Double-R supporting structure of injection molding machine

A technology of support structure and injection molding machine, applied in the field of support structure of injection molding machine, can solve the problems of increased wear of the support device and the rail surface of the rack, affecting the quality of plastic parts in the mold clamping state, and inability to compensate for the bending deformation of the fixed template. The effect of uniform force, simple structure and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

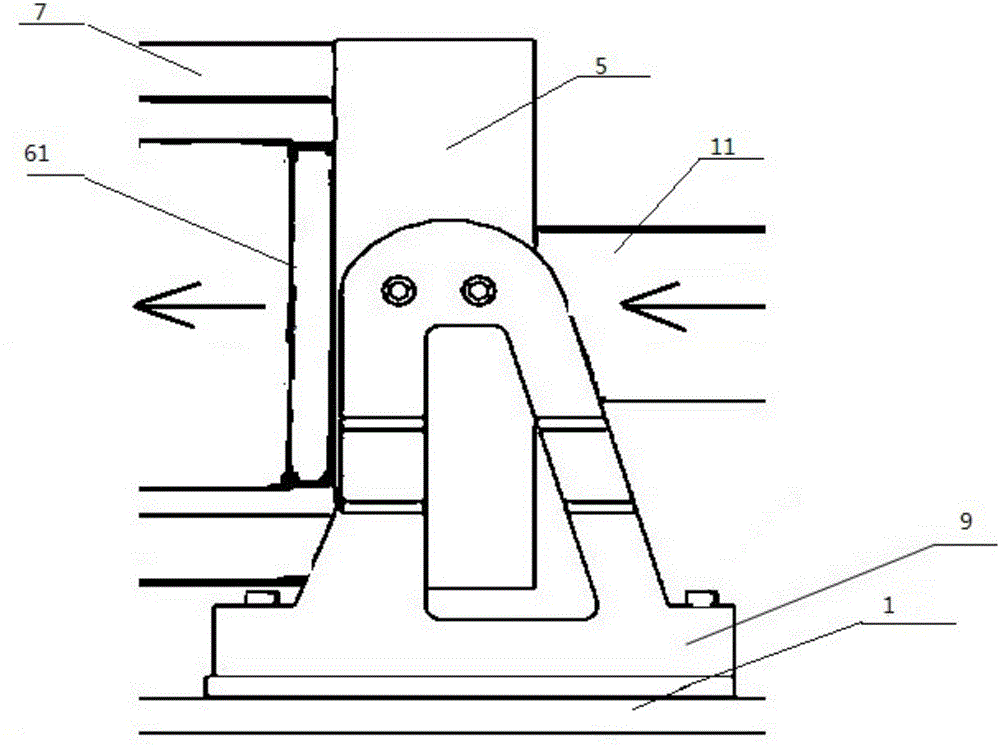

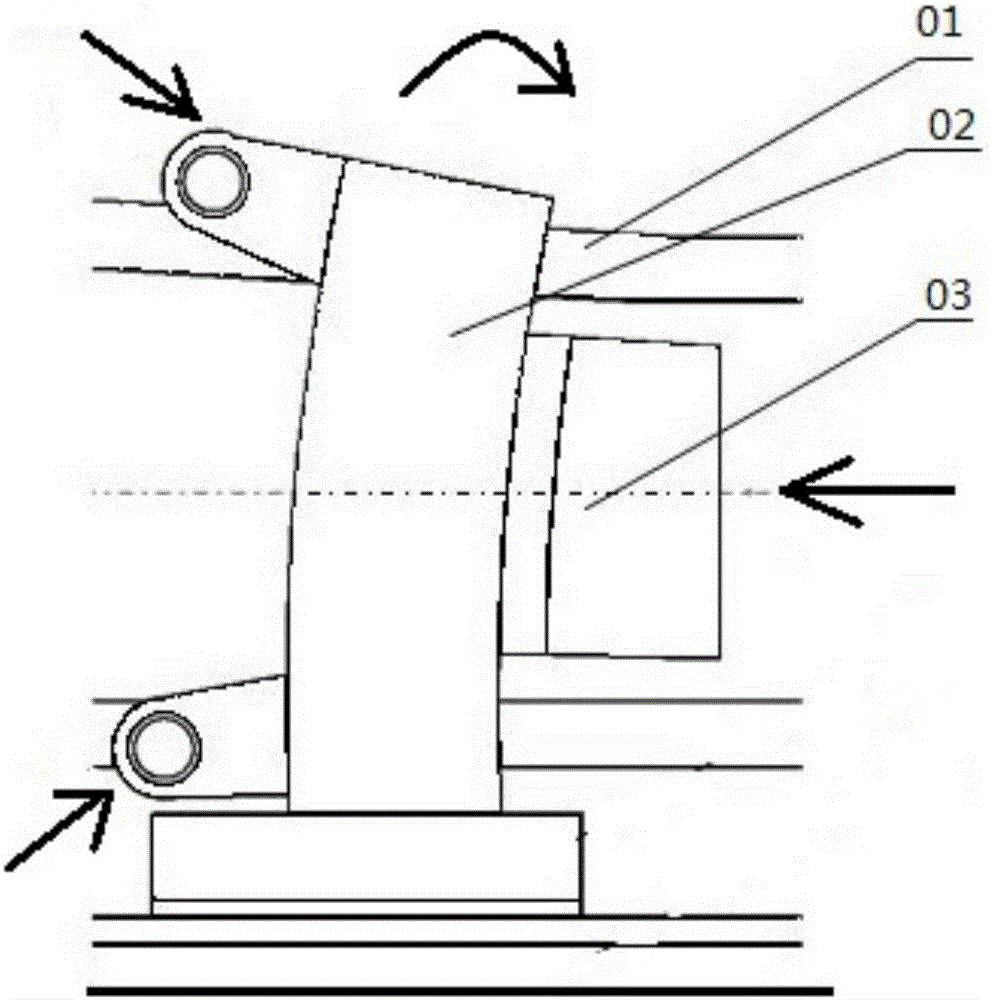

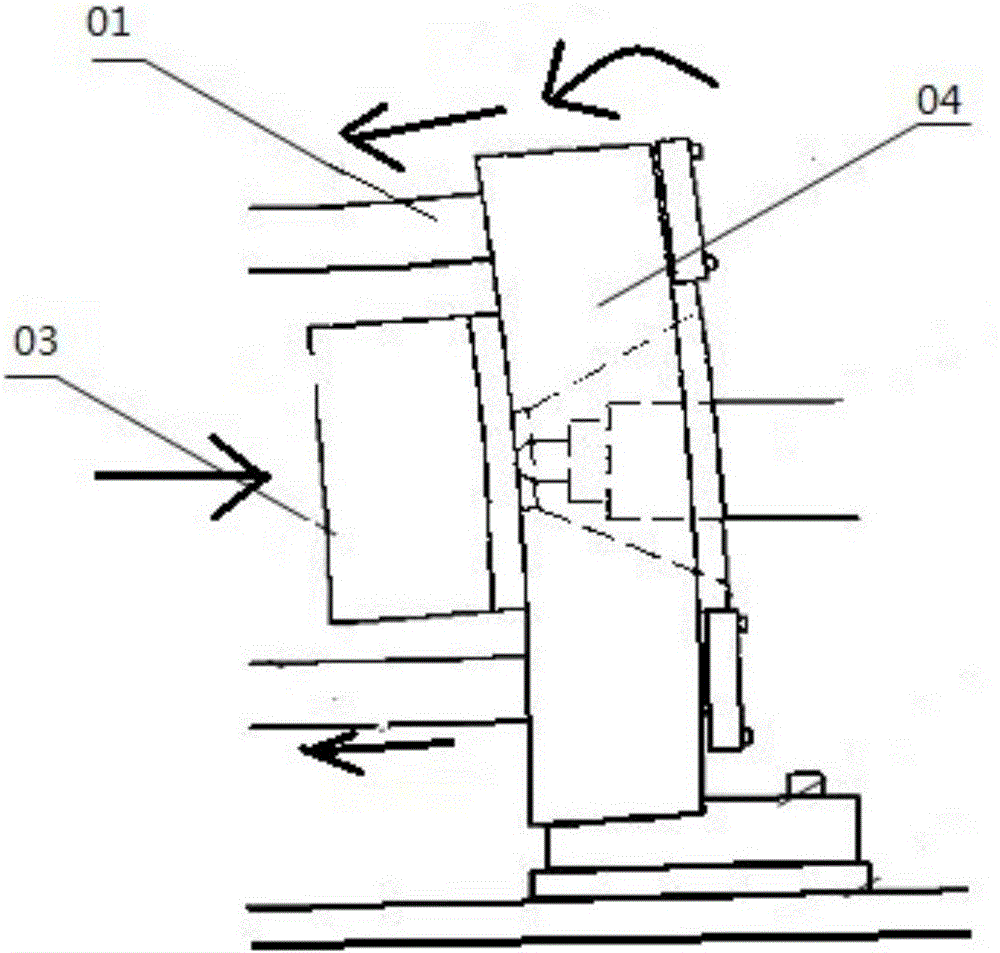

[0035] Embodiment: A double R support structure for an injection molding machine, including a base 1, two linear guide rails 2, several sliders 3, a moving template 4, a fixed template 5, a mold 6, and four Corinthian pillars 7 , one end of the Corinthian column is positioned on the fixed formwork, the other end passes through the mobile formwork, the mobile formwork can move on the Corinthian column, and the mold is installed on the mobile formwork and the fixed formwork Between the templates, the linear guide rail is fixed on the base, the slider is slidably positioned on the linear guide rail, and a reverse R-shaped support block 8 is respectively fixed on both sides of the mobile template symmetrically. A positive R-shaped support block 9 is fixed symmetrically to each other on both sides of the formwork, the reverse R-shaped support block is reverse R-shaped, the positive R-shaped support block is positive R-shaped, and the bottom of the reverse R-shaped support block is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com