Longitudinal vibration sandwiched transducer-based piezoelectric ultrasonic driver and application method thereof

A piezoelectric ultrasonic and transducer technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve complex structure design, mode degeneracy, difficult Realize mass production and other issues, and achieve the effect of simple structure, degenerate mode and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

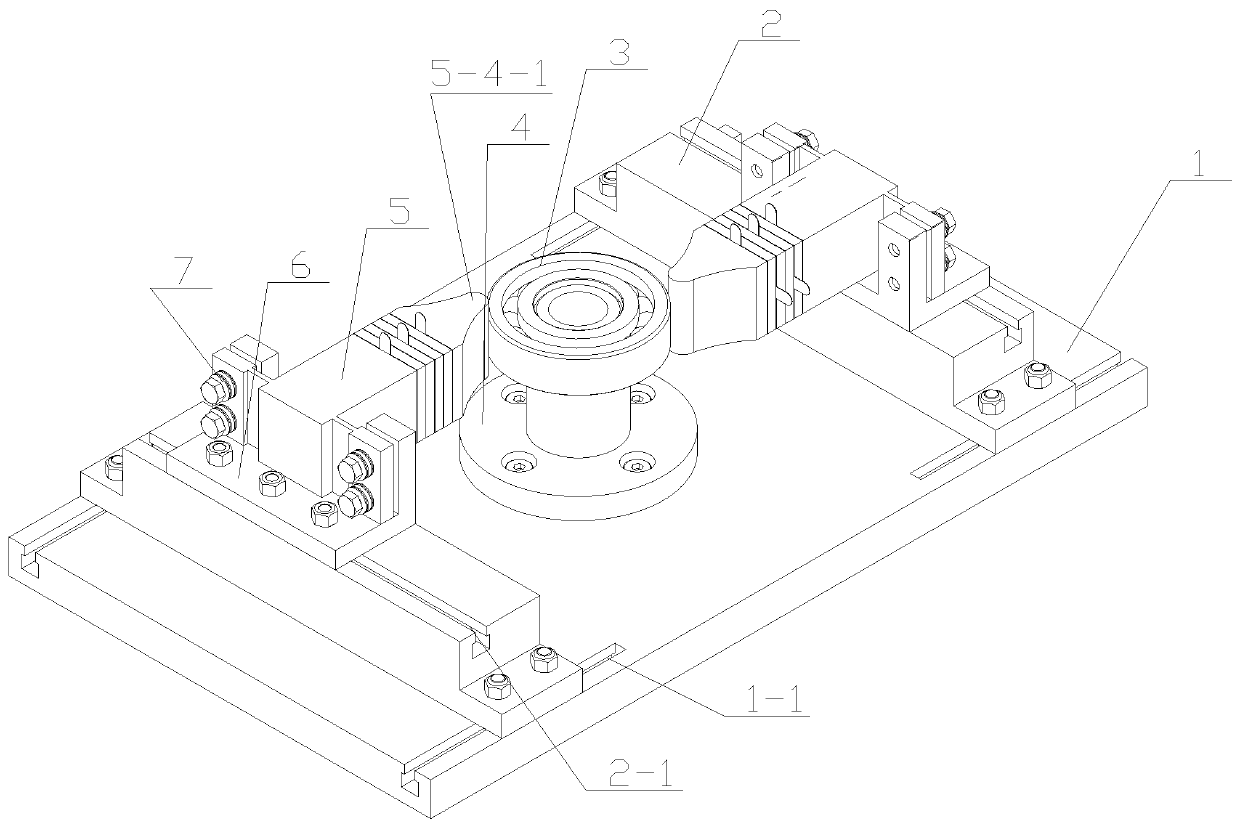

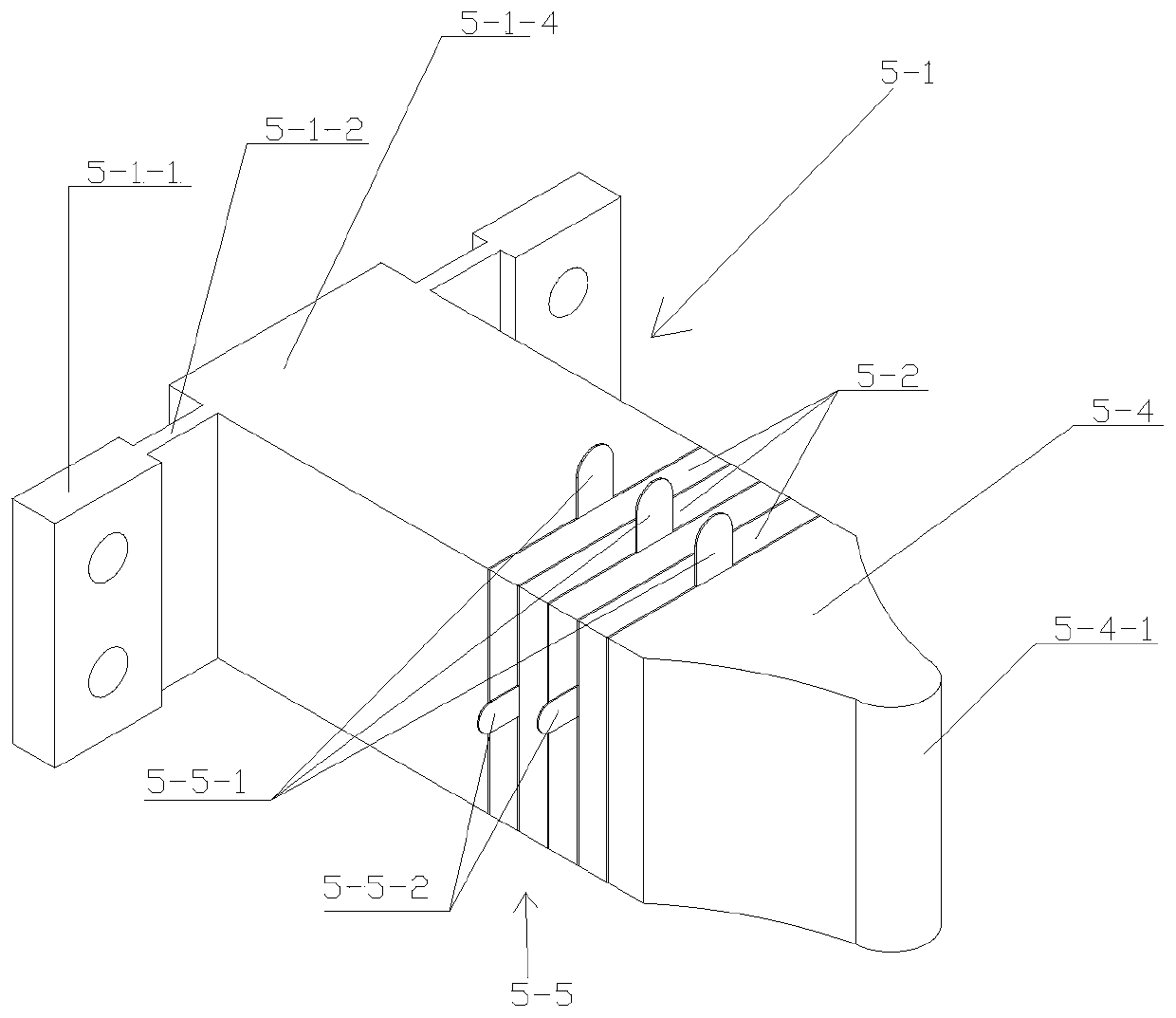

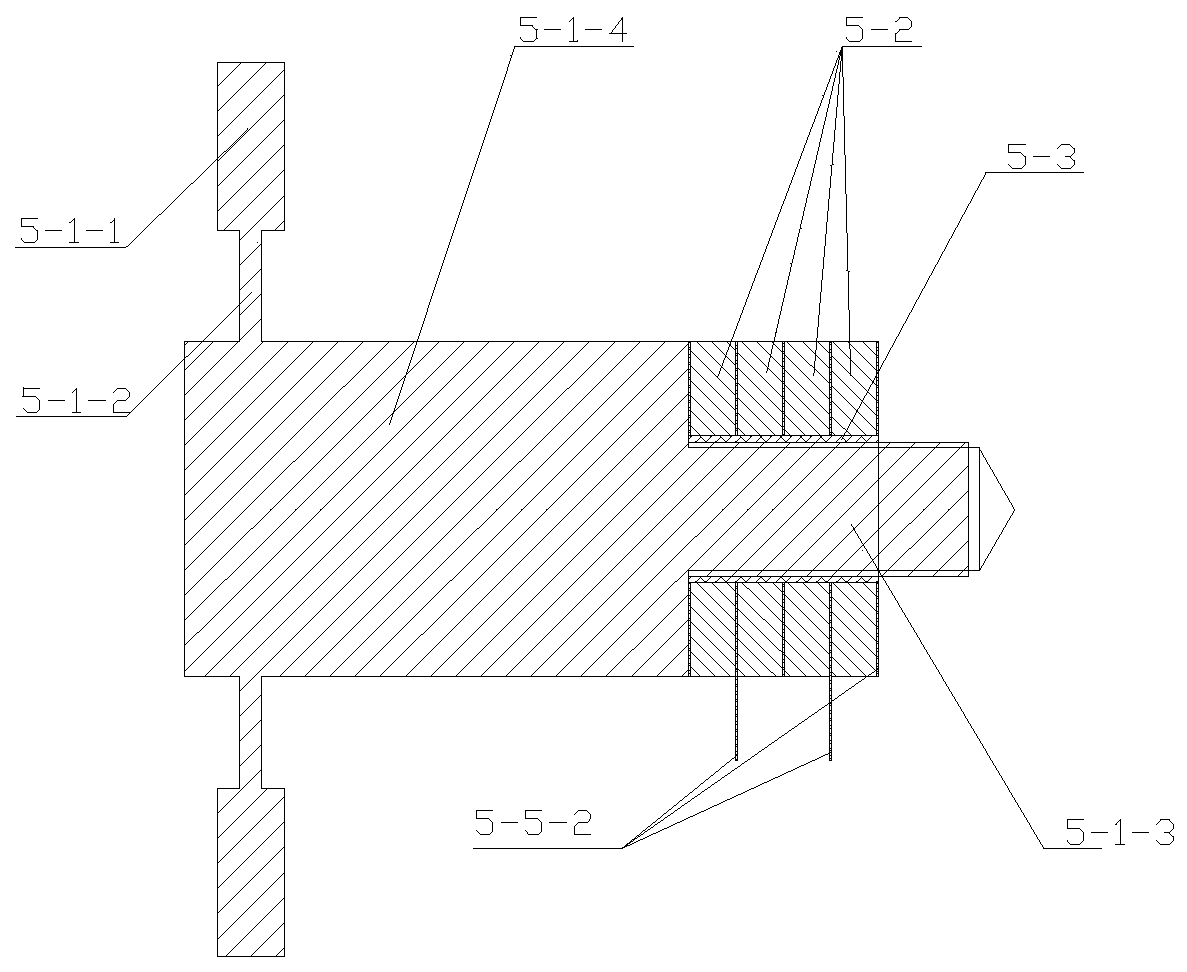

[0047] like figure 1 As shown, the present invention includes a horizontally arranged base 1, two adjustment seats 2 symmetrically installed on the base 1 and arranged along the width direction of the base 1, a stator mechanism installed on the adjustment base 2, and a stator mechanism installed on the base 1 and The rotor 3 is located between the two adjustment bases 2, the base 1 is provided with a flange shaft 4 for the installation of the rotor 3, the stator mechanism includes two longitudinal vibration sandwich transducers 5, and the two longitudinal vibration The sandwich transducer 5 is arranged rotationally symmetrically about the axis of the flange shaft 4;

[0048] The adjustment base 2 can move close to or away from the rotor 3 along the length direction of the base 1. The adjustment base 2 is provided with a transducer fixing device for installing the longitudinal vibration sandwich transducer 5 and moving along the length direction of the adjustment base 2. Seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com