A Dead Reckoning Positioning Robot Chassis Using Vertical Shock Absorbing Device

A shock absorbing device and dead reckoning technology, which is applied in transportation and packaging, elastic suspension, vehicle parts, etc., can solve the problem of slippage of the omnidirectional wheel mobile platform, reduced accuracy and stability, and the structure of the robot's shock absorbing mechanism is prone to deflection. load and other problems, to achieve good shock absorption and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

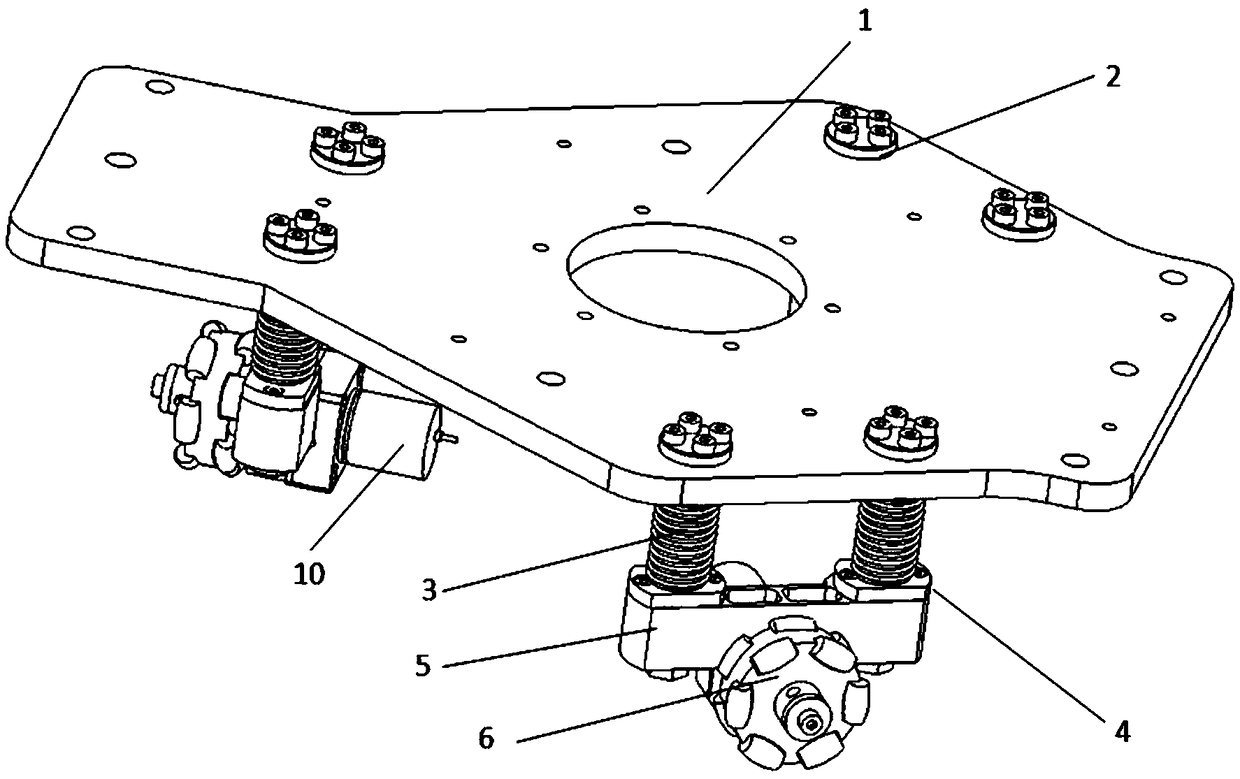

[0023] Such as figure 1 As shown, the positioning robot chassis includes a chassis 1 and 3 mutually independent shock absorbers, and the 3 shock absorbers are evenly distributed under the chassis with a circumferential direction of 120°.

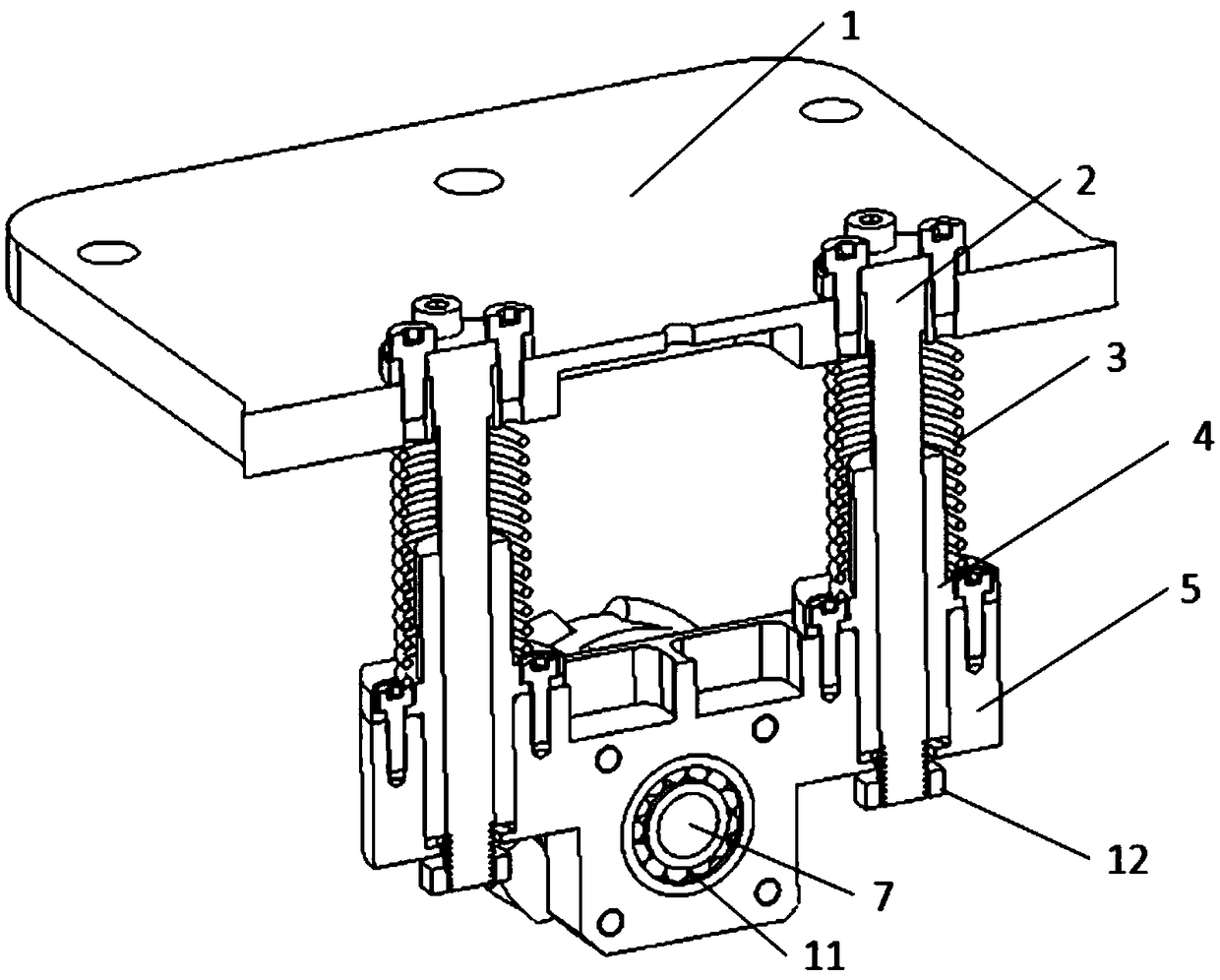

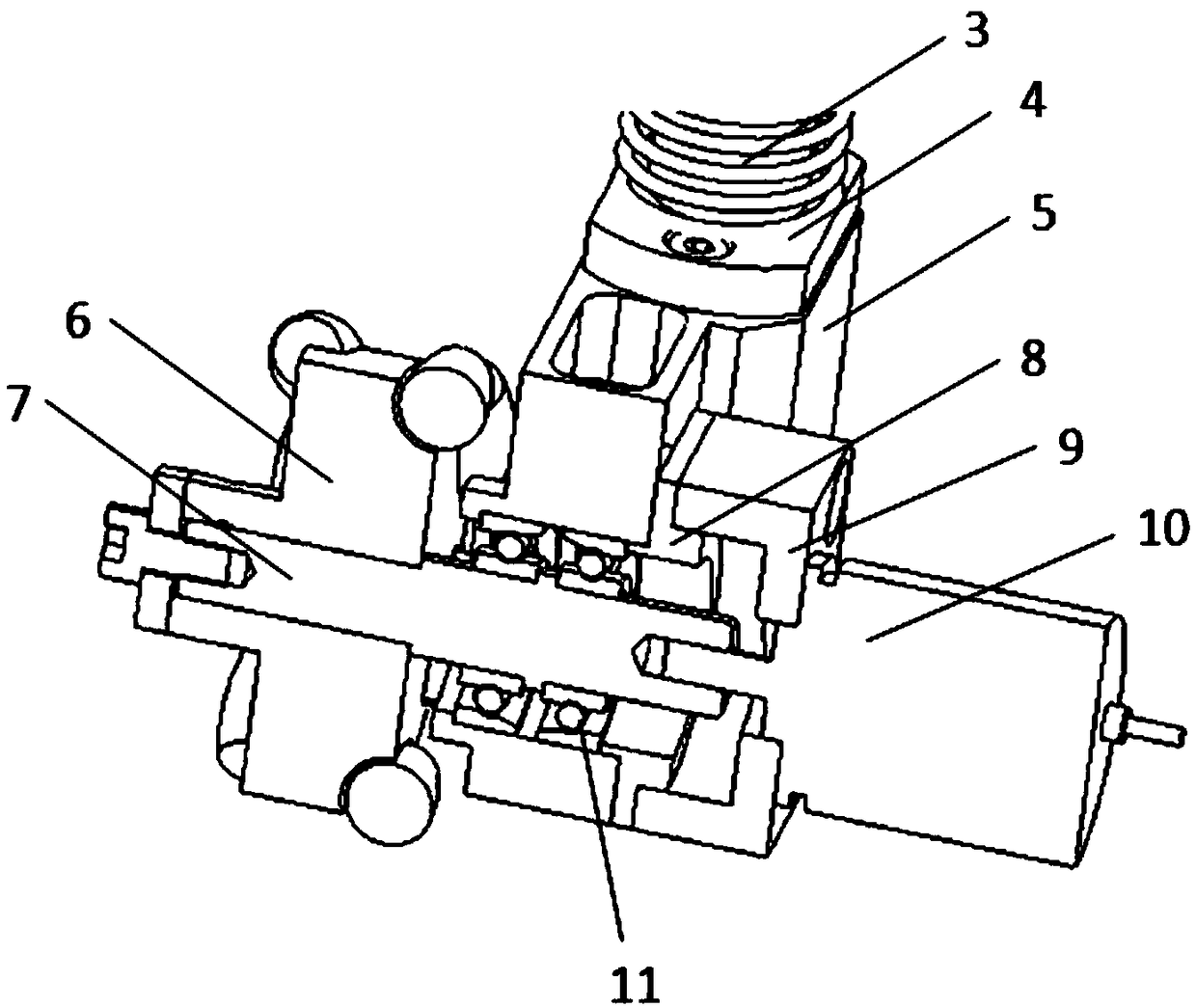

[0024] Such as figure 2 As shown, each damping device includes two guide rods 2, the guide rod 2 is provided with a stepped shaft, the chassis 1 is provided with 6 through holes, the stepped shaft is sleeved in the through holes provided on the chassis 1, and the guide rod 2 is fixedly connected with the chassis 1, the axis of the guide rod 2 is perpendicular to the plane of the chassis 1, the bottom end of the guide rod 2 is provided with a self-locking nut 12, and the bottom end of the guide rod 2 extends out of the through hole on the side of the bracket 5.

[0025] Such as figure 2 As shown, each damping device includes two linear bearings 4, the outer circle of the lower end of the flange of the linear bearing 4 is set in the steppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com