Roof mounting method

An installation method and roof technology, which can be applied to roofs, buildings, building components, etc., can solve problems such as the inability to meet the construction needs of larger spans and heavier roofs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

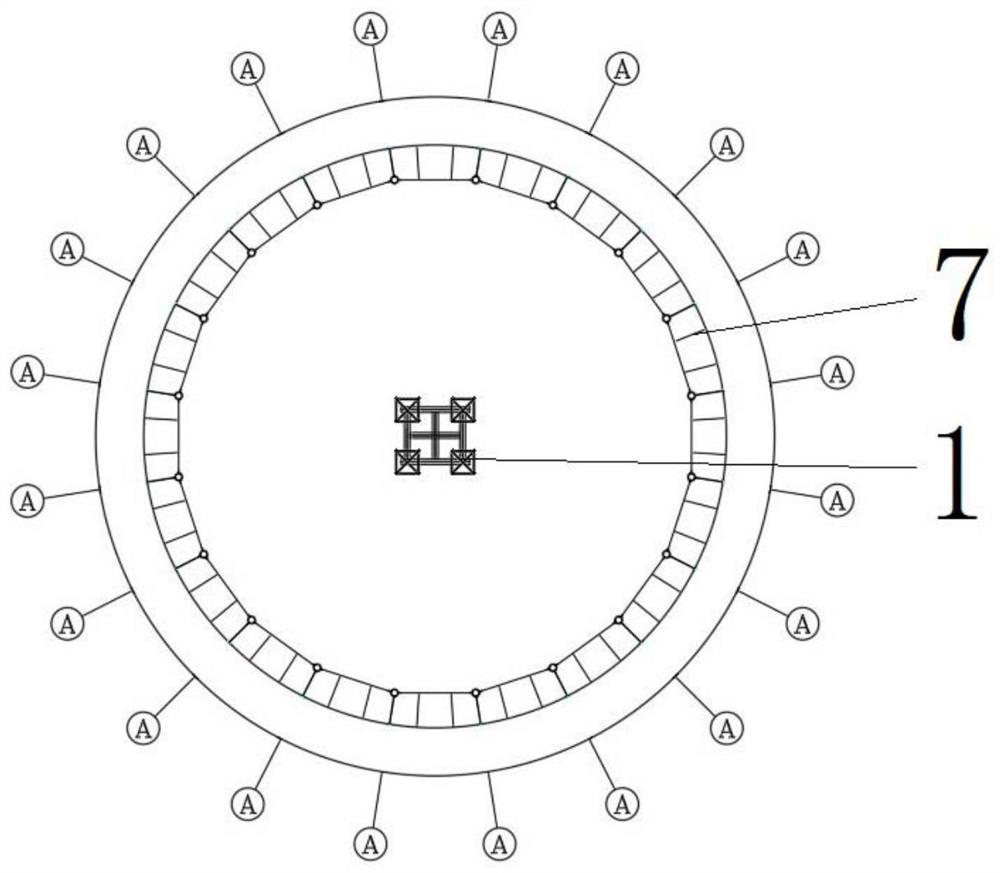

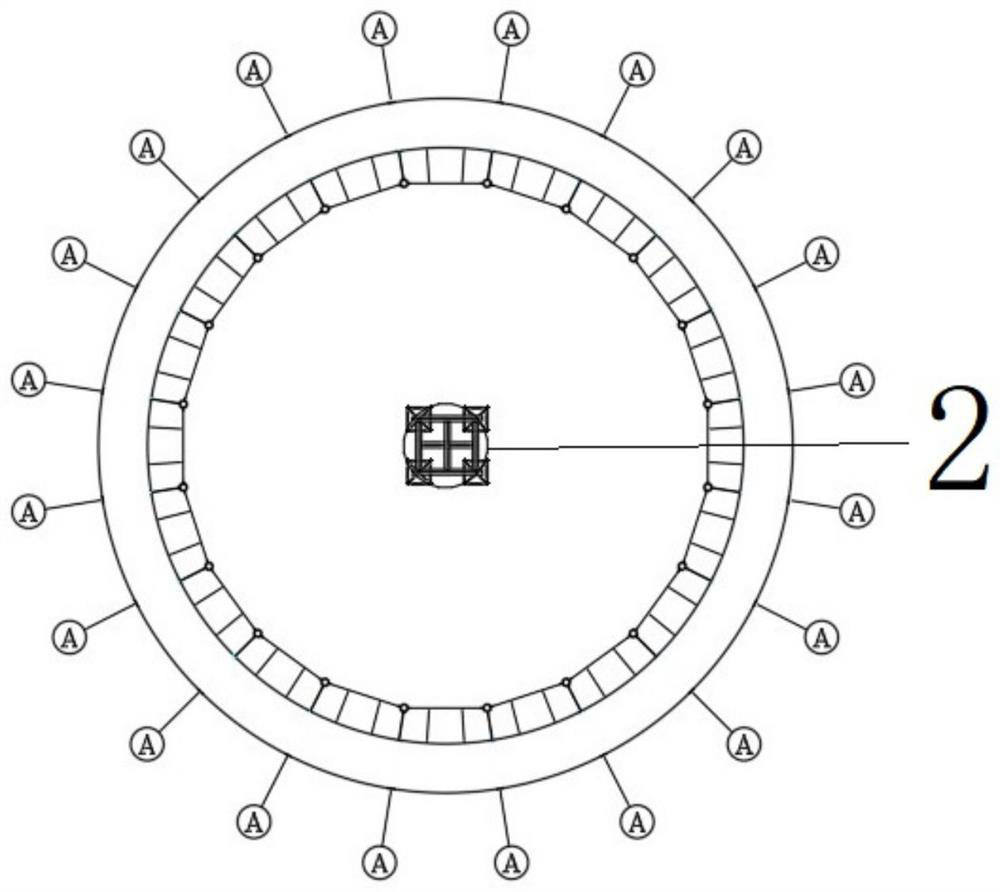

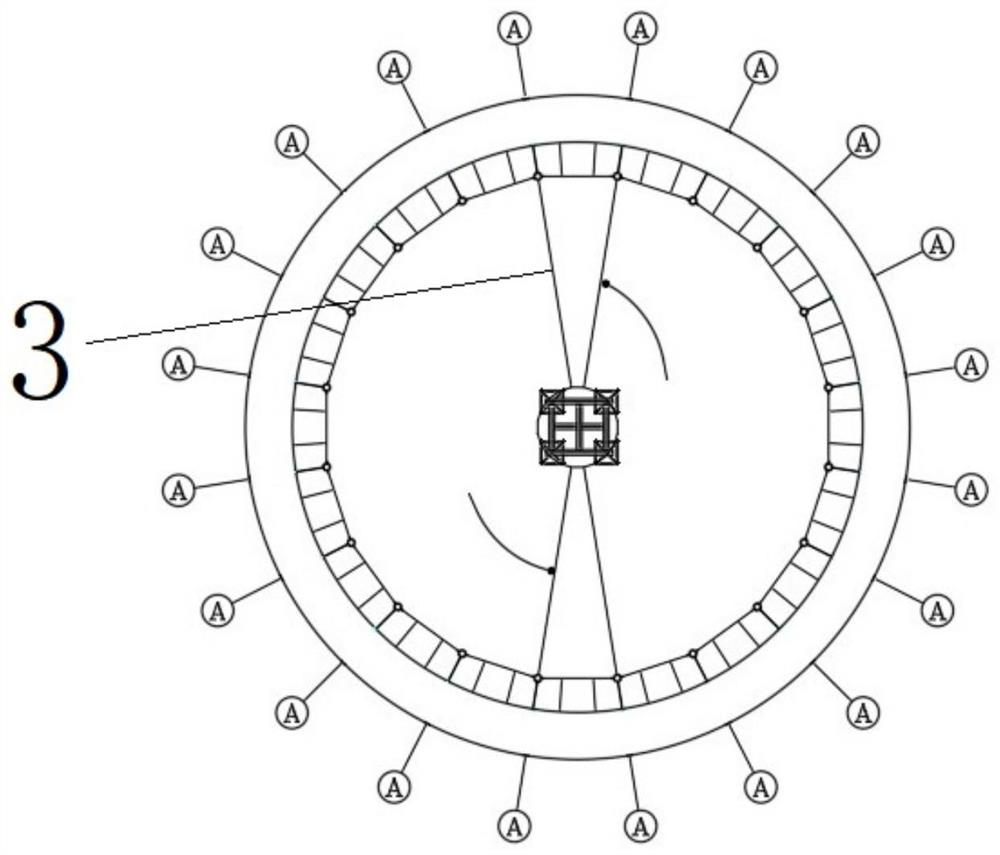

[0061] This embodiment provides as Figure 1 to Figure 20 A roof installation method shown includes the following steps:

[0062] Such as figure 1 As shown, install the construction support platform 1: measure and position through the total station, where as Figure 8 As shown, the construction support platform 1 includes multiple sets of lattice support frames 11, horizontal connecting beams 12, diagonal bars 13 and a construction operation platform. The beam 12, the oblique bar 13 and the lattice support frame 11 are welded and fixed; if Figure 8 with Figure 11 As shown, the operating platform is arranged on the top of the lattice type support frame 11, the operation platform includes a skirting board 141, a steel wire mesh sheet 142 and a guardrail 143, the skirting board 141 is arranged on the top of the lattice type supporting frame 11, and the guardrail 143 is located on the skirting board 141 , The steel wire mesh sheet 142 is set in the guardrail 143, the skirtin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com