Self-compensating constant-force spring hanger

A constant force spring, self-compensating technology, applied in the field of supports and hangers, can solve the problems of high cost, large lateral size, and difficult layout of supports and hangers, and achieve the effects of reducing production costs, symmetrical force, and compact shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

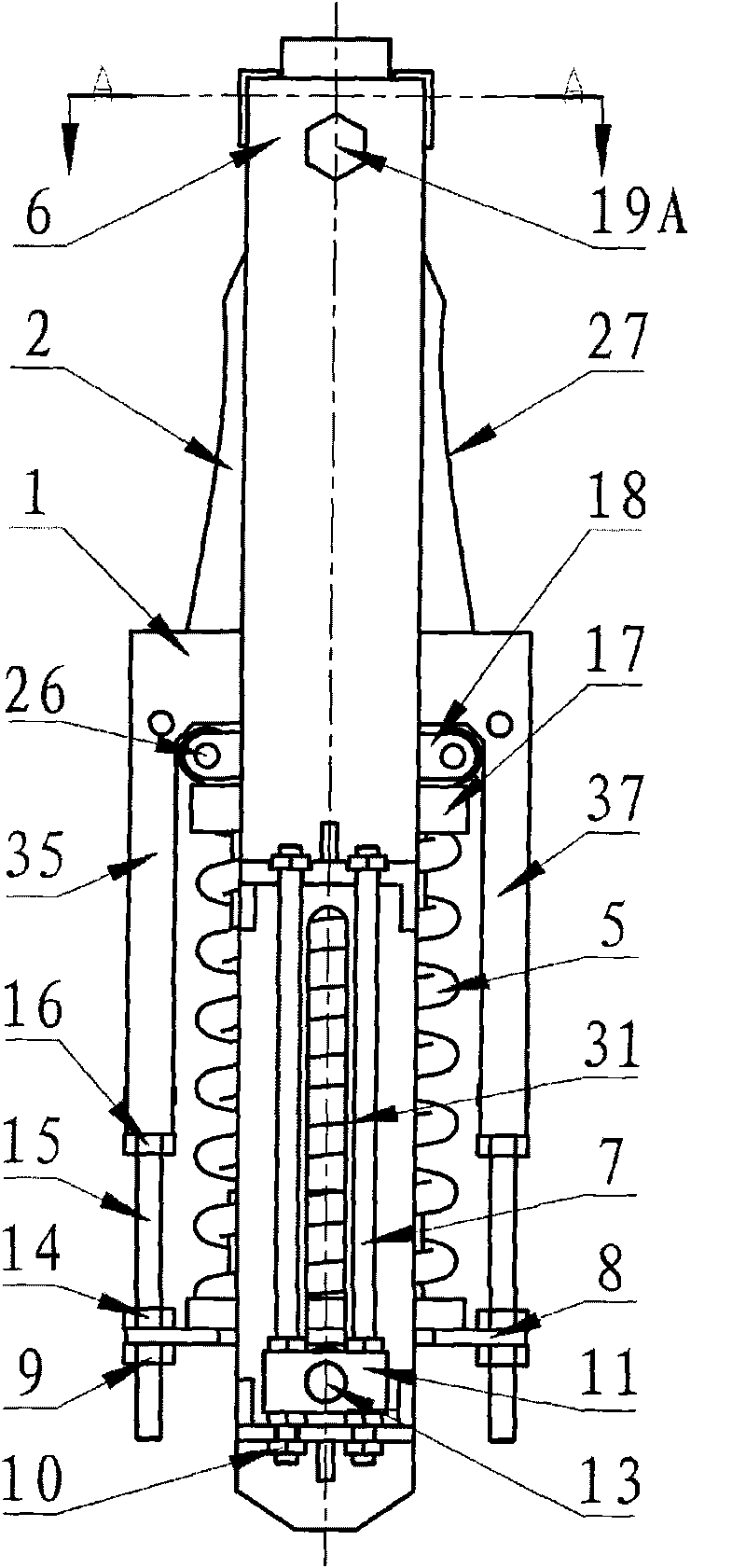

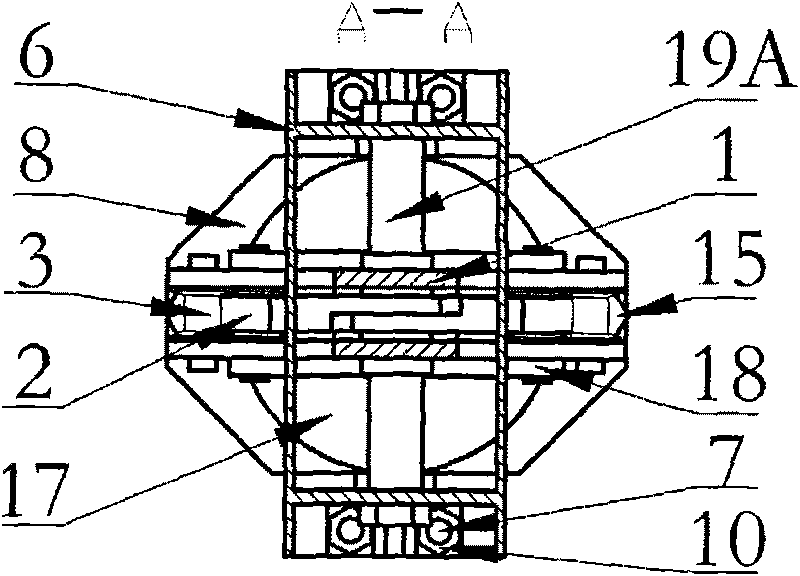

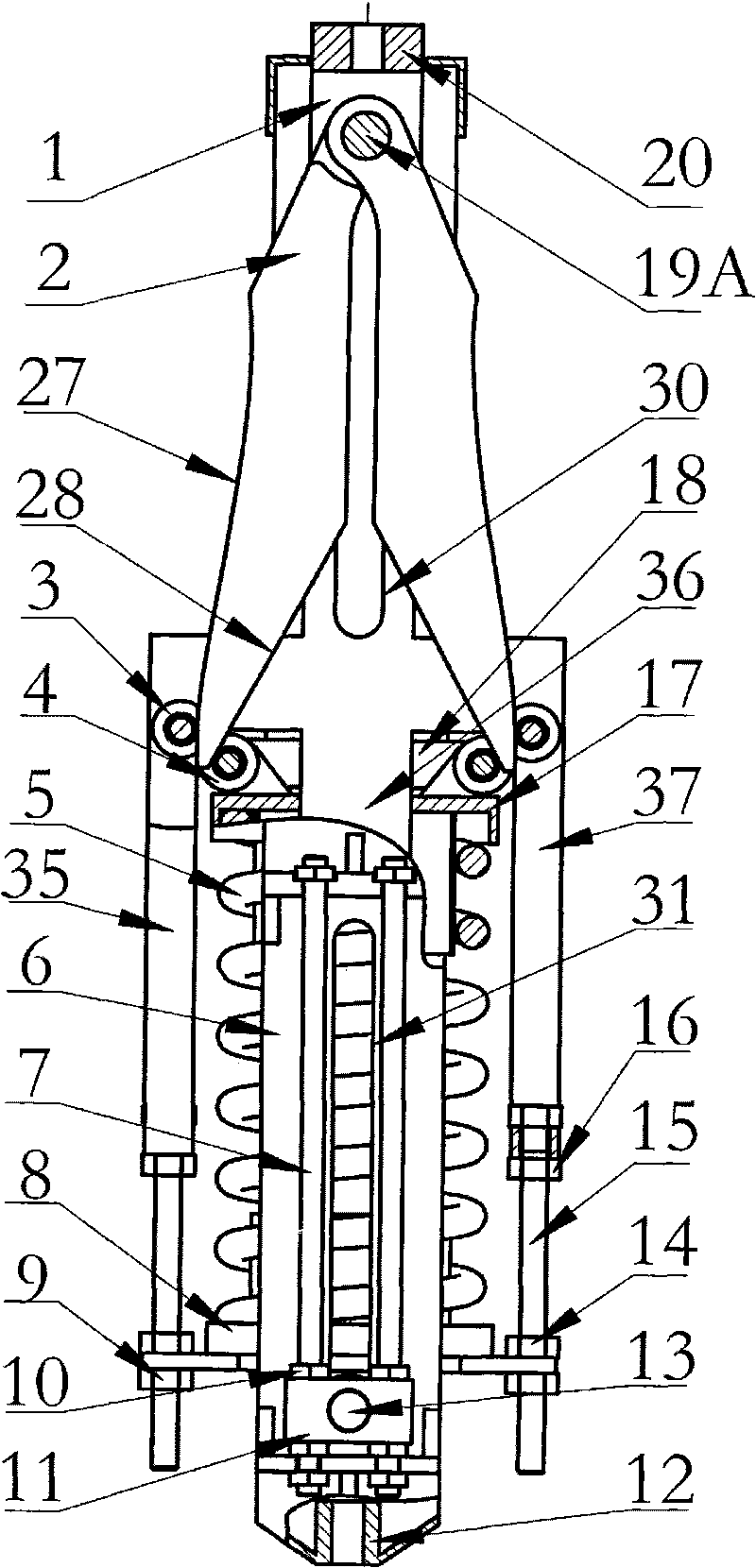

[0044] Such as figure 1 , figure 2 and image 3 As shown, this embodiment is mainly composed of a static frame 1, a cam 2, a static roller 3, a moving roller 4, a spring 5, a moving frame 6, a locking screw 7, a lower spring end cover 8, an adjusting nut 9, a locking nut 10, and a locking block. 11. Connecting nut 12, indicating pin 13, locking nut 14, adjusting bolt 15, locking nut 16, upper spring end cover 17, roller connecting rod 18, camshaft 19A, connecting nut 20, etc.

[0045] The moving frame 6 is mainly welded by two rectangular plates, and its overall structure and composition are symmetrical. The static frame 1 is located in the middle of the two symmetrical plates of the moving frame 6. The moving frame 6 has multiple functions: a camshaft is used on the top 19A is hinged with two cams 2, and the cam is formed with an inner working curve 28 and an outer working curve 27. The above two working curves cooperate with the moving roller 4 and the static roller 3 res...

Embodiment 2

[0052] Such as Figure 4 As shown, the overall structure, composition and working principle of the present embodiment are basically the same as those of the first embodiment, and the supporting method is also the same as that of the first embodiment: the static frame 1 is hung on the external support structure through the suspender 39 and the locking nut 38 , the moving frame 6 is connected to the pipeline and equipment through the suspension rod 23 and the lock nut 24 . There are mainly two differences: first, the two cams 2 of this embodiment are not coaxial, and are hinged on both sides of the moving frame 6 with a camshaft 19B respectively. Another guide shaft 21 is installed between 19B; the second, the outer working curve 27 of the cam is a straight line reference curve, and the inner curve 28 is a calculation curve.

Embodiment 3

[0054] Such as Figure 5As shown, the overall structure, composition, supporting mode and working principle of the present embodiment are basically the same as those of the second embodiment, and there are two main differences: first, the two camshafts 19B of this embodiment are placed between the moving roller 4 and the static roller. Below the gap of the roller 3, when the camshaft 19 moves downward, the cam 2 is "drawn out" from the gap between the driven and static rollers 4 and 3, rather than "inserted". This design can reduce the longitudinal dimension; Two, the outer working curve 27 of the cam 2 is a curve, while the inner curve 28 is a straight line reference curve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com