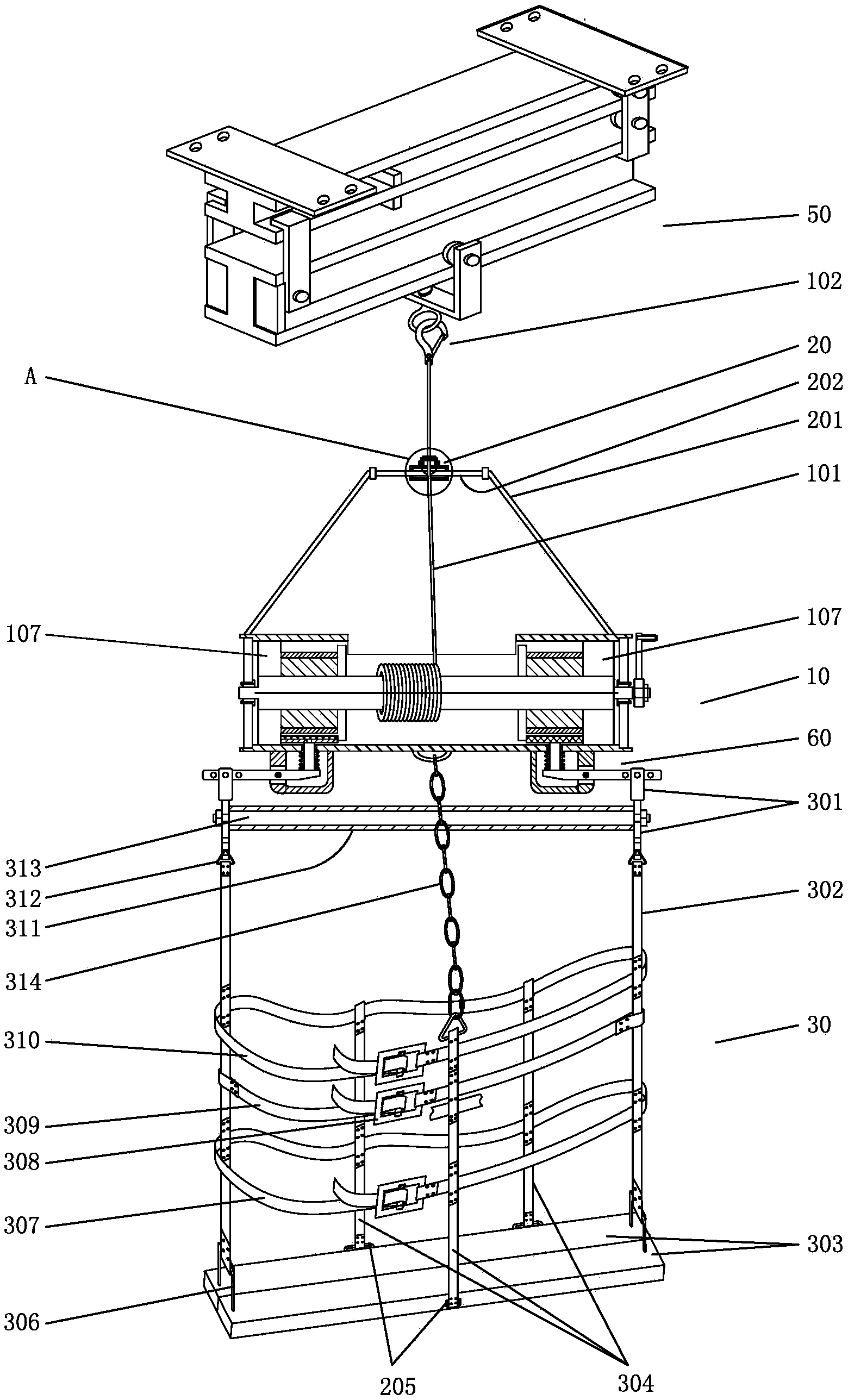

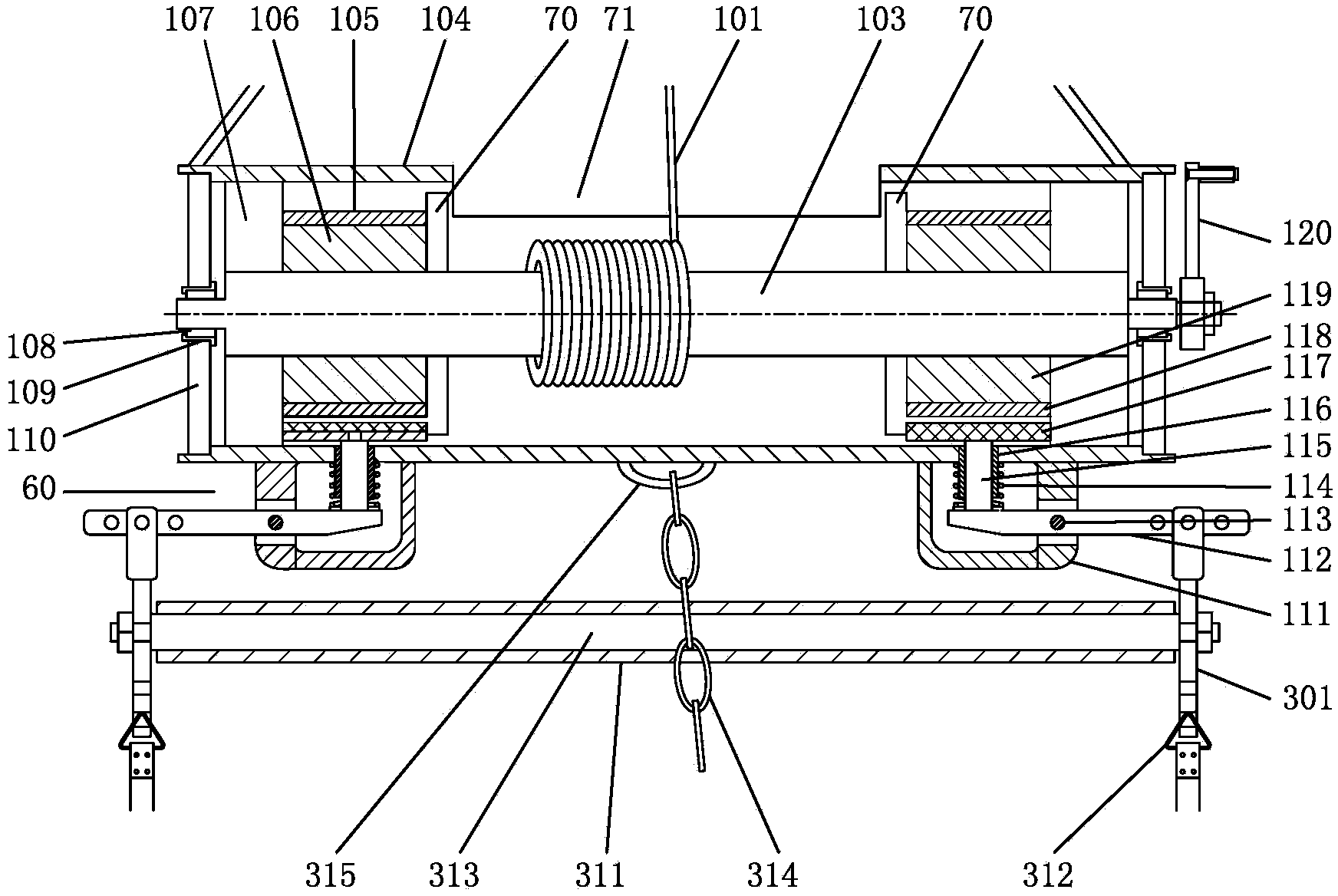

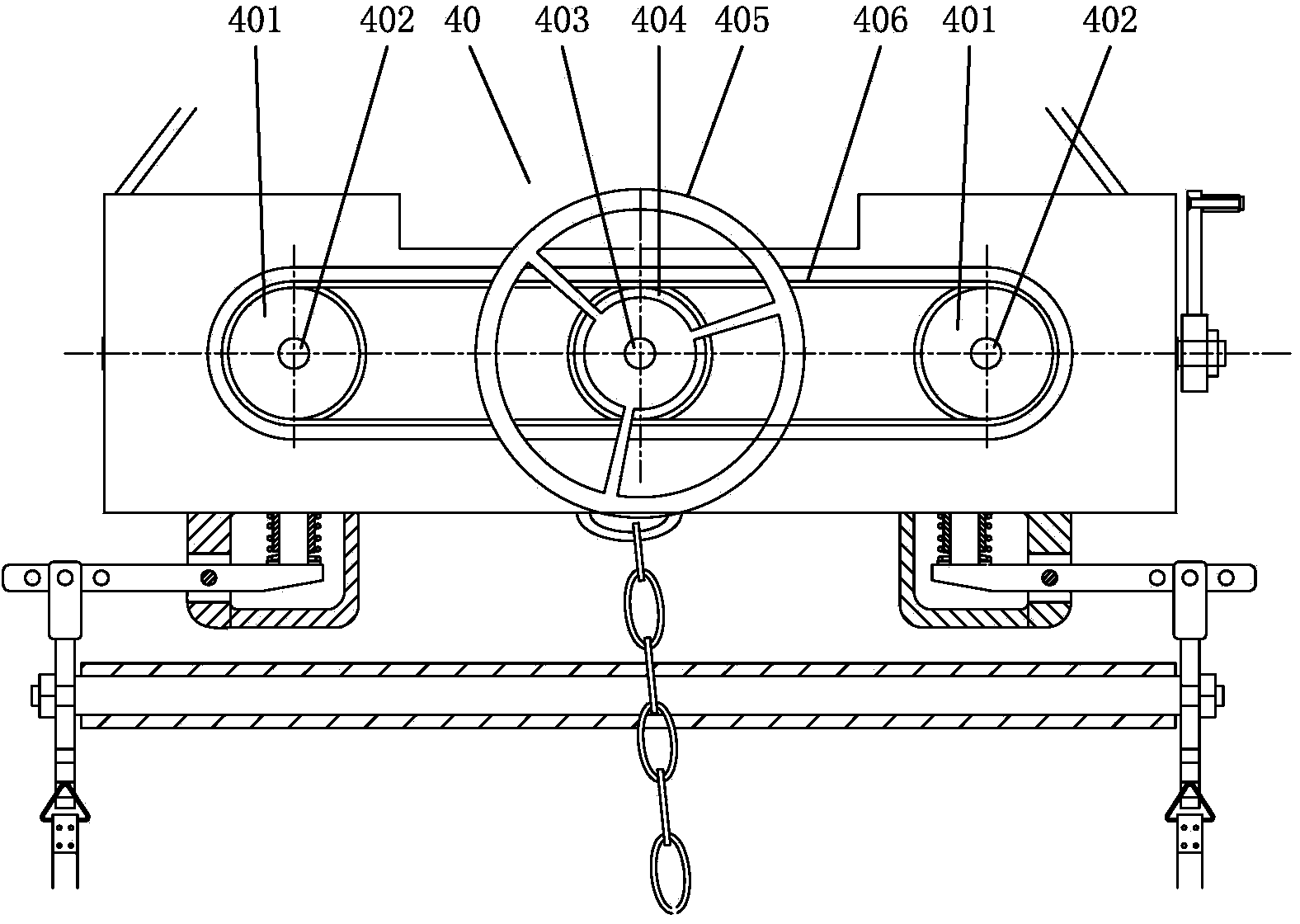

Multi-friction-wheel controllable brake swing-type high-rise rescue device

The invention belongs to the technical field of high-rise rescue, and relates to a multi-friction-wheel controllable brake swing-type high-rise rescue device. A wire rope released and collected by a host is released and collected by virtue of a guide rail type rope releasing and collecting mechanism; the host is provided with a lever type brake mechanism, a centrifugal reduction gear, a double-friction-wheel linked brake mechanism and a manual wire rope winding mechanism; the lever type brake mechanism is cooperated with a main spindle of the host; more than one safety seat basket for bearing a human body is hung on a connecting rod arranged on adjustment levers on two sides of the lever type brake mechanism. The multi-friction-wheel controllable brake swing-type high-rise rescue device has the advantages that the structure is more perfect, the rescue device is safer and more reliable to use, and is higher in practicability, especially, the double-friction-wheel linked brake mechanism can ensure that the brake is powerful, the stress is symmetrical and the like, and the rescue device is suitable for high-rise rescue, fire fighting rescue and rock climbing rescue.

Owner:金来兴

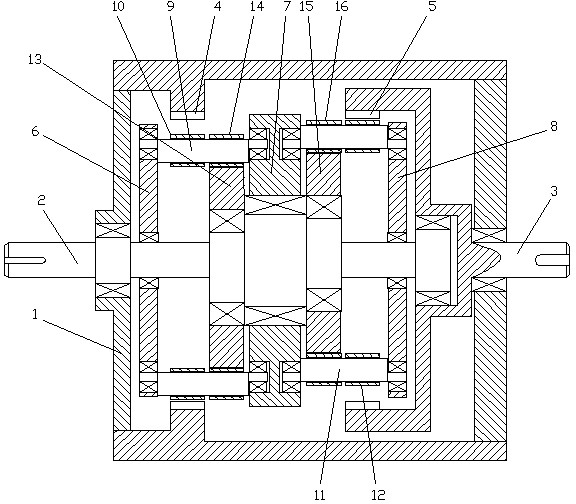

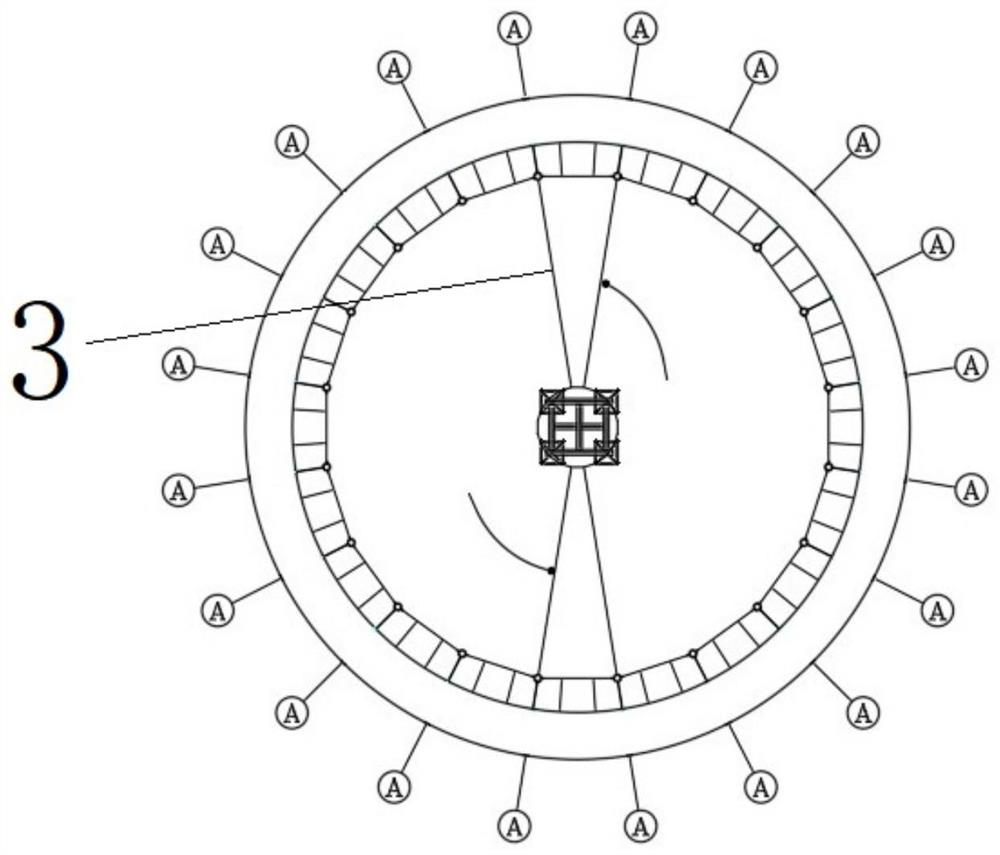

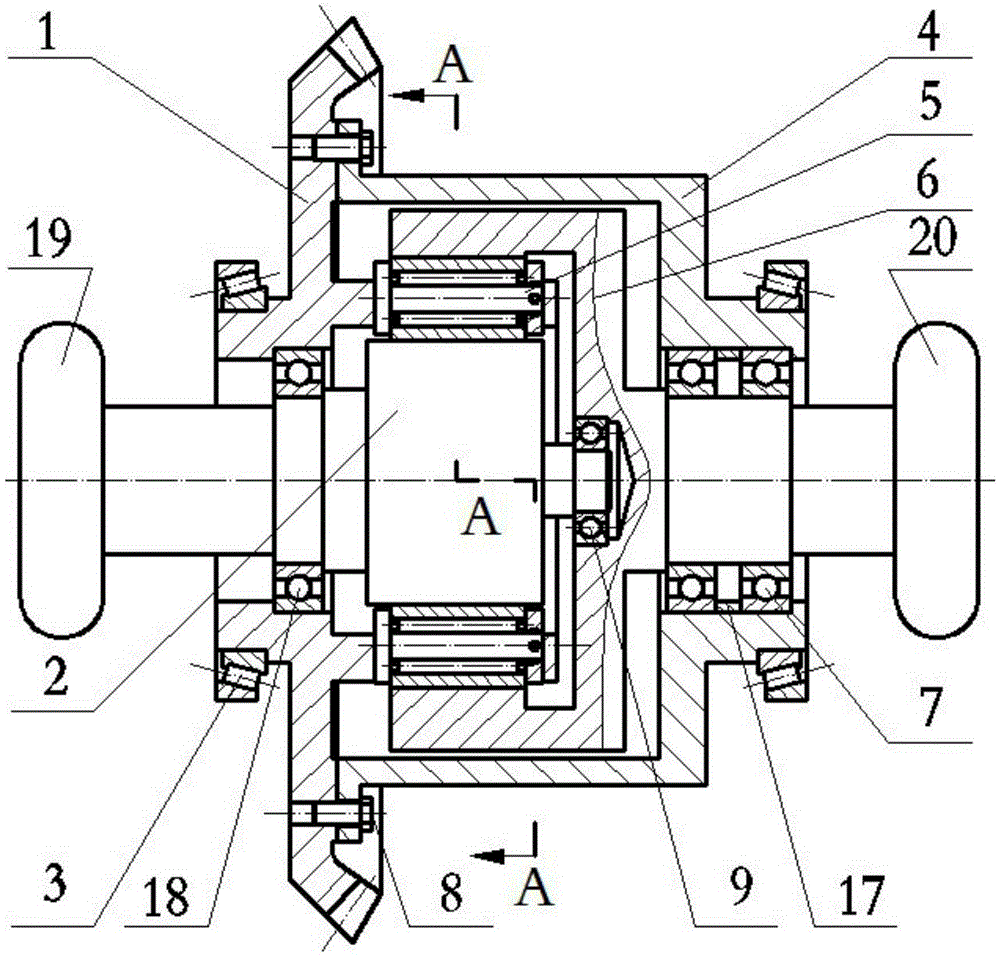

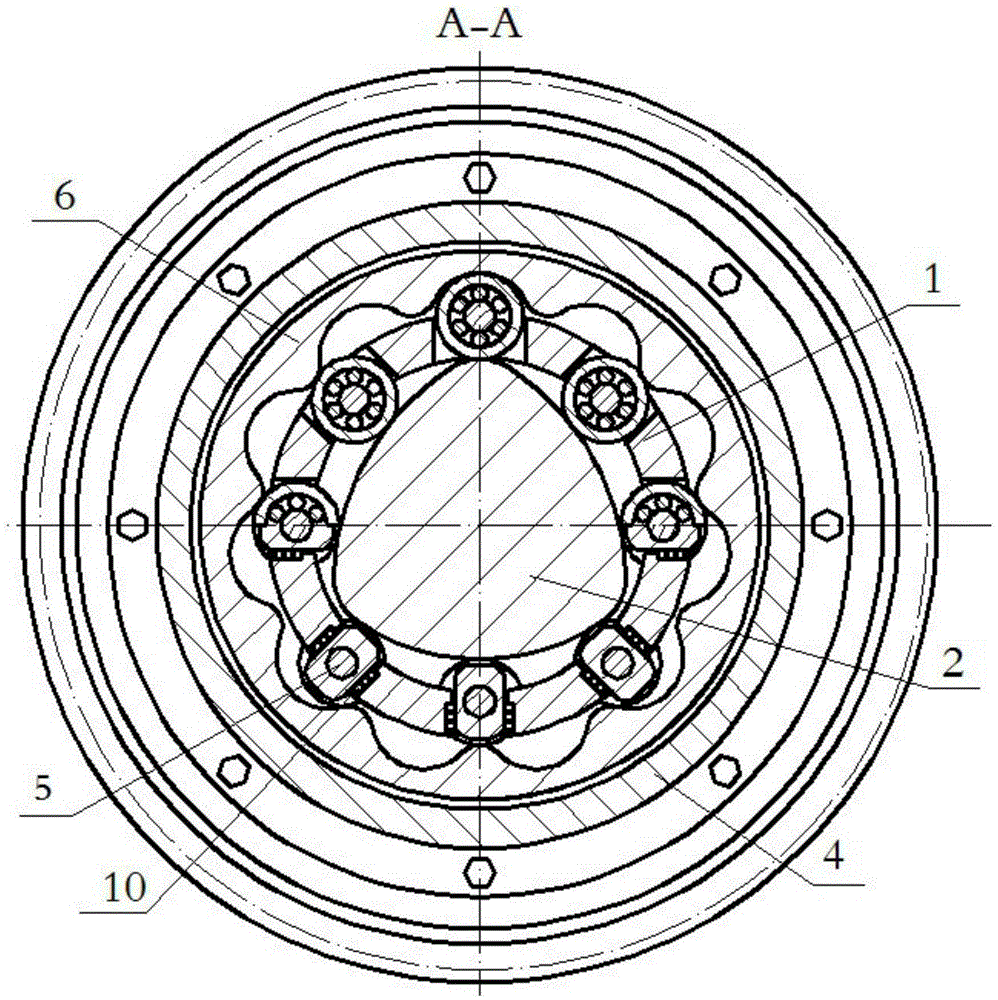

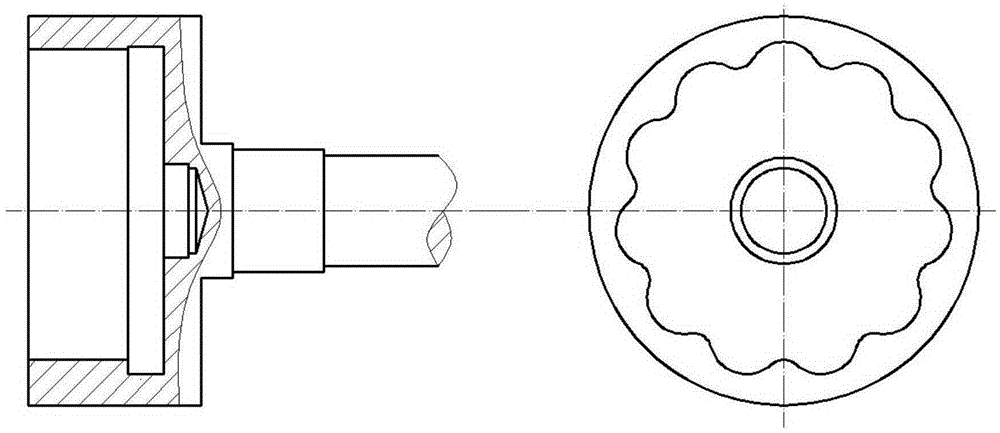

Two-stage movable tooth speed reducing transmission device

InactiveCN102678835ASimple structureReduce volumeToothed gearingsTransmission delayElectrical and Electronics engineering

The invention discloses a two-stage movable tooth speed reducing transmission device which comprises a housing, an eccentric input shaft, an output shaft, first-stage internal gears and second-stage internal gears, wherein a first movable gear frame, a first-stage driving disc, a central disc, a second-stage driving disc and a second movable gear frame are arranged on the eccentric input shaft in sequence; the two-stage movable tooth speed reducing transmission device further comprises a first eccentric frame formed by first-stage cranks; first-stage movable gears are arranged on the first-stage cranks; a first-stage movable gear cluster is meshed with the first-stage internal gears with few tooth differences; the two-stage movable tooth speed reducing transmission device further comprises a second eccentric frame formed by second-stage cranks; and second-stage movable gears are arranged on the second-stage cranks and meshed with the second-stage internal gears with few tooth differences. According to the two-stage movable tooth speed reducing transmission device, only one pair of meshed internal and movable gears is arranged in each stage of speed reducing transmission device, so that the whole device has a simple structure and a small volume; a rotation center of the eccentric input shaft is coaxial with a rotation center of the output shaft, so that the transmission device can be conveniently connected with other transmission structures and the mounting space of the transmission device is reduced; and the two ends of the first-stage crank and the two ends of the second-stage crank are all supported, so that the cranks are stressed symmetrically and have great carrying ability.

Owner:CHONGQING UNIV

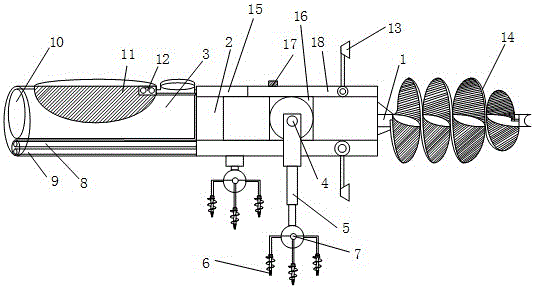

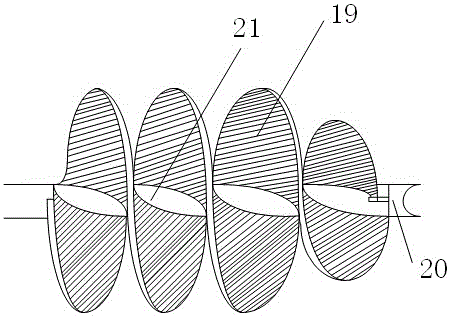

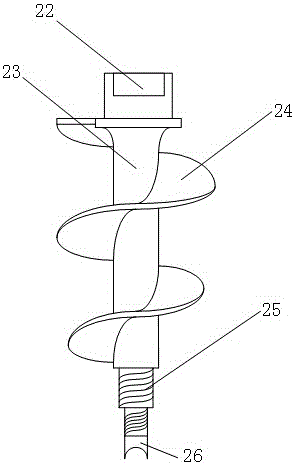

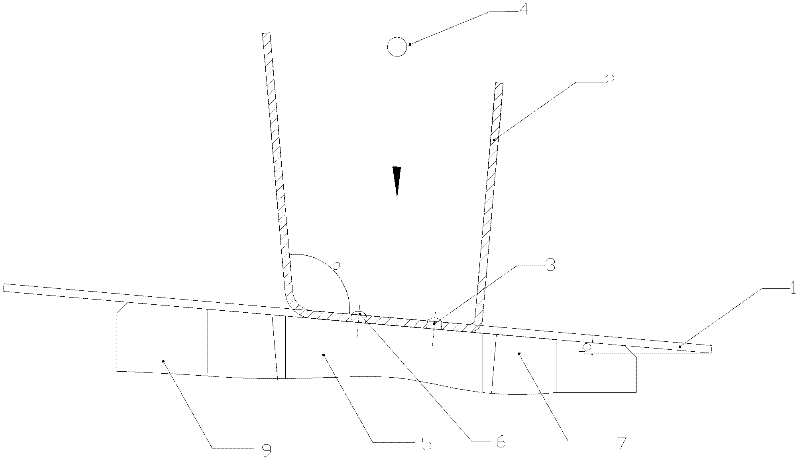

Mine tunnel water gushing-out advance rescue real-time embedded control device

ActiveCN106020025ANot easy to skewNot prone to vibrationProgramme controlMining devicesSound sourcesWater source

The invention relates to a mine tunnel water gushing-out advance rescue real-time embedded control device, and belongs to the technical field of real-time embedded detection control. The device is composed of device front part, a device middle part and a device rear part. The device front part comprises a device front part spiral bit. The device middle part is composed of a rotary joint, a telescopic rod, a claw part spiral bit, a forward driving claw, an external sound source receiving device, a communication module, a circulating moving plate, an LED light source and a three-dimensional imaging device. The device rear part comprises a cable data wire I, a power supply line I, an air channel, a rescue goods bin and a sound transmit-receive device. The mine tunnel water gushing-out advance rescue real-time embedded control device is capable of entering a rescue point to contact trapped persons in time after a water gushing-out accident of a mine tunnel and before a life channel is available, determining the trapped position and the surrounding environment, and providing bases and guidance for the next search and rescue decision; in addition, the device is internally provided with the rescue goods bin and the air channel, thereby providing the basic water source, food, drugs and fresh air to the trapped persons.

Owner:KUNMING UNIV OF SCI & TECH

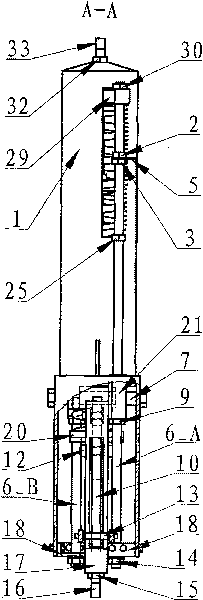

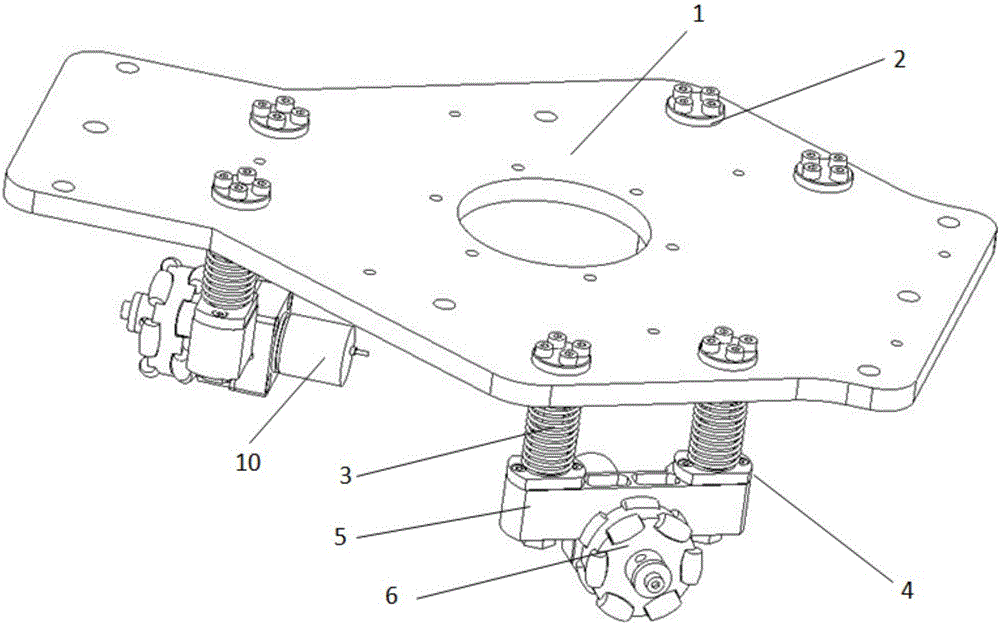

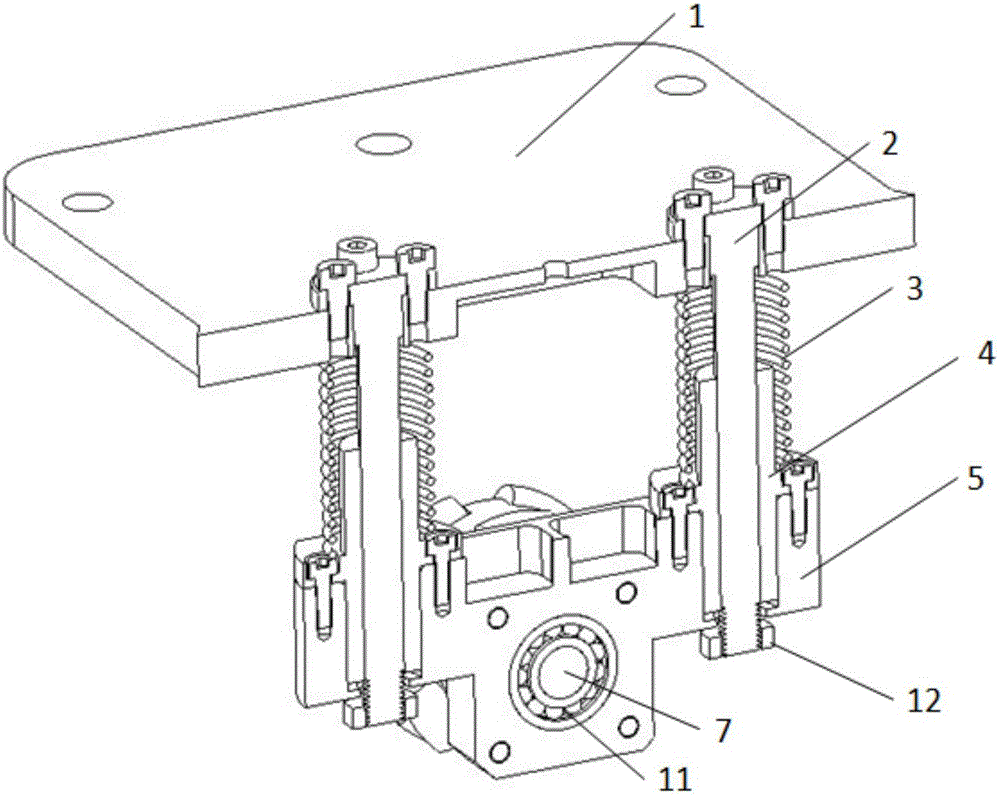

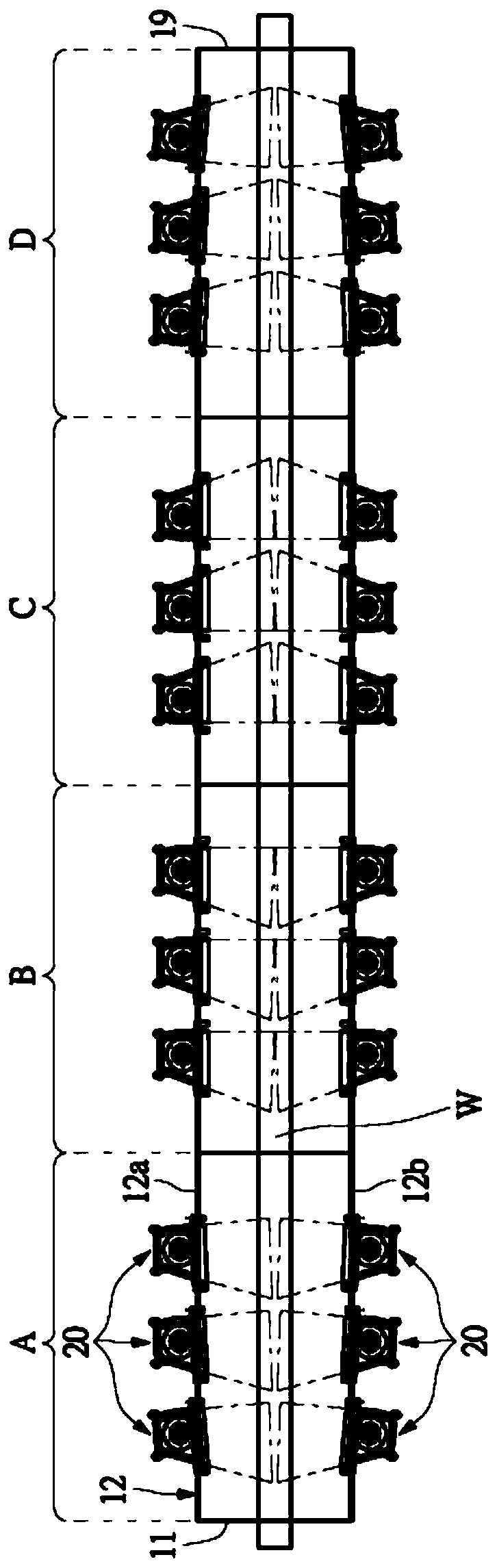

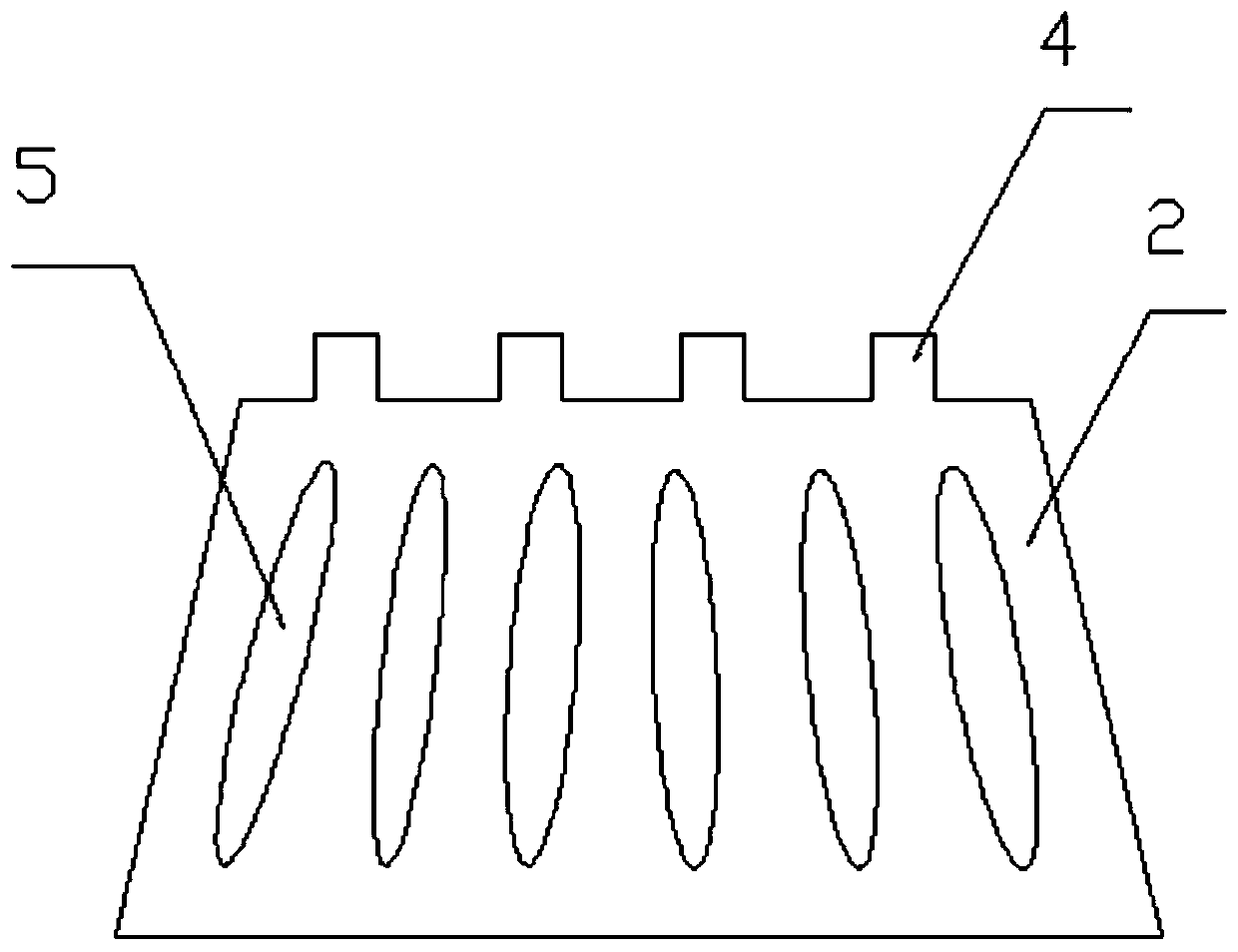

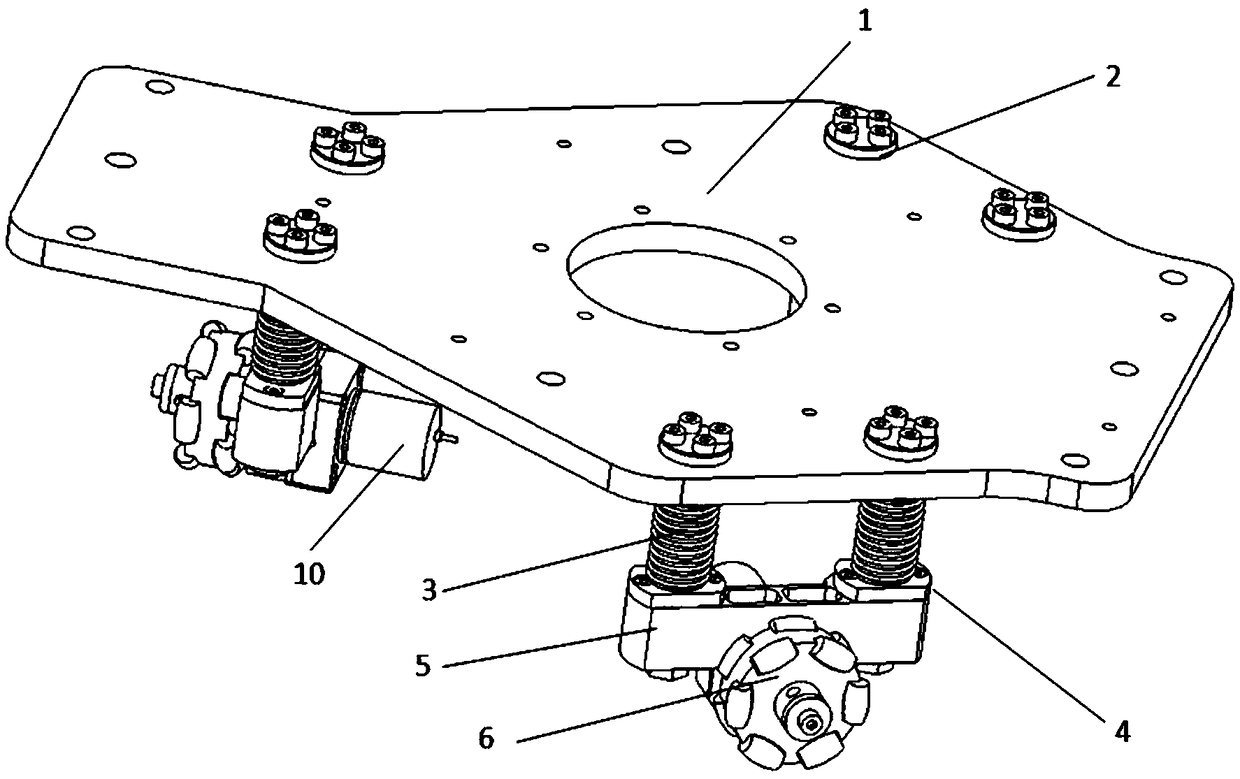

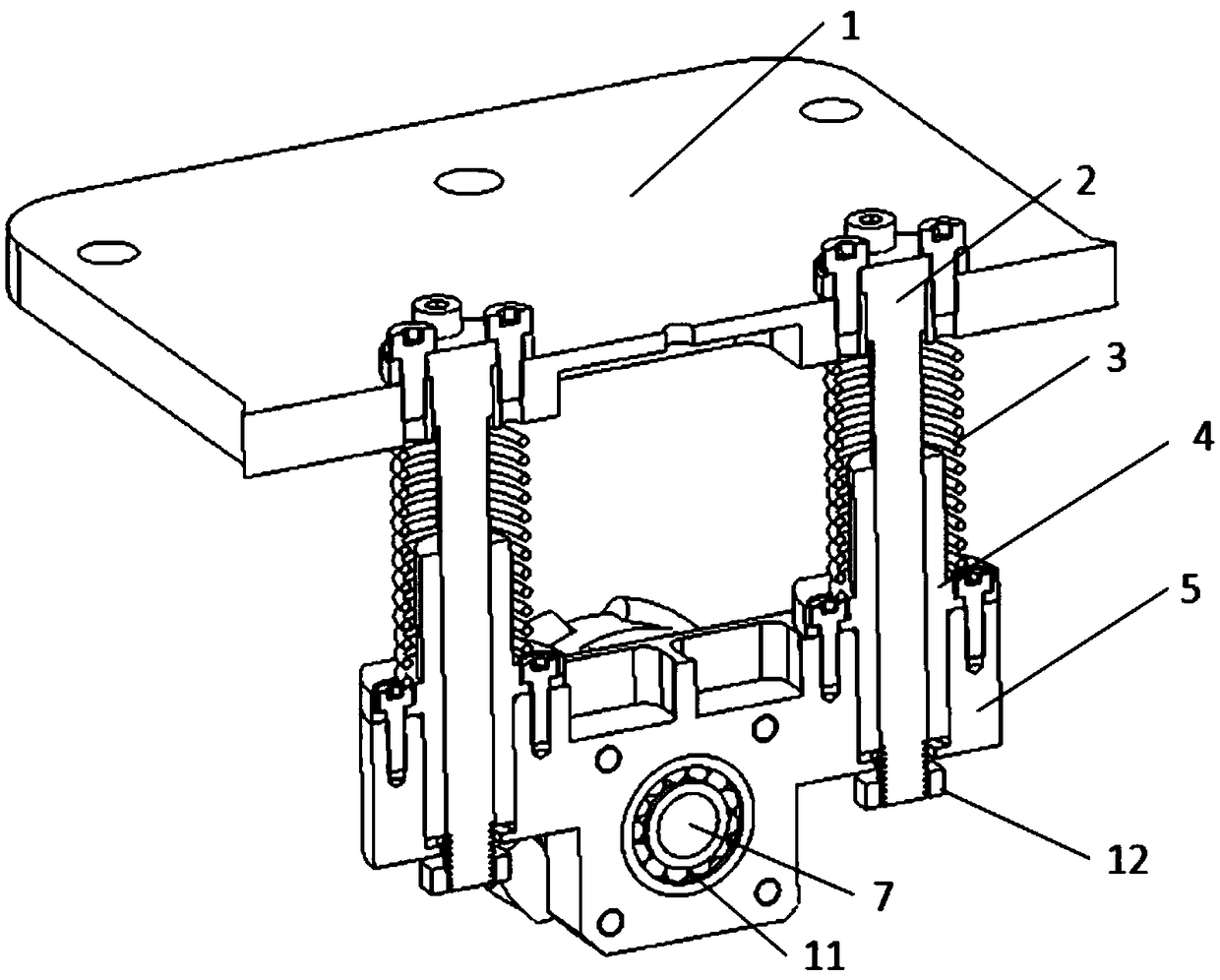

Track dead reckoning robot chassis adopting vertical damping devices

ActiveCN106256568ASymmetrical forceReduce the impact of the accuracy of the collected dataResilient suspensionsDrive wheelSelf locking

The invention discloses a track dead reckoning robot chassis adopting vertical damping devices. The track dead reckoning robot chassis comprises a chassis body, the three identical vertical damping devices and driven wheel systems, wherein the vertical damping devices are arranged below the chassis body, and each driven wheel system is arranged below the corresponding vertical damping device; each vertical damping device comprises guide rods, springs, linear bearings and self-locking nuts; the tail end of each guide rod is sleeved with the corresponding self-locking nut, each guide rod is sleeved with the corresponding linear bearing, and the outer circle of the upper end of each linear bearing step is sleeved with the corresponding spring; every two guide rods are symmetrically distributed on the left side and right side of the axis of the corresponding driven wheel system, and the lower ends of every two linear bearing steps are fixedly connected with the corresponding driven wheel system. The three vertical damping mechanisms are installed and work independently, each damping mechanism is provided with two vertical springs, symmetry of stress on the two sides of an omnibearing wheel system is guaranteed, unbalance loading is avoided, and long-term operation stability is high.

Owner:NANJING UNIV OF SCI & TECH

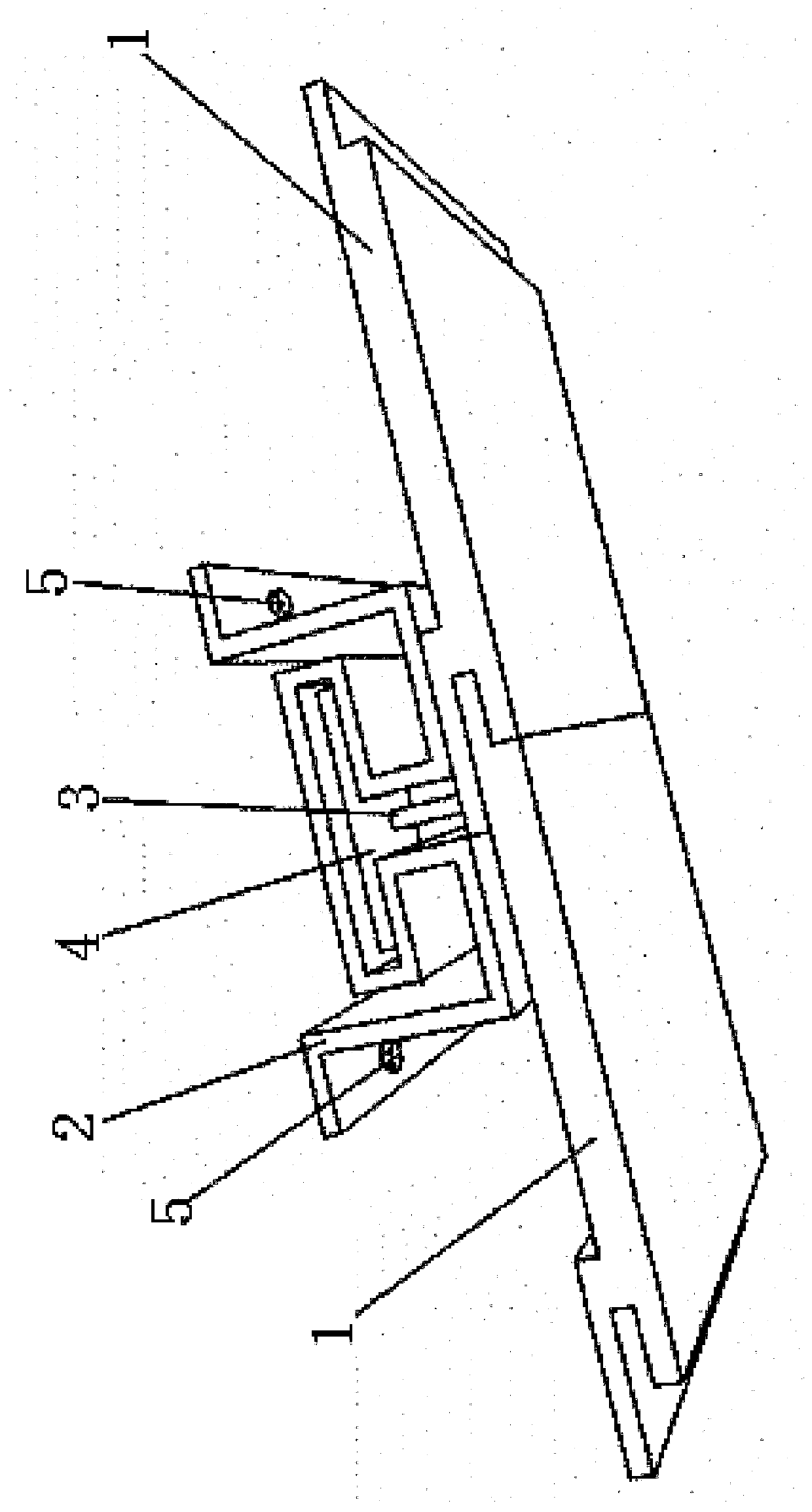

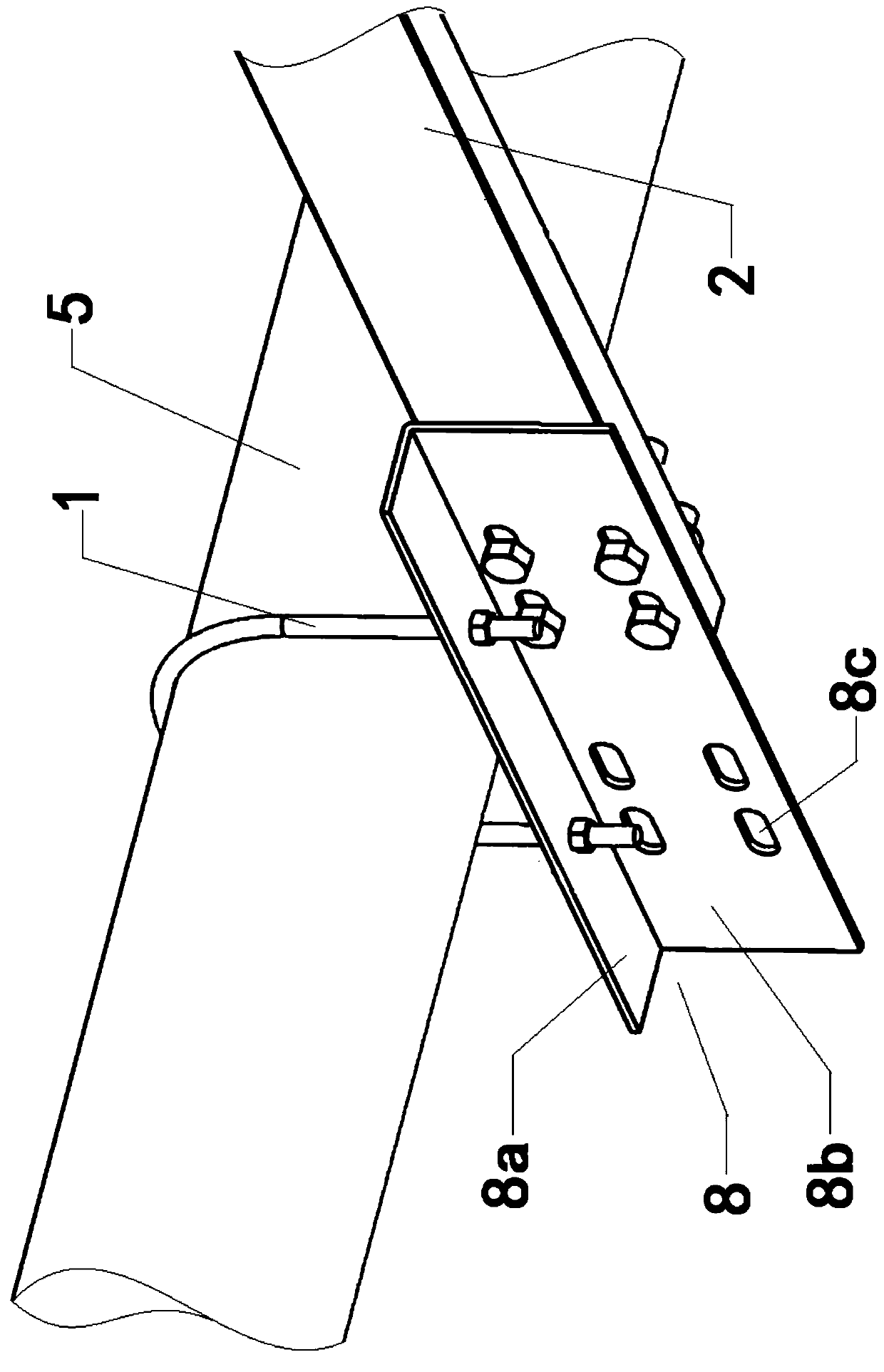

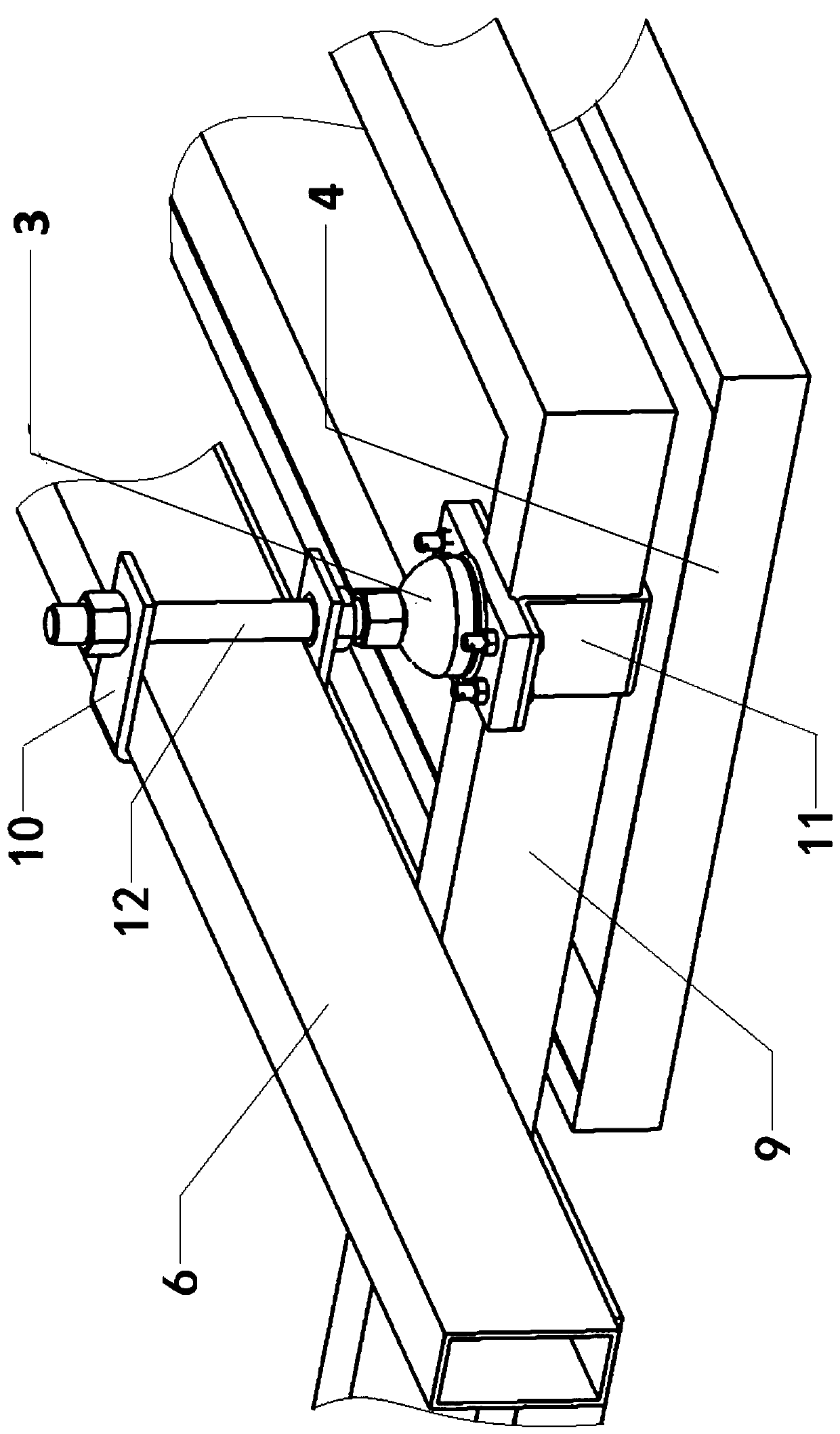

Adjustable special-shaped curved surface aluminum plate mounting structure

PendingCN110145085AImprove general performanceLong-term fixationCovering/liningsTransverse grooveEngineering

The invention discloses an adjustable special-shaped curved surface aluminum plate mounting structure. The adjustable special-shaped curved surface aluminum plate mounting structure comprises veneers,a profile component and a connecting piece. One pair of opposite sides of each veneer are provided with a first spigot edge and an inserting groove correspondingly, wherein a first spigot edge of oneveneer is connected with an inserting groove of the adjacent veneer in a splicing mode. A second spigot edge and a third spigot edge extend in parallel and are arranged on the same side of the corresponding veneer, wherein the inserting groove is formed by a gap between the second spigot edge and the third spigot edge. The profile component is provided with a T-type groove, wherein the T-type groove is formed by a vertical groove and a transverse groove which are connected in a perpendicular mode. One end of the vertical groove is a groove opening of the T-type groove. The two sides of the profile component are provided with flanges which are in fixed contact with the wall surface. The second spigot edge is attached to the groove opening of the T-type groove. The connecting piece comprises a fixing plate and a connecting bolt which are perpendicularly connected, wherein the fixing plate is located in the transverse groove, and the connecting bolt is located in the vertical groove. Oneend, away from the fixing plate, of the connecting bolt is movably connected with the second spigot edge. By adopting the adjustable special-shaped curved surface aluminum plate mounting structure, the adjacent veneers installed in an inserting mode, the component cost is low, and the position precision of the veneers can be conveniently adjusted.

Owner:GOLD MANTIS CONSTR DECORATION

Adjustable impeller spraying chamber

The invention provides an adjustable impeller spraying chamber, and relates to the technical field of workpiece surface treatment. The adjustable impeller spraying chamber comprises a chamber, a plurality of impeller devices and a plurality of adjusting devices, the chamber is provided with an inlet and an outlet, a spraying work line is arranged between the inlet and the outlet, the plurality ofimpeller devices are symmetrically arranged on the upper side and the lower side of the chamber, each impeller device is provided with a protection box, a driving device, a pair of rotary discs and aplurality of blades, the blades are connected between the pair of rotary discs in a radial mode, the driving device is connected to one of the rotary discs, the protective box bodies are provided withfirst baffles and second baffles, the protective box bodies cover the pair of rotary discs and the plurality of blades, the protective box bodies are provided with spraying outlet surfaces, and the spraying outlet surfaces communicate with the interior of the chamber. The plurality of adjusting devices correspond to a plurality of impeller devices, and each adjusting device is used for adjustingthe angle and distance, corresponding to the spraying work line, of the spraying outlet surface. According to the scheme, the surface of the workpiece can be effectively treated.

Owner:KUNSHAN AIRBAG PACKING CORP

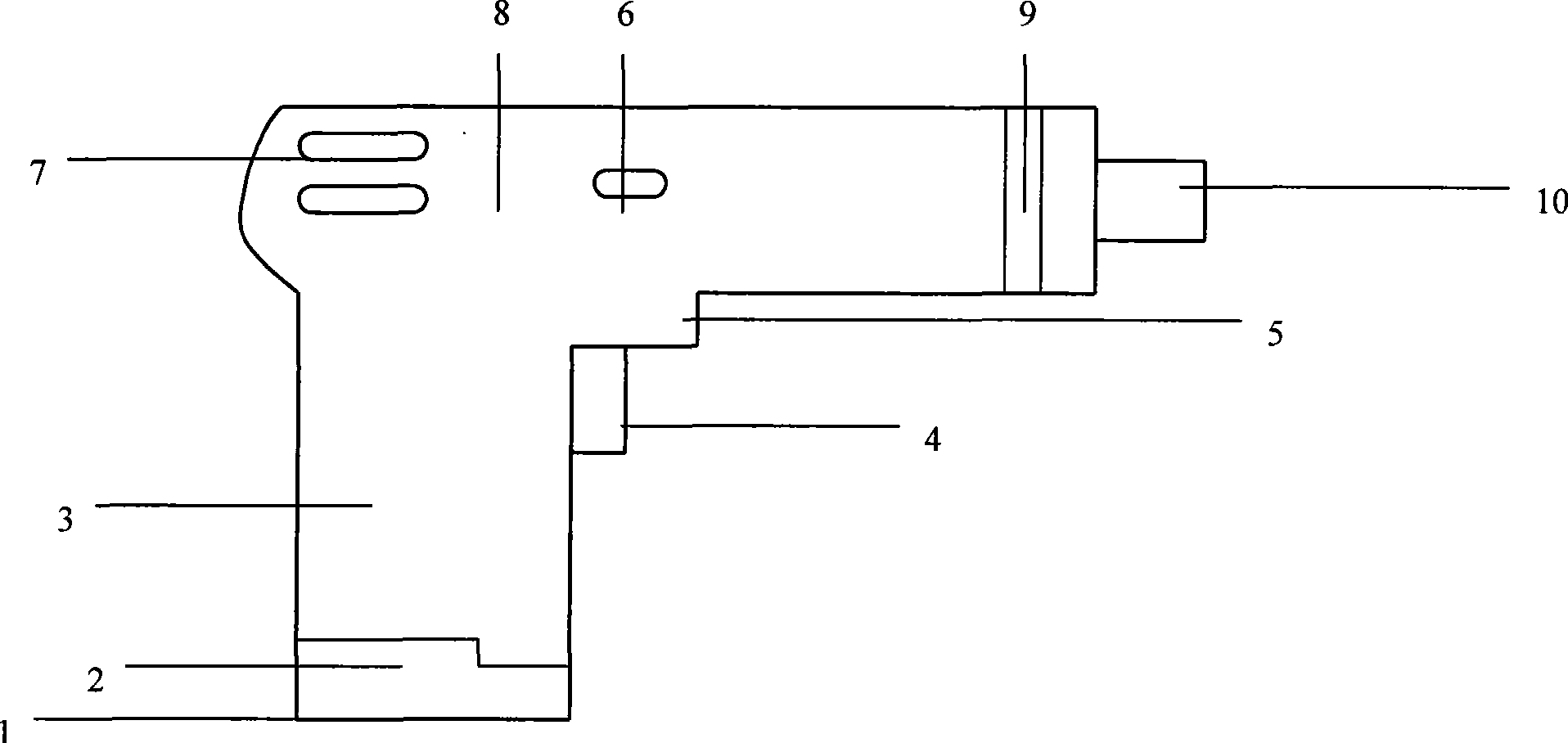

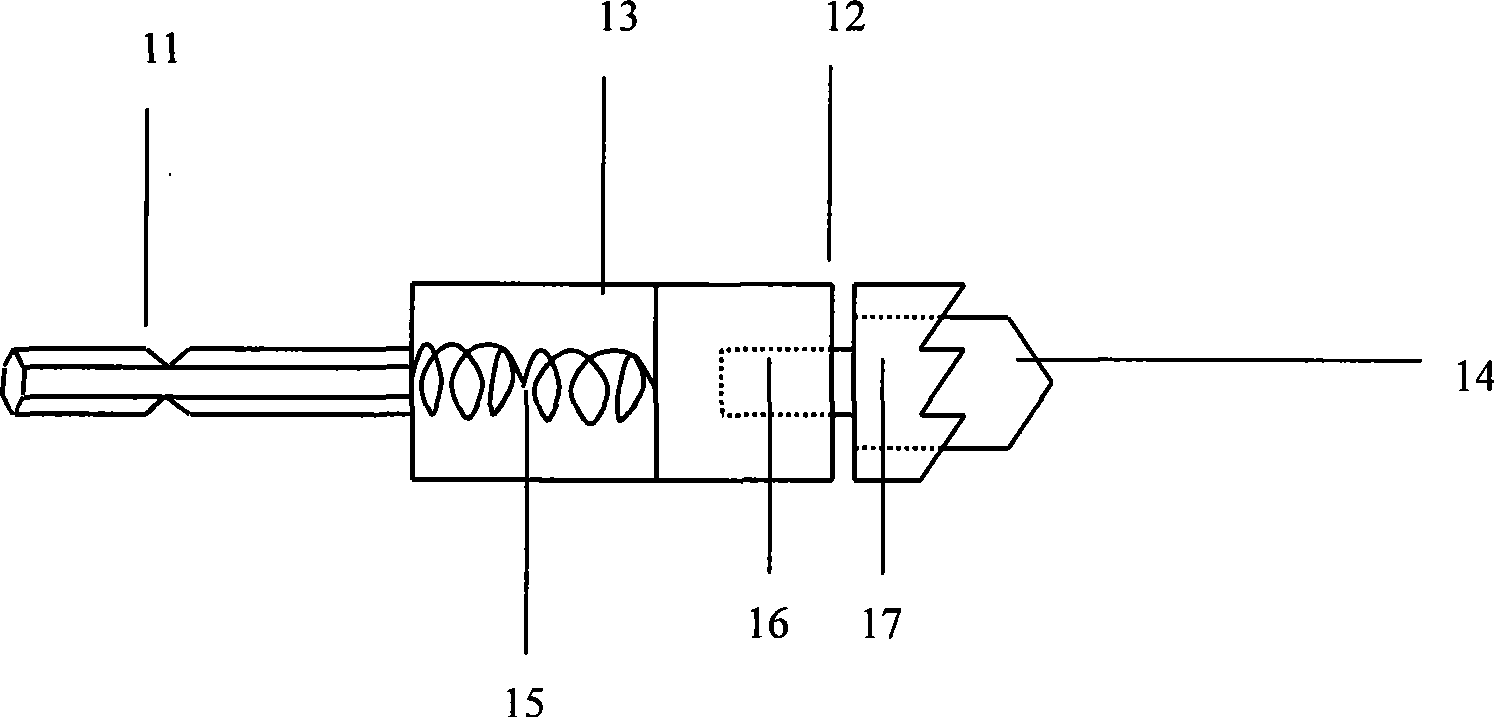

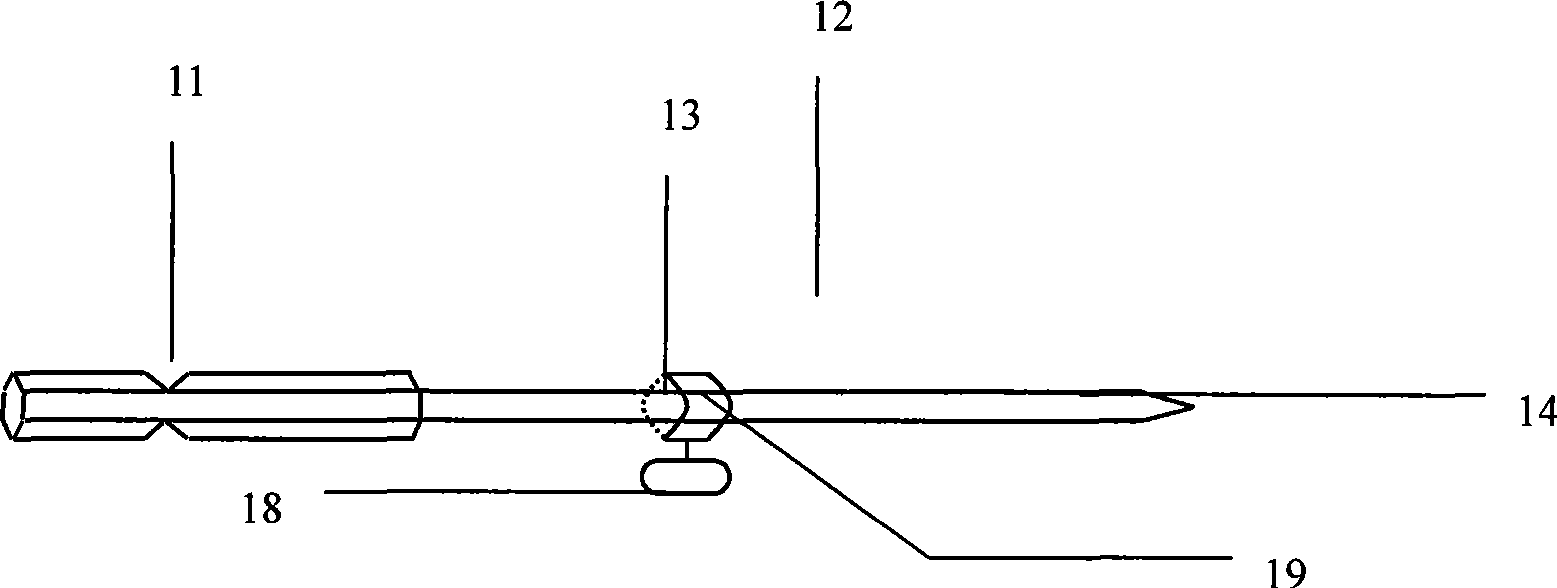

Portable chargeable multifunctional skull brad awl

InactiveCN101507647AIncrease drilling speedDynamic stabilitySurgeryClosed head injuryNeurosurgical Procedure

The invention relates to a portable rechargeable multifunctional skull drill and application thereof. The skull drill is a novel multifunctional neurosurgical electric tool, can be used for checking, diagnosing, preventing, treating and researching severe closed craniocerebral injury patients, particularly extremely severe craniocerebral injury patients, has simple structure, easy operation, low use cost, small volume, symmetrical force application, stable drilling, and improved utilization safety, and is more suitable for emergent treatment of pre hospitals, 120 ambulances, low level hospitals and emergency rooms in large size hospitals to provide possibility of early and super-early neurosurgical operation interference so as to greatly facilitate protraction of emergency medical treatment, achieve the aim of reducing the pre-hospital death rate of battling craniocerebral injury, and improve the effects and quality of the emergent medical treatment. The portable rechargeable multifunctional skull drill can be effectively combined into a complete set as a portable craniocerebral injury first-aid equipment kit which can be applied to field fight first aid for various battling craniocerebral injuries.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

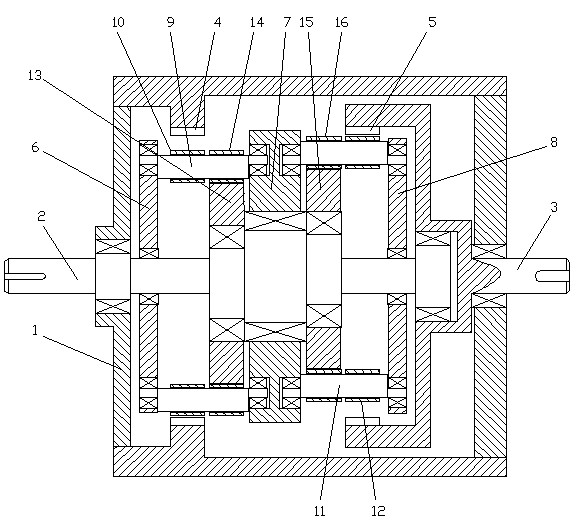

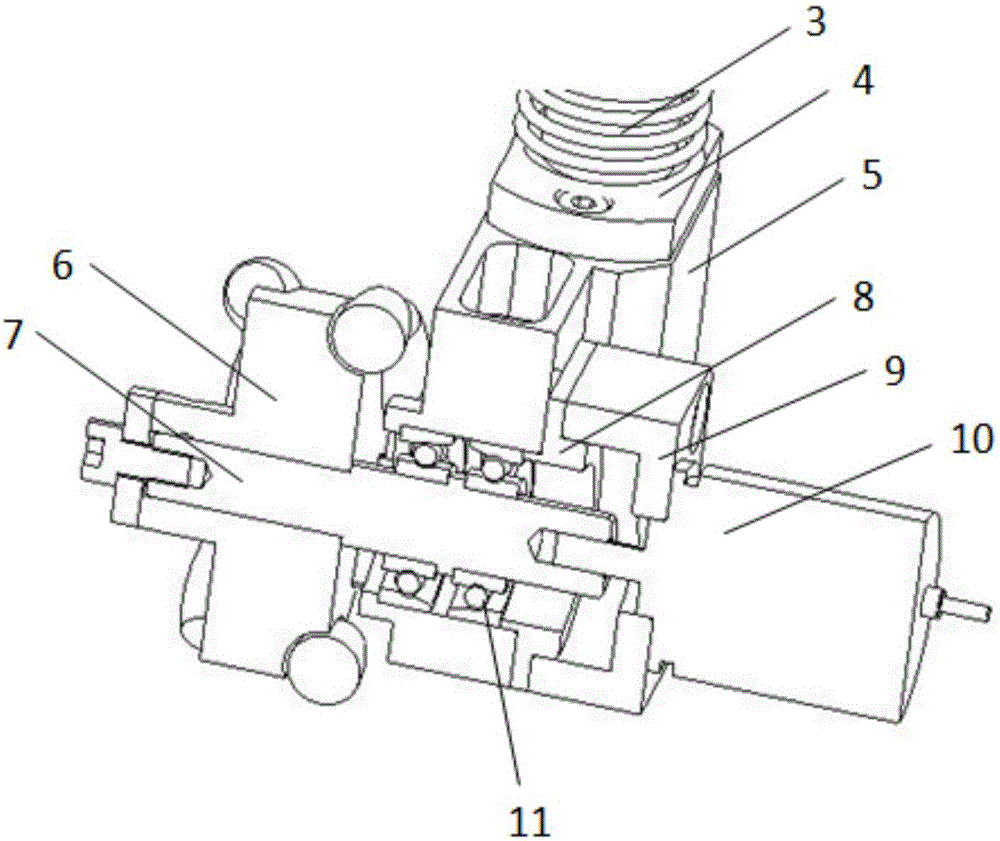

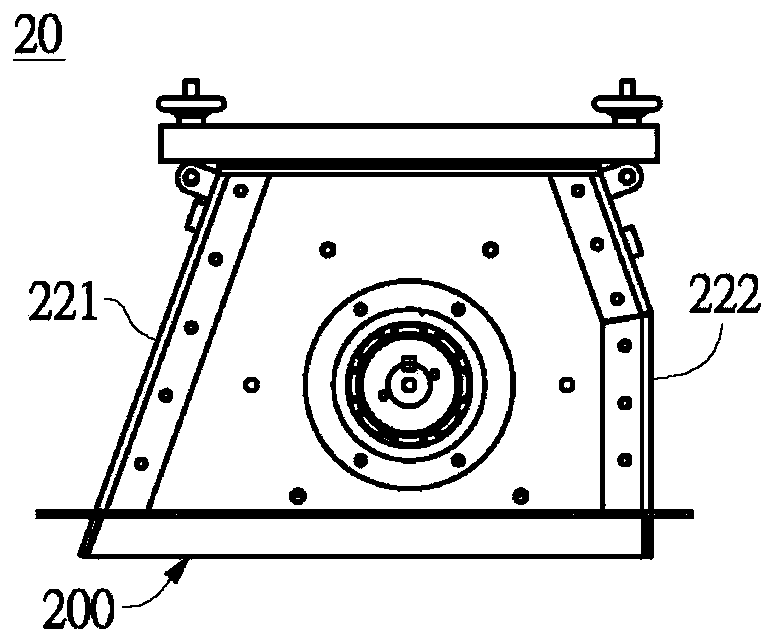

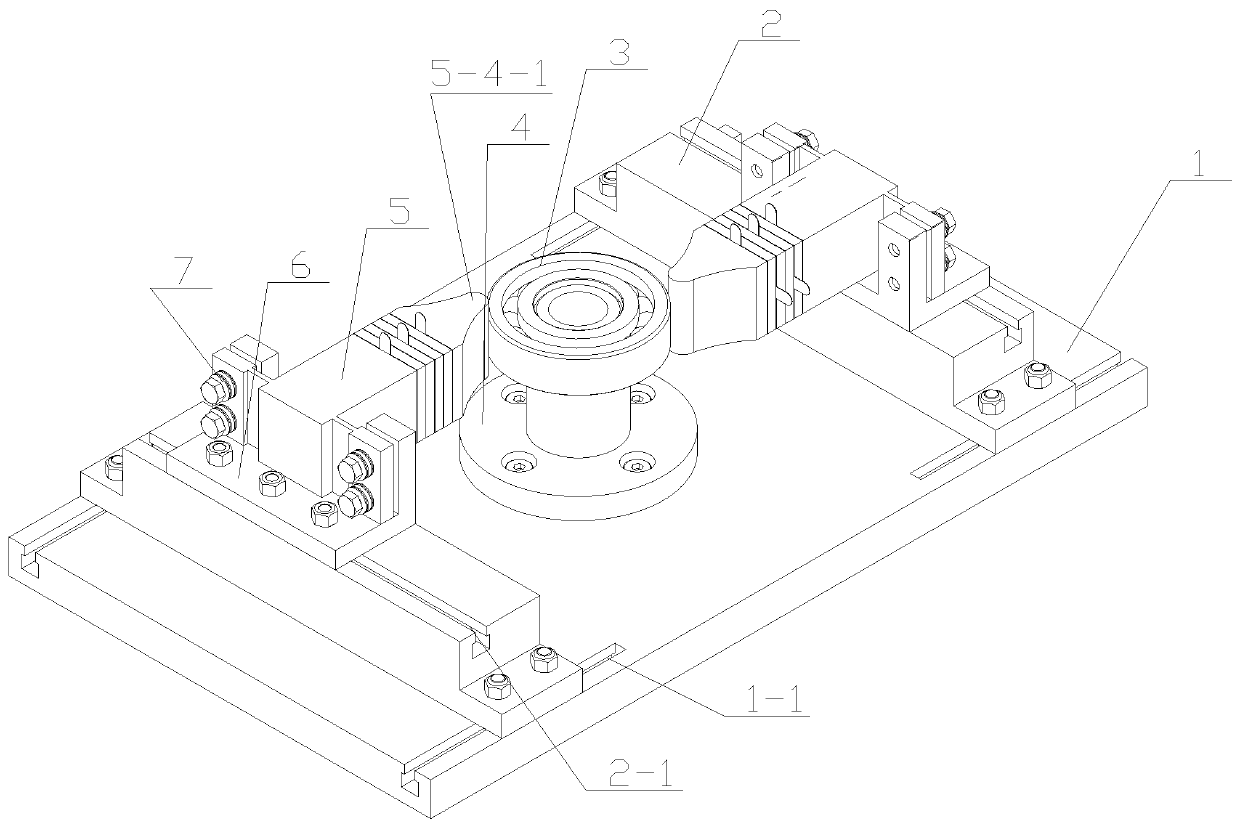

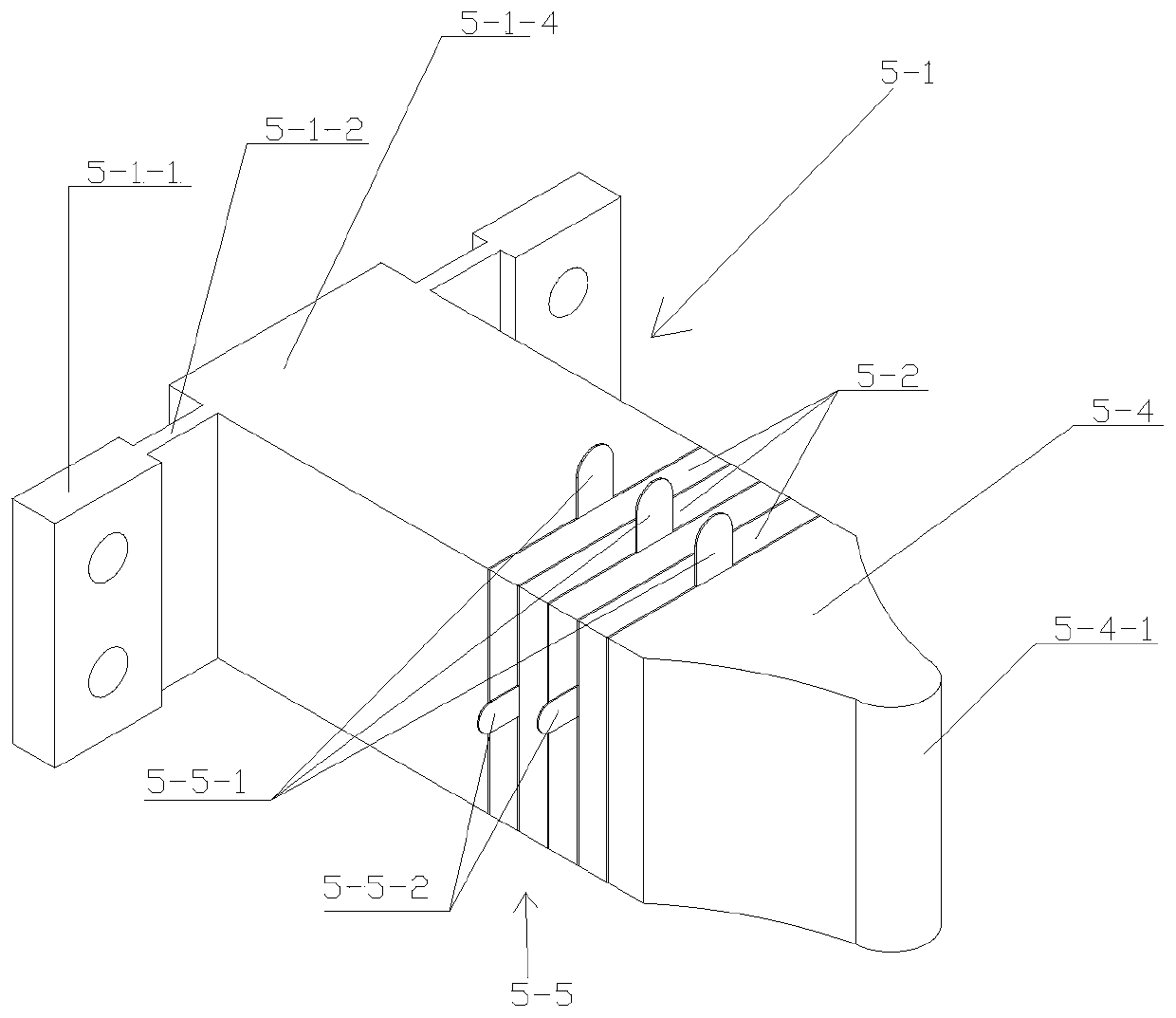

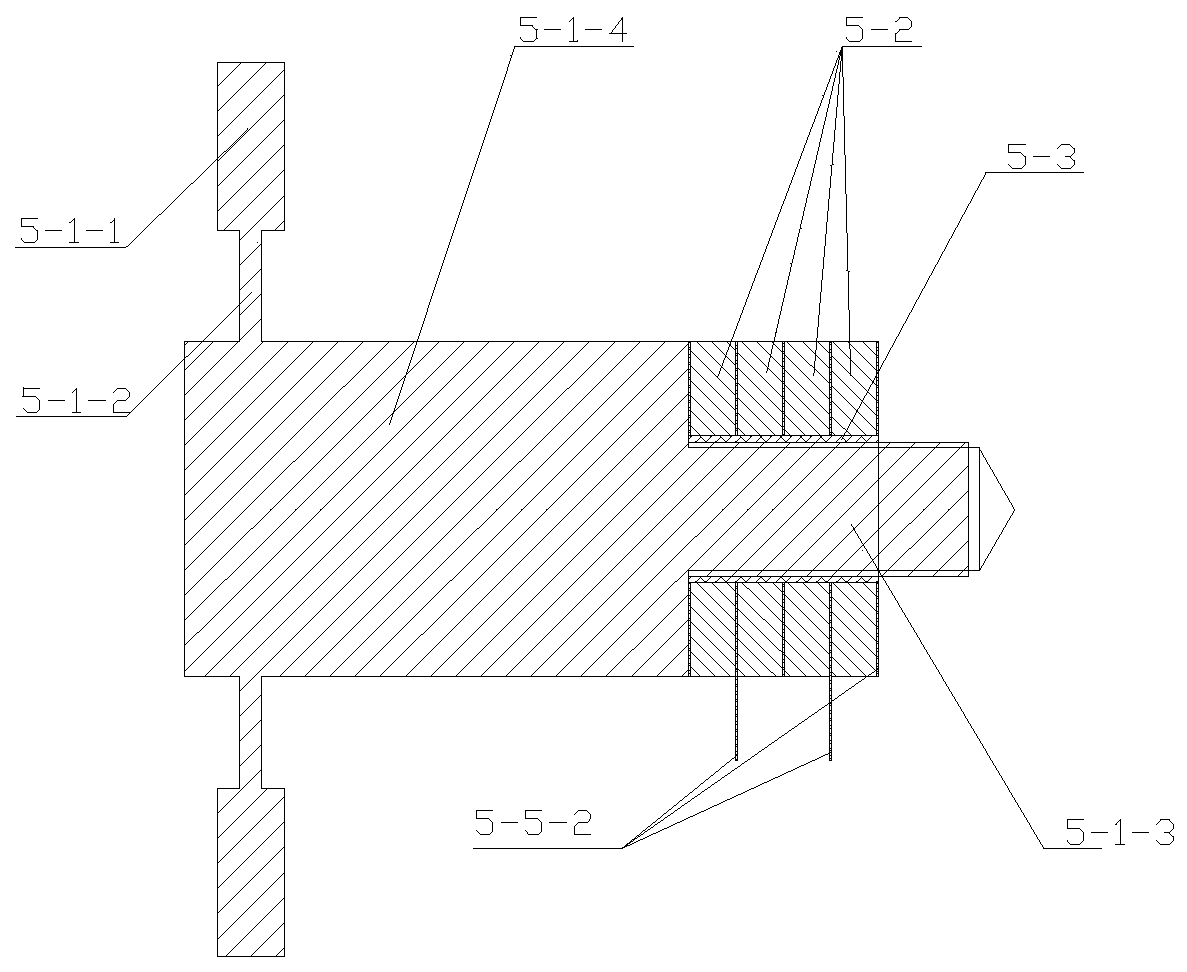

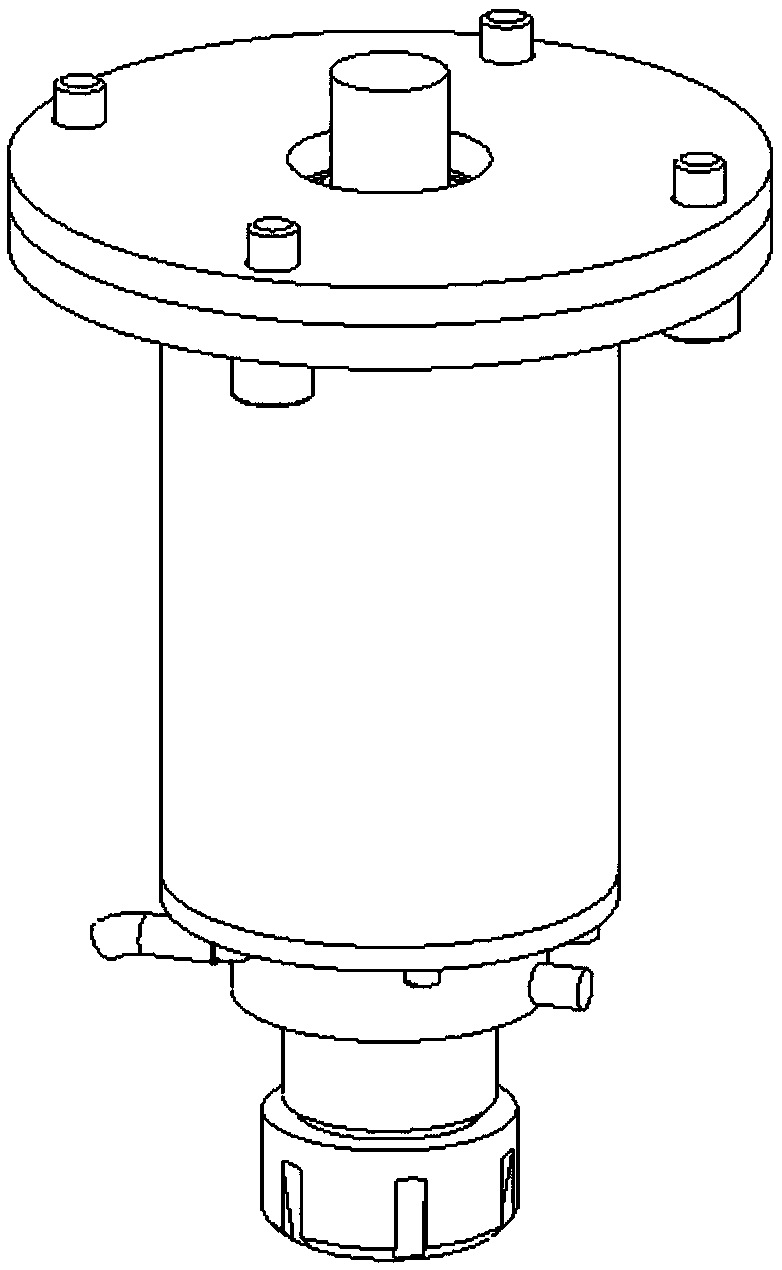

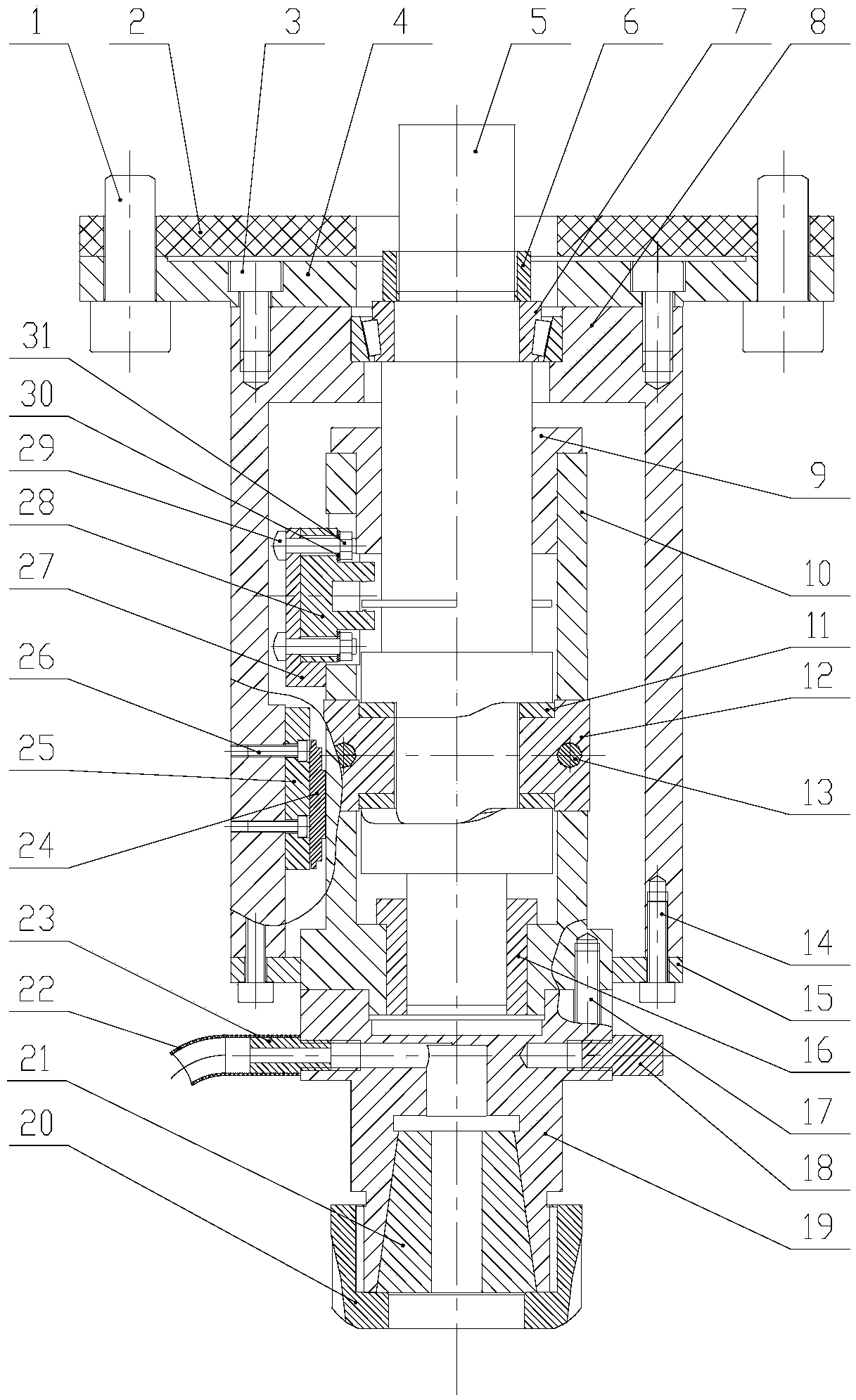

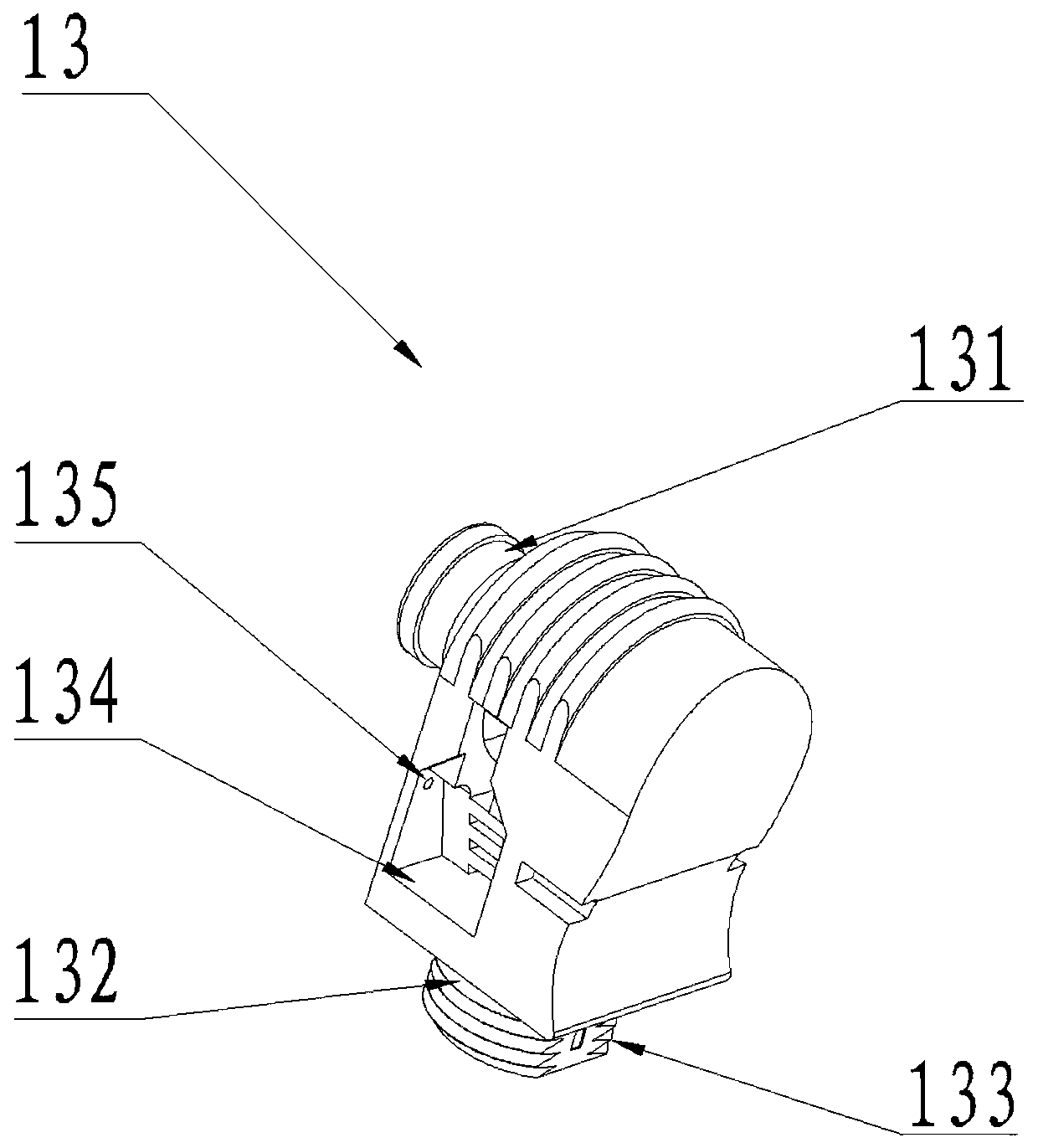

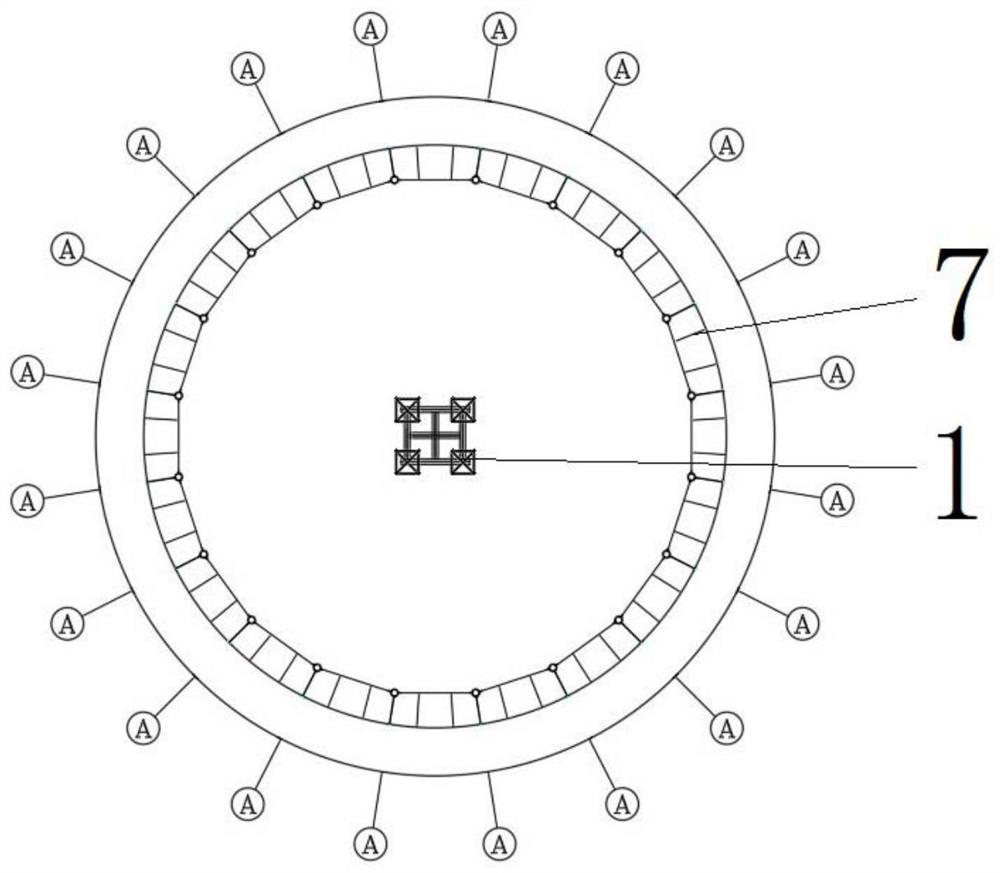

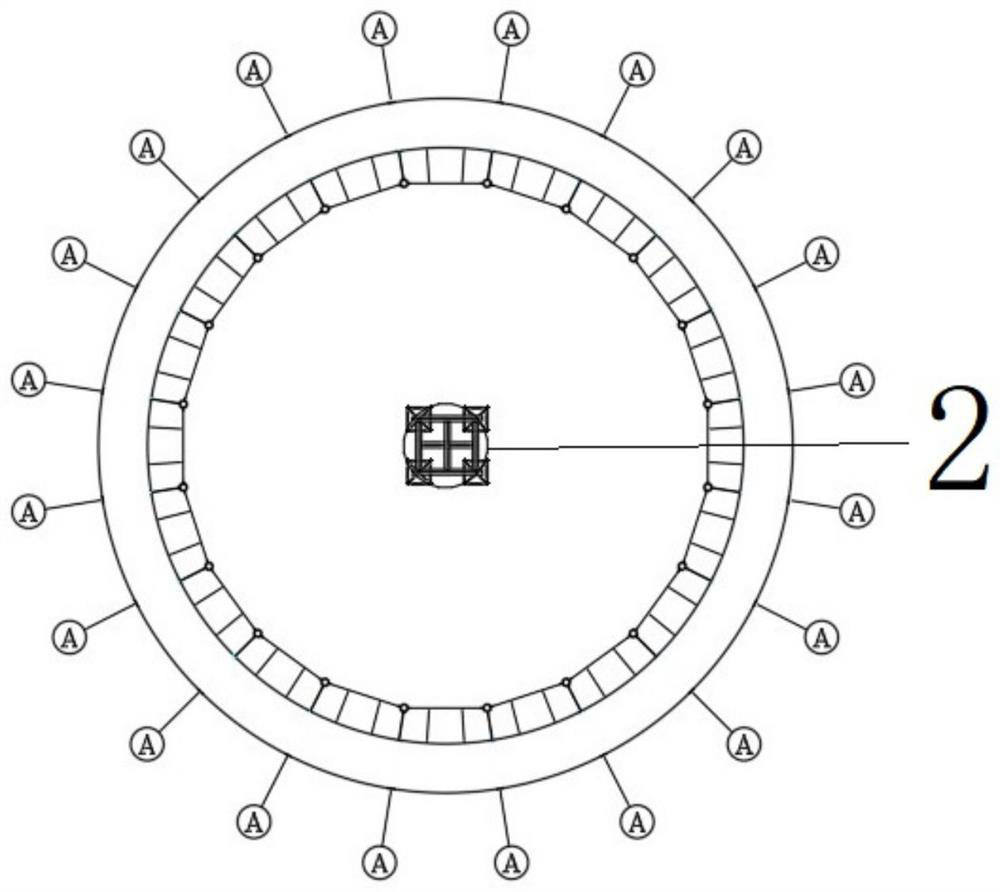

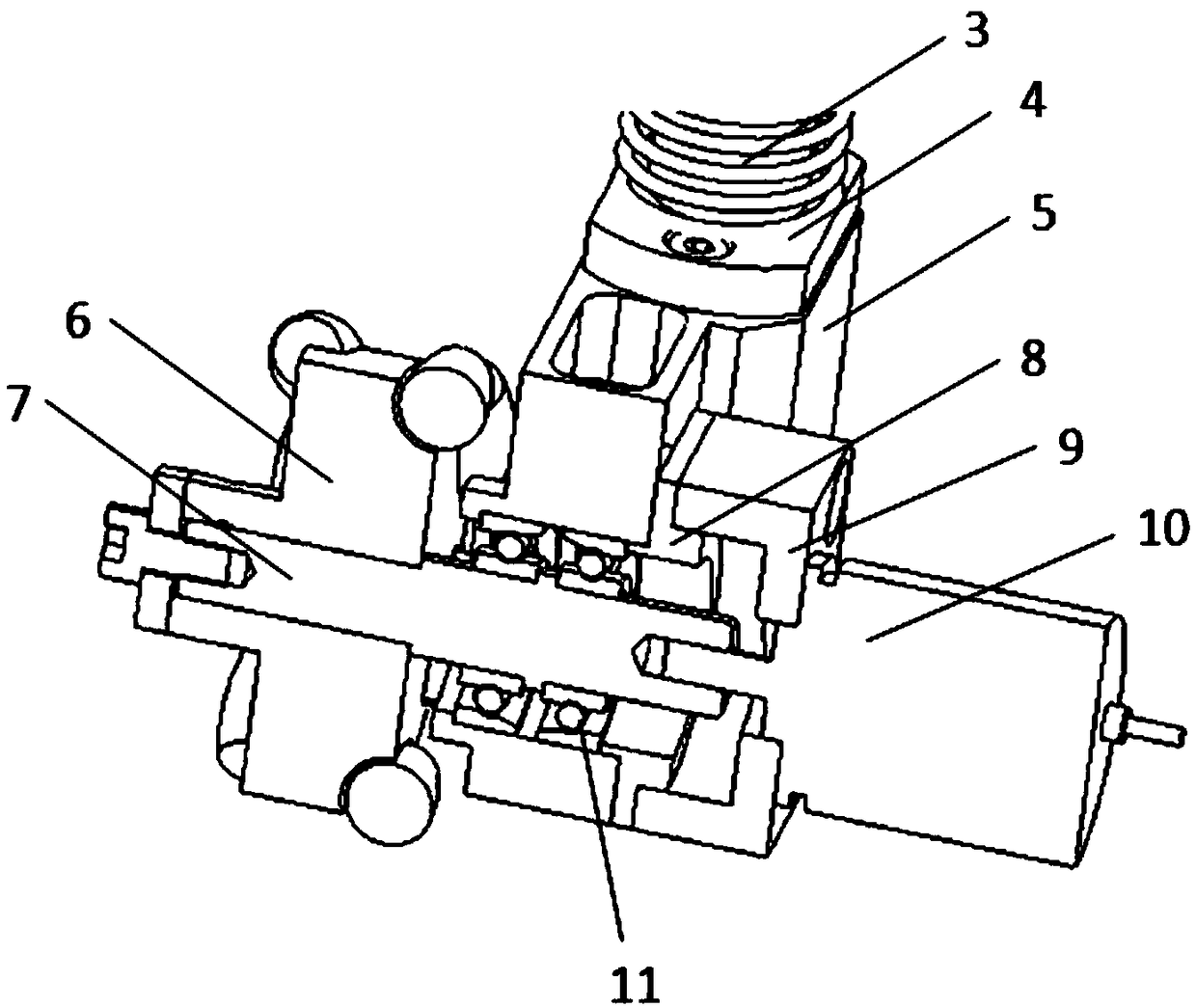

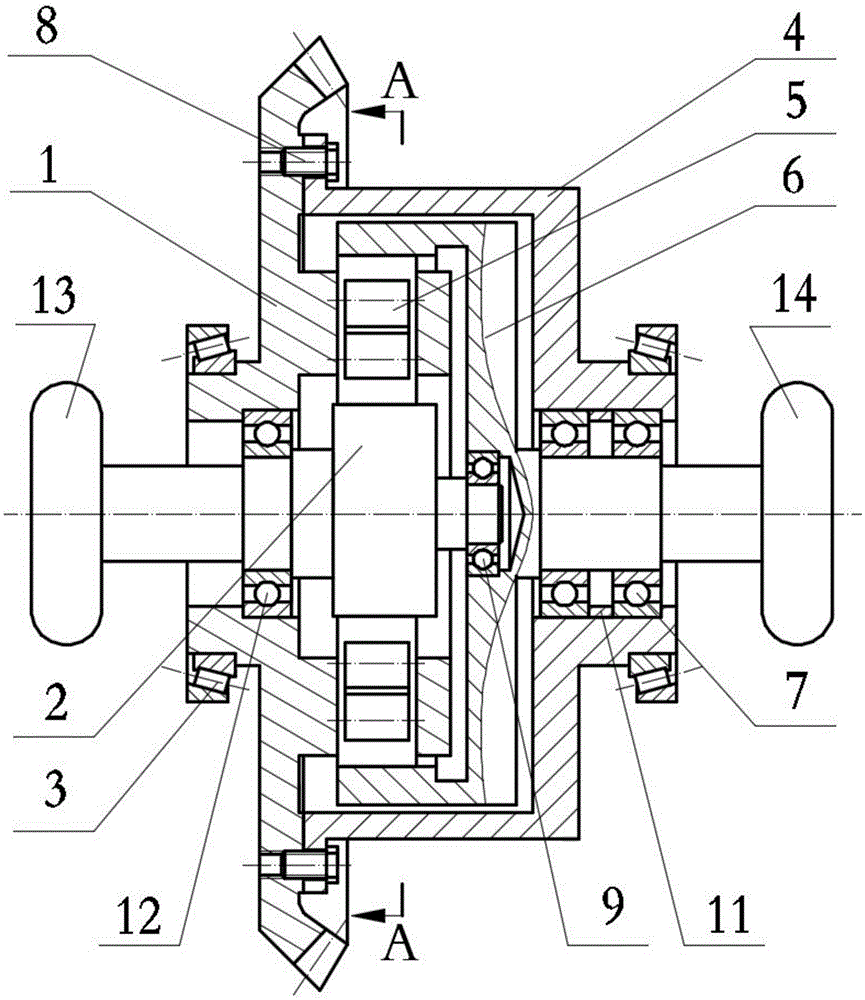

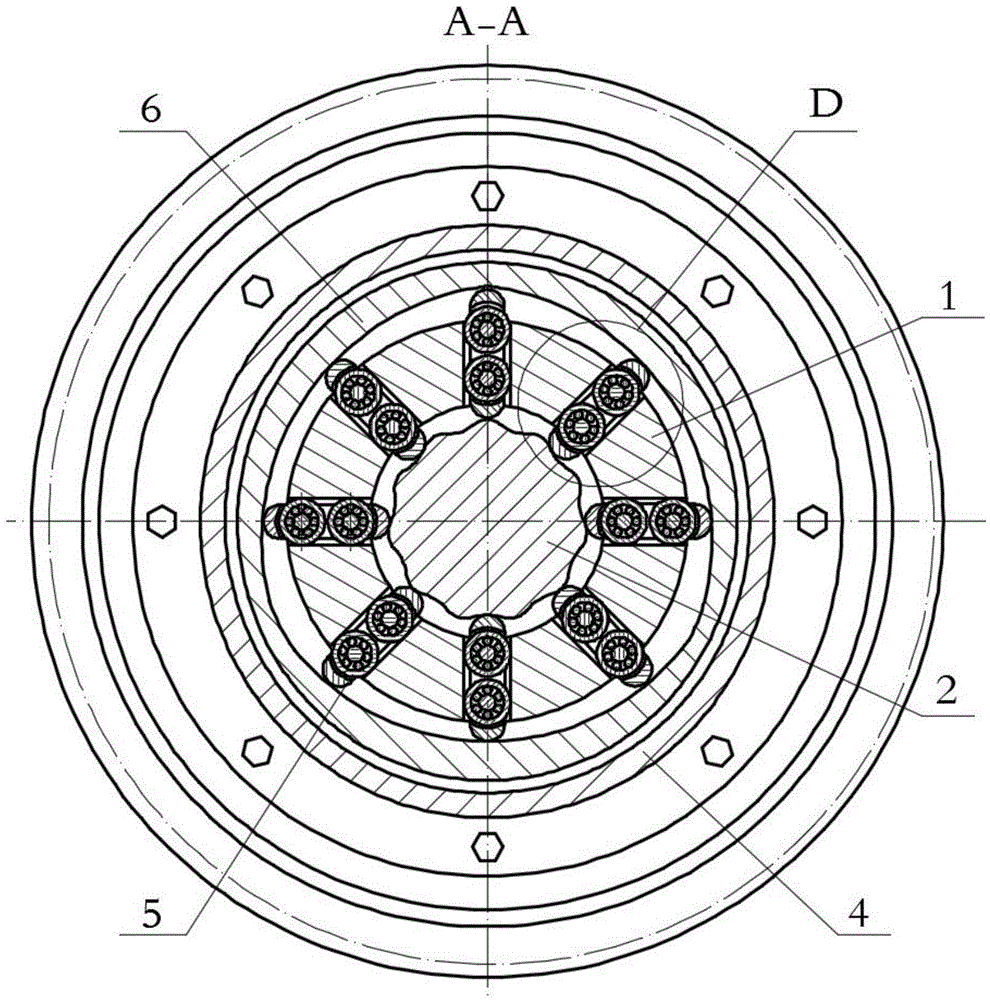

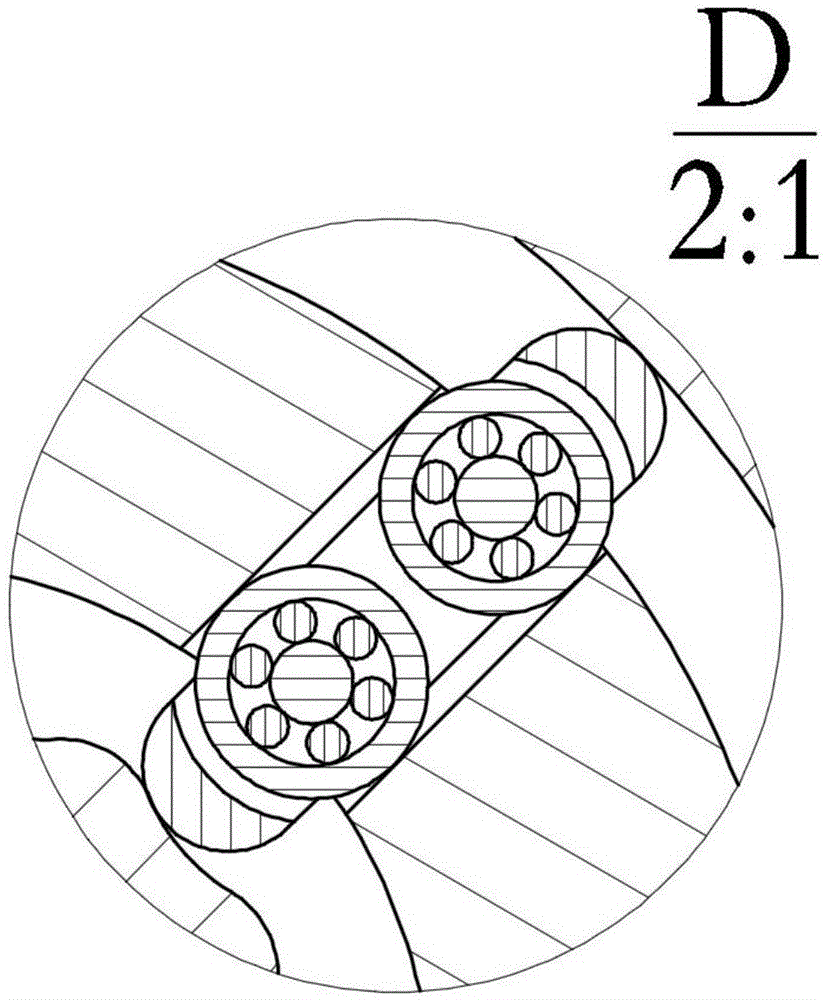

Longitudinal vibration sandwiched transducer-based piezoelectric ultrasonic driver and application method thereof

InactiveCN110048636ASimple structureReasonable designPiezoelectric/electrostriction/magnetostriction machinesTransducerEngineering

The invention discloses a longitudinal vibration sandwiched transducer-based piezoelectric ultrasonic driver and an application method thereof. The piezoelectric ultrasonic driver comprises a horizontally-arranged base, two adjustment seats, a stator mechanism and a rotor, wherein the stator mechanism comprises two longitudinal vibration sandwiched transducers, the two longitudinal vibration sandwiched transducers are rotatably and symmetrically arranged around an axis of a flange shaft, and included angles among driving feet of the longitudinal vibration sandwiched transducers, a tangent direction of a rotor contact point and telescopic directions of the longitudinal vibration sandwiched transducers are smaller than 90 degrees. The application method comprises the following steps of 1, assembling and adjusting the piezoelectric ultrasonic driver; and 2, applying a sine excitation voltage by the longitudinal vibration sandwiched transducers and allowing the rotor to rotate. The piezoelectric ultrasonic driver is simple in structure, single-mode driving is achieved, and the piezoelectric ultrasonic driver is mainly used for solving the problems that a piezoelectric ultrasonic driverin a composite mode such as longitudinal vibration, bending vibration, longitudinal vibration and torsional vibration requires a simplified mode and is complicated in structure design and mass production is difficult to achieve.

Owner:XIAN UNIV OF SCI & TECH +2

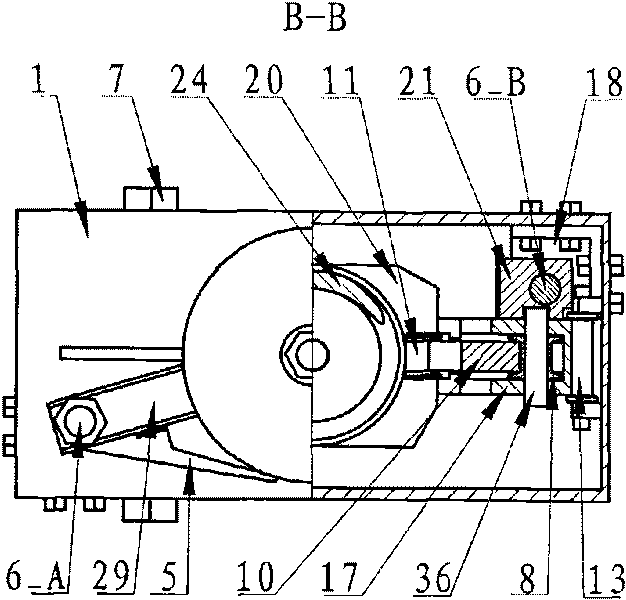

Cathode vibration device for electrolytic machining

InactiveCN109570661ASymmetrical forceQuick updateMachining electrodesElectrical-based machining electrodesElectrolysisEngineering

The invention discloses a cathode vibration device for electrolytic machining. The cathode vibration device comprises a cam shaft, wherein the cam shaft and a machine tool spindle rotate synchronously, a vibration shaft is arranged on the cam shaft, the end of a rotating shaft is connected with a chuck, a cam groove profile curve is arranged on the cam shaft, sliding blocks which protrude inwardsare arranged on the vibration shaft, the sliding blocks cooperate with the cam groove profile curve, so that the up-down movement of the vibration shaft is realized, and the cam shaft and the vibration shaft are provided with a photoelectric door which is consistent with the up-down movement direction of the vibration shaft. According to the cathode vibration device for electrolytic machining, twopairs of sliding block shafts and the sliding blocks are symmetrically installed, so that the stress of the vibration shaft is symmetrical; and the pulse current and vibration feeding of the cathodevibration device for electrolytic machining are synchronous, when the cathode vibration is fed to the position closest to an anode, a pulse power supply sends pulses, when the cathode vibration is away from the anode, machining gaps start to increase, the dissolution speed of the anode starts to be slowed, an electrolyte can be quickly updated, the pulse power supply does not generate the pulses,thus, stray corrosion can be reduced, energy consumption can be reduced, and the precision of electrolytic machining can be improved.

Owner:CHANGZHOU INST OF TECH

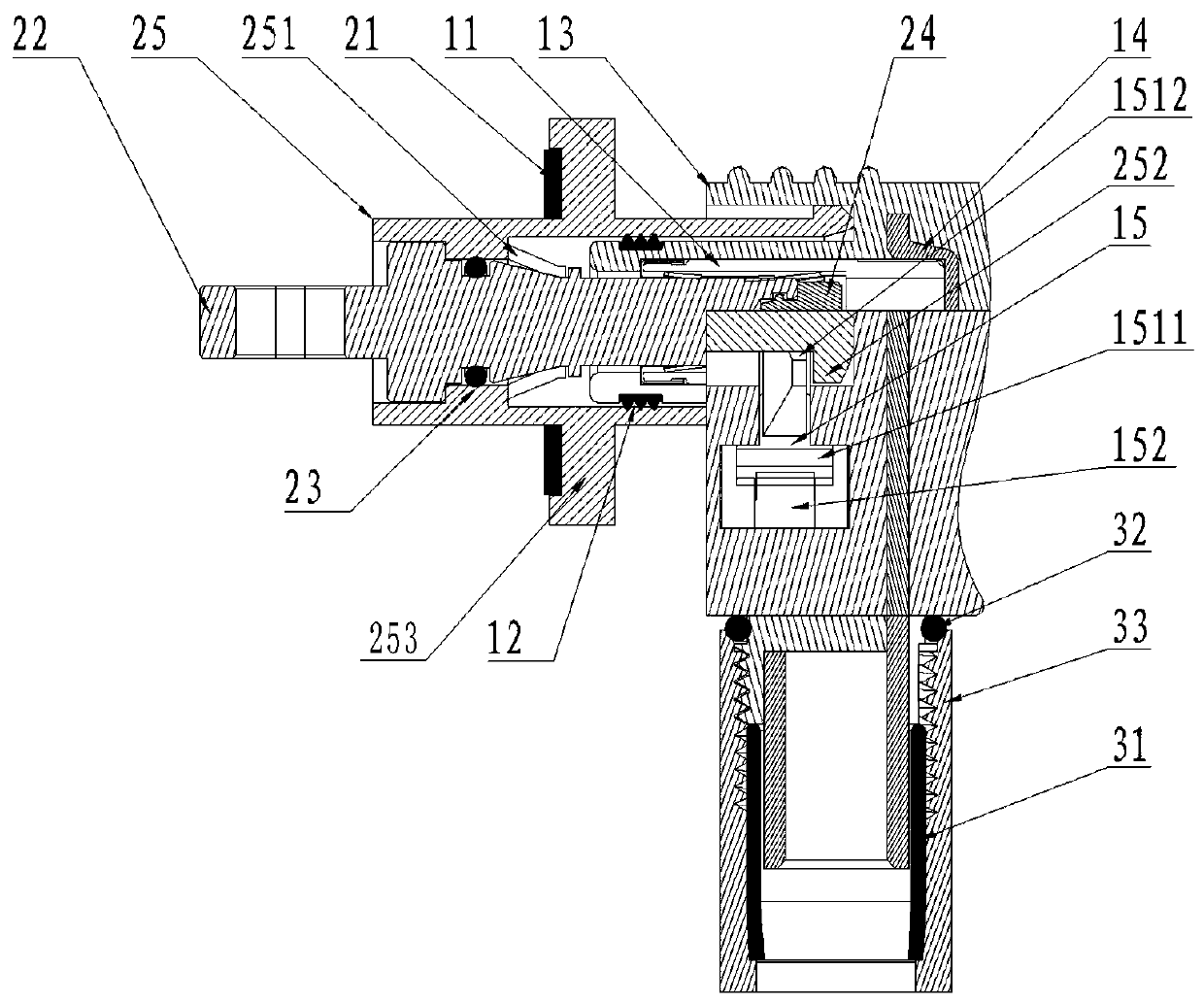

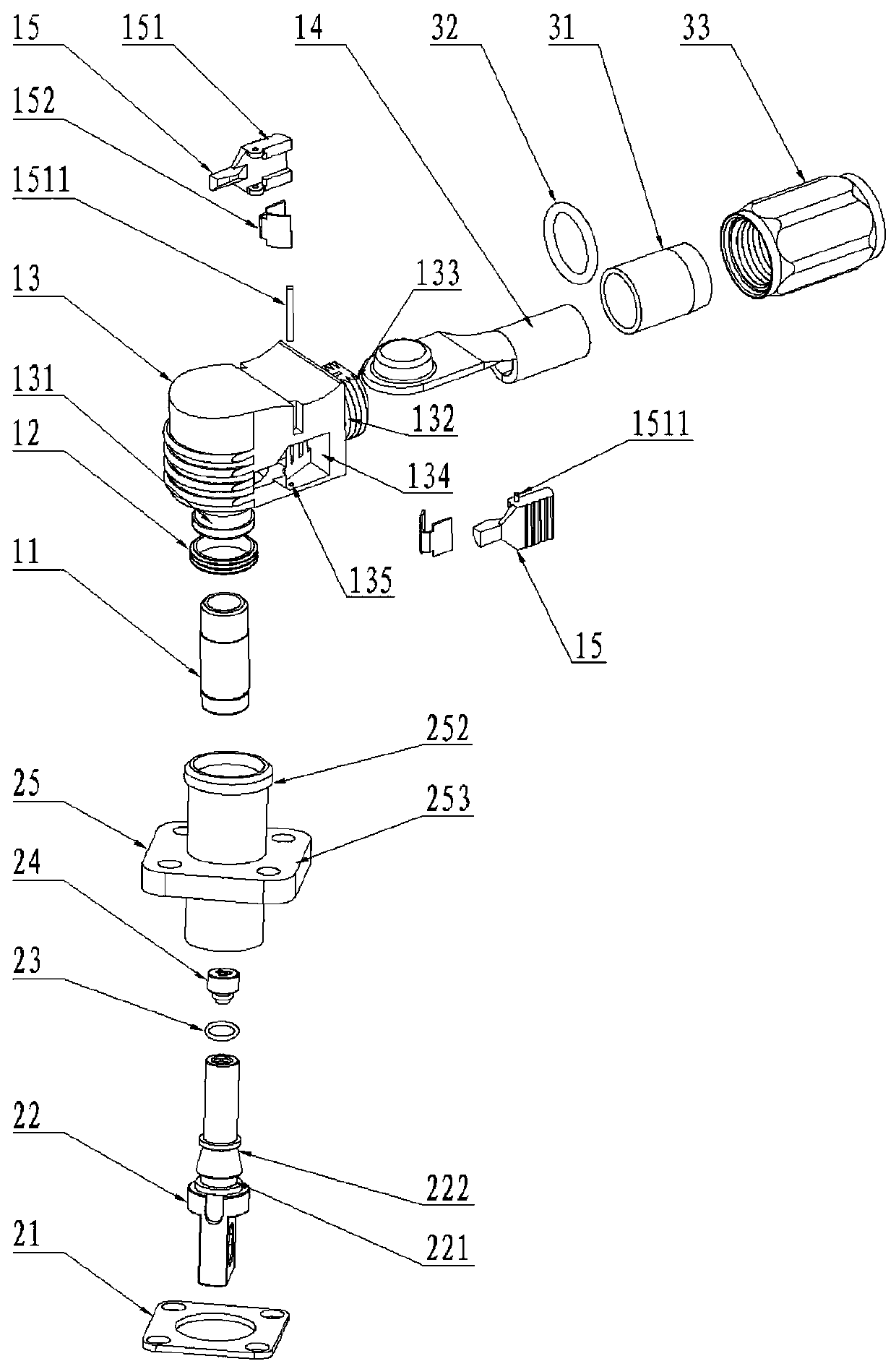

Double-side locking connector for transmitting large current

InactiveCN111355082AImprove connection stabilityGood locking reliabilityCoupling device detailsElectrical and Electronics engineeringMechanical engineering

The invention discloses a double-side locking connector for transmitting large current. The connector comprises a plug, a socket and a tail connecting piece, the locking button assemblies are arrangedon two sides of a plug shell, when the plug and the socket are locked or unlocked, the locking or unlocking of the plug and the socket can be achieved only by triggering the locking button assembliesarranged on the two sides at the same time, the connector has the advantages of being good in stability and high in locking reliability, and the mistaken unlocking and self-unlocking of the connectorare avoided. A structure that the plug shell, a jack contact piece and an OT terminal are fixedly connected into a whole in an injection molding mode and a structure that an annular cavity of the plug shell is connected with a cylinder of a socket shell in an inserted mode are adopted, and a first sealing ring is arranged between the plug shell and the socket shell; a second sealing ring is arranged between a pin contact piece and the socket shell; and a sealing ring is arranged between the plug shell and a tail cover. The double-side locking connector has the advantages of simple structure,small volume, convenience in operation, high contact reliability, symmetrical stress during locking or unlocking, and good insulating property and sealing property.

Owner:SUZHOU HUAZHAN SPACE APPLIANCE

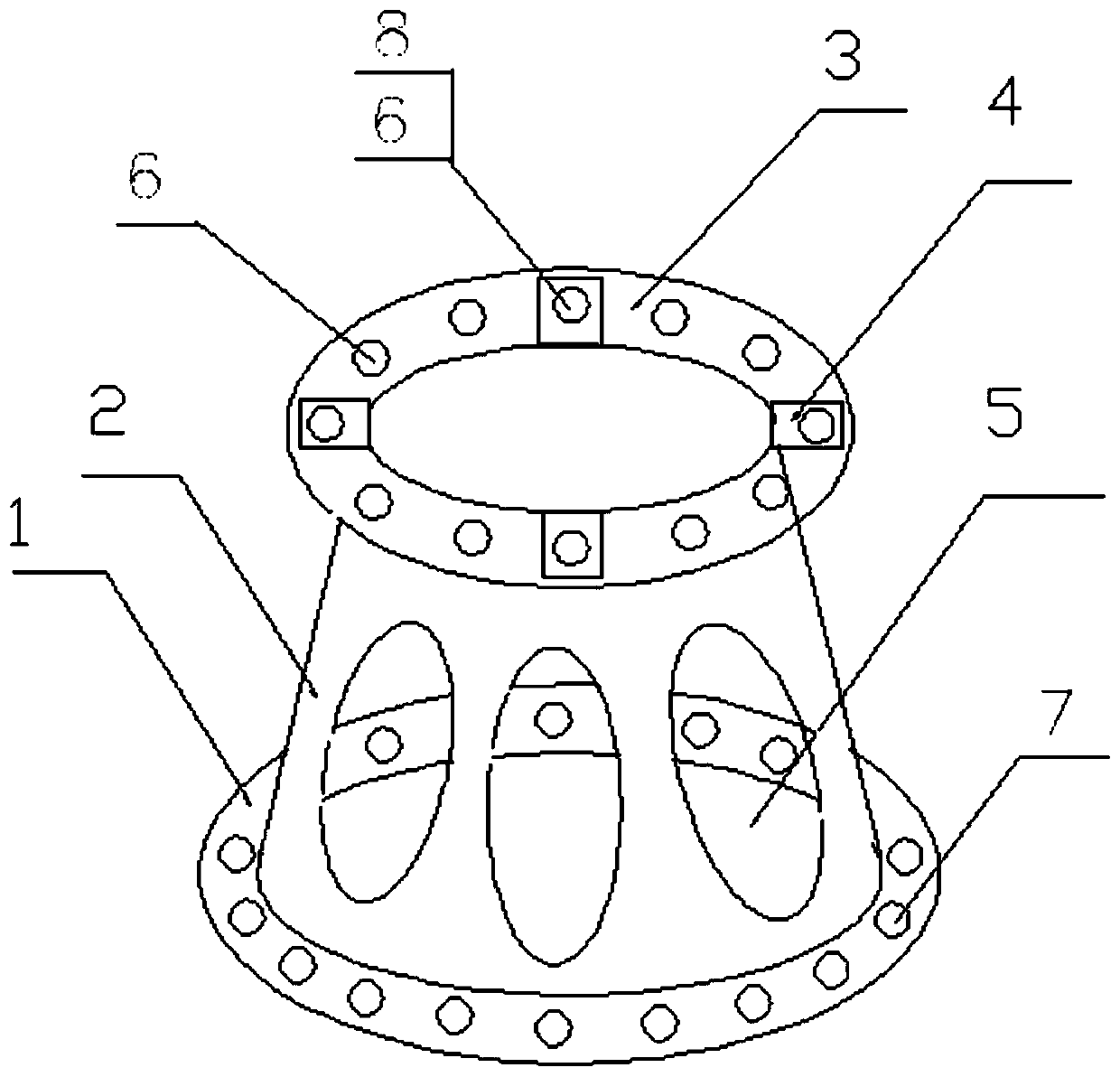

Front support of fairing of wind generating set

PendingCN111207045AGuaranteed safe operationImprove support strengthWind motor supports/mountsMachines/enginesEngineeringStructural engineering

The invention discloses a front support of a fairing of a wind generating set, and belongs to the technical field of wind power generation. The front support comprises a conical cylinder, a large annular plate fixedly connected with the large end of the conical cylinder and a small annular plate fixedly connected with the small end of the conical cylinder; and the small end of the conical cylinderis connected with a plurality of hanging lugs, the hanging lugs are fixedly connected with the small annular plate, and the lower planes of the hanging lugs are tightly attached to the upper plane ofthe small annular plate. Compared with an existing front support of a fairing of a wind generating set, an integrated conical cylinder structure is adopted, the large annular plate and the small annular plate are fixedly connected with the large end and the small end of the conical cylinder respectively, due to the fact that the stress of a hub connecting end is large, the connecting strength between the small annular plate and the conical cylinder is enhanced through the hanging lugs, the supporting strength of the front support is enhanced, stress is uniform, stress concentration is avoided, and the problem that a hub and the fairing front support crack due to stress concentration is solved. The structure design is reasonable, connection is reliable, and safe operation of a fan is guaranteed.

Owner:HUANENG CLEAN ENERGY RES INST

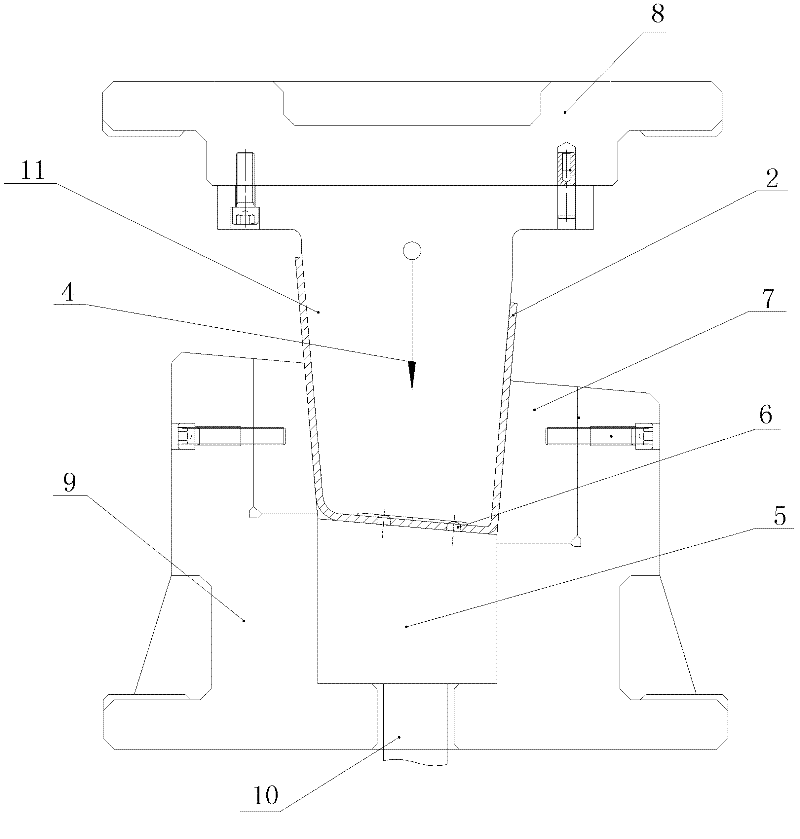

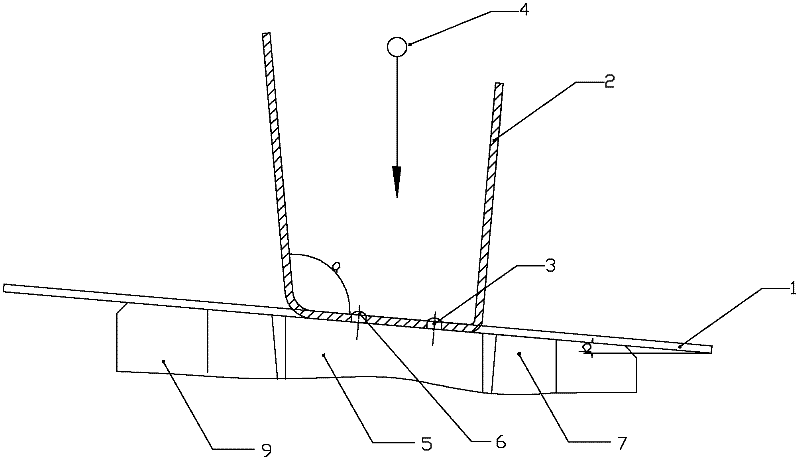

Method for bending rear crossbeam of heavy truck and bending die

ActiveCN102248044AReduce the difficulty of debuggingQuality improvementShaping toolsEngineeringBending force

The invention relates to a method for bending a rear crossbeam of a heavy truck. The method comprises the following steps that: a bending die which is debugged to be qualified is arranged on a press; two positioning holes on a punched blank pass through two positioning pins on the upper surface of an ejector so that the blank is placed on the ejector of a lower die of the bending die; and a working pushbutton of the press is pressed so that a male die of the bending die moves downward along with a sliding block of the press, the bending force acts on the blank in a direction vertical to the horizontal plane, and the blank is pressed by the bending force and the ejector of the bending die so as to move downward and enter a cavity of a female die of the bending die, the sliding block of the press moves downward to the bottom of the female die of the bending die, the blank is formed in the female die of the bending die, the sliding block of the press moves upward, the ejector of the bending die, a bent part and the male die of the bending die synchronously move upward to the position before bending, the male die of the bending die and the bent part are separated, and the wing surface and the bottom surface of the rear crossbeam are in an ideal state due to the rebound of a steel plate. Meanwhile, the invention also discloses the bending die matched with the method.

Owner:SINO TRUK JINAN POWER

Roof mounting method

Owner:CHINA CONSTR STEEL STRUCTURE TIANJIN CO LTD

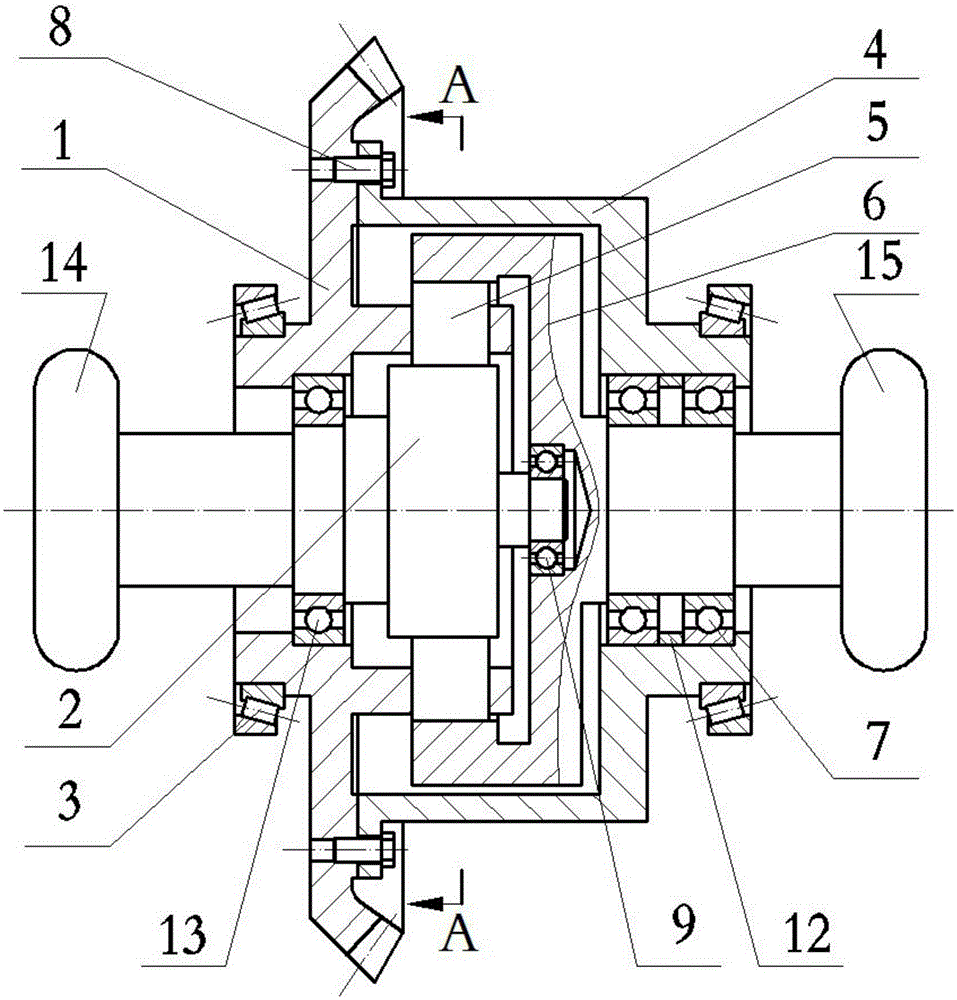

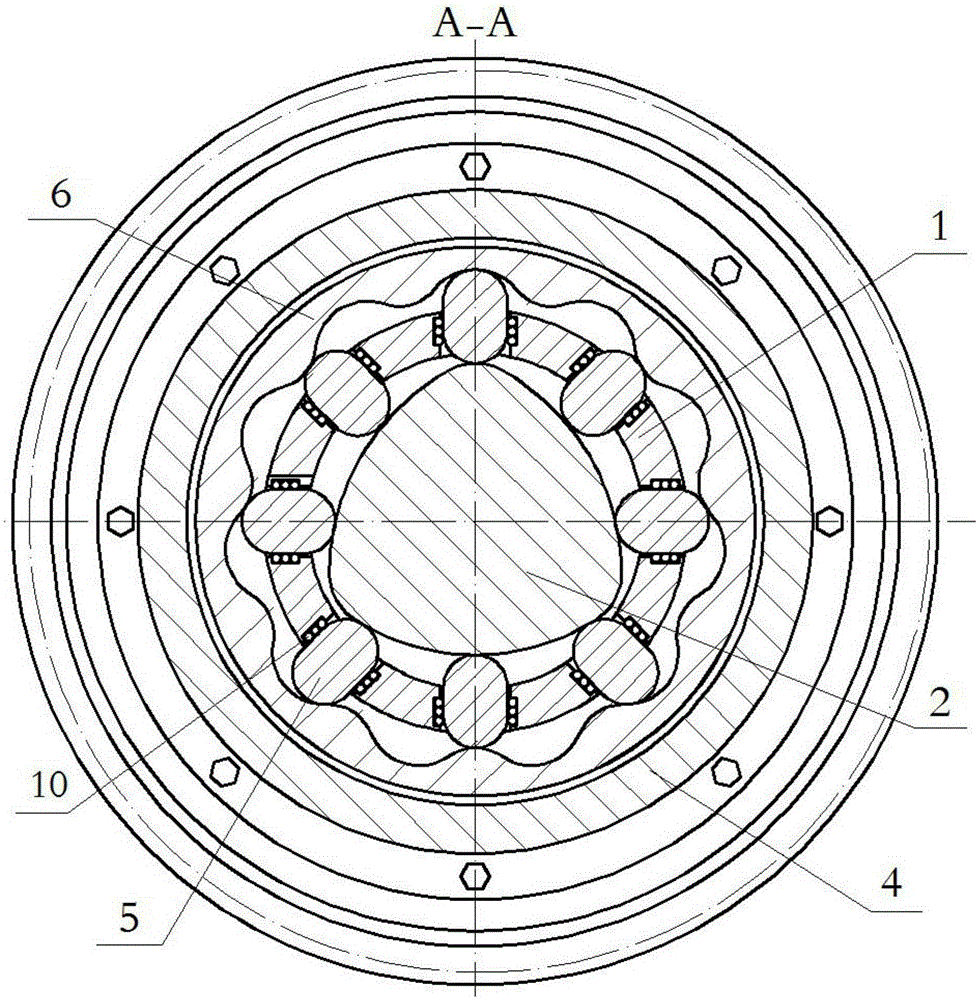

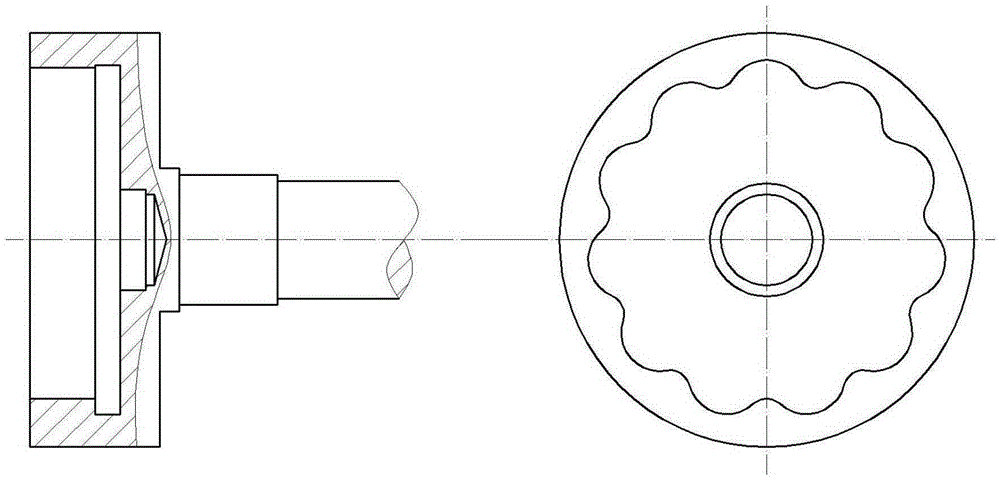

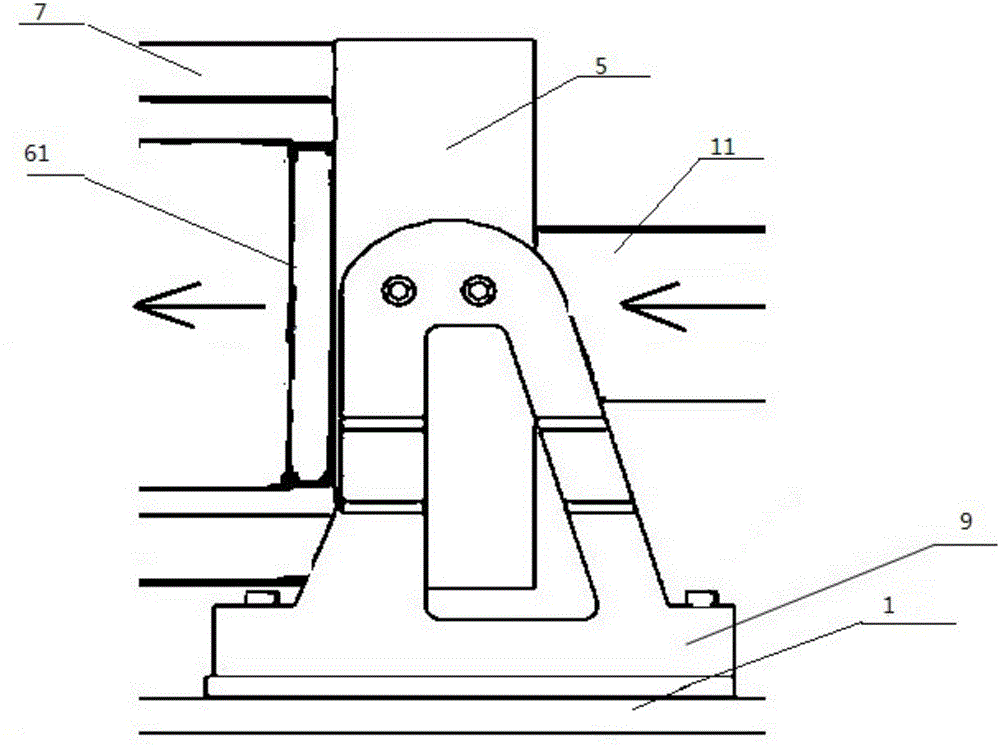

Outer cam shock wave-type pure rolling automobile differential mechanism with arbitrary tooth difference

InactiveCN105370839AImprove transmission efficiencyCompact structureDifferential gearingsShock waveGear wheel

The invention discloses an outer cam shock wave-type pure rolling automobile differential mechanism with an arbitrary tooth difference and belongs to the technical field of mechanical transmission. The invention provides a novel automobile differential. A bevel gear is arranged at the outer part of an outer tooth inner retainer; the inner part of the outer tooth inner retainer has a sleeve structure; a movable sleeve roller is in multi-tooth meshing with the outer tooth inner retainer, and a left half shaft multiphase outer cam and a right half shaft inner gear are in multi-tooth meshing; and all meshing parts are in pure rolling contact. According to the outer cam shock wave-type pure rolling automobile differential mechanism provided by the invention, the power is input by the bevel gear arranged at the outer part of the outer tooth inner retainer, transferred to the movable sleeve roller through the outer tooth inner retainer and then transferred to the left half shaft multiphase outer cam which is fixedly connected with a left automobile wheel and the right half shaft inner gear which is fixedly connected with a right automobile wheel through the movable sleeve roller, so that a differential velocity between the left automobile wheel and the right automobile wheel is realized. The outer cam shock wave-type pure rolling automobile differential mechanism eliminates a planetary gear system in the traditional automobile differential mechanism, has compact structure, small size, light weight, large coincidence degree, high carrying capacity and high transmission efficiency, is in multi-tooth meshing and can be widely used in various wheeled vehicles needing differential mechanisms, such as automobiles, construction vehicles and the like.

Owner:SICHUAN UNIV

Automobile differential with any tooth difference between outer cam and shock-wave rolling block

An automobile differential with any tooth difference between an outer cam and a shock-wave rolling block belongs to the technical field of mechanical transmission. The invention provides a novel automobile differential; a bevel gear is arranged outside an outer-tooth internal retainer of the novel automobile differential, while a sleeve structure is formed inside the outer-tooth internal retainer; a rolling block is in multi-teeth engagement with all of the outer-tooth internal retainer, a left half axle multi-phase outer cam and a right half axle internal gear. Power is input by the bevel gear outside the outer-tooth internal retainer and transmitted to the rolling block through the sleeve structure of the outer-tooth internal retainer, and then the rolling block transmits the power to the left half axle multi-phase outer cam fixedly connected with left wheels and the right half axle internal gear fixedly connected with right wheels, and therefore, differential speeds between the left and right wheels are realized. The differential has no planetary gear system in a traditional automobile differential, and as the rolling block of the differential is in rolling contact connection with the outer-tooth internal retainer, the differential has the advantages of compact structure, small volume, multi-tooth engagement, large contact ratio, high carrying capacity and high transmission efficiency and thus can be widely applied to various wheeled vehicles needing the differential, such as automobiles, engineering vehicles and so on.

Owner:SICHUAN UNIV

Double-R supporting structure of injection molding machine

The invention discloses a double-R supporting structure of an injection molding machine. The double-R supporting structure comprises a base, two linear guide rails, a plurality of sliding blocks, a movable die plate, a fixed die plate, a die and four tie bars. One end of each tie bar is positioned on the fixed die plate, and the other end of each tie bar penetrates the movable die plate; the movable die plate can move on the tie bars, and the die is mounted between the movable die plate and the fixed die plate; the linear guide rails are fixed to the base, and the sliding blocks are positioned on the linear guide rails in a sliding manner; the two sides of the movable die plate are symmetric, and are each fixedly provided with a reverse-R-shaped supporting block; the two sides of the fixed die plate are symmetrically and fixedly provided with a positive-R-shaped supporting block; the bottoms of the reverse-R-shaped supporting blocks are fixed to the sliding blocks, and the sliding blocks are connected with the linear guide rails and can side on the guide rails; the bottoms of the positive-R-shaped supporting blocks are fixed to the base; and the double-R supporting structure of the injection molding machine can effectively prevent stress deformation of the fixed die plate and the movable die plate, the injection precision is improved, the production efficiency is improved, and the service life is prolonged.

Owner:SUZHOU UNIV

Double-curved-surface aluminium plate suspended ceiling structure

The invention discloses a double-curved-surface aluminium plate suspended ceiling structure. The suspended ceiling structure comprises a hoop, a keel, panels and a three-dimensional adjusting mechanism, wherein the hoop is assembled with a roof truss of a building; the keel is assembled with the hoop, the keel comprises a plurality of main keels arranged in parallel with one another, and further comprises a plurality of secondary keels arranged in parallel with one another, the length direction of the main keels is perpendicular to the length direction of the secondary keels, and framed keels are further arranged on the lower parts of the main keels and the secondary keels; a plurality of panels are fixed to the lower parts of the framed keels; and the three-dimensional adjusting mechanism comprises vertical threaded rods connected with the main keels and the secondary keels, universal joints connected with the framed keels are arranged at the bottoms of the threaded rods, the universal joints are provided with threaded holes assembled with the threaded rods, and the universal joints are provided with the rotation freedom degree of the universal joints and the rotation freedom degree of the threaded rods around the axis of the threaded rods. According to the double-curved-surface aluminium plate suspended ceiling structure, the structural strength is high, on-site welding is eliminated, maintenance and disassembly are convenient, and when the effect of the curved surface top is needed to be created on the overall, the local panel can conveniently fine adjust the height and adaptively change the angle.

Owner:GOLD MANTIS CONSTR DECORATION

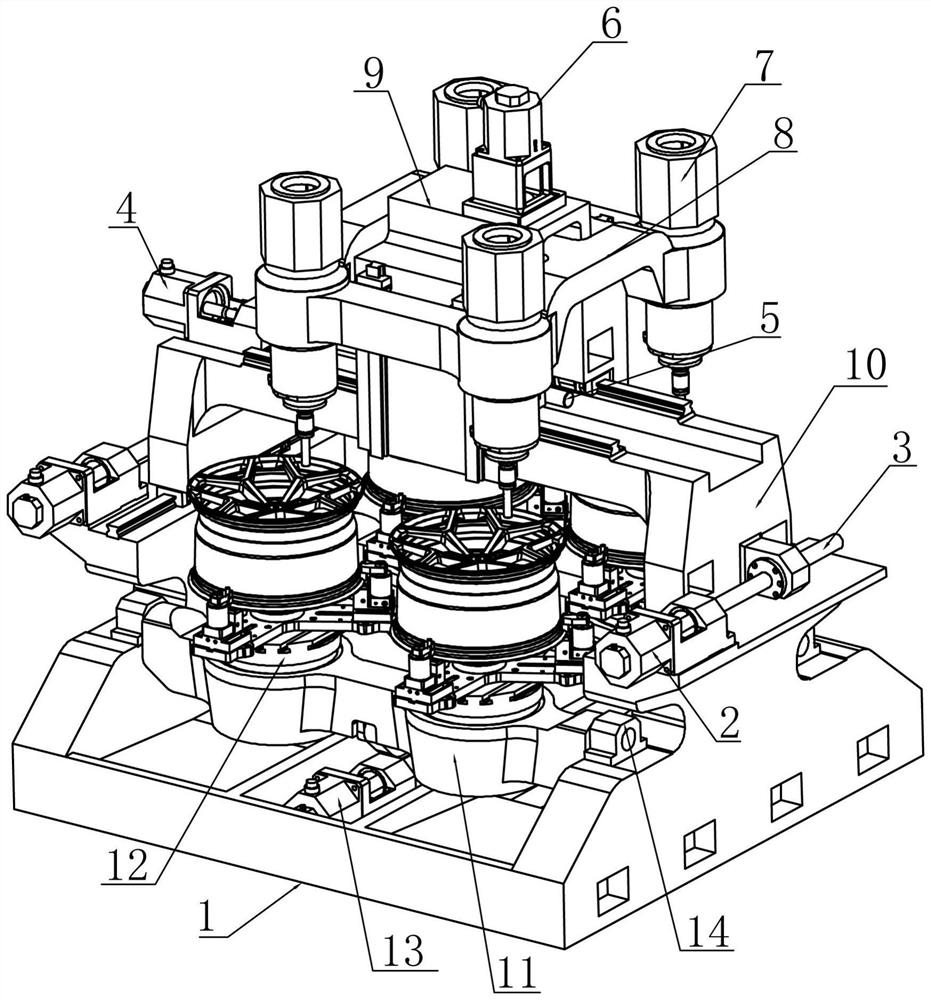

Multi-head five-axis vertical machining center

PendingCN112846947AImprove rigiditySymmetrical forceMetal working apparatusStructural engineeringMachine tool

The invention discloses a multi-head five-axis vertical machining center. The multi-head five-axis vertical machining center is characterized in that a B-axis swing driving device is installed on a lathe bed, the output end of the B-axis swing driving device is connected to a B-axis swing table, a C-axis rotary table is fixed in the B-axis swing table, the two ends of the B-axis swing table are fixed to the lathe bed through bearing pedestals, a hub is connected to the upper portion of the C-axis rotary table in a clamped mode, X-direction feeding driving devices are fixed to the two sides of the lathe bed, an X-axis driving rod is arranged at the output end of each X-direction feeding driving device, a cross beam is arranged on the upper portion of the lathe bed, a Y-direction feeding driving device is arranged on the cross beam, a Y-axis driving rod is arranged at the output end of the Y-direction feeding driving device, a Y-axis sliding table is clamped to the upper portion of the cross beam, a Z-direction feeding driving device is arranged at the top of the Y-axis sliding table, and a multi-head spindle box is arranged at the output end of the Z-direction feeding driving device. According to the multi-head five-axis vertical machining center, multi-head spindles are located on the two sides of the cross beam, stress is more symmetrical during machining, and the rigidity of a machine tool is improved; and the multiple spindles move at the same time, the X shaft, the Y shaft and the Z shaft share one servo driving device, cost is saved, and meanwhile machining consistency is guaranteed.

Owner:NINGBO DEMA INTELLIGENT MACHINERY CO LTD

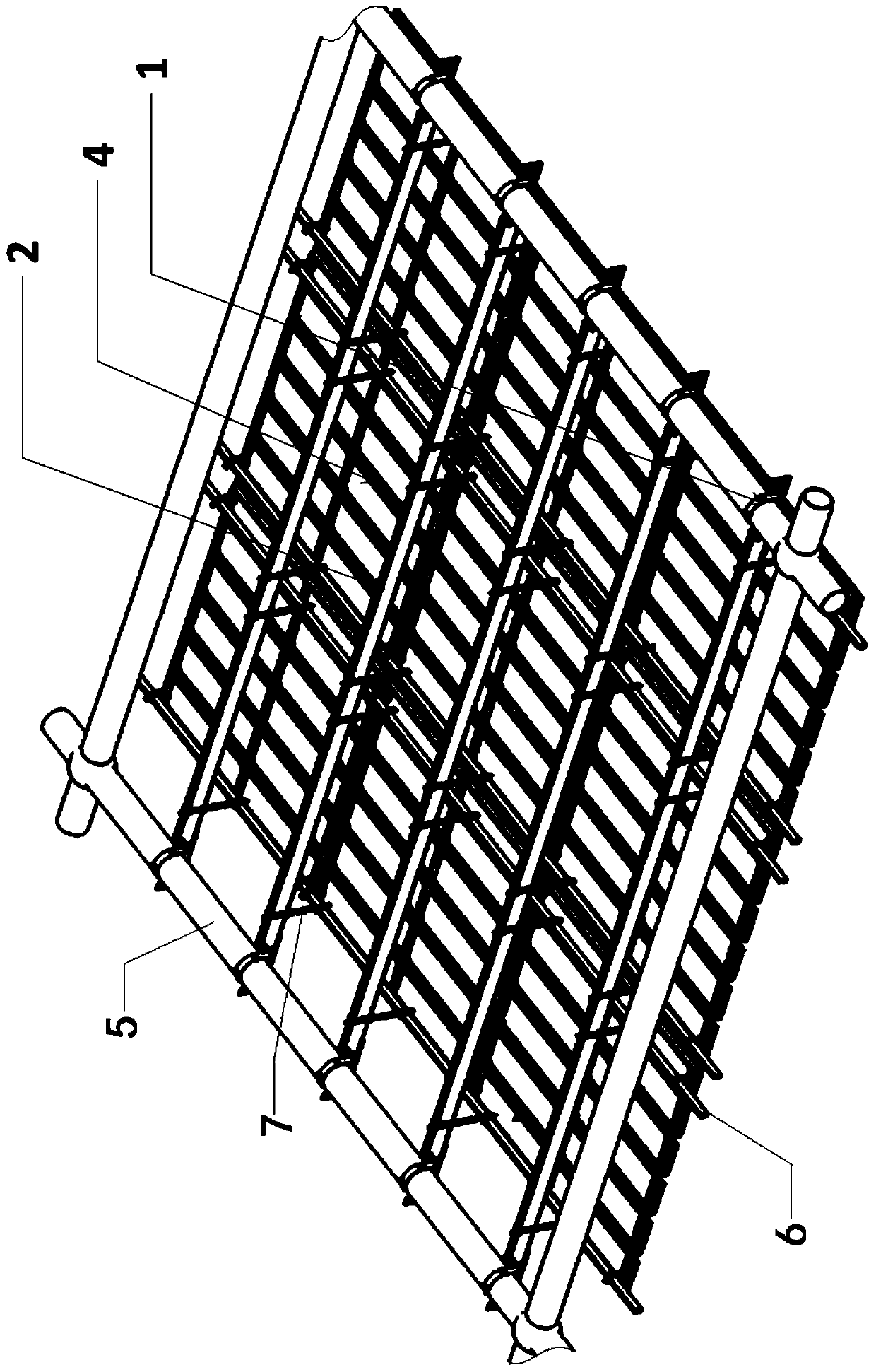

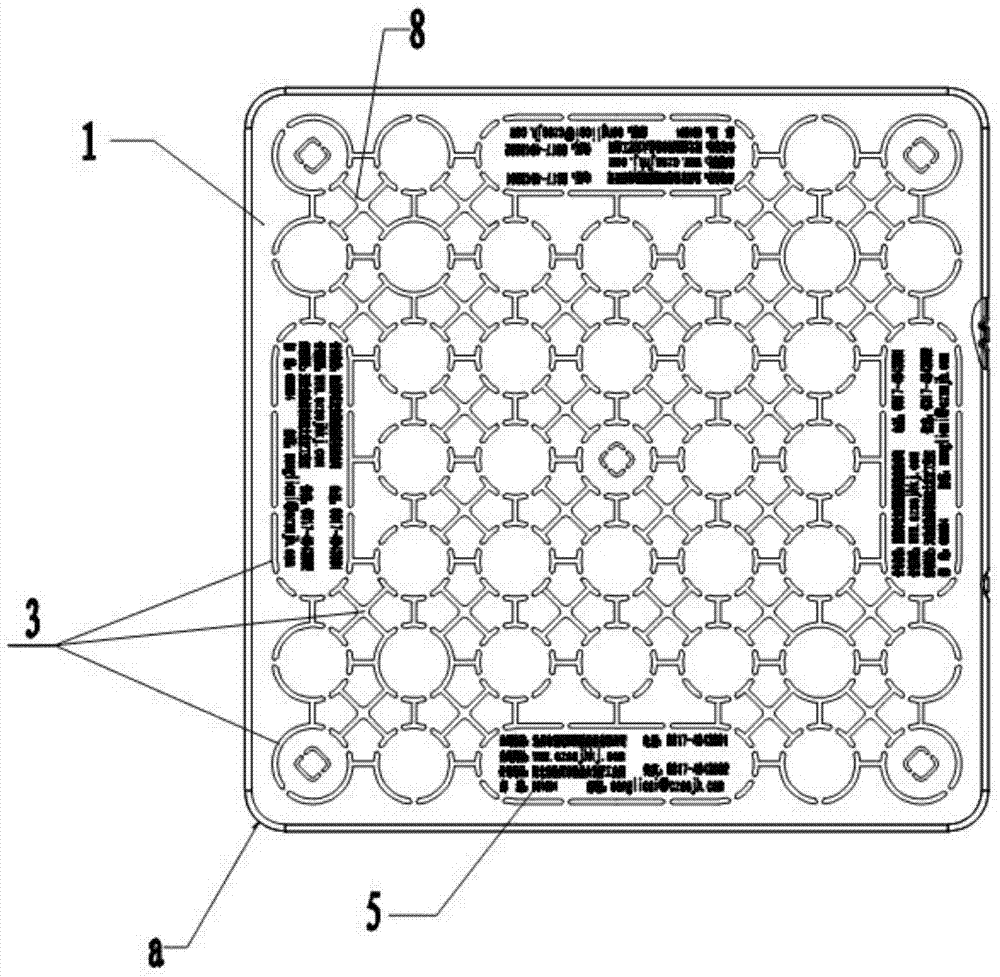

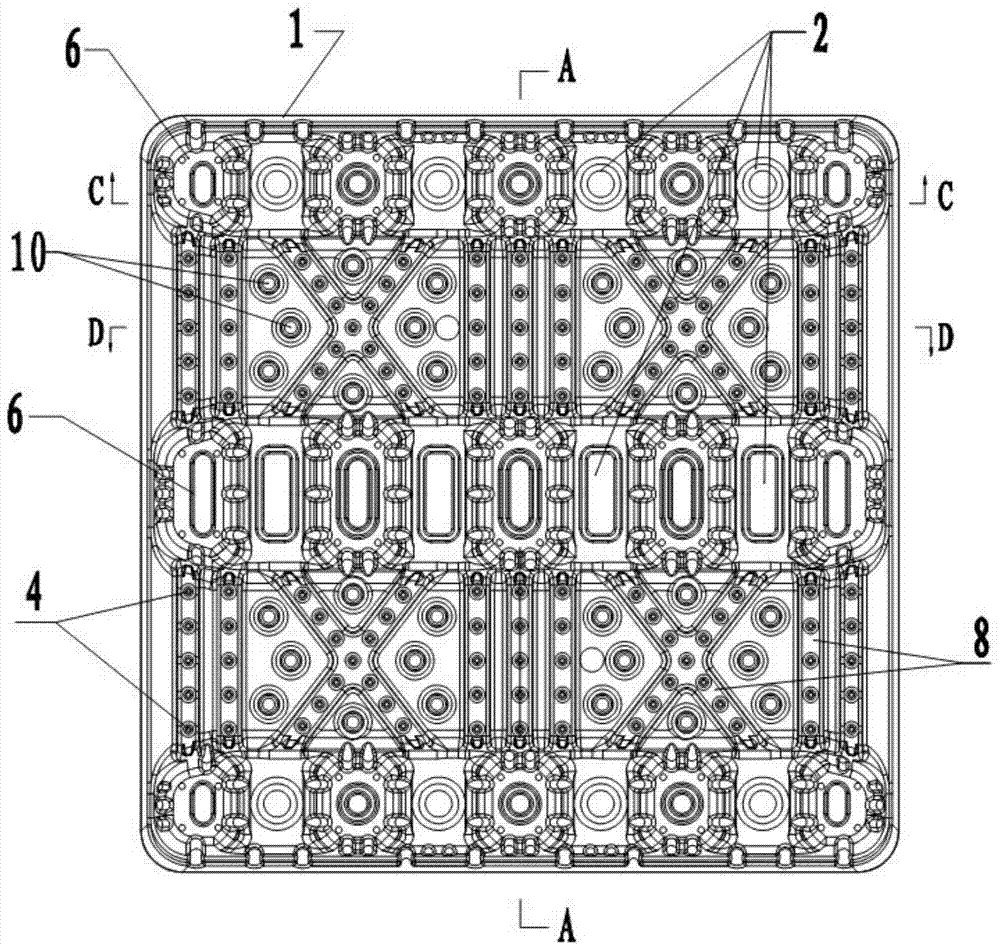

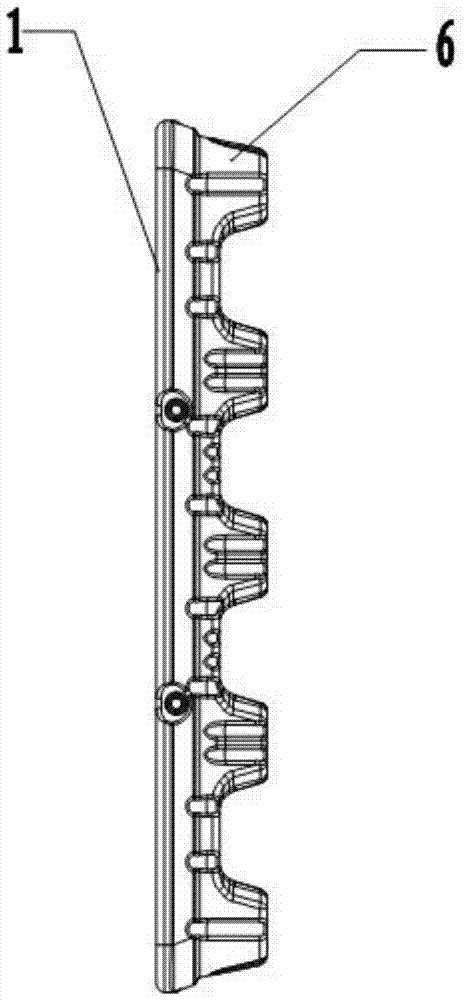

Novel two-way forking type single-face flat tray

The invention provides a novel two-way forking type single-face flat tray and belongs to the technical field of transport equipment. The novel two-way forking type single-face flat tray aims at solving the problems that an existing goods tray is unreasonable in structure design, the surface is difficult to clean, a panel is poor in anti-skidding performance, and potential safety hazards exist. The novel two-way forking type single-face flat tray is a single-face tray of a hollow structure shaped like a Chinese character 'chuan', wherein a bearing face and bottom linked supporting foot seats are integrally closed, the four rectangular angles of the bearing face are arc angles, multiple protruding-edge-shaped anti-skidding mechanisms are arranged on the bearing face discontinuously, the four angles of the bearing face are the arc angles, the four sides of the bearing face are arc sides, and the supporting foot seats are manufactured on the lower edge, convex and concave reinforcing bars are manufactured on the four faces of each supporting foot seat, circular supports are connected with the inclined angles, the centers of the lower supporting foot seats are convex and concave, and the four faces of each supporting foot seat incline to the corresponding center and is deformed and enhanced. The novel two-way forking type single-face flat tray is high in overall structural strength and especially suitable for goods storage and transport in the industries of food, medicine and the like.

Owner:宋玉平

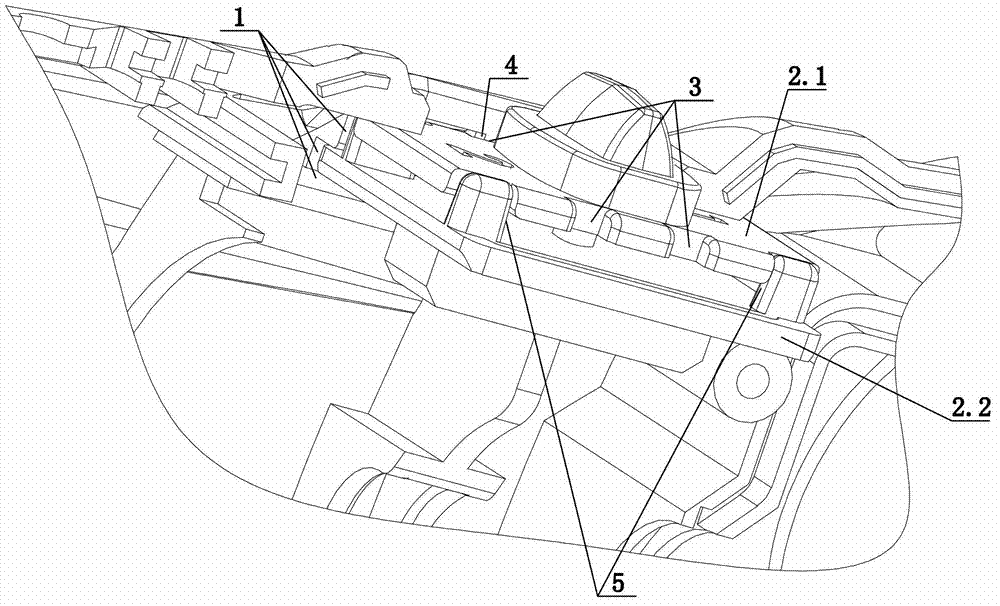

Pushbutton structure

InactiveCN102789912AImprove reliabilityUp and down relative movement is stableContact operating partsEngineeringBiomedical engineering

Owner:NINGBO HANPU TOOLS

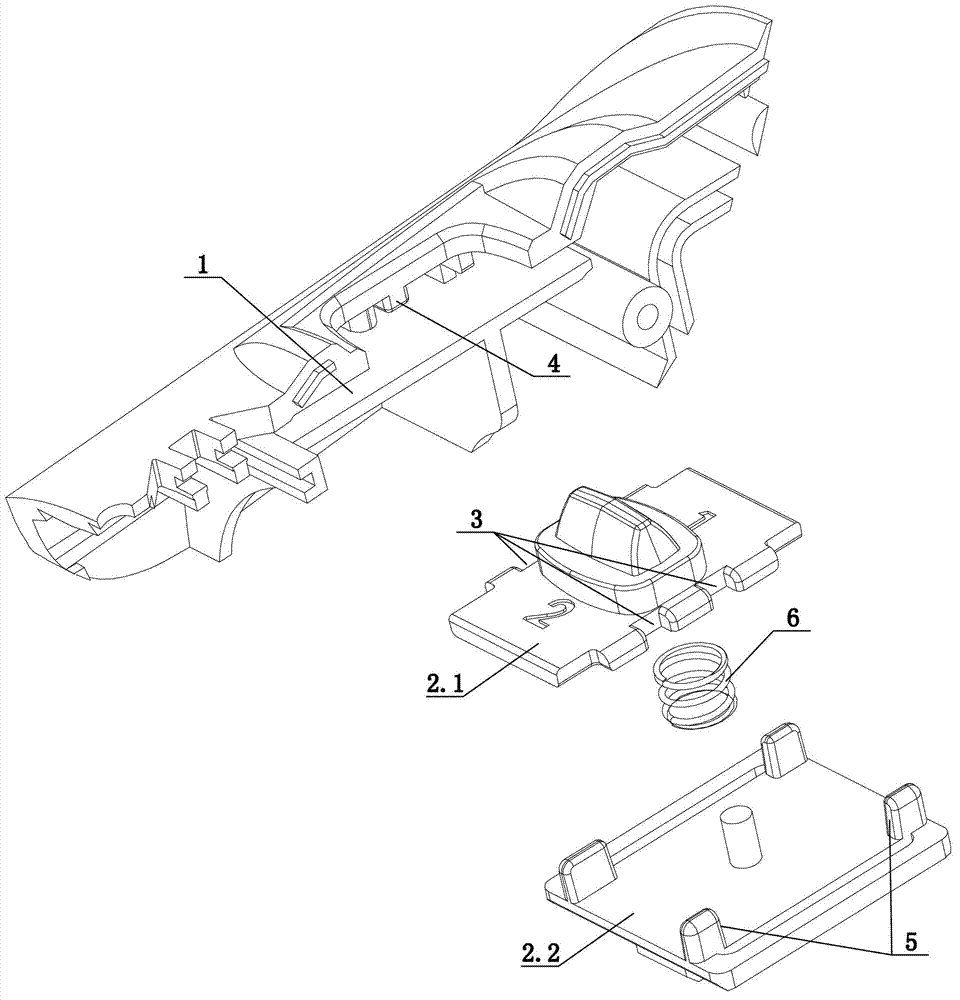

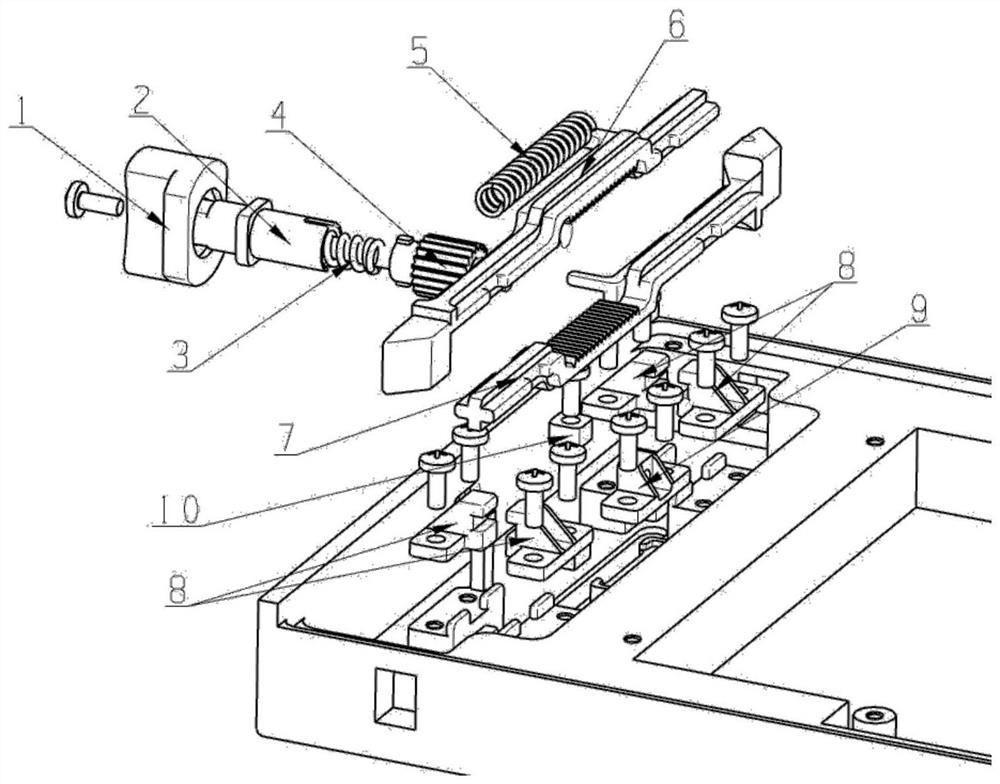

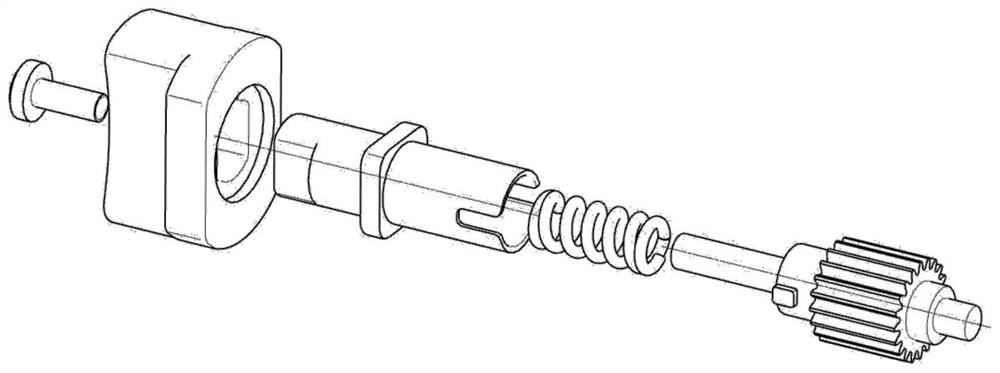

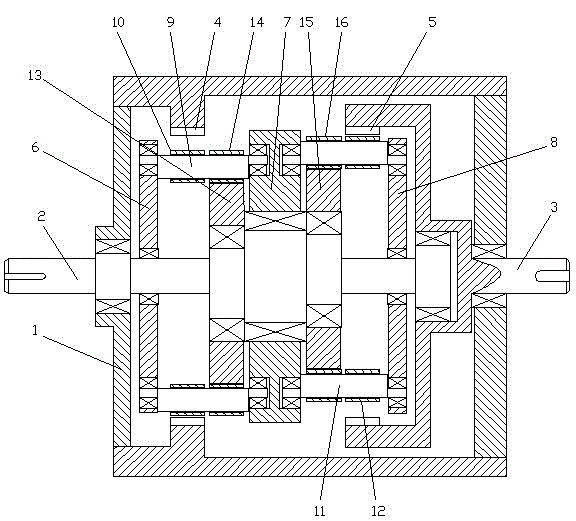

A push-knob type storage disk quick release structure

ActiveCN112447199BReliable lockingThere will be no lagCarrier constructional parts dispositionApparatus modification to store record carriersGear wheelEngineering

The invention discloses a push-knob type storage disk quick release structure, which belongs to the field of structural design of airborne electronic equipment. The structure can provide a new and reliable idea for the quick release method of the airborne recorder storage disk. The main structural parts include Knobs, knob shafts, knob springs, gear shafts, bolt return springs, upper rack bolts, lower rack bolts, bolt guide rails, gear bearings, stops, etc. When the storage disk is mated with the connector of the chassis, the operator presses down the knob and rotates it 90° counterclockwise, then the lock tongues on both sides of the storage disk retract into the disk body, the constraint between the storage disk and the chassis is released, and the storage disk can be Unplugged smoothly. When inserting the disk again, press down the knob in the same way. When the storage disk is inserted in place, the knob will receive an obvious restoring torque. The operator will rotate the knob clockwise to return to the position according to the torque and let go, and the knob will pop out for a short distance. Indicates that the storage disk is firmly inserted and cannot be pulled out.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

Two-stage movable tooth speed reducing transmission device

InactiveCN102678835BSimple structureReduce volumeToothed gearingsEngineeringElectrical and Electronics engineering

The invention discloses a two-stage movable tooth speed reducing transmission device which comprises a housing, an eccentric input shaft, an output shaft, first-stage internal gears and second-stage internal gears, wherein a first movable gear frame, a first-stage driving disc, a central disc, a second-stage driving disc and a second movable gear frame are arranged on the eccentric input shaft in sequence; the two-stage movable tooth speed reducing transmission device further comprises a first eccentric frame formed by first-stage cranks; first-stage movable gears are arranged on the first-stage cranks; a first-stage movable gear cluster is meshed with the first-stage internal gears with few tooth differences; the two-stage movable tooth speed reducing transmission device further comprises a second eccentric frame formed by second-stage cranks; and second-stage movable gears are arranged on the second-stage cranks and meshed with the second-stage internal gears with few tooth differences. According to the two-stage movable tooth speed reducing transmission device, only one pair of meshed internal and movable gears is arranged in each stage of speed reducing transmission device, so that the whole device has a simple structure and a small volume; a rotation center of the eccentric input shaft is coaxial with a rotation center of the output shaft, so that the transmission device can be conveniently connected with other transmission structures and the mounting space of the transmission device is reduced; and the two ends of the first-stage crank and the two ends of the second-stage crank are all supported, so that the cranks are stressed symmetrically and have great carrying ability.

Owner:CHONGQING UNIV

A Dead Reckoning Positioning Robot Chassis Using Vertical Shock Absorbing Device

ActiveCN106256568BSymmetrical forceReduce the impact of the accuracy of the collected dataResilient suspensionsDrive wheelSelf locking

Owner:NANJING UNIV OF SCI & TECH

Method for bending rear crossbeam of heavy truck and bending die

ActiveCN102248044BReduce the difficulty of debuggingQuality improvementShaping toolsBending forceTruck

The invention relates to a method for bending a rear crossbeam of a heavy truck. The method comprises the following steps that: a bending die which is debugged to be qualified is arranged on a press; two positioning holes on a punched blank pass through two positioning pins on the upper surface of an ejector so that the blank is placed on the ejector of a lower die of the bending die; and a working pushbutton of the press is pressed so that a male die of the bending die moves downward along with a sliding block of the press, the bending force acts on the blank in a direction vertical to the horizontal plane, and the blank is pressed by the bending force and the ejector of the bending die so as to move downward and enter a cavity of a female die of the bending die, the sliding block of the press moves downward to the bottom of the female die of the bending die, the blank is formed in the female die of the bending die, the sliding block of the press moves upward, the ejector of the bending die, a bent part and the male die of the bending die synchronously move upward to the position before bending, the male die of the bending die and the bent part are separated, and the wing surface and the bottom surface of the rear crossbeam are in an ideal state due to the rebound of a steel plate. Meanwhile, the invention also discloses the bending die matched with the method.

Owner:SINO TRUK JINAN POWER

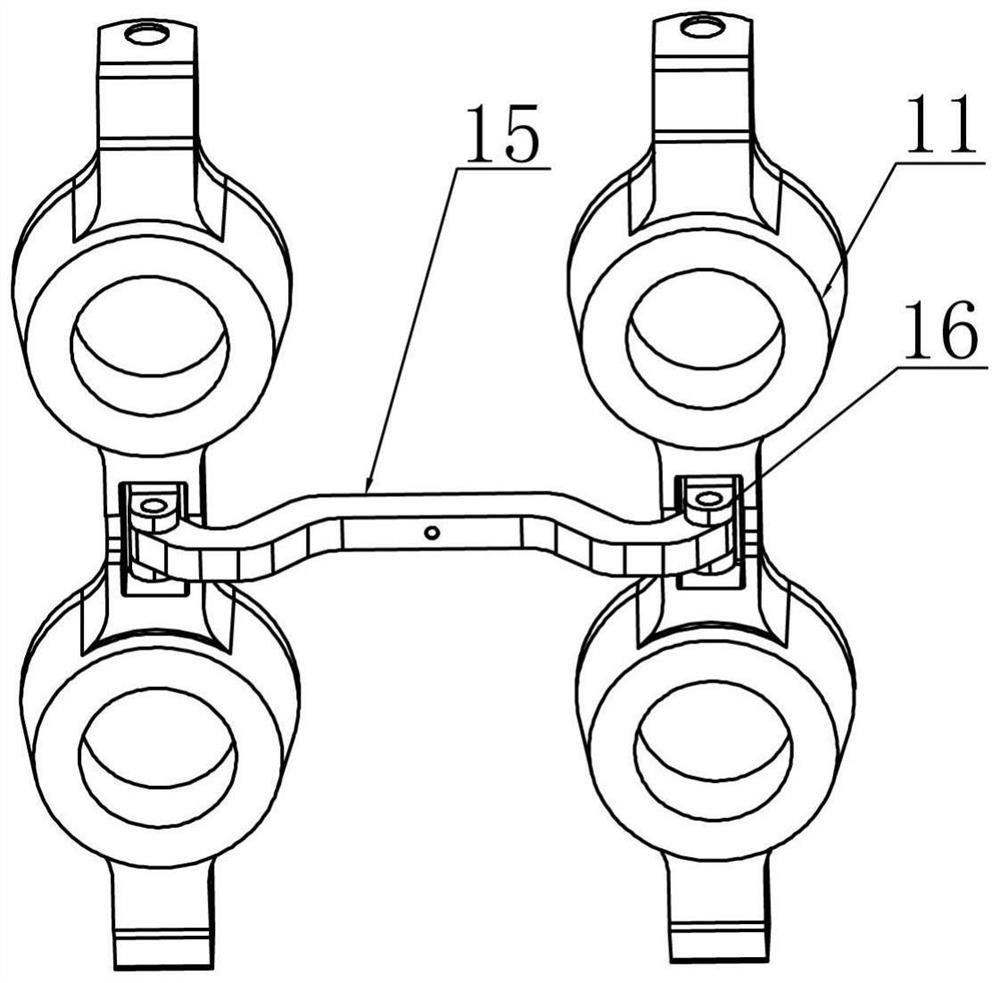

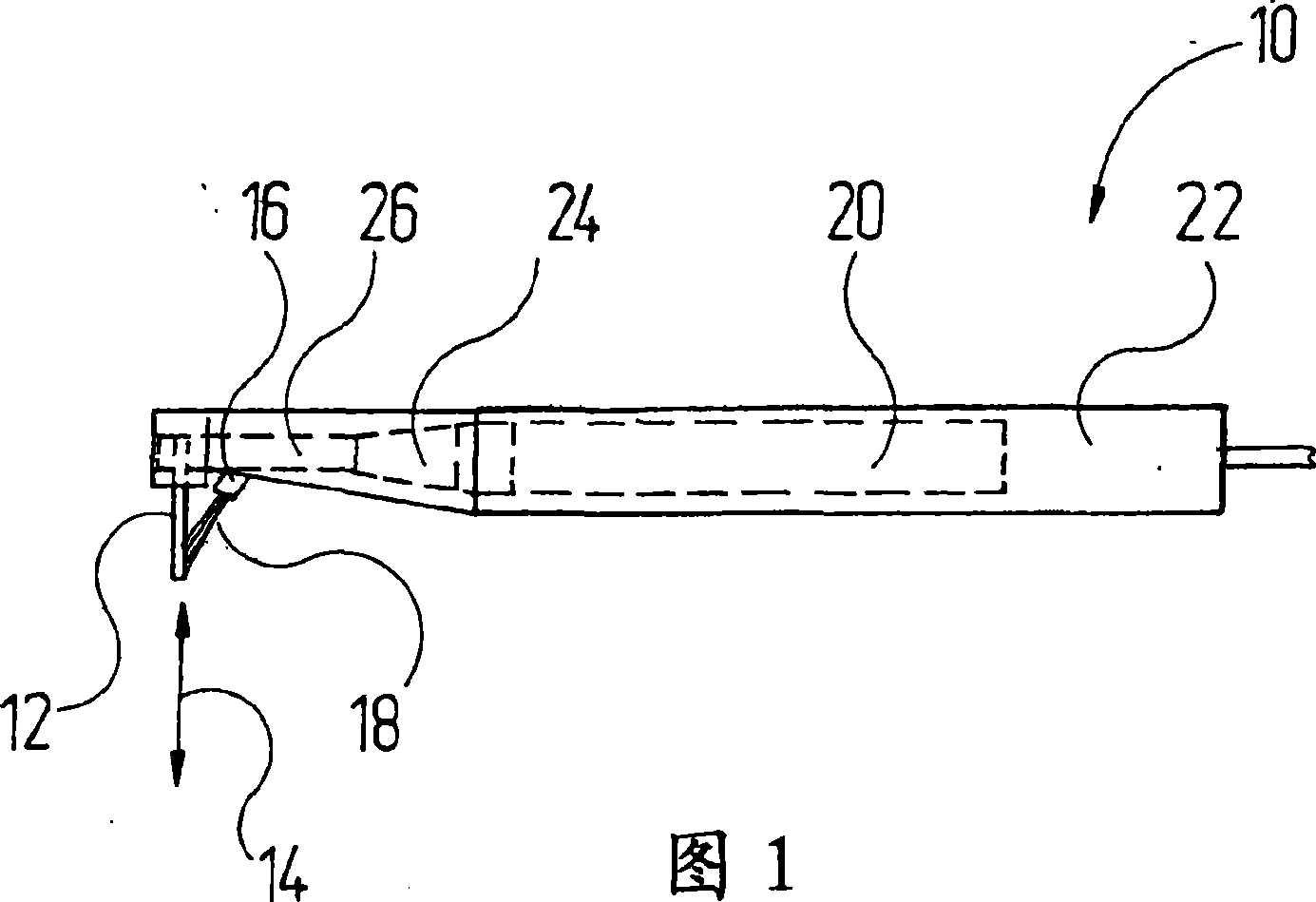

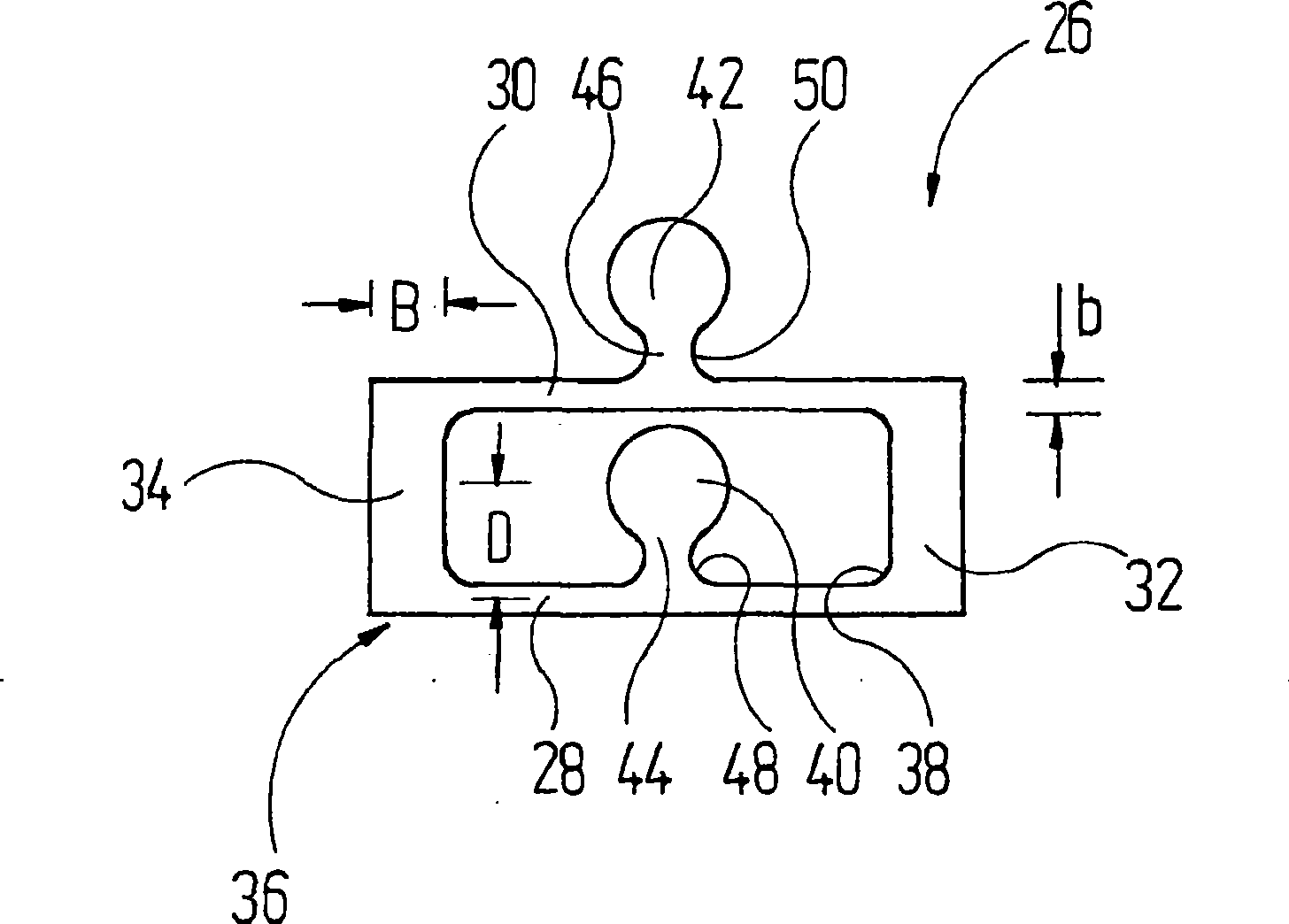

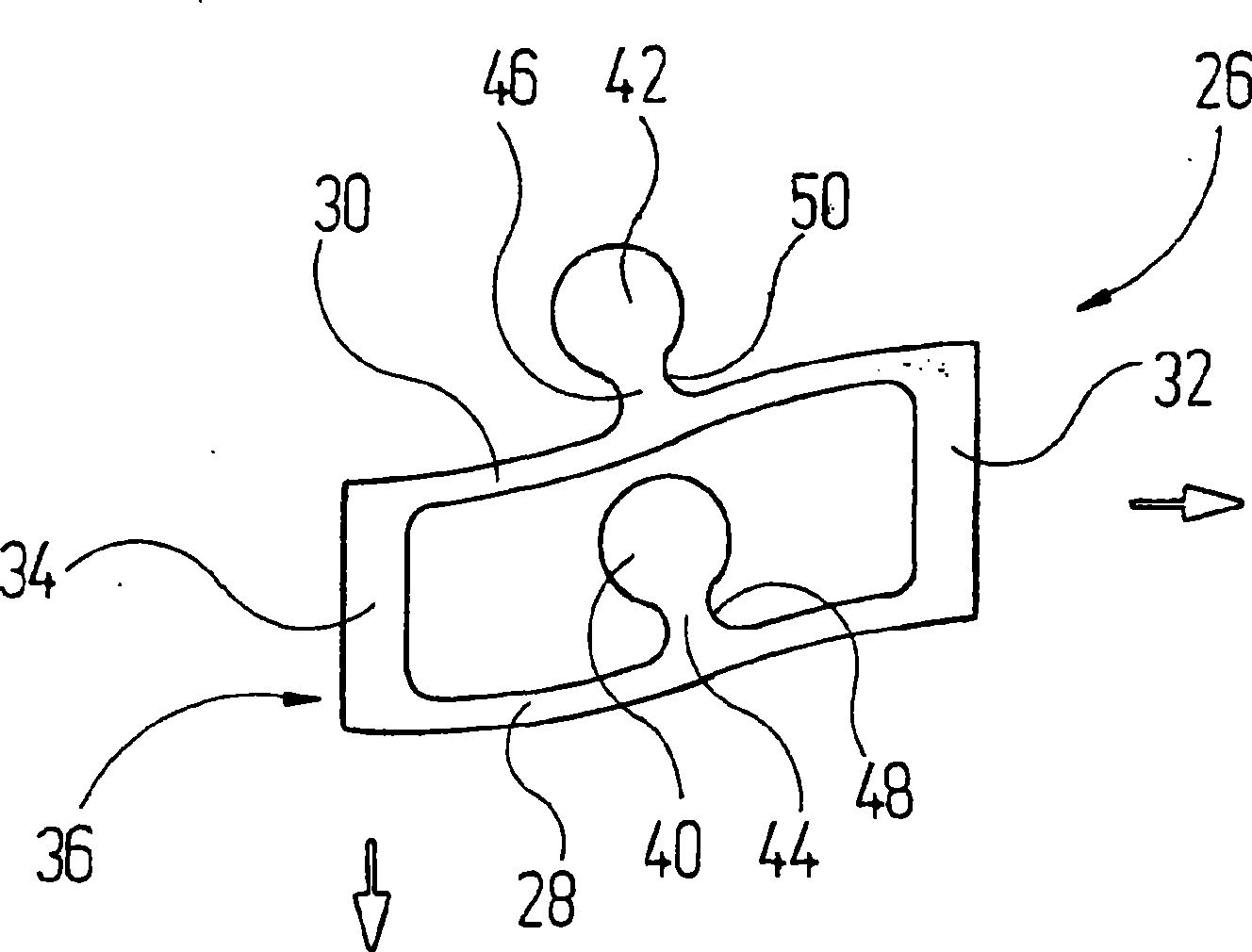

Elastically flexible coupling body

InactiveCN101400314AEffective excitationSymmetrical forceMechanical vibrations separationBoring toolsCouplingEngineering

The invention relates to a coupling body (26) that can convert a linear input movement into a linear output movement transversal to the input movement. Said coupling body comprises two parallel flexional arms (28, 30) of the same length, the ends of said flexional arms being connected by means of transversal connection arms (32, 34). The connection arms (28, 30) carry driving bodies (40, 42) which represent load bodies arranged at the same distance from the neutral lines of the connection arms, in the same direction.

Owner:DURR DENTAL GMBH & CO KG

Any tooth difference type internal shock automobile differential provided with double-roller block

InactiveCN105526333AImprove transmission efficiencySmooth runningDifferential gearingsLeft halfControl engineering

The invention discloses an any tooth difference type internal shock automobile differential provided with a double-roller block and belongs to the technical field of mechanical transmission. According to the novel automobile differential, a bevel gear is arranged outside an outer tooth internal retainer, and a sleeve structure is arranged in the outer tooth internal retainer; power is input through the bevel gear outside the outer tooth internal retainer and transmitted to the double-roller block through the sleeve structure of the outer tooth internal retainer, and then the double-roller block transmits the power to a left half axle central wheel fixedly connected with left wheels and a right half axle multi-phase internal cam fixedly connected with right wheels, so that the speed difference between the left wheels and the right wheels is achieved. According to the differential, a planetary gear system in a traditional automobile differential is omitted, and the double-roller block is in multi-tooth engagement with the left half axle central wheel, the outer tooth internal retainer and the right half axle multi-phase internal cam and is also in rolling engagement with the outer tooth internal retainer, so that the differential is compact in structure, small in size, low in weight, capable of achieving multi-tooth engagement, large in overlap ratio, high in bearing capacity, high in transmission efficiency and can be widely applied to various wheeled vehicles, such as automobiles and engineering vehicles, needing differentials.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com