Method for bending rear crossbeam of heavy truck and bending die

A rear beam and bending technology, applied in the field of vehicle parts processing methods and molds, can solve the problems of difficult to control rebound, different rebound sizes of the two wing surfaces, affecting the frame assembly rhythm and the quality of the whole vehicle, etc., to reduce the difficulty of debugging, The effect of improving the quality of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

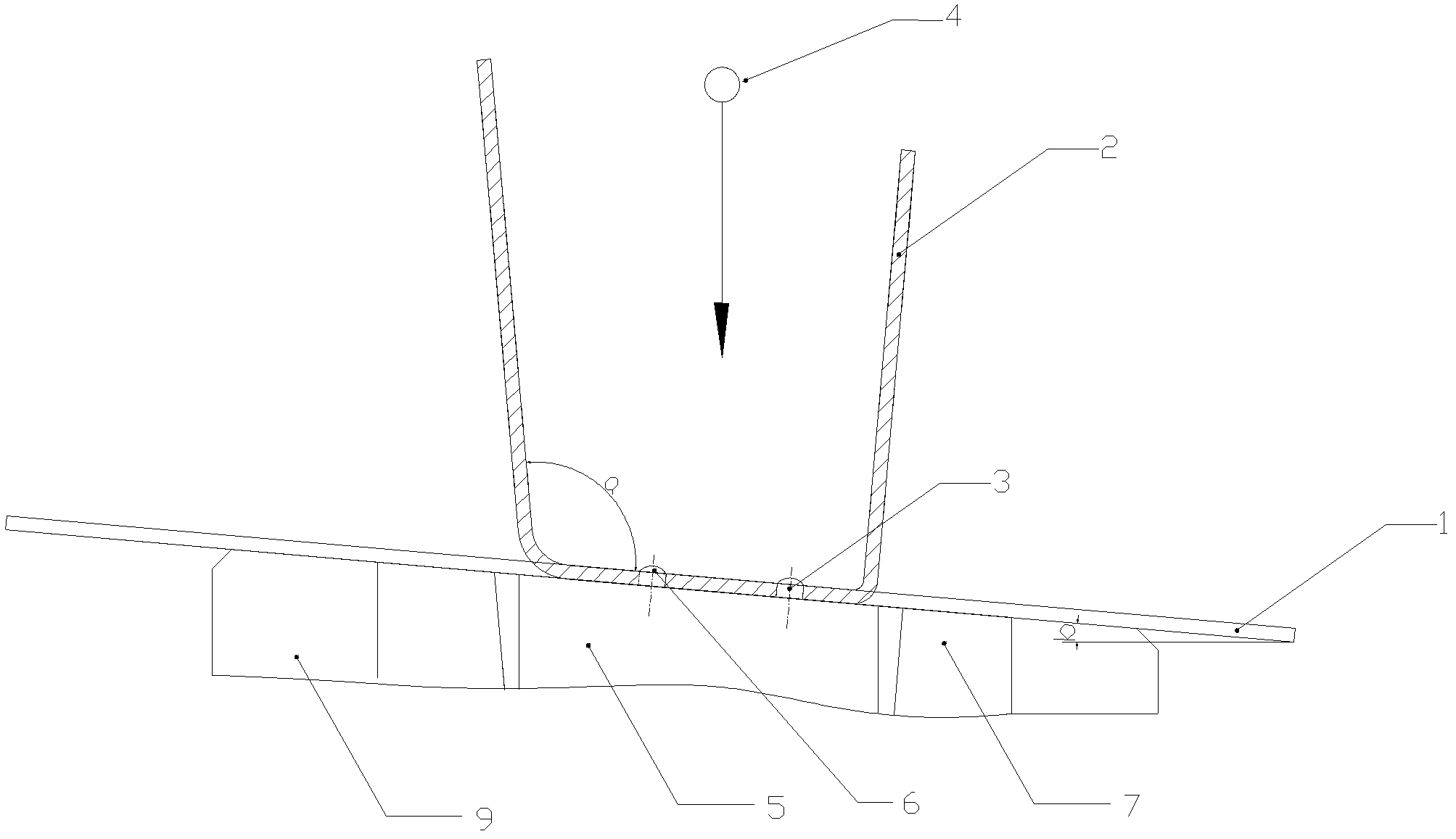

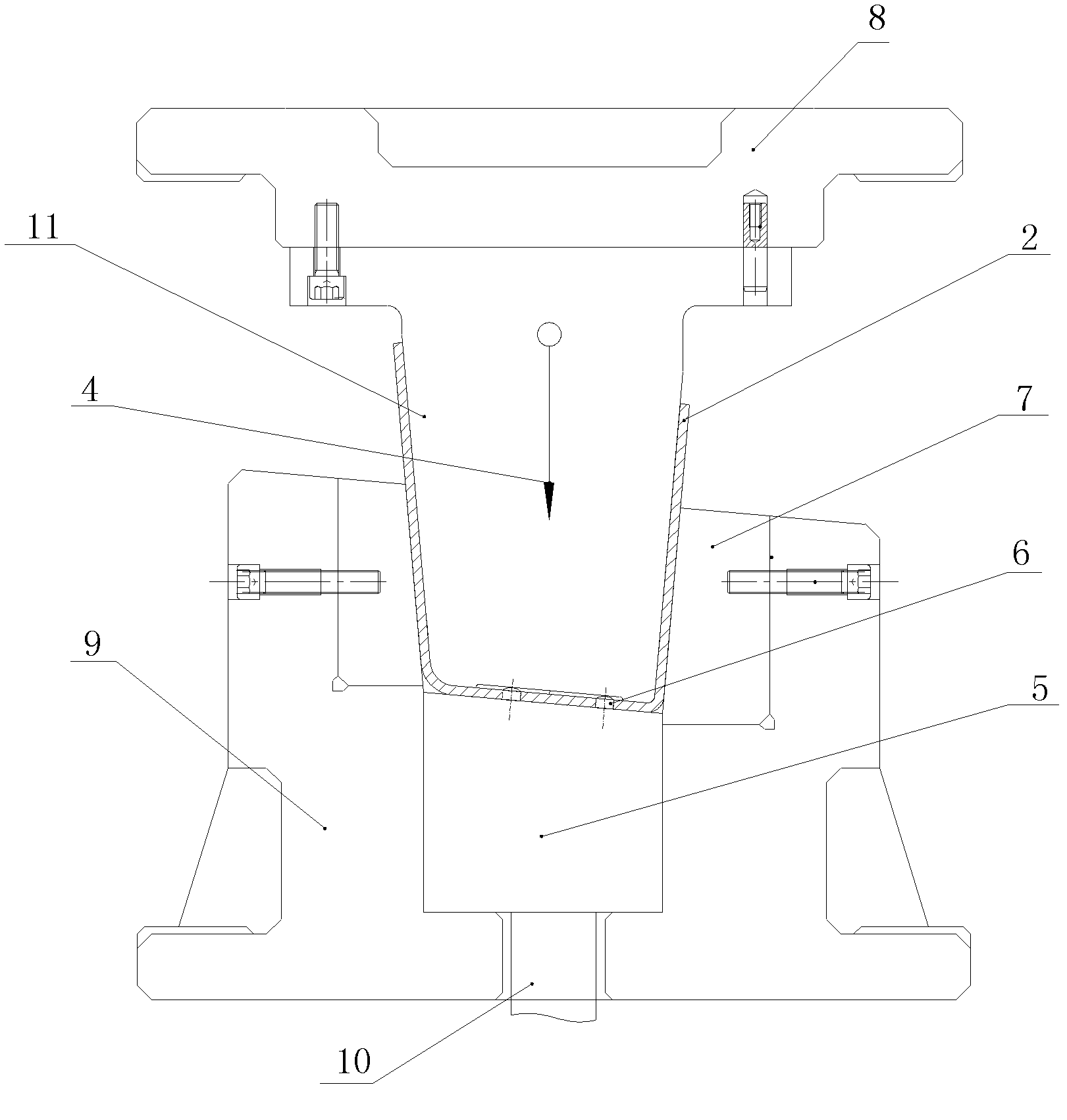

[0017] Such as figure 1 , figure 2 As shown, a bending method of the rear beam of a heavy truck includes the following steps:

[0018] 1). Install the qualified bending mold on the press;

[0019] 2). The two positioning holes 3 on the blank 1 of the falling punch are penetrated into the two positioning pins 6 provided on the upper surface of the ejector 5, and placed on the ejector 5 of the lower die 9 of the bending die; the blank 1. Place it on the top piece 5 of the bending mold at an angle of b degrees with the horizontal plane, where b=(a-90°) / 2, a is an angle greater than 90° between an airfoil of the rear beam and the bottom surface;

[0020] 4). Press the working button of the press, the punch 11 of the bending mold goes down with the slider of the press, the bending force acts on the blank 1 in a direction perpendicular to the horizontal p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com