Patents

Literature

36results about How to "Improve injection precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

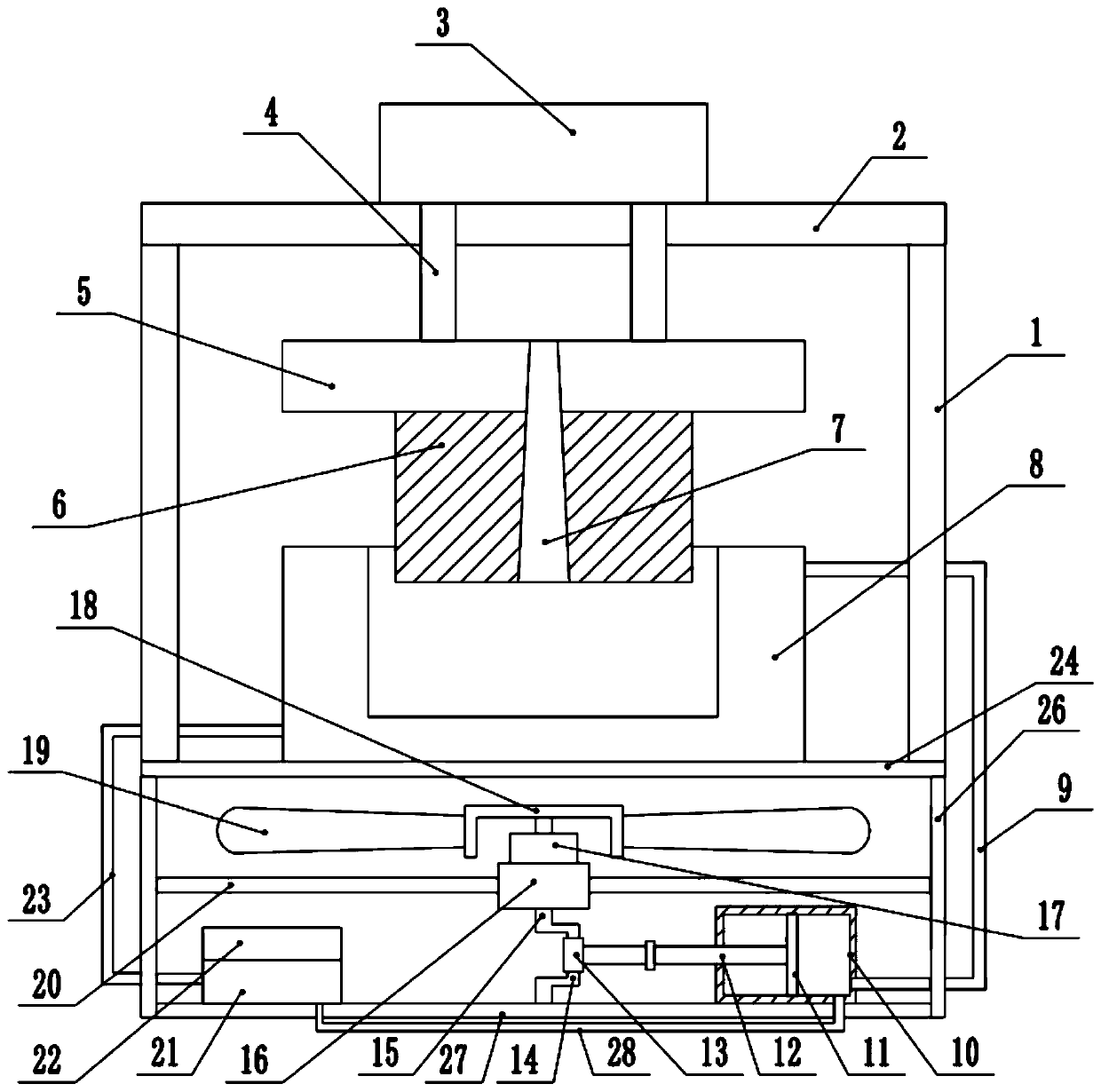

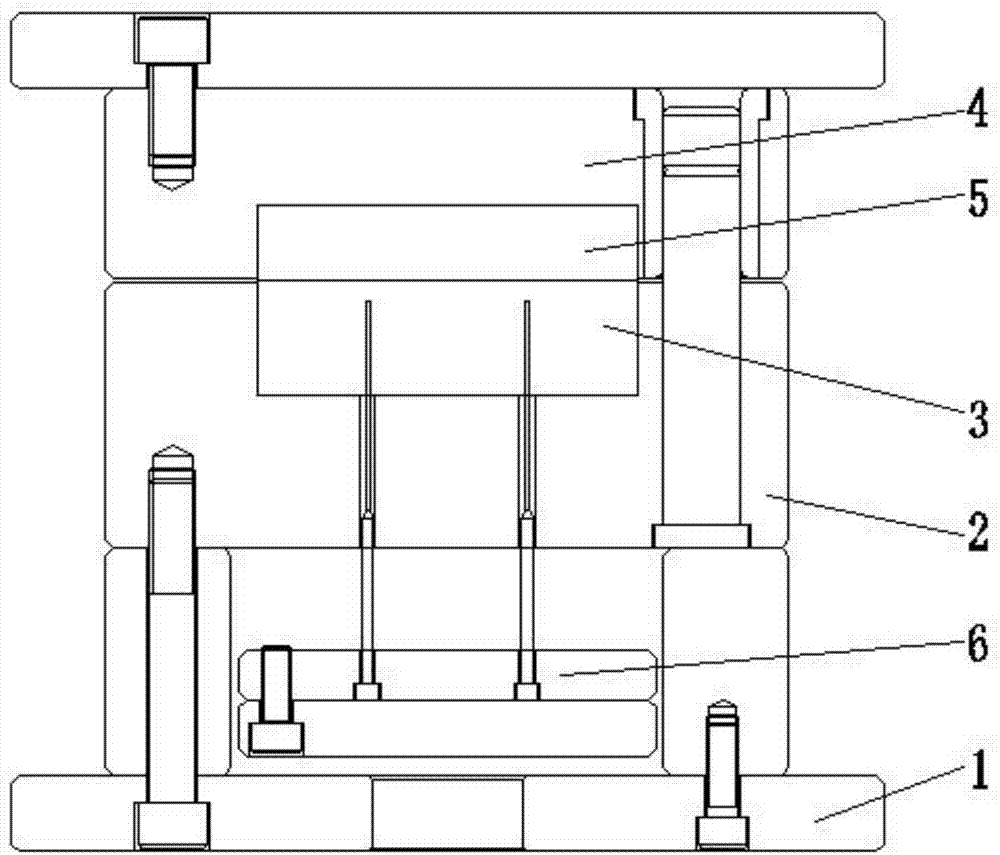

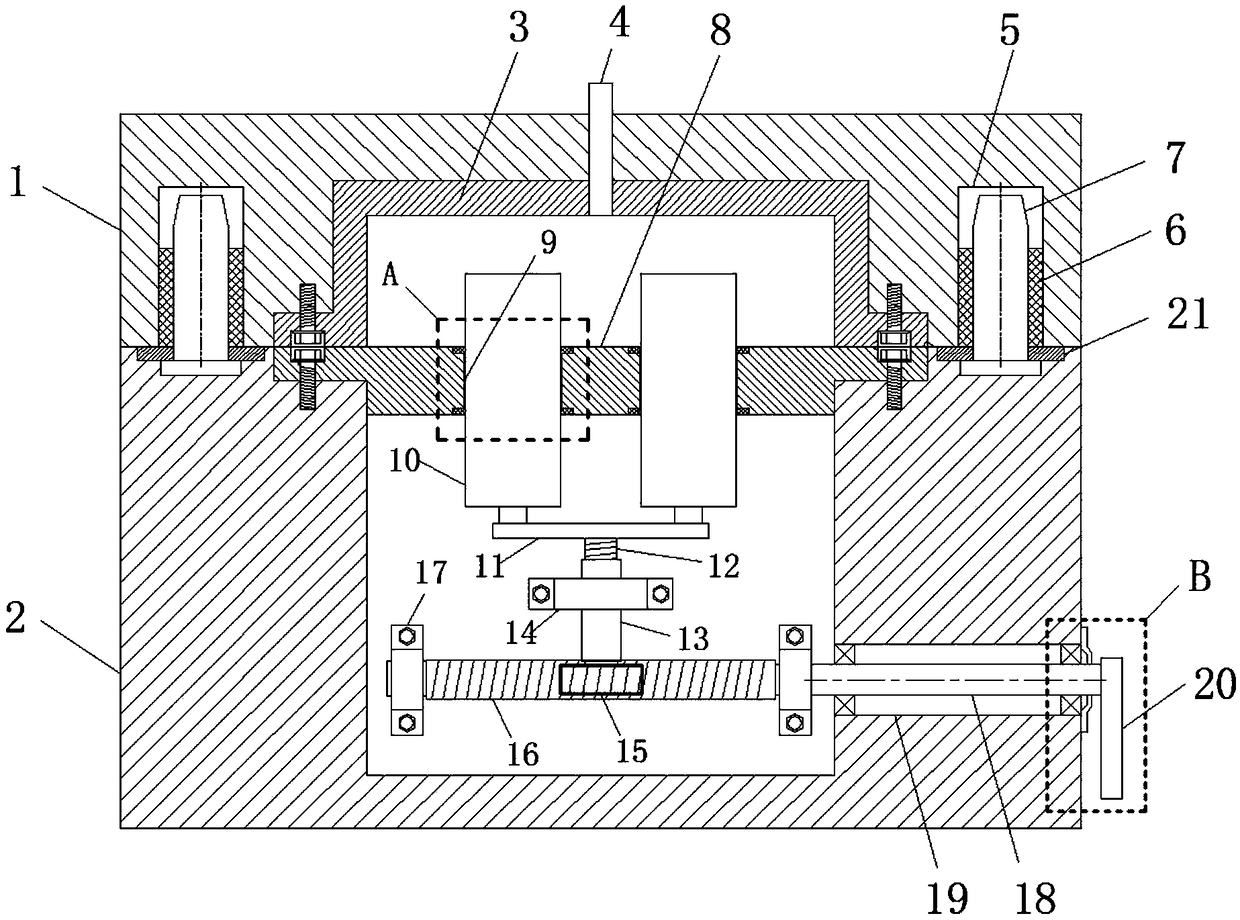

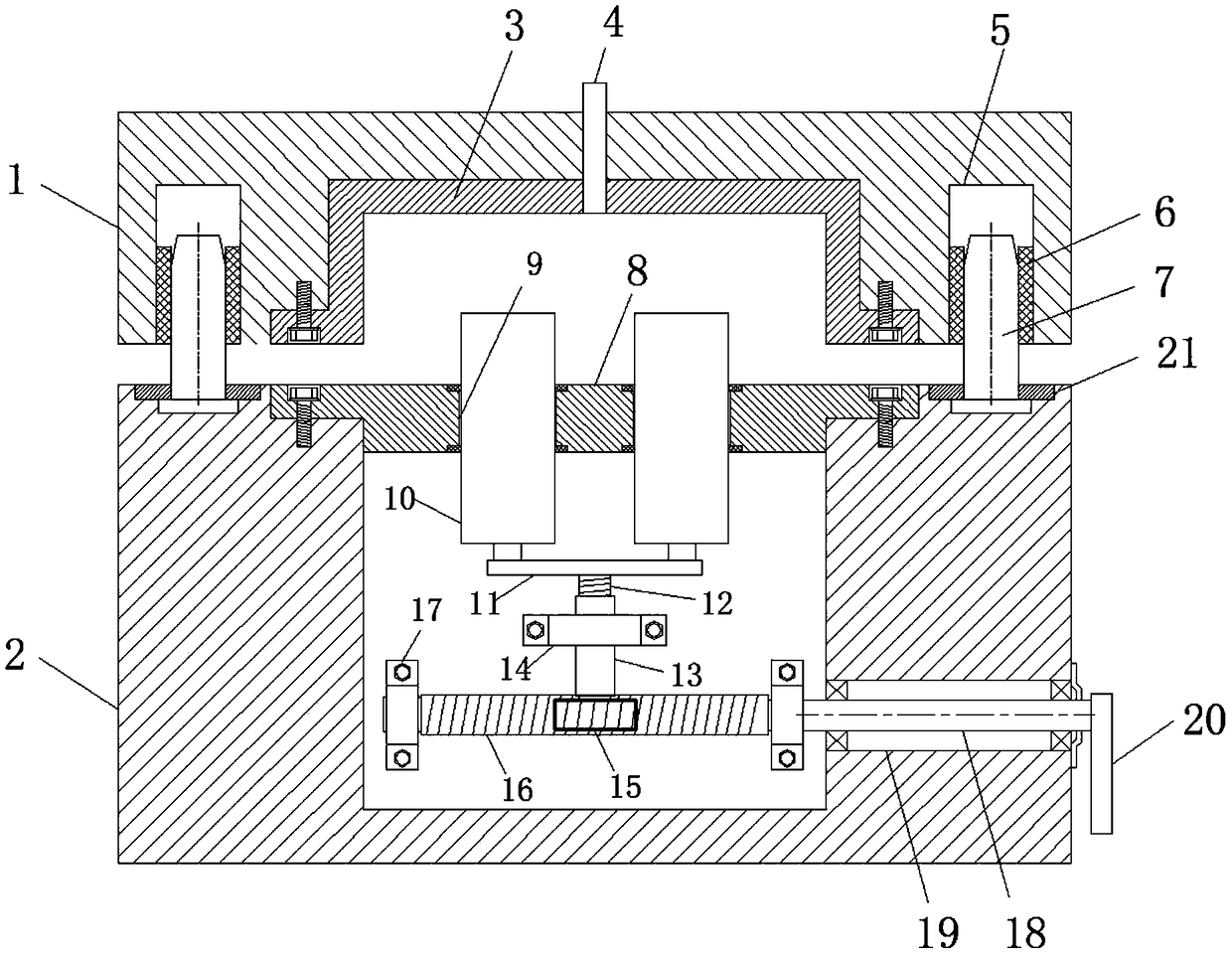

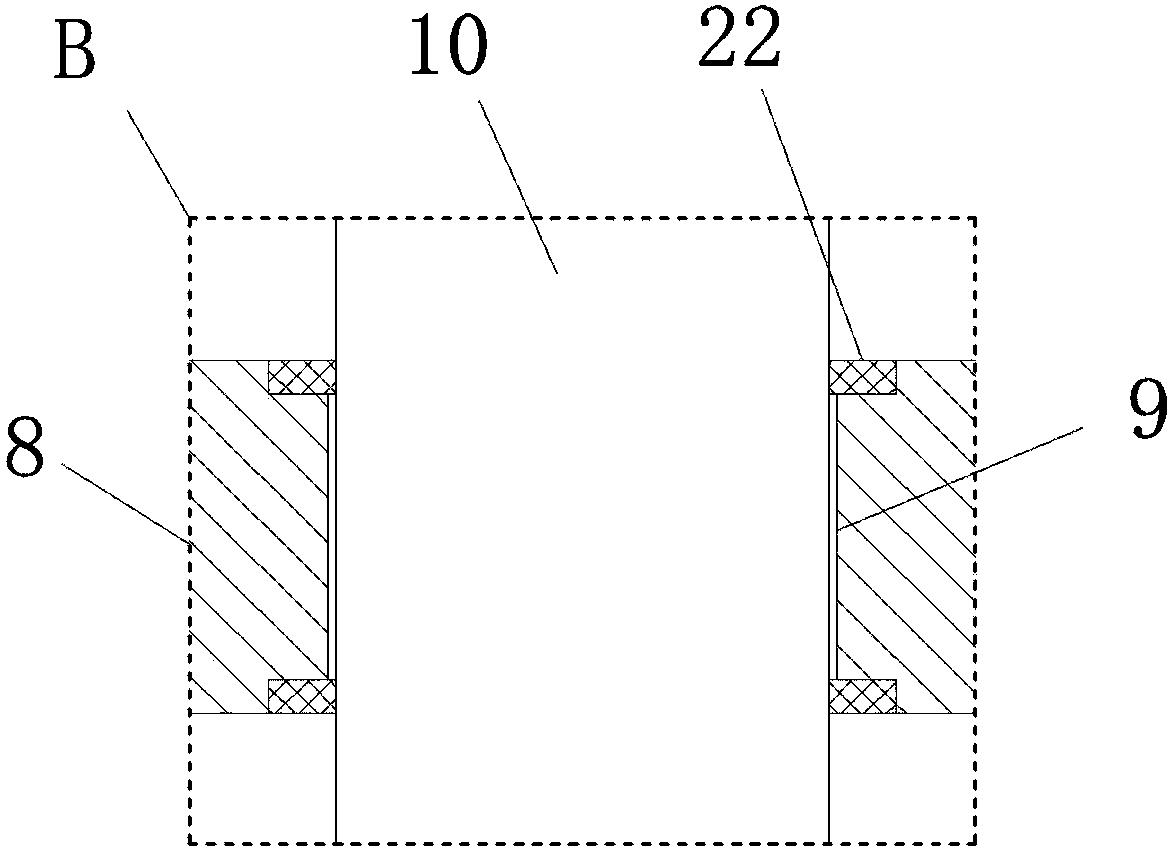

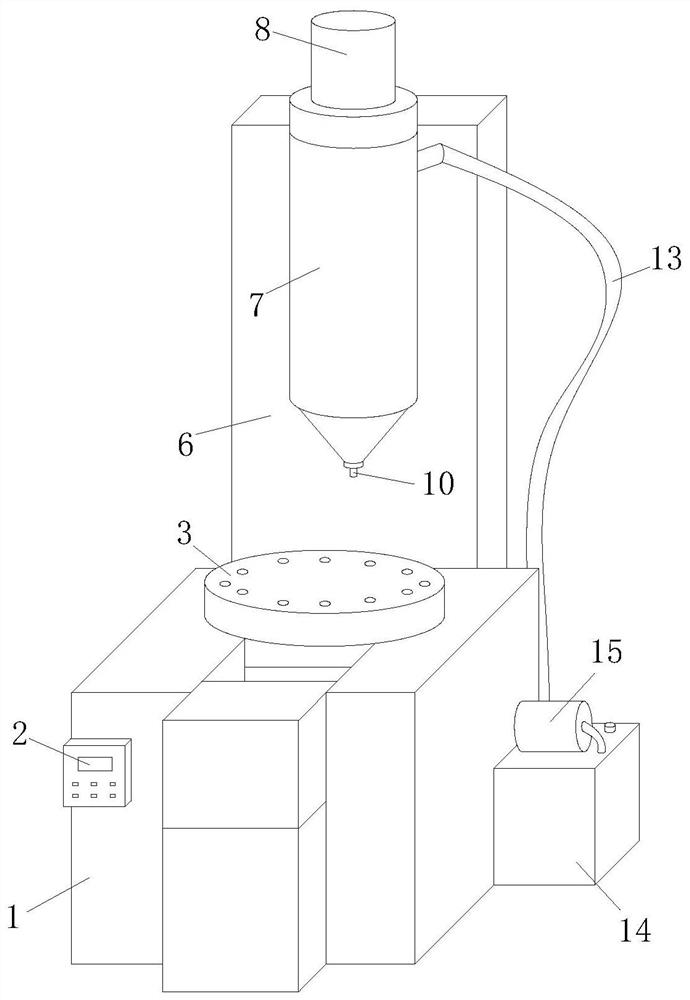

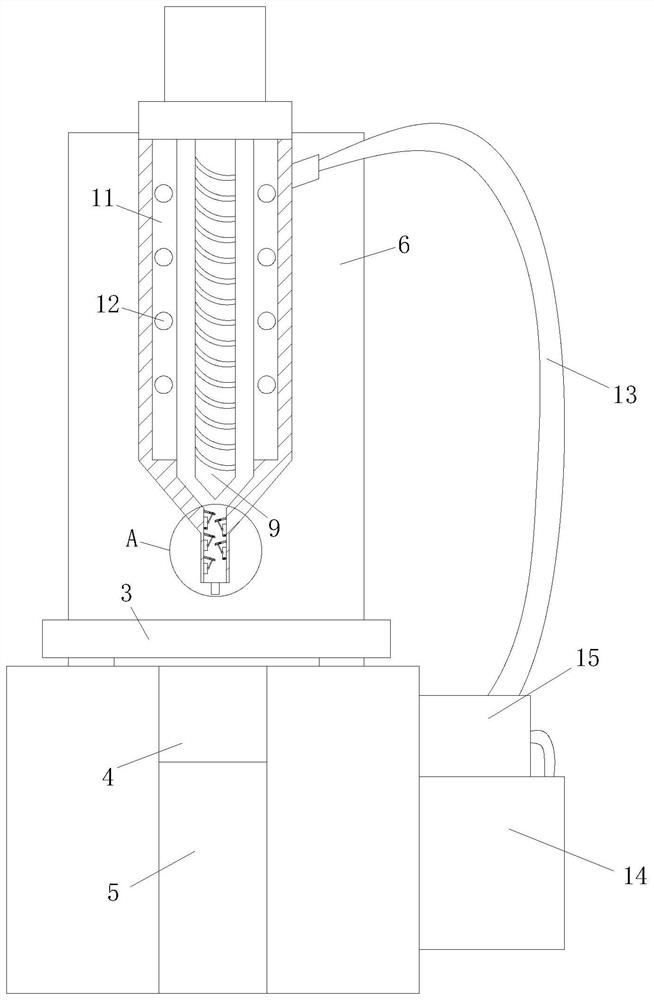

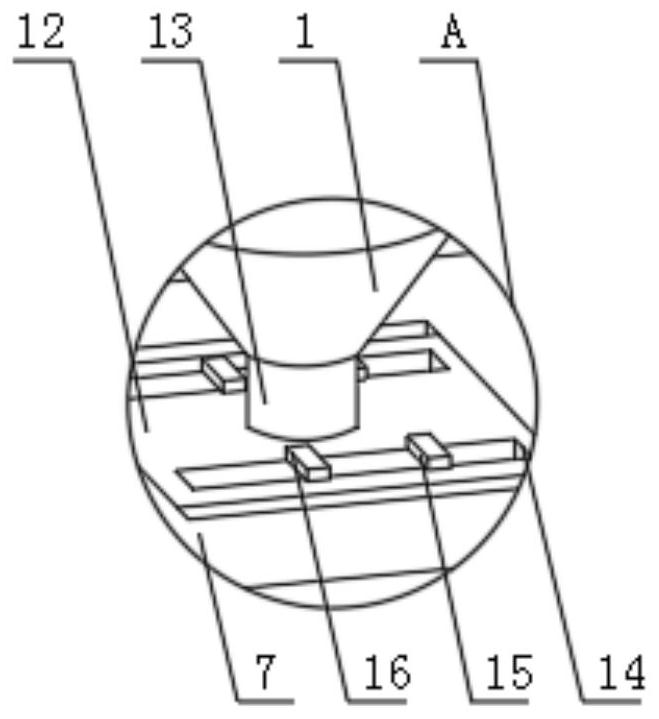

Rapid cooling type injection molding device

The invention relates to the technical field of injection molding equipment, and discloses a rapid cooling type injection molding device. The rapid cooling type injection molding device comprises a supporting frame, a top plate is installed at the upper end of the supporting frame, a power piece is installed at the upper end of the top plate, a power shaft is installed at the lower end of the power piece, a mold base is installed at the bottom end of the power shaft, an upper mold is installed at the lower end of the mold base, a supporting plate is installed at bottom end of the supporting frame, a lower mold is installed in middle of upper end of supporting plate, fixing frames are installed on the two sides of the lower end of the supporting plate, a limiting plate is installed betweenthe middles of the fixing frames, a motor base is installed in the middle of the limiting plate, a driving motor is installed at the upper end of the motor base, a driving shaft is installed at the upper end and the lower end of the driving motor, a blade base is installed at the upper end of the driving shaft, rotating blades are installed at two ends of the blade base, the middle of the lower end of driving shaft is provided with a crank, and the middle of the crank is provided with a sliding sleeve. According to the rapid cooling type injection molding device, distribution of refrigeratingfluid among a piston cavity, a refrigerating box and the lower mold is achieved, the refrigerating effect during injection molding is achieved, meanwhile, rapid cooling is further achieved, and the injection molding precision is greatly improved.

Owner:廖素英

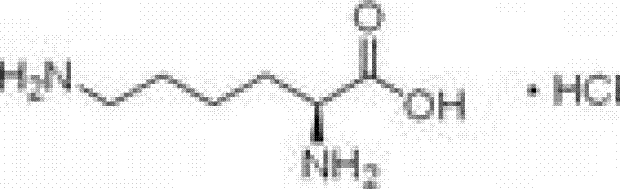

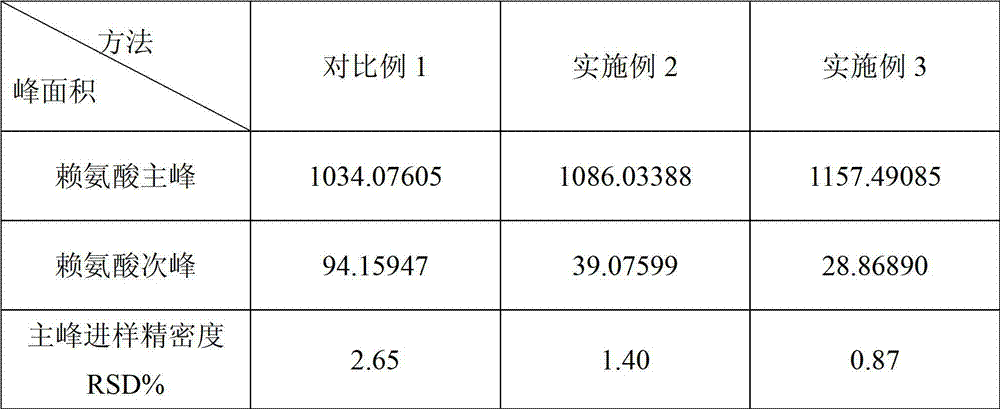

Content detection method for lysine of compound ketoacid tablet

InactiveCN103048407ASolve the double peak problemImprove injection precisionComponent separationBimodalityBORATE BUFFER

The invention relates to a content detection method for lysine of a compound ketoacid tablet, which comprises the following steps: preparing an o-phthalaldehyde reaction liquid (OPA reagent) with the concentration of 10 mg / ml, wherein 2-3 percent (v / v) of 3-thiohydracrylic acid is contained; afterwards, mixing lysine and the reaction liquid at ratio of 1:1(v / v) in a borate buffer system with a pH valve of 10.2 plus or minus 0.1 through an automatic pre-column derivation method, and then carrying out ambient temperature reaction; and finally, adopting a high performance liquid chromatography to measure the content of the lysine at 338 nm. The method provided by the invention can effectively solve the problem that bimodality of the lysine occurs in the current OPA pre-column derivation method, improves the sample introduction precision of the lysine in the detection through the automatic pre-column derivation method, greatly shortens the detection time, and is particularly suitable for detecting the content of the lysine of amino acid samples in a laboratory.

Owner:SHANGHAI JINGFENG PHARMA

Injection molding device for processing educational toy

The invention discloses an injection molding device for processing an educational toy. The injection molding device comprises an injection molding machine body and a collecting bucket, wherein one side of a limiting block is provided with a first telescopic mechanism, the other side of the limiting block is provided with a second telescopic mechanism, a quantitative injection mechanism is fixedlymounted on the top of a fixing base, the collecting bucket is fixedly mounted on the top end of a connecting pipe, and a driving scraping mechanism is embedded and installed inside the collecting bucket. The injection molding device is provided with the quantitative injection mechanism, and quantitative water sources can be injected into the collecting bucket, so that the viscosity of materials attached to the collecting bucket is guaranteed, and the injection precision of the materials is improved; the driving scraping mechanism is arranged, the materials attached to the inner wall of the collecting bucket can be effectively scraped off, waste of the materials is reduced, and the production cost is reduced; and through combination of the first telescopic mechanism and the second telescopic mechanism, a user can conveniently and quickly install and detach the collecting bucket, and the user can conveniently overhaul and wash the inside of the collecting bucket in real time.

Owner:狼伙伴(苏州)影视产业有限公司

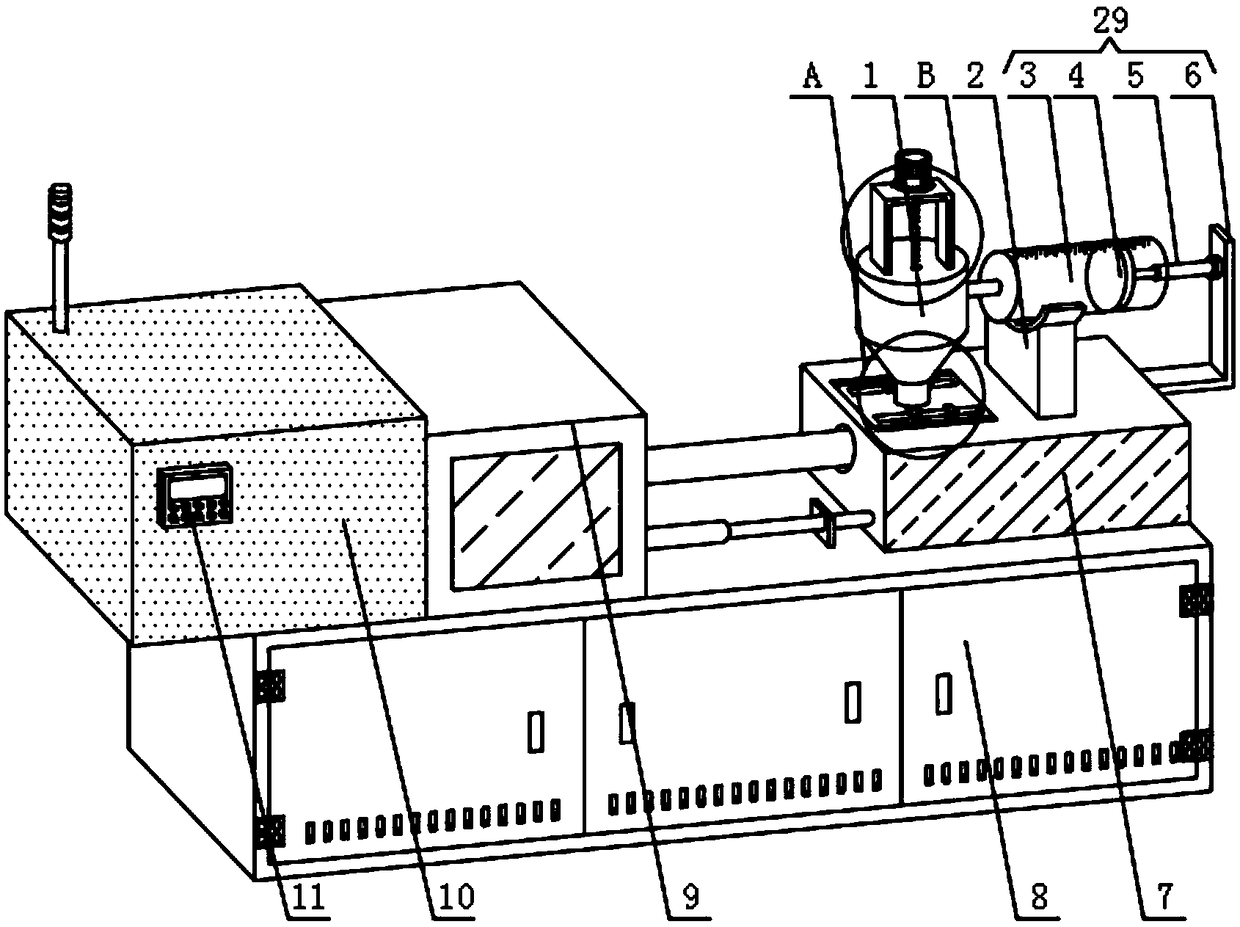

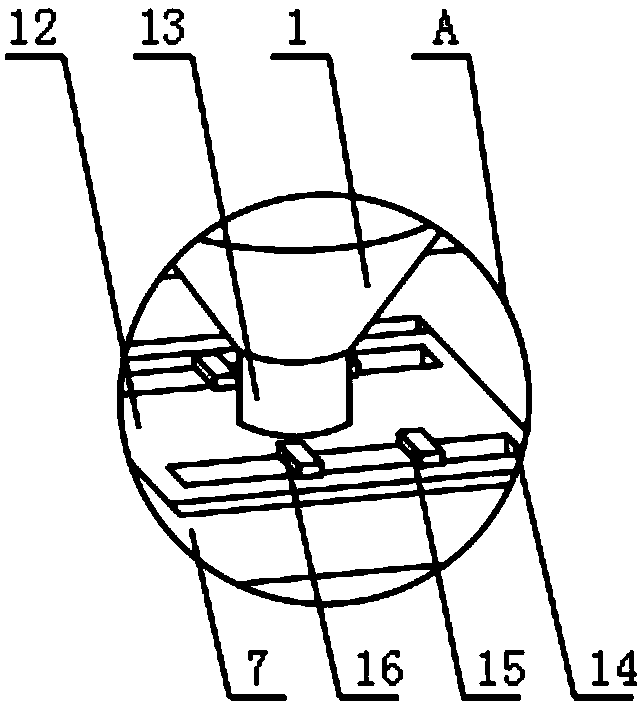

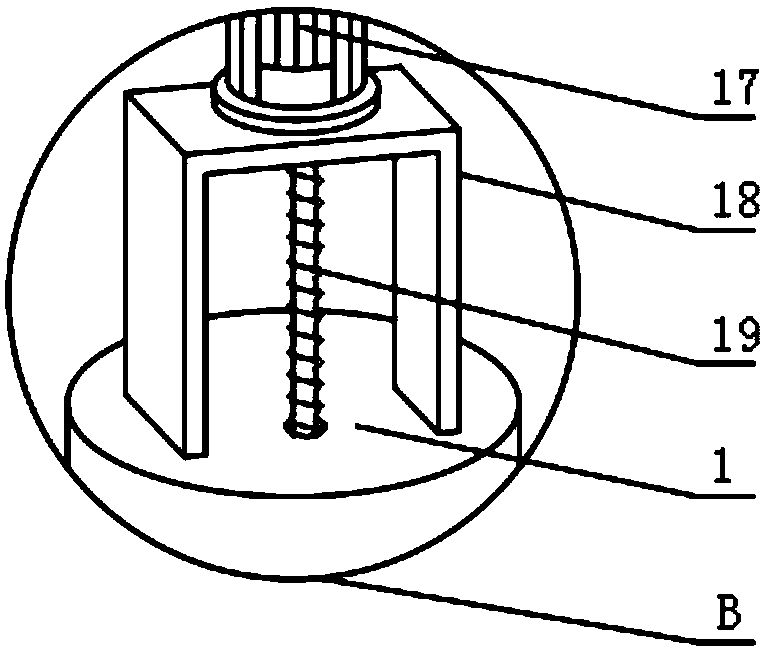

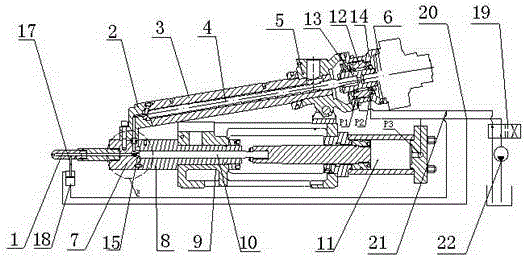

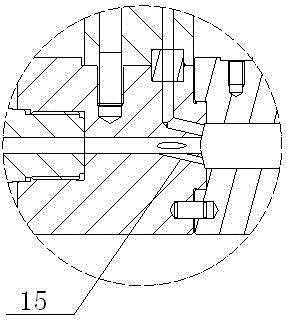

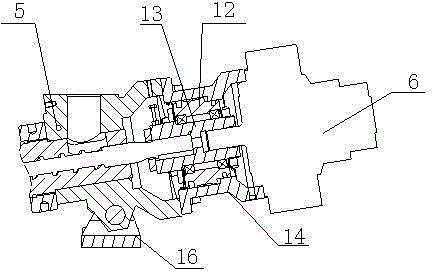

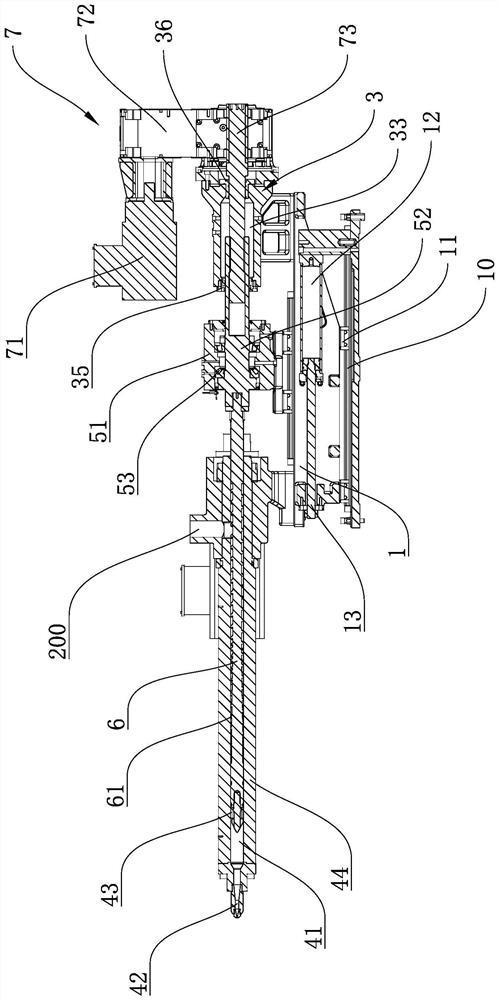

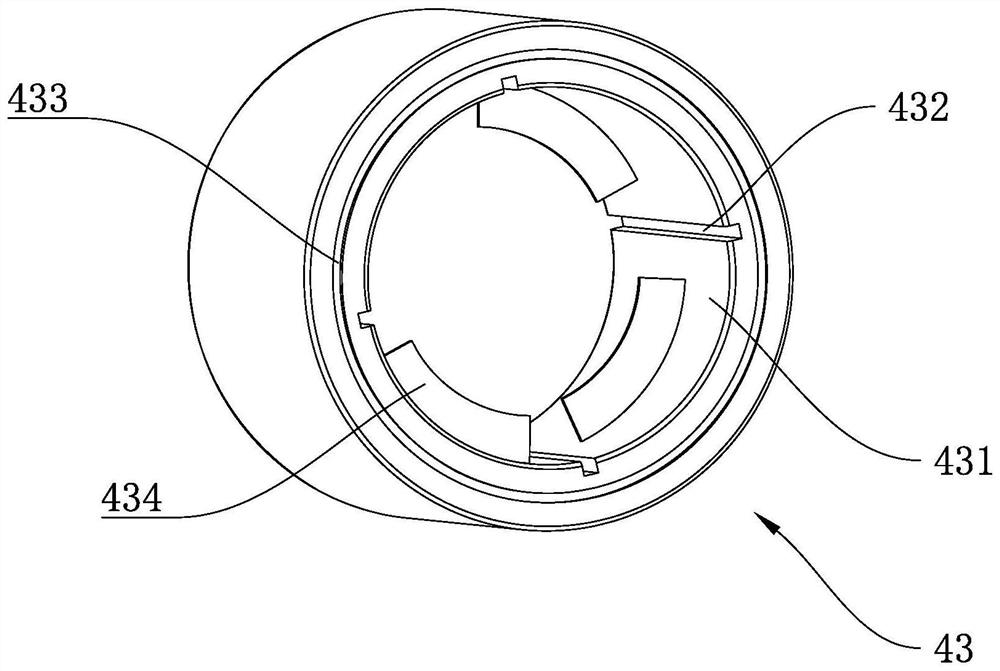

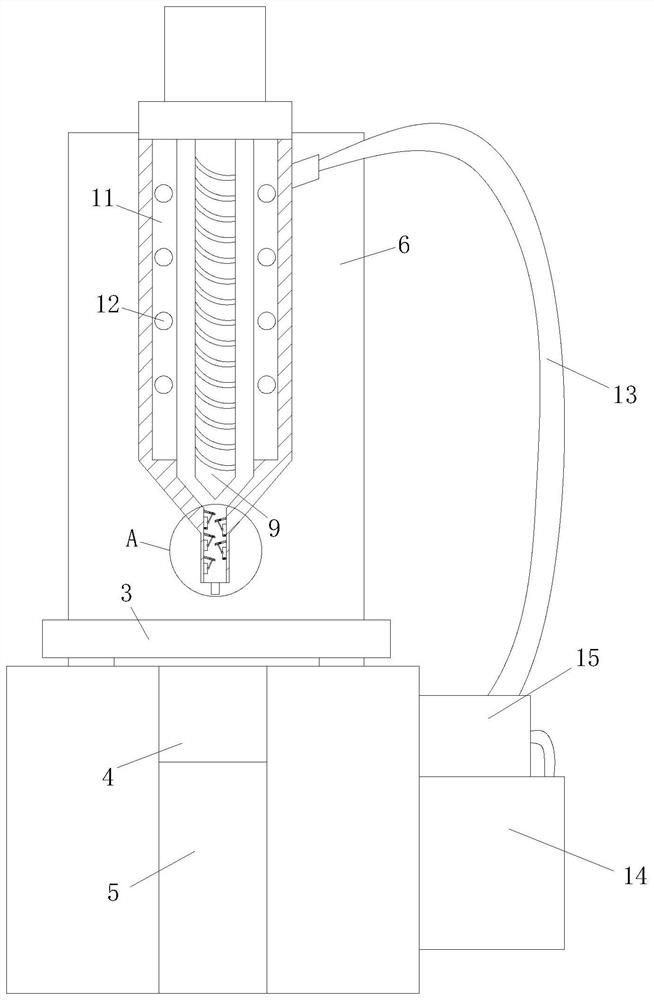

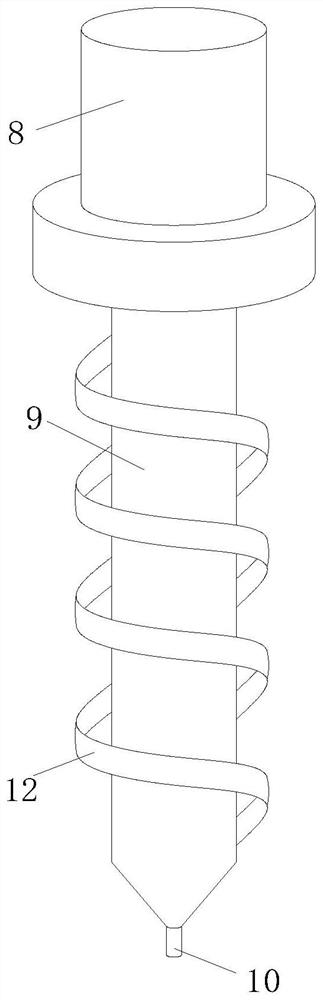

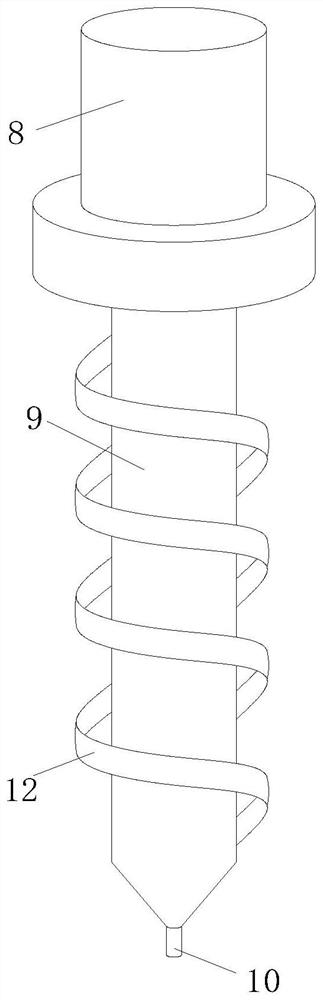

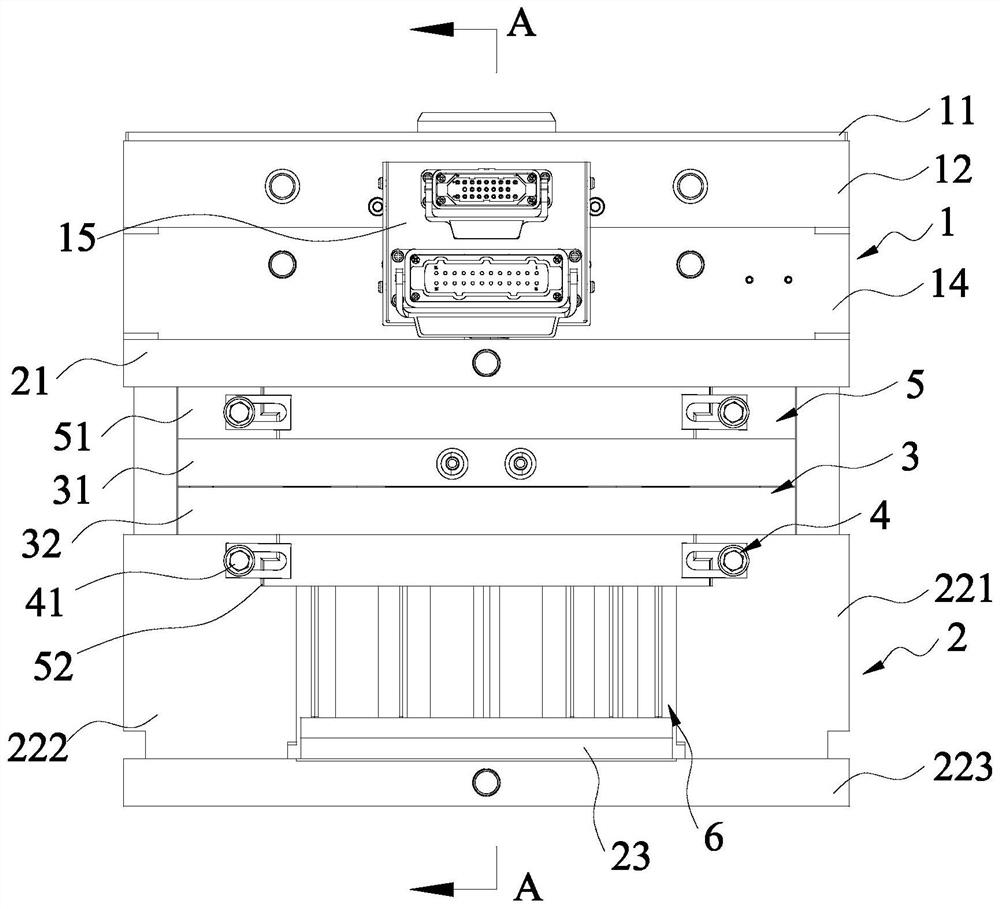

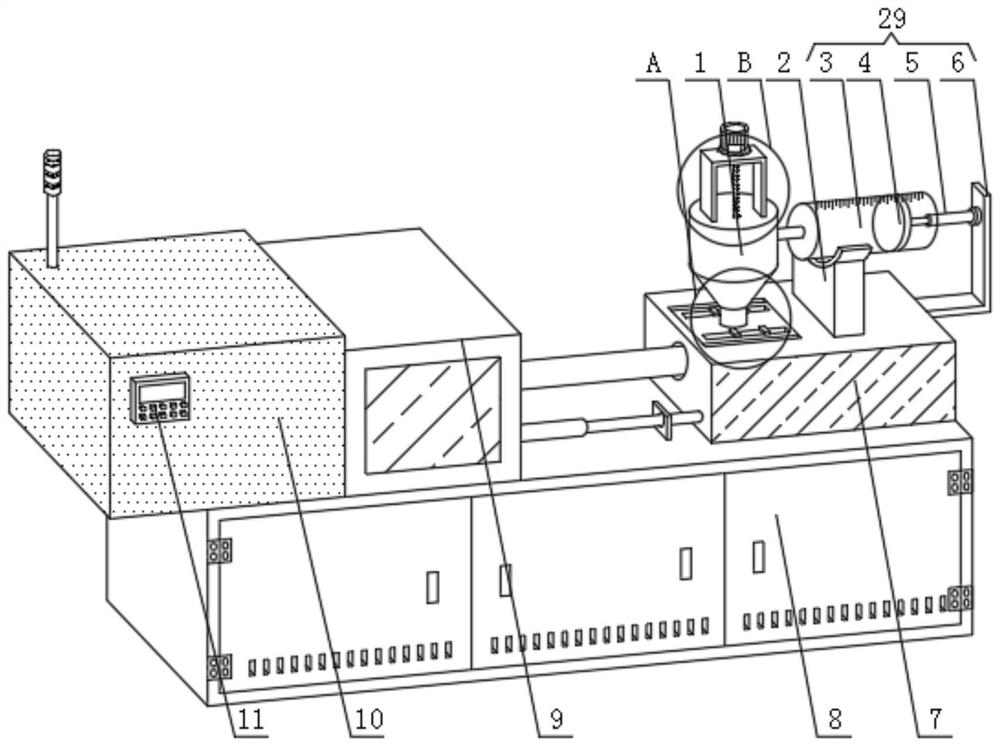

Double-step precision injection molding device

InactiveCN104441403ARealize self-locking sealNot prone to material stagnationHydraulic motorThrust bearing

The invention relates to the field of injection molding machines, in particular to a double-step precision injection molding device. The invention discloses the double-step precision injection molding device with the following structure, the device comprises a pre-injection storing mechanism, an injection mechanism, a hydraulic system and a spray nozzle, wherein the pre-injection storing mechanism comprises a front premolding material barrel, a premolding material barrel, a screw rod, a feeding seat and a hydraulic motor, and the hydraulic motor is used for driving the screw rod to rotate; the injection mechanism comprises a front material barrel, a material barrel, an injection seat, a plunger rod and an injection electro-hydraulic system; a double-acting cylinder is arranged between a thrust bearing and a sealed groove, and movements of the pre-injection storing mechanism, the injection mechanism and the spray nozzle are coordinated and controlled by the hydraulic system. The double-step precision injection molding device has the advantages that the flow channel is short, the stagnation of materials is avoided, and the injection precision is high.

Owner:浙江泰瑞重型机械有限公司

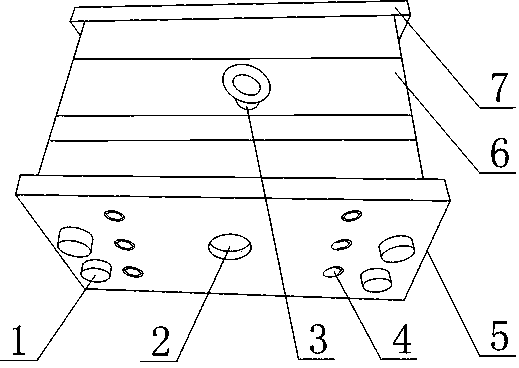

Injection mold device

InactiveCN103407077AReduce contact areaReduce the degree of deformationEngineeringInjection moulding

The invention discloses an injection mold device which comprises a front baffle (5), a plurality of cavity plates (6) with cavities on the inner sides, and a rear baffle (7), wherein the cavity plates (6) are positioned between the front baffle (5) and the rear baffle (7), and are arranged in sequence; the side surfaces of the two adjacent cavity plates, the side surfaces of the front baffle and one cavity plate (6) as well as the side surface of another cavity plate (6) and the rear baffle (7) are attached to each other; an injection hole (2) is formed in the front baffle (5); an exhaust hole is formed in the rear baffle (7). Compared with the prior art, the cavity part of a mold cavity comprise a plurality of parts, the mold unloading is still smoothly completed after the cavity body of the mold cavity is arranged in a more complex shape, and the injection precision of plastic products of more complex shapes in the injection molding process is beneficial to improvement, so that the subsequent reprocessing is avoided or reduced, and the enterprises' production efficiency is beneficial to improvement.

Owner:成都万顺达模具零件有限公司

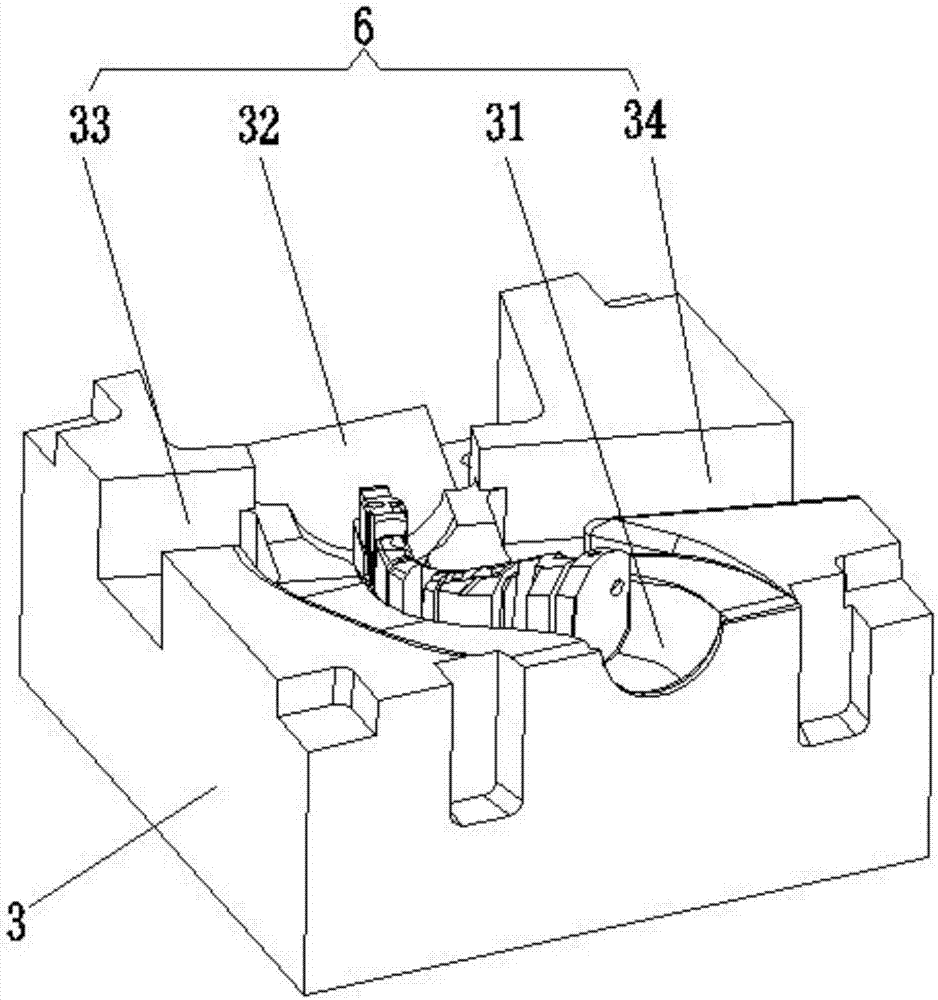

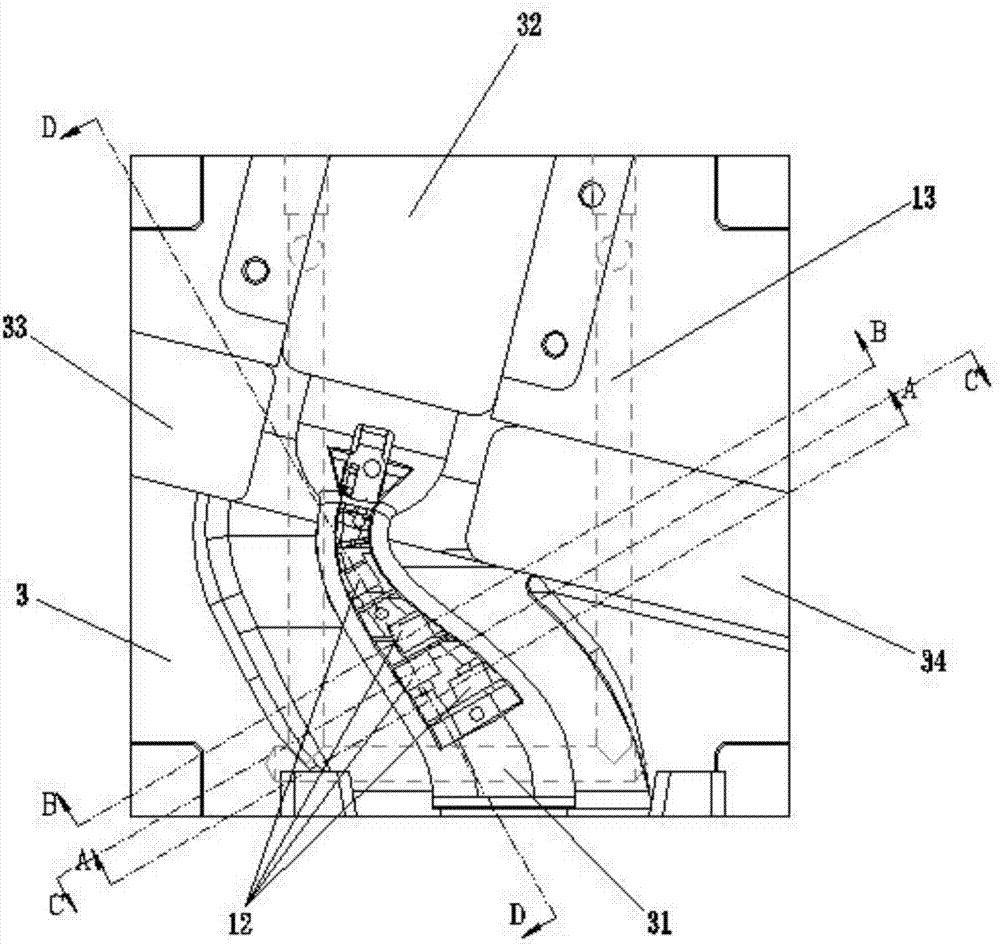

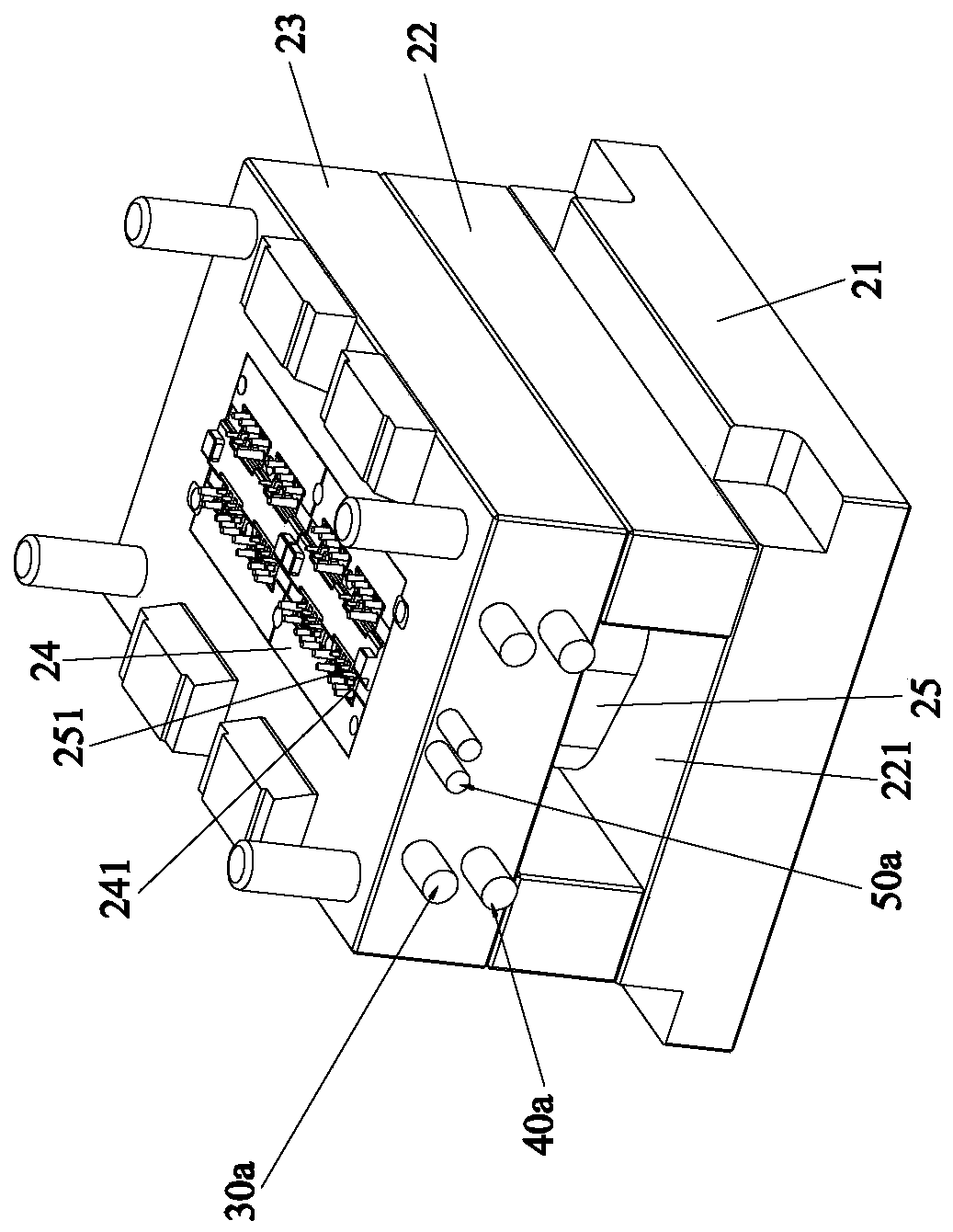

Injection moulding mould for automobile steering lamp holder

InactiveCN107263807AHigh cavity precisionImprove product qualification rateDomestic articlesInjectorEngineering

The invention discloses an injection mold for an automobile steering lamp seat, which comprises a mold base, a male mold base, a male mold core, a female mold base, a female mold core and an ejection mechanism; four slides are arranged between the male mold core and the female mold core Block cavity; four slider cavities are respectively provided with a front slider assembly, a rear slider assembly, a left slider assembly and a right slider assembly; four inclined top cavities are also arranged in the male die core; the inclined top The center line of the cavity forms an angle of 83° with the bottom surface of the male mold core; the inclined roof is detachably installed in the inclined roof cavity; form a mold cavity between them; the injection mold of the present invention solves the problem of high local precision requirements of the product by inlaying the inclined top in the male mold core, and the inclined top is easy to disassemble. The cavity of the injection mold is formed by the enclosing of the mother mold, which has a high precision of the mold cavity and a high qualification rate of the injection molded product.

Owner:SUZHOU CITY XIANGCHENG CITY LUMUXINCHENG PRECISION MOLD FACTORY

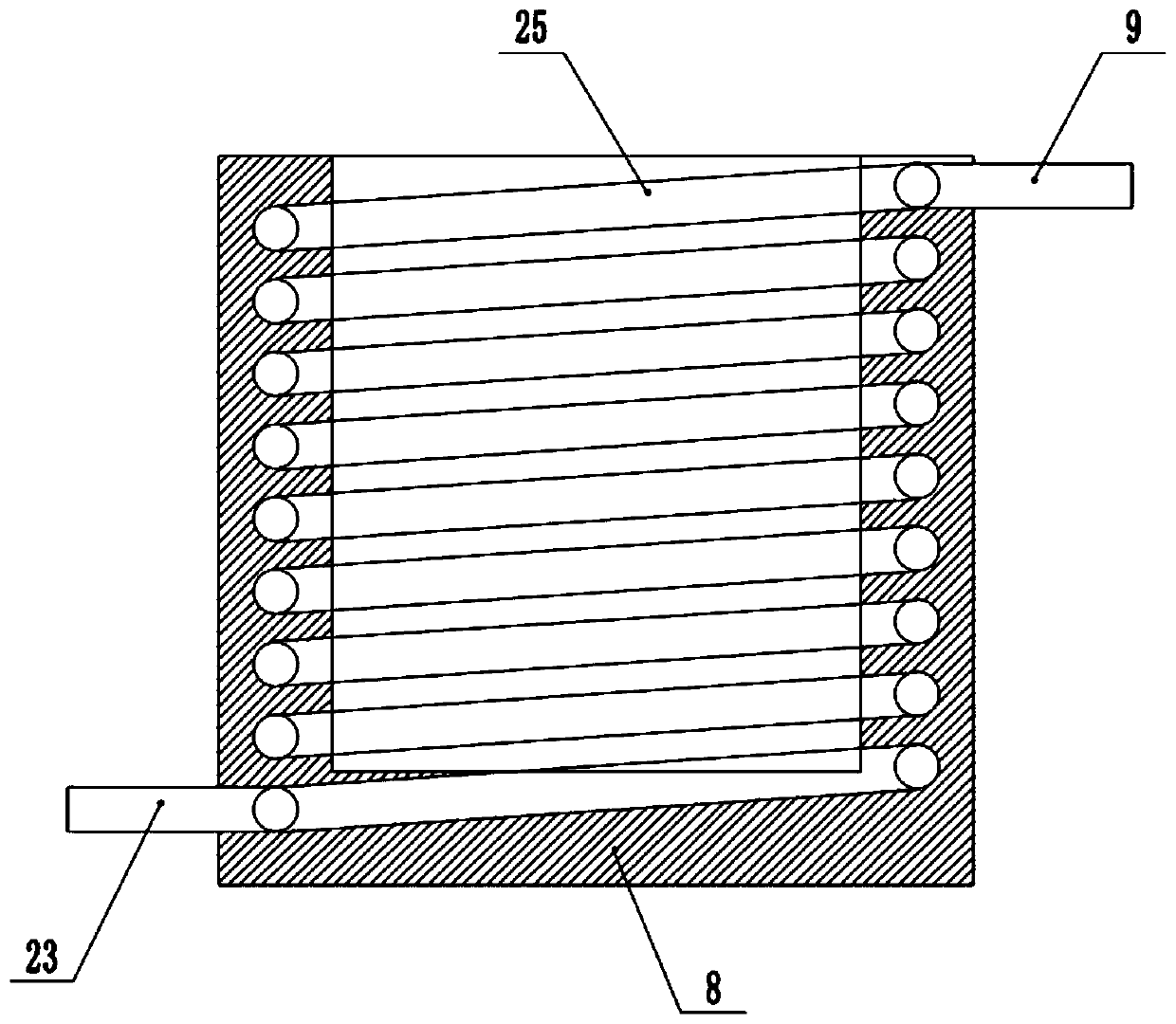

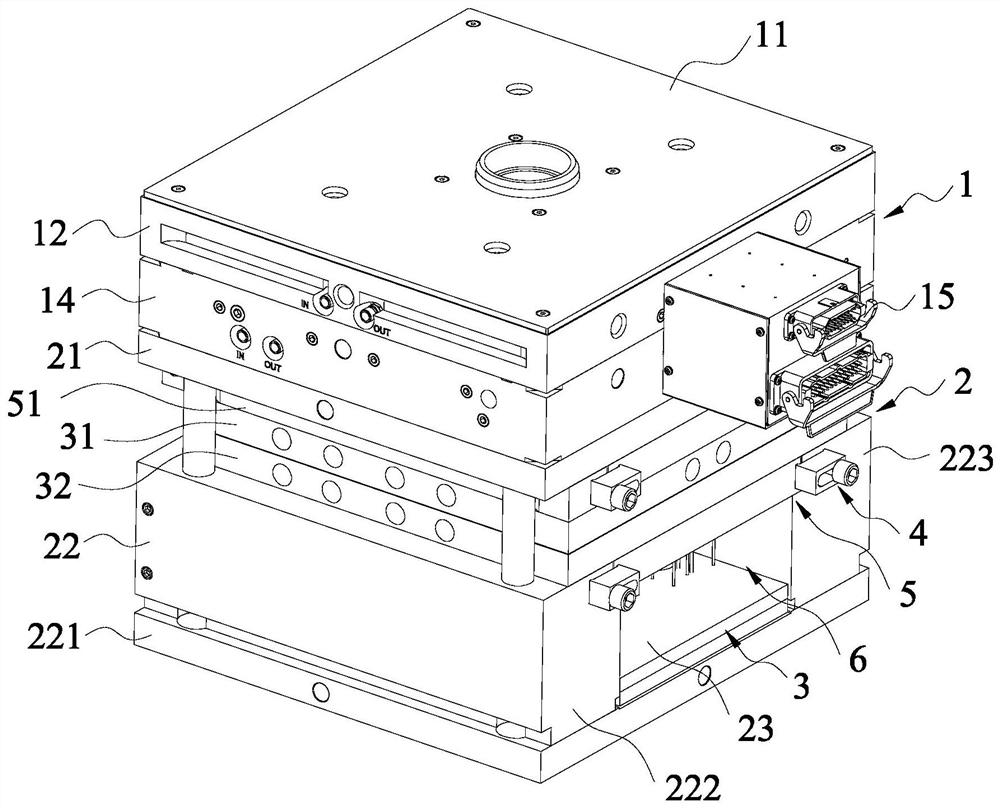

Forced cooling injection mold device

InactiveCN103407079AReduce contact areaReduce the degree of deformationPlastic injection moldingEngineering

The invention discloses a forced cooling injection mold device, which comprises a front baffle (5), a plurality of mold cavity boards (6) with cavities formed in inner sides, and a back baffle (7), wherein the plurality of mold cavity boards (6) are positioned between the front baffle (5) and the back baffle (7), a plurality of flow passages of which the upper parts and the lower parts are communicated are arranged in the front baffle (5), the mold cavity boards (6), and the back baffle (7) respectively; a injection molding hole (2) is formed in the front baffle (5); an exhaust hole is formed in the back baffle (7). The cavity parts of mold cavities are formed by the combination of a plurality of parts, so that the mold is allowed to be able to adapt to mold opening of the mold cavities with complex shapes, the enhance of the injection molding precision of plastic products with complex shapes is facilitated, and subsequent reprocessing is eliminated or reduced; the arranged flow passages facilitate the selection of an optimum cooling manner according to a specific material property for better adapting to requirements of cooling speed required to be maintained of the plastic injection molding of different plastics, and therefore, the improvement of the production efficiency of enterprises and the quality of products are facilitated.

Owner:成都万顺达模具零件有限公司

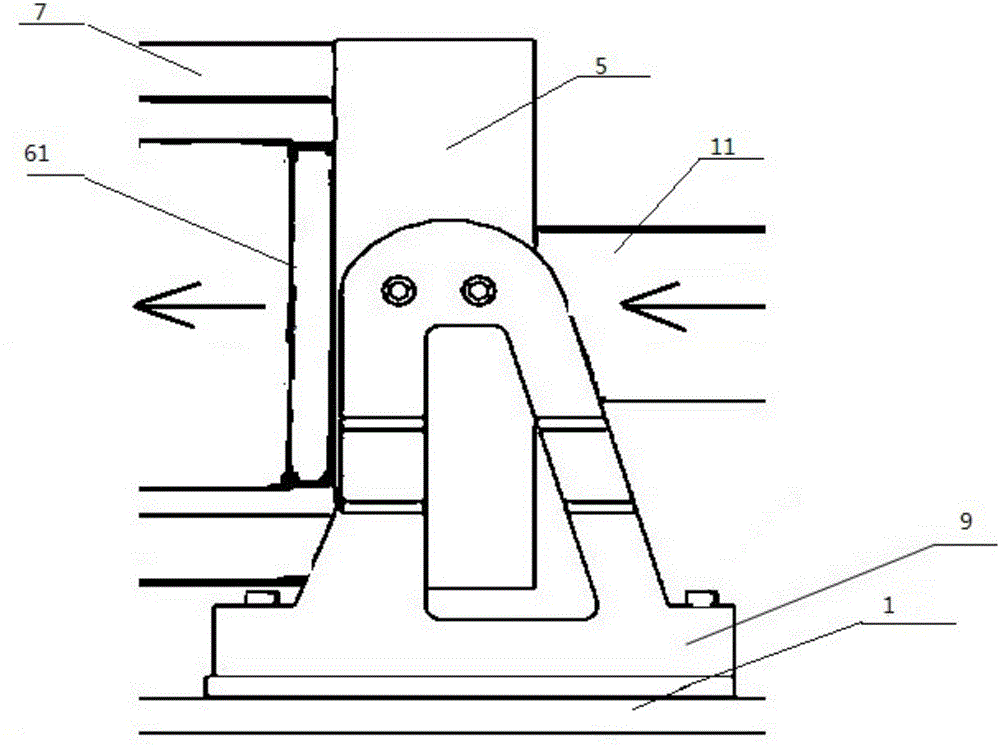

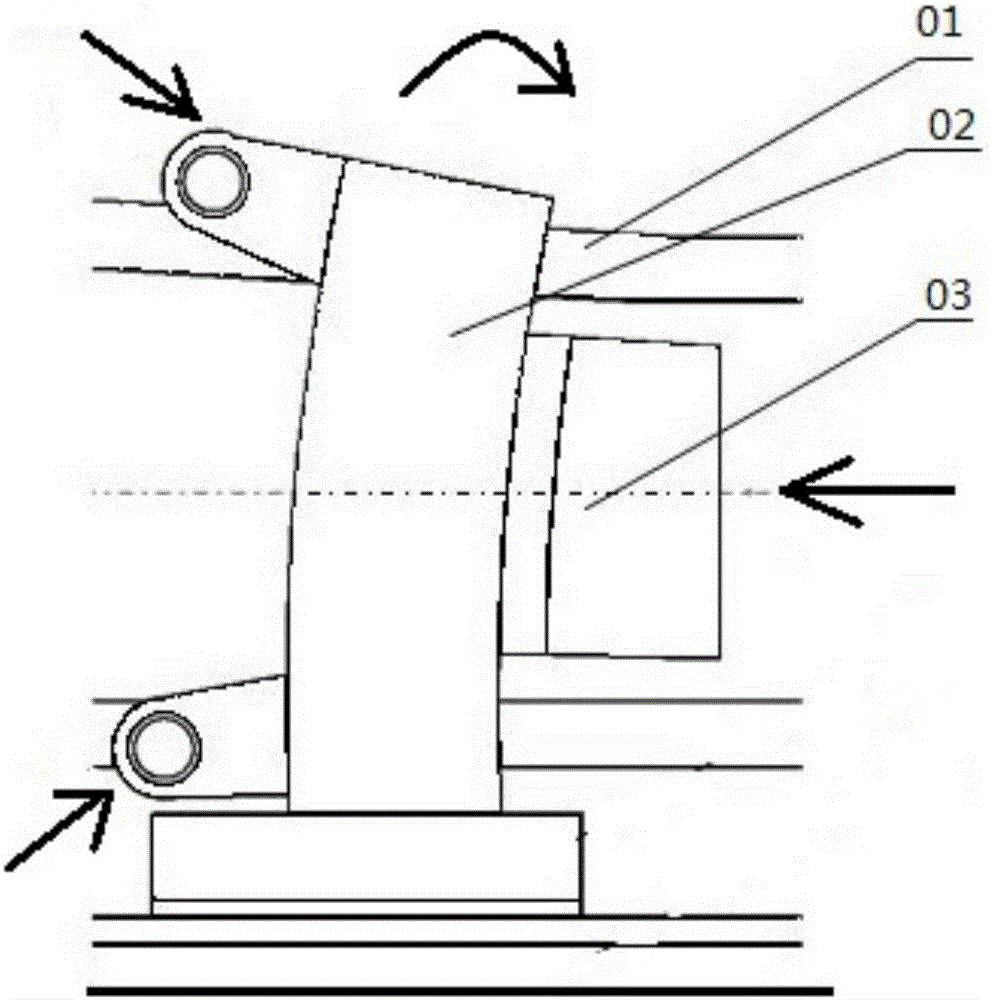

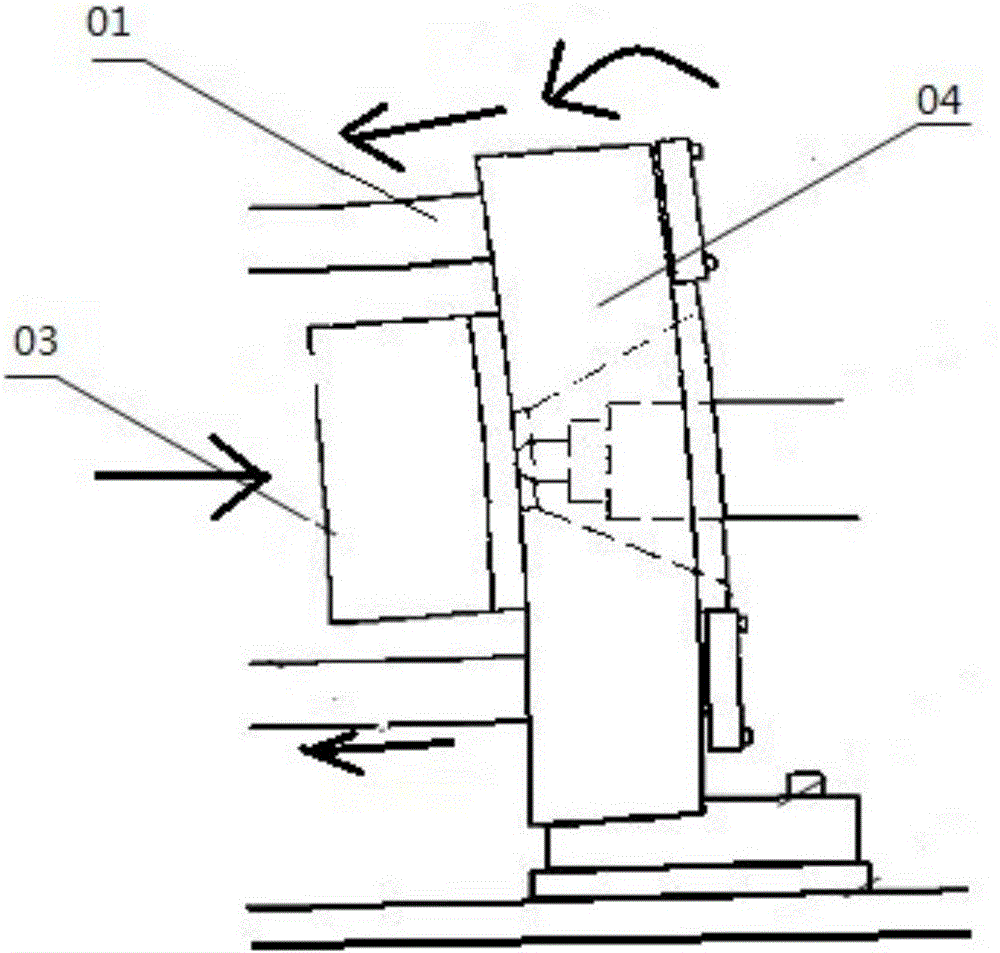

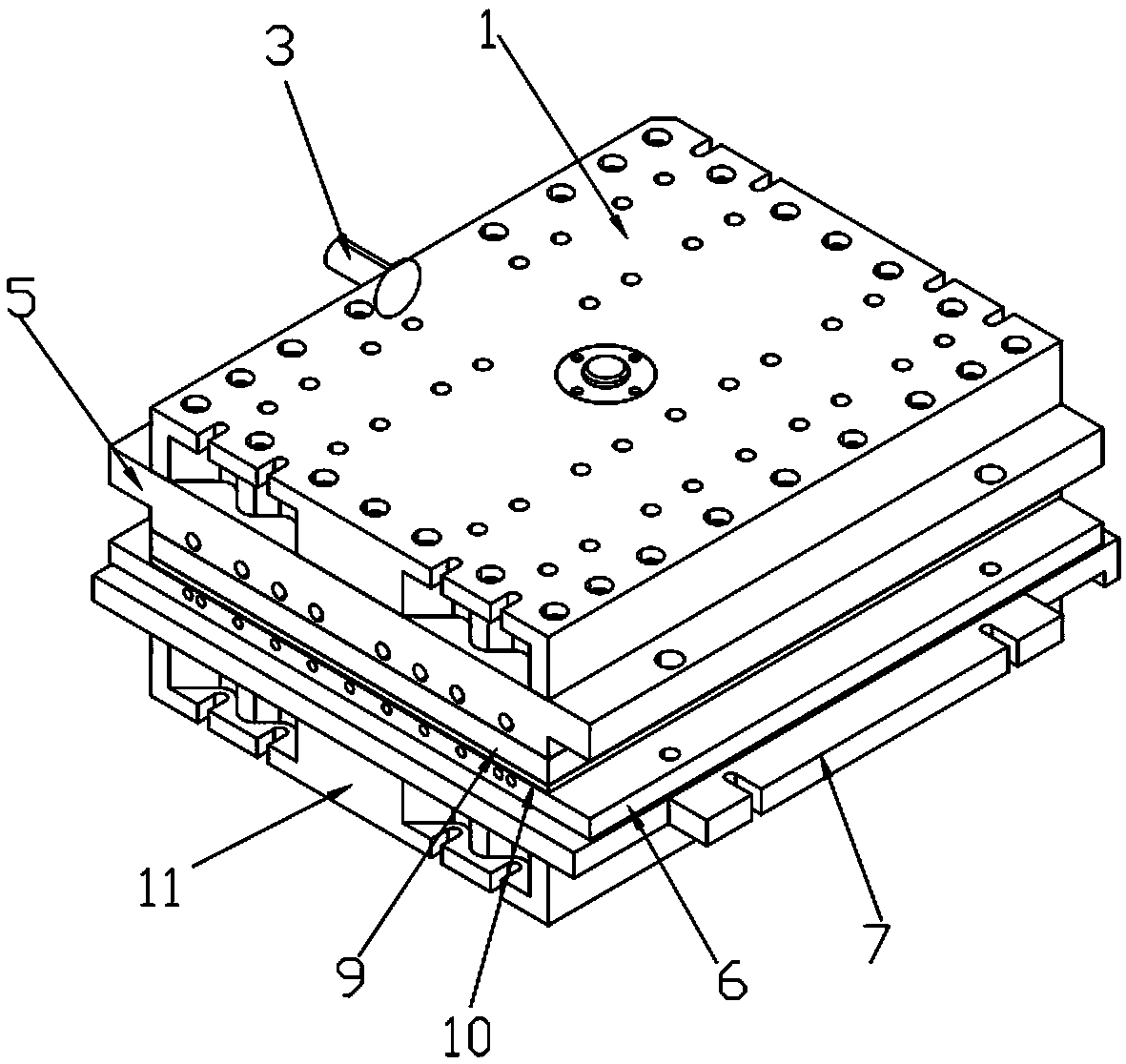

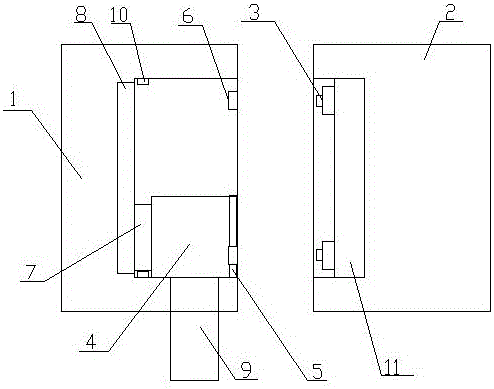

Double-R supporting structure of injection molding machine

The invention discloses a double-R supporting structure of an injection molding machine. The double-R supporting structure comprises a base, two linear guide rails, a plurality of sliding blocks, a movable die plate, a fixed die plate, a die and four tie bars. One end of each tie bar is positioned on the fixed die plate, and the other end of each tie bar penetrates the movable die plate; the movable die plate can move on the tie bars, and the die is mounted between the movable die plate and the fixed die plate; the linear guide rails are fixed to the base, and the sliding blocks are positioned on the linear guide rails in a sliding manner; the two sides of the movable die plate are symmetric, and are each fixedly provided with a reverse-R-shaped supporting block; the two sides of the fixed die plate are symmetrically and fixedly provided with a positive-R-shaped supporting block; the bottoms of the reverse-R-shaped supporting blocks are fixed to the sliding blocks, and the sliding blocks are connected with the linear guide rails and can side on the guide rails; the bottoms of the positive-R-shaped supporting blocks are fixed to the base; and the double-R supporting structure of the injection molding machine can effectively prevent stress deformation of the fixed die plate and the movable die plate, the injection precision is improved, the production efficiency is improved, and the service life is prolonged.

Owner:SUZHOU UNIV

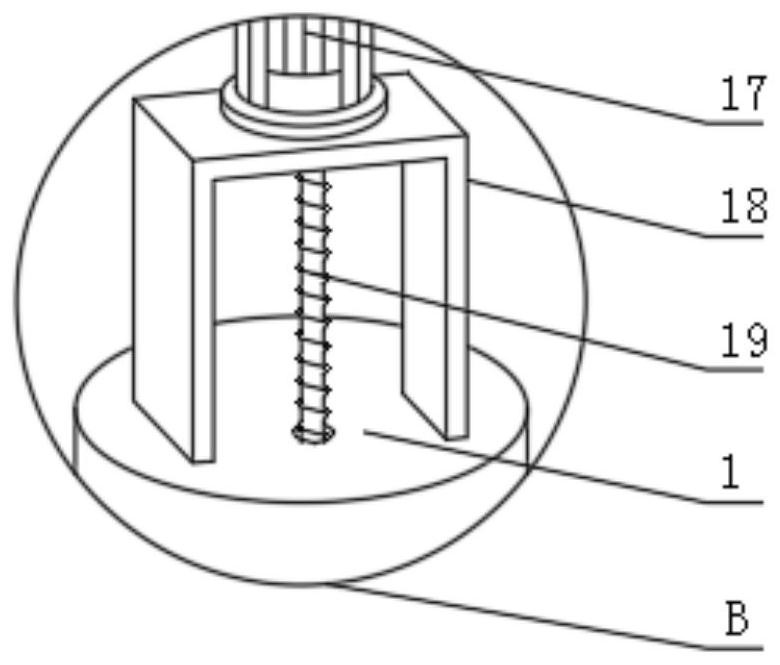

Deformable injection mold

The invention discloses a deformable injection mold in the technical field of injection molds. The deformable injection mold comprises a movable mold fixing plate and a fixed mold fixing plate, an upper mold plate is installed on the center position of the bottom part of the movable mold fixing plate, a pouring gate is formed on the center position of the top part of the movable mold plate, and the left and right sides of the bottom part of the movable mold fixing plate are symmetrically provided with guiding installing grooves and guide sleeves; guide pillars are arranged on the left and right sides of the top part of the fixed mold fixing plate, a lower mold plate is installed on the center part of the top part of the fixed mold fixing plate, and two sets of lifting mold cores are arranged on the lower mold plate side by side; a connecting transverse plate is connected to the bottoms of the two sets of the lifting mold cores, a lifting threaded rod and a rotating screw tube are connected to the center part of the bottom part of the connecting transverse plate, a driving turbine and a driving worm sleeve the bottom end of the rotating screw tube fixedly, and the right end of the driving worm is connected with a driving connecting rod, a connecting rod through hole and an adjusting handle. According to the deformable injection mold, the cost of development of molds is lowered,the production cycle is shortened, and remarkable industrial benefits are obtained.

Owner:钟锋良

Rotating discharging injection mold for terminal cover

Owner:WUHU WANHUA PLASTIC PROD

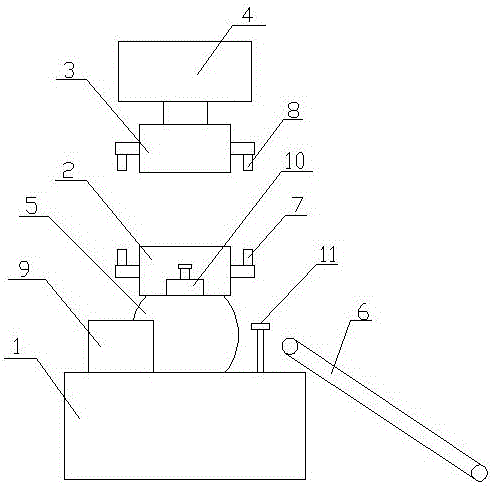

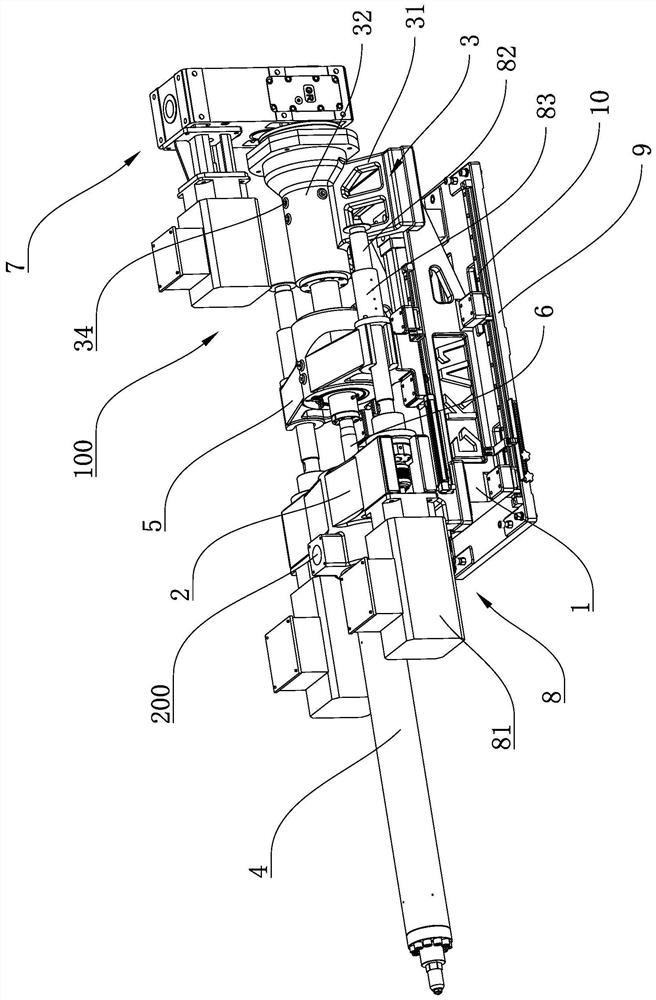

High-speed low-inertia structure applied to injection molding machine and injection molding machine with high-speed low-inertia structure

PendingCN112917821AExtended service lifeImprove injection precisionEngineeringInjection molding machine

The invention belongs to the technical field of injection molding machines, and particularly relates to a high-speed low-inertia structure applied to an injection molding machine and the injection molding machine with the high-speed low-inertia structure. The high-speed low-inertia structure applied to the injection molding machine and the injection molding machine with the high-speed low-inertia structure are provided for solving the problem that in the prior art, large moving inertia is generated during high-speed injection, the high-speed low-inertia structure comprises a base, wherein a front plate and a rear plate are fixedly arranged on the base, an injection molding barrel is connected to the front plate, a moving assembly is arranged between the front plate and the rear plate, a charging barrel screw rod is connected to the moving assembly, the end, far away from the moving assembly, of the charging barrel screw rod extends into the injection molding material barrel, the injection molding machine further comprises a charging opening communicated with the interior of the injection molding material barrel, and the charging opening is formed in the injection molding material barrel or the front plate. The charging barrel screw is connected to the moving assembly capable of independently moving, and the rear plate is fixedly arranged to ensure that the rear plate cannot move along with the charging barrel screw during injection, so that the moving inertia is reduced, the service life of the injection molding machine is prolonged, and the injection molding precision of the injection molding machine is improved.

Owner:SINO HLDG GRP

Injection mold device with heating device

InactiveCN103407137AReduce contact areaReduce the degree of deformationPlastic injection moldingEngineering

The invention discloses an injection mold device with a heating device. The injection mold device comprises a front baffle plate (5), a plurality of cavity plates (6) provided with cavities formed in the inner sides, a rear baffle plate (7) and an electric heater (8), wherein the front baffle plate (5), the cavity plates (6) and the rear baffle plate (7) are provided with a plurality of flow passages of which the upper parts and the lower parts are communicated; the front baffle plate (5) is further provided with an injection molding hole (2); the rear baffle plate (7) is further provided with an exhaust hole. The injection mold device can adapt to mold opening of cavities in complex shapes, is conducive to improving injection molding precision of plastic products with complex shapes, and can eliminate and reduce follow-up reprocessing; with the flow passages and the electric heater, the injection mold device can well adapt to cooling speeds required to be kept in different plastic injection molding processes and requirements of mold temperature during injection molding, and is conducive to improving production efficiency of enterprises and product quality.

Owner:成都万顺达模具零件有限公司

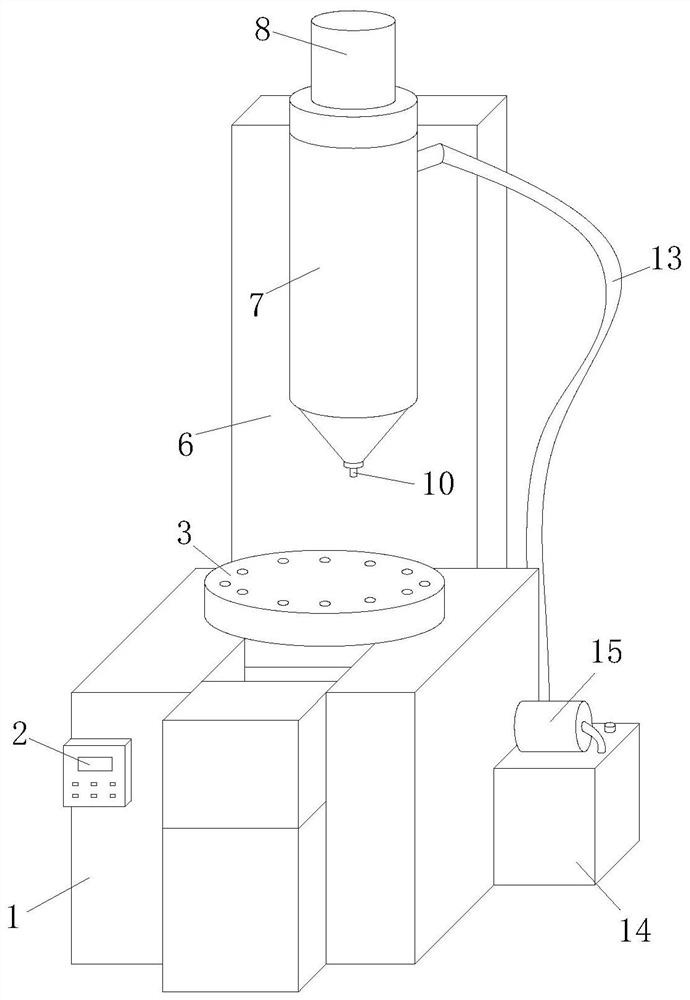

Multi-station temperature control injection molding machine

The invention relates to the field of injection molding machines, in particular to a multi-station temperature control injection molding machine. The multi-station temperature control injection molding machine comprises an injection molding machine base, a control panel is arranged on the outer surface of the front end of the injection molding machine base, a multi-station turntable is arranged onthe outer surface of the upper end of the injection molding machine base, an electric cylinder is arranged at the front end of the multi-station turntable, and a supporting arm is arranged on the outer surface of the rear end of the injection molding machine base; and an injection molding barrel is arranged on the outer surface of the front end of the supporting arm, a threaded rod is arranged onthe inner side of the injection molding barrel, an injection molding opening is formed in the lower end of the injection molding barrel, a heating cavity is formed in the injection molding barrel, and a spiral electric heating pipe is arranged on the inner side of the heating cavity. The injection molding machine is good in temperature control effect and uniform in heating process, the injectionmolding effect of plastic materials is improved, simultaneous injection molding of multiple sets of molds is convenient, the positions of the injection molds are flexibly adjusted, the precision in the injection molding process is improved, and better use prospects are brought.

Owner:长春华众延锋彼欧汽车外饰有限公司

Endoscope rear end structure

PendingCN111839433AEasy assembly and commissioningImprove image qualitySurgeryEndoscopesOphthalmologyMicroscope objective

The invention discloses an endoscope rear end structure which comprises a shell, a shell mounting groove is formed in the rear end surface of the shell; an objective lens assembly is mounted in the shell mounting groove; the objective lens assembly comprises an objective lens assembly and an objective lens mounting base matched with the shell mounting groove; the objective lens mounting base is fixed in the shell mounting groove; the objective lens assembly is installed in the objective lens mounting base and is in sliding connection with the objective lens mounting base, the objective lens assembly comprises a first objective lens, an objective lens base and a second objective lens, the first objective lens and the second objective lens are fixed to the two ends of the objective lens baserespectively and located on the same straight line, and an ocular lens is fixed to the rear end of the objective lens mounting base and the ocular lens and the objective lens are located on the samestraight line. The endoscope rear end structure has the beneficial effects that the original rear end fixing structure is subjected to injection molding and integrated molding, and meanwhile, the objective lens system is integrally designed so that the endoscope is more convenient and faster to assemble and debug, and the imaging quality of the ocular lens is obviously improved; and the gluing surface of the objective lens system is increased so that the packaging quality is remarkably improved.

Owner:杭州汇桐泽瑞医疗科技有限公司

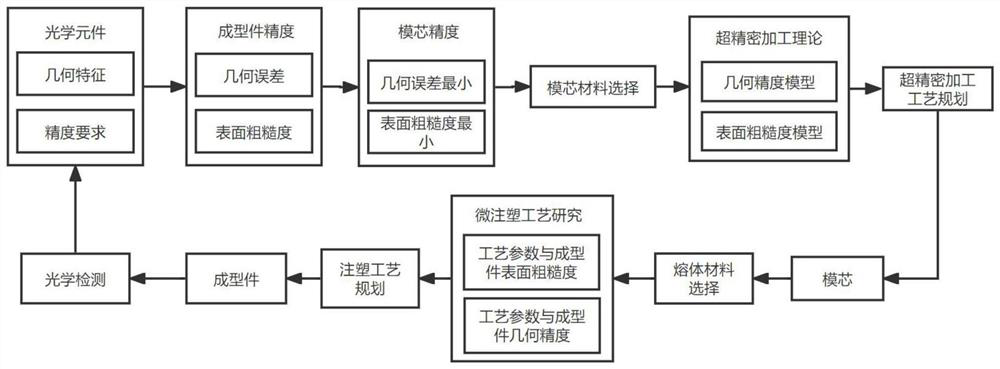

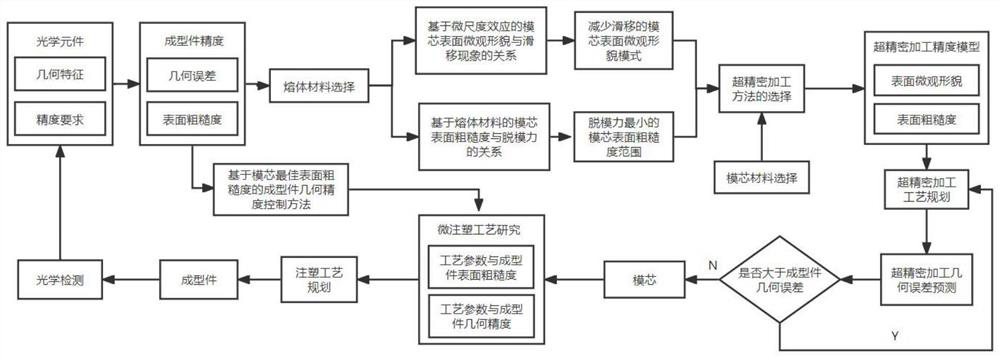

Optimization method for improving injection molding precision of optical element

PendingCN114662171AImprove injection precisionGood optical performanceGeometric CADForecastingSurface roughnessEngineering

The invention discloses an optimization method for improving the injection molding precision of an optical element, which provides an injection molding process considering melt materials and mold core surface roughness on the premise that injection molding process parameters and the like are all optimal, selects different mold core surface roughness intervals according to different melt materials, and predicts the injection molding precision of the optical element on the basis of an existing ultra-precision machining quality prediction model. Compared with the extremely high quality requirement for the surface of the mold core in a traditional method, the optimization method for improving the injection molding precision of the optical element improves the molding precision of the optical element and reduces the surface roughness of the optical element on the basis of improving the machining efficiency of the mold core; and optimization of a micro injection molding process of the optical element and improvement of the optical performance of the element are facilitated.

Owner:GUANGDONG UNIV OF TECH

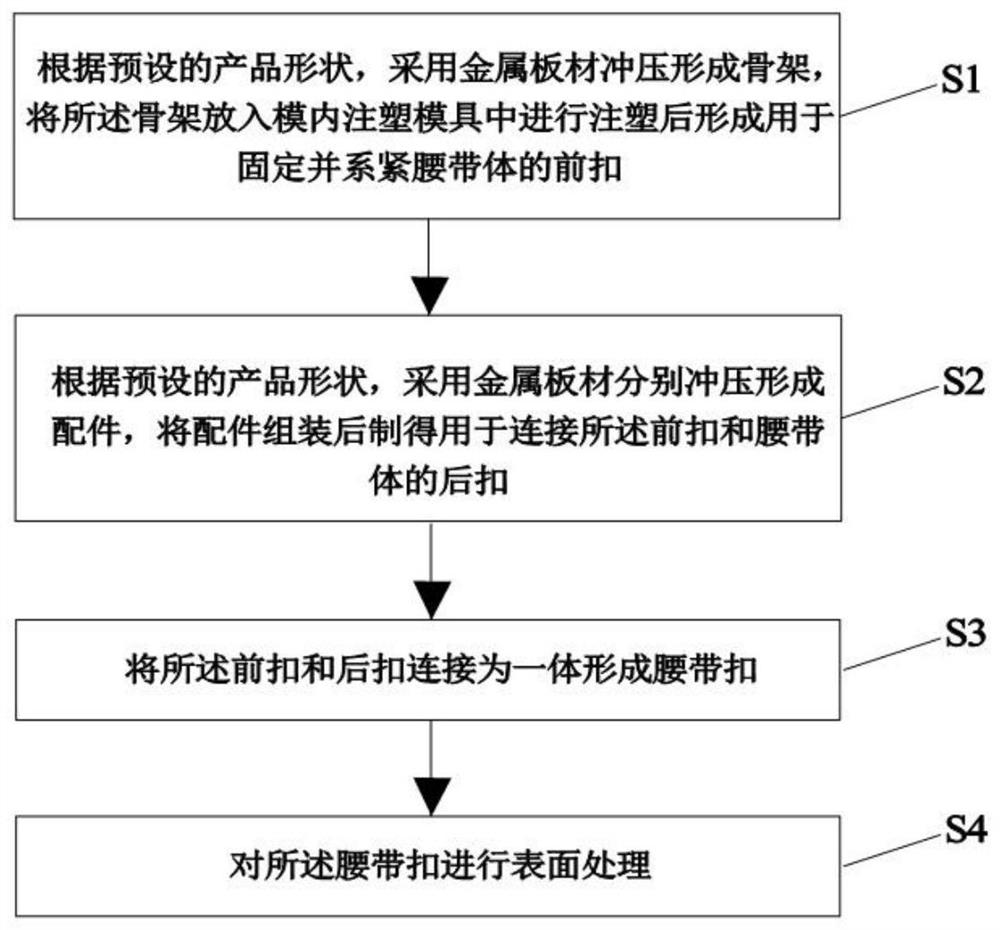

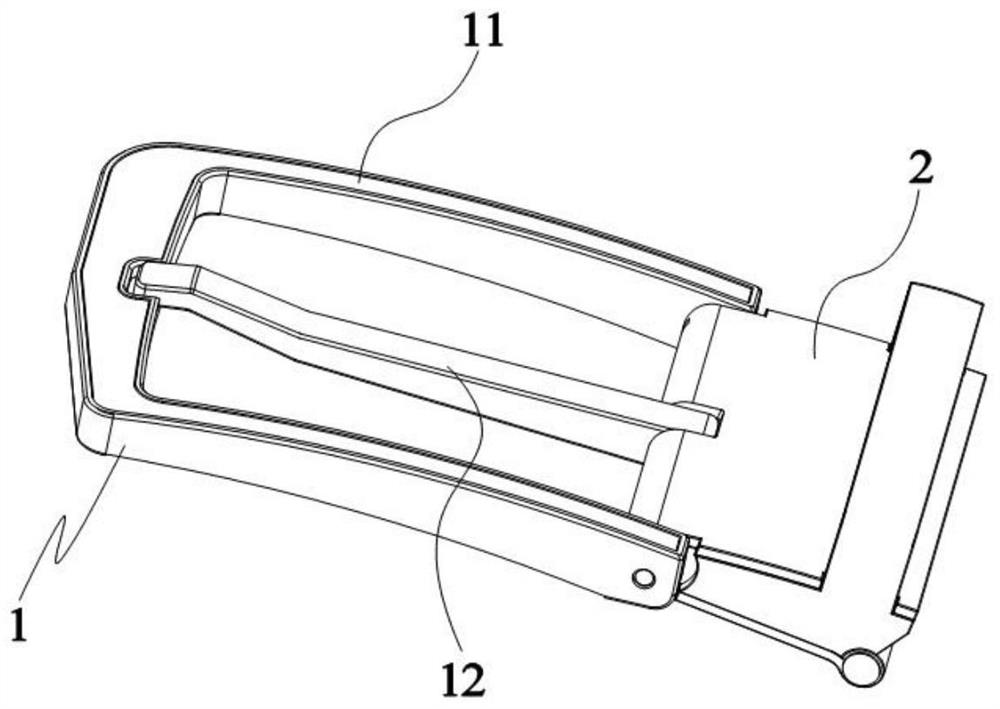

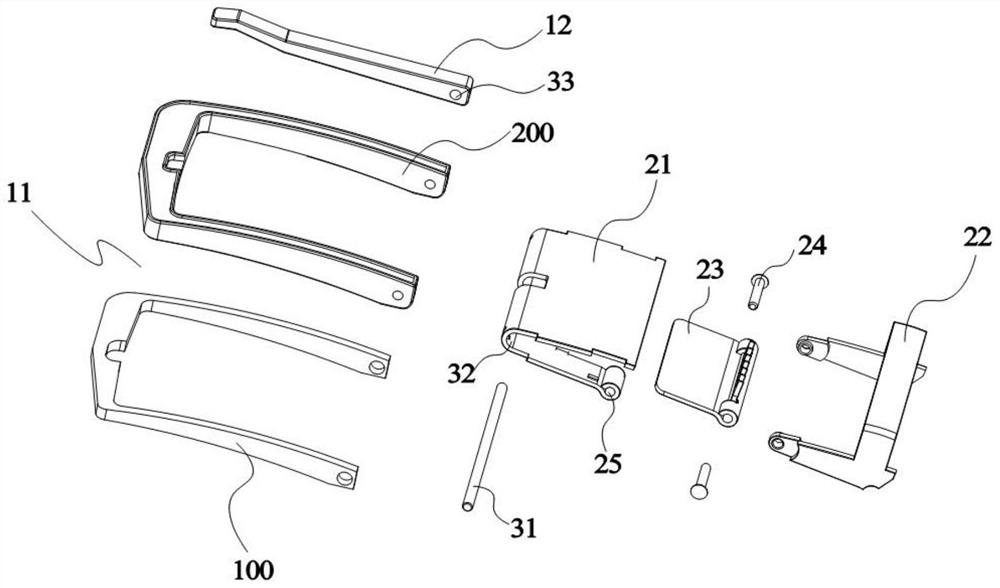

Manufacturing method of waistband buckle and waistband buckle manufactured by manufacturing method

InactiveCN112248360AHigh strengthEasy to shapeBucklesStructural engineeringInjection molding process

The invention discloses a waistband buckle manufacturing method and a waistband buckle manufactured by the manufacturing method. The method comprises the steps that according to the preset product shape, a metal plate is adopted for stamping to form a framework, and the framework is put into an in-mold injection mold to be subjected to injection molding to form a front buckle used for fixing and tying a waistband body; according to the preset product shape, metal plates are adopted for punching to form accessories, and the accessories are assembled to obtain a rear buckle used for connecting the front buckle and the waistband body; and the front buckle and the rear buckle are connected into a whole to form the waistband buckle. The front buckle is manufactured by adopting an in-mold injection molding process, a metal stamping part is used as the framework, the strength is good, the weight is proper, the injection molding precision is high, the molding capacity is good, a product obtained after injection molding does not need grinding, polishing and other procedures, and the product is attractive and exquisite in appearance molding and flat, smooth, tidy and uniform in surface; andthe rear buckle is formed by stamping the metal plate, so that the product is clear in corner angle after being formed, the curved surface modeling is clean and neat, the grinding and polishing procedures are not needed, the product taste is improved, and the manufacturing cost is reduced.

Owner:施尚君

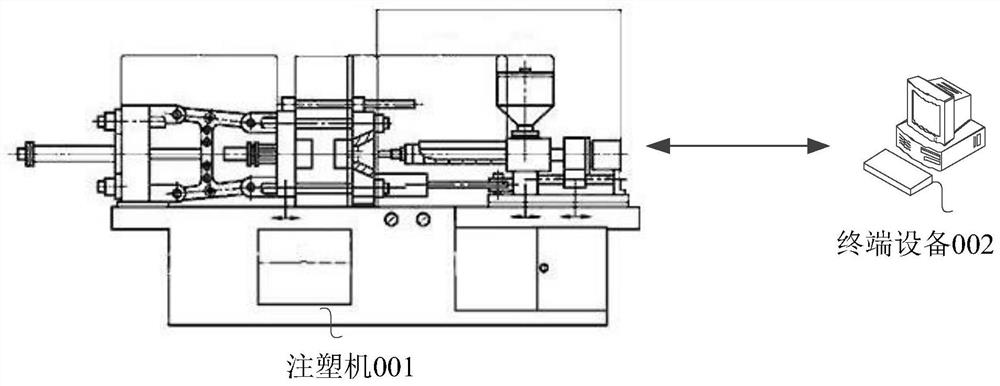

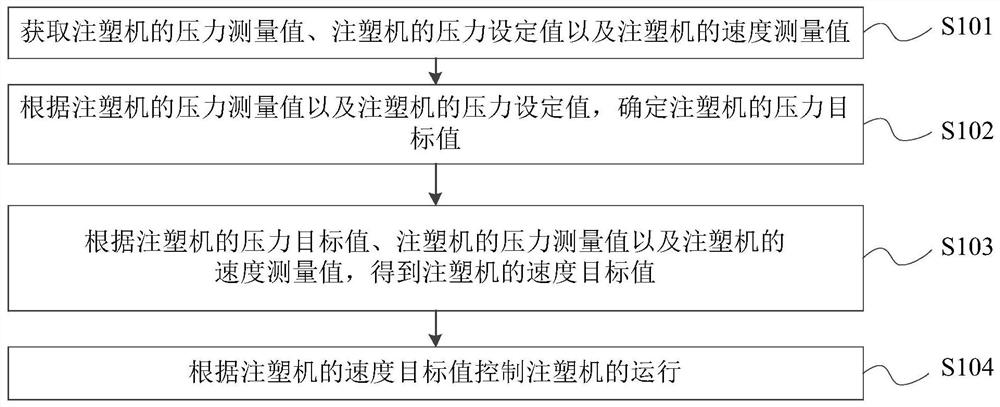

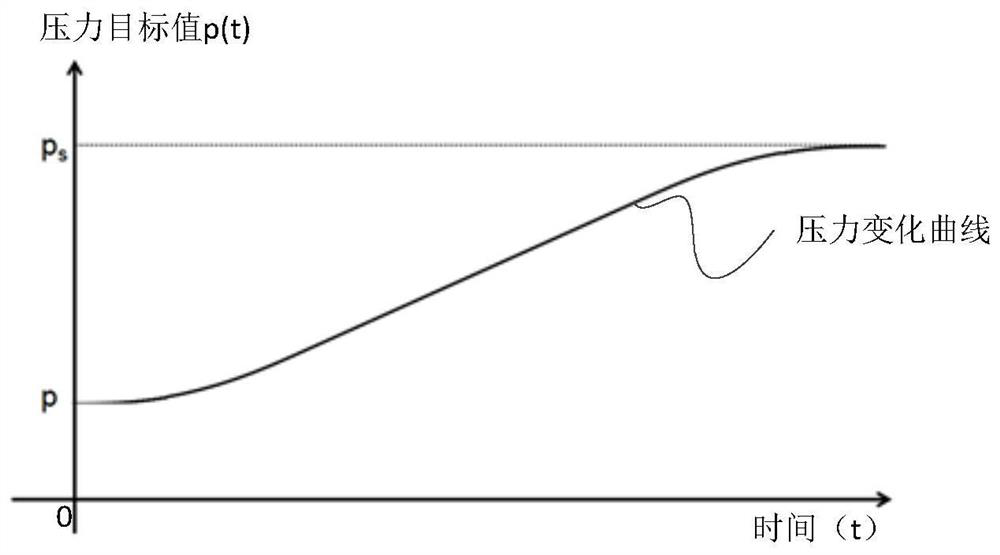

Flexible switching control method and device for injection molding machine

ActiveCN112917855AImprove injection precisionSmooth switchingProcess engineeringInjection molding machine

The invention provides a flexible switching control method and device for an injection molding machine. The method comprises the following steps: acquiring a pressure measurement value of the injection molding machine, a pressure set value of the injection molding machine and a speed measurement value of the injection molding machine; determining a pressure target value of the injection molding machine according to the pressure measurement value of the injection molding machine and the pressure set value of the injection molding machine; obtaining a speed target value of the injection molding machine according to the pressure target value of the injection molding machine, the pressure measurement value of the injection molding machine and the speed measurement value of the injection molding machine; and controlling operation of the injection molding machine according to the speed target value of the injection molding machine. Compared with the prior art, when the injection process of the injection molding machine is switched to the pressure maintaining process, slow change of the speed of the injection molding machine is controlled by controlling the variable quantity of the pressure, so that stable switching from the injection process to the pressure maintaining process of the injection molding machine is realized, and the injection molding precision of the injection molding machine is improved.

Owner:HANGZHOU DIANZI UNIV

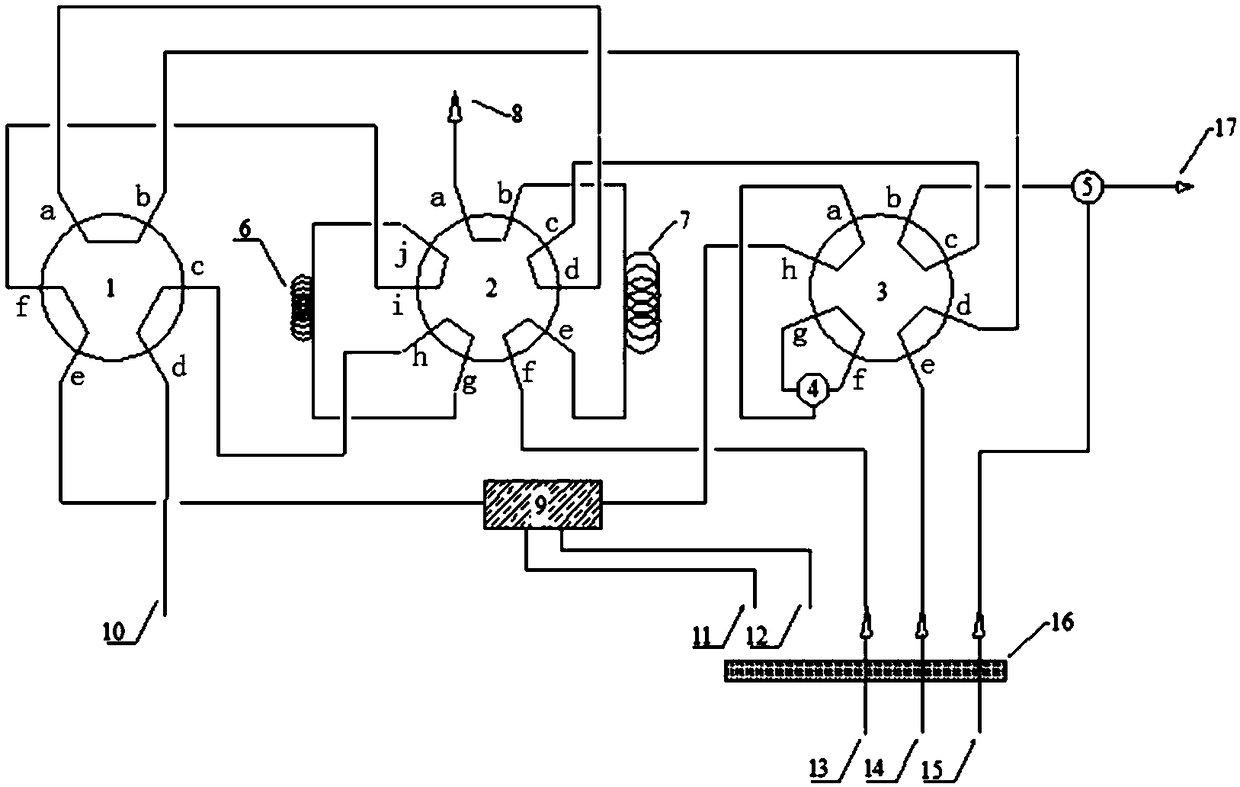

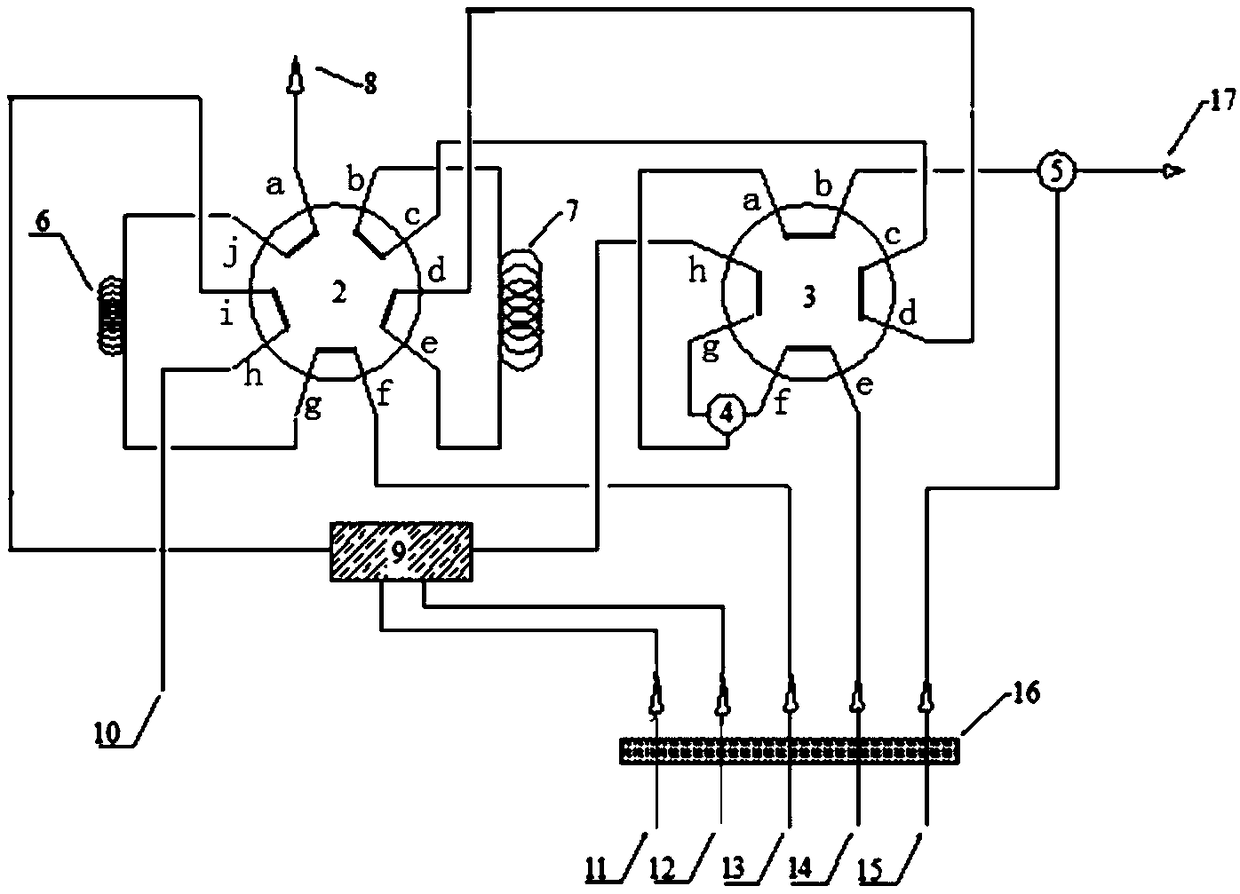

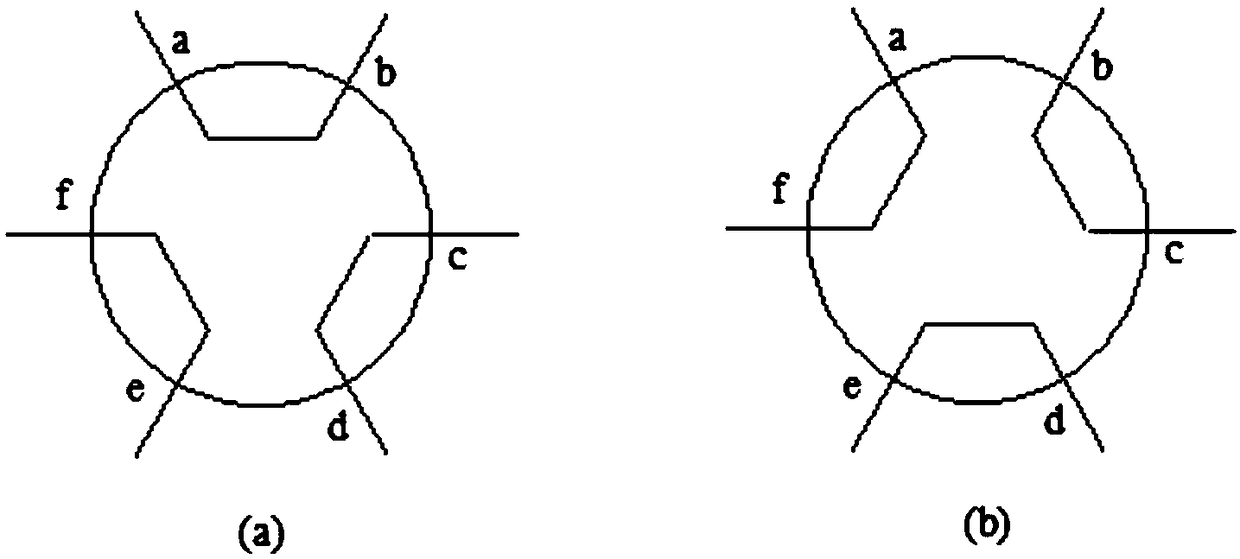

Integrated speciation and total analysis atomic fluorescence sampling and pretreatment system

The invention relates to an integrated speciation and aggregate analysis atomic fluorescence sample feeding and pre-treating system comprising a multi-way valve A, a multi-way valve B and a multi-way valve C which are connected with one another. Two ports of the multi-way valve A are connected with a speciation analysis mobile phase inlet and a speciation analysis pre-treating system respectively, the multi-way valve B is connected with a sample feeding port, three ports of the multi-way port C are connected with a reductant inlet, the speciation analysis pre-treating system and a three-way joint B respectively, the three-way joint B is connected with a flow carrying inlet, the speciation analysis pre-treating system is connected with a speciation analysis pre-treating reagent inlet, and element aggregate analysis or element speciation analysis is performed by rotating the multi-way valve A, the multi-way valve B and the multi-way valve C for selection. One sample feeding and pre-treating system can be shared during element aggregate or speciation analysis, so that size and production cost of LC-HG-AFS equipment are reduced.

Owner:成都市食品药品检验研究院

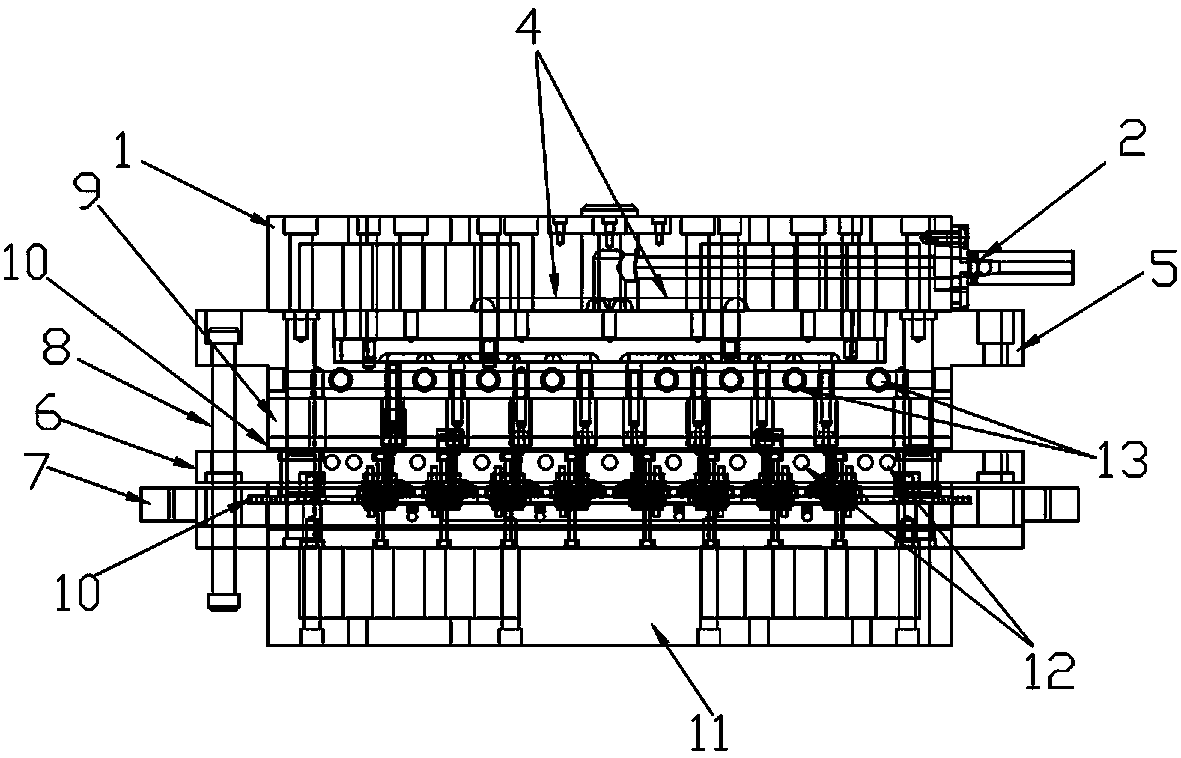

Hydraulic injection mold

The invention relates to an oil pressure injection mold and belongs to the field of silicone product molds. The oil pressure injection mold comprises a base plate and a forming mold set arranged at the top of the base plate. A material injection plate used for injecting a glue solution in is arranged at the top of the forming mold set. Glue injection openings are formed in the side face of the material injection plate. The forming mold set comprises a material pressing plate, a middle plate, a male mold and a female mold. Main channels communicating with the glue injection openings are formed in the material injection plate. A flow channel plate is arranged between the material injection plate and the material pressing plate and provided with a plurality of distributing channels connected with the main channels in a communicating mode. A reinforcing plate and a heat insulating bakelite plate are arranged between the material pressing plate and the female mold. The surface of the reinforcing plate, the surface of the heat insulating bakelite plate and the surface of the material pressing plate are all provided with injection molding channels matched with mold holes in number and position. The heat insulating bakelite plate with good heat insulating effect is additionally arranged, the whole mold is partitioned into a low temperature zone and a high temperature zone through the heat insulating bakelite plate, the effect that the glue solution is not formed due to heating before entering the mold holes is ensured, and therefore the injection efficiency of the glue solution can be improved.

Owner:DONGGUAN BITE SILICONE RUBBER MOLD CO LTD

A multi-station temperature control injection molding machine

The present invention relates to the field of injection molding machines, in particular to a multi-station temperature-controlled injection molding machine, comprising an injection molding machine base, a control panel is arranged on the front end outer surface of the injection molding machine base, and a multi-station turntable is arranged on the upper end outer surface of the injection molding machine base. The front end of the multi-station turntable is provided with an electric cylinder, the outer surface of the rear end of the base of the injection molding machine is provided with a support arm, the outer surface of the front end of the support arm is provided with an injection cylinder, the inner side of the injection cylinder is provided with a threaded rod, and the lower end of the injection cylinder is provided with a The injection port and the injection cylinder are provided with a heating chamber inside, and a spiral electric heating tube is provided inside the heating chamber. The invention has better temperature control effect, uniform heating process, improved injection molding effect of plastic materials, more convenient injection molding of multiple groups of molds at the same time, and more flexible adjustment of injection mold positions, improves the accuracy of the injection molding process, and brings more Good prospects for use.

Owner:长春华众延锋彼欧汽车外饰有限公司

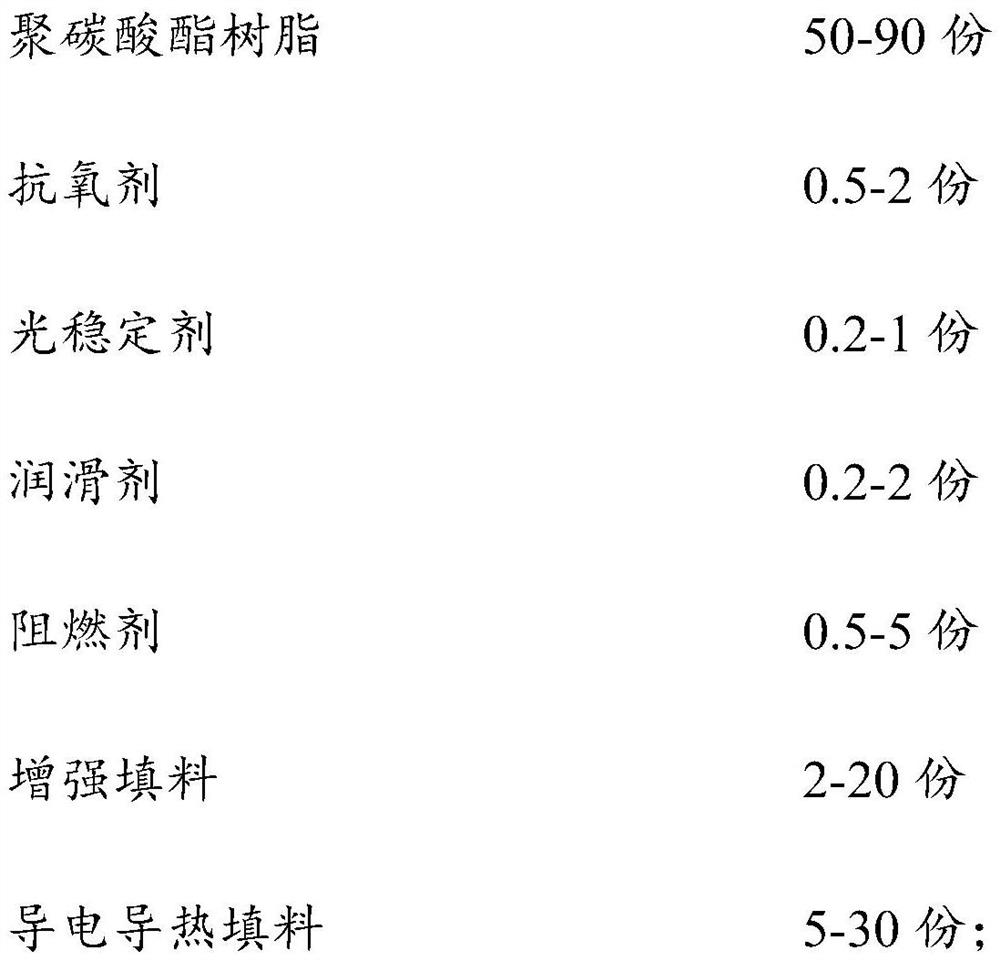

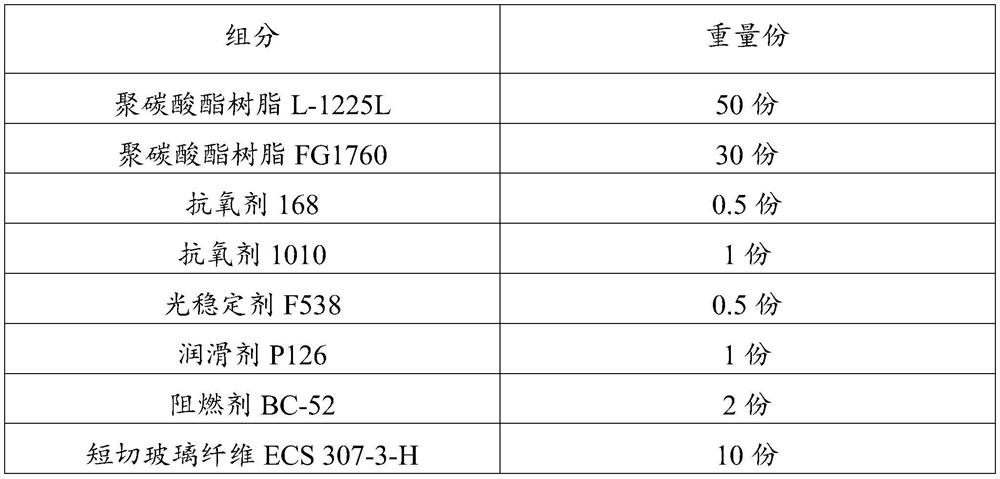

Polycarbonate engineering plastic with electromagnetic shielding and heat conduction functions and preparation method thereof

PendingCN112592574AWith electromagnetic shielding functionAlso has heat conduction functionHeat conductingEngineering plastic

The invention discloses polycarbonate engineering plastic with electromagnetic shielding and heat conduction functions and a preparation method thereof. The polycarbonate engineering plastic comprisesthe following components in parts by weight: 50-90 parts of polycarbonate resin, 0.5-2 parts of antioxidant, 0.2-1 part of light stabilizer, 0.2-2 parts of lubricant, 0.5-5 parts of flame retardant,2-20 parts of reinforcing filler, and 5-30 parts of a compound electric conduction and heat conduction filler; wherein the compound electricity conduction and heat conduction filler is obtained by compounding 2-20 parts of electricity-conducting filler and 2-20 parts of heat-conducting filler, the electricity conduction filler is selected from one of fibrous carbon powder, expanded graphite, graphene, carbon nanotubes and chopped stainless steel fibers, and the heat-conducting filler is selected from one of boron nitride, aluminum nitride, aluminum oxide and silicon carbide. The polycarbonateengineering plastic disclosed by the invention has electromagnetic shielding and heat conducting functions, can be applied to electronic equipment, saves material consumption and volume occupation, and enables electronic products to be economical and attractive.

Owner:中广核高新核材科技(苏州)有限公司 +1

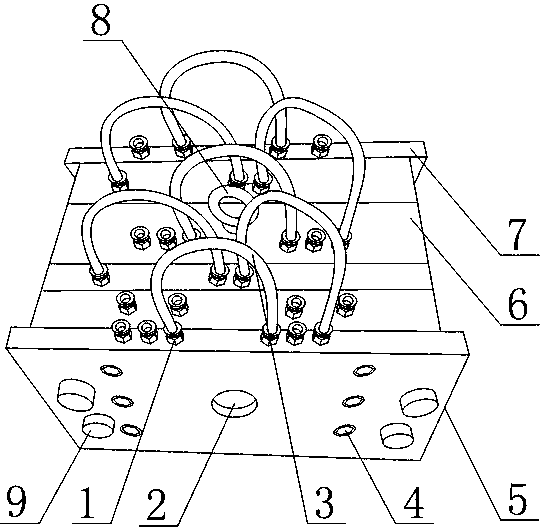

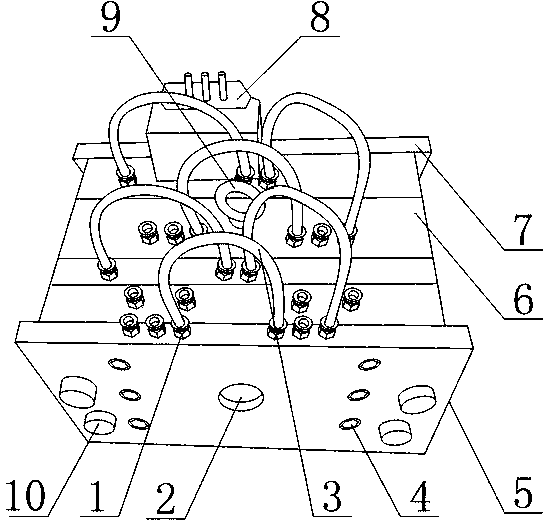

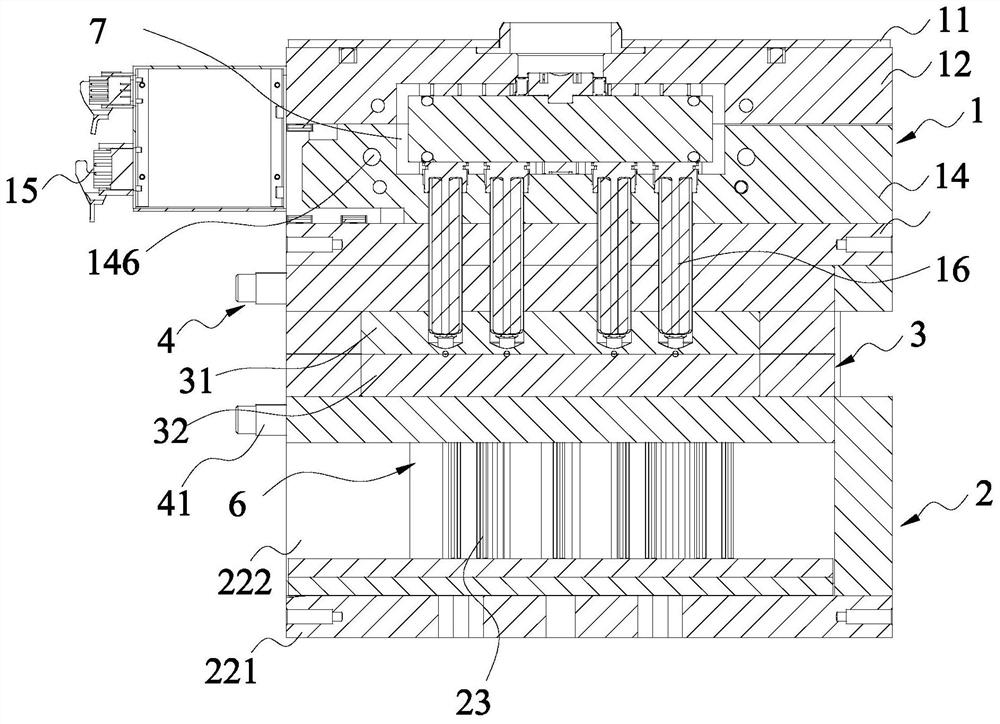

Mold temperature control injection molding mold and system and process

PendingCN111421768APrecise temperature controlShorten the production cycleTemperature controlCooling effect

The invention relates to a mold temperature control injection molding mold and system and process. The mold temperature control injection molding system comprises an injection molding machine and themold temperature control injection molding mold, and the mold temperature control injection molding mold comprises an oil temperature device, a first cooling device and a second cooling device; and alower mold oil temperature device is arranged on a forming lower mold of the oil temperature device, and a first lower mold cooling device and a second lower mold cooling device are arranged on the forming lower mold and pass through a lower mold core. The process further comprises the steps of preparation, mold closing, injection molding, pressure maintaining, first cooling, second cooling, and mold opening. According to the process, the temperature control of the mold can be accurately achieved, the injection molding production cycle is effectively reduced, the product quality and the production efficiency are improved, a heating device is prevented from being additionally arranged, and the machining cost is reduced; meanwhile, the lower mold core can be cooled, and the cooling effect isimproved; and in addition, when cooling is required in the injection molding process, the energy consumption is reduced.

Owner:东莞市安域实业有限公司

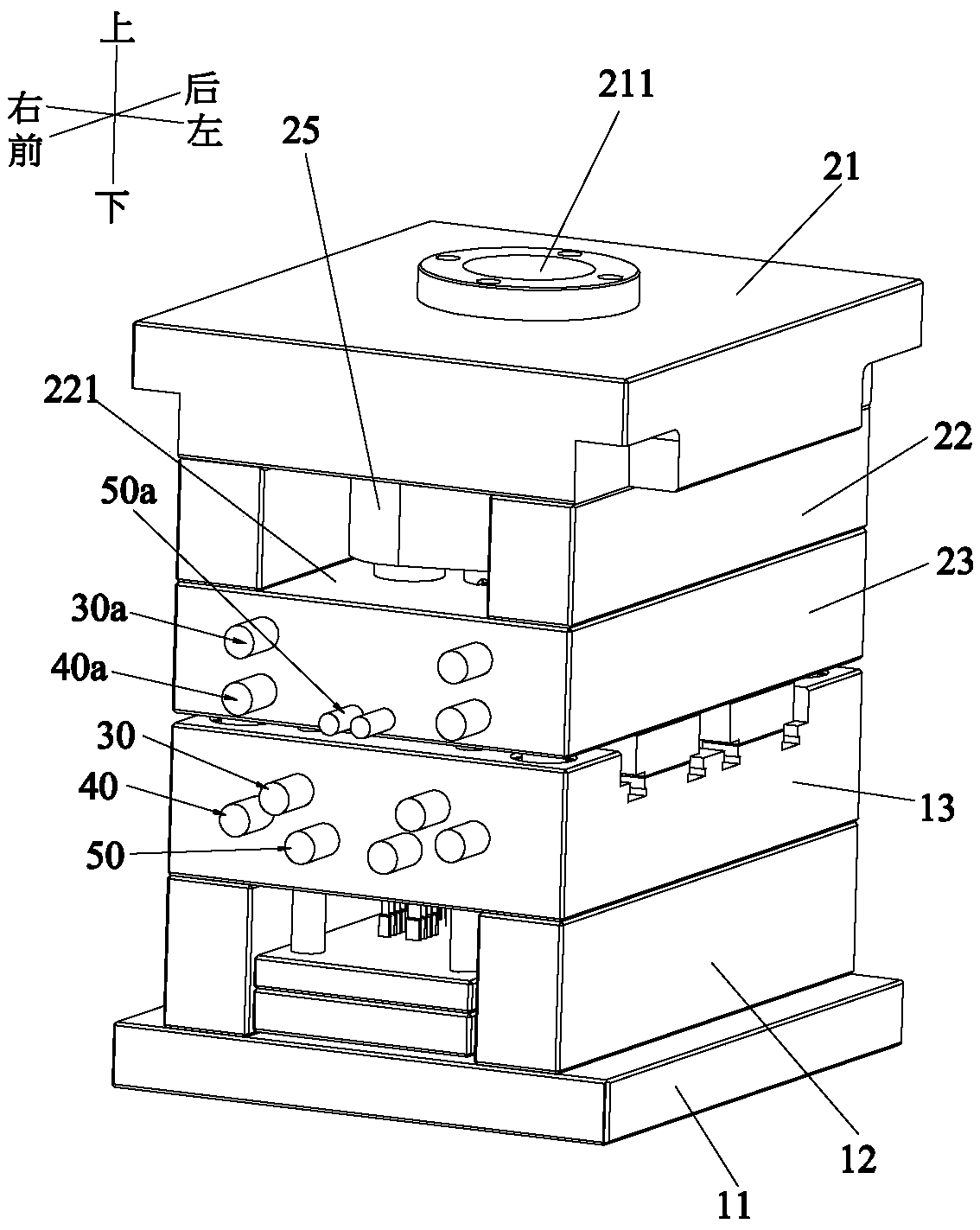

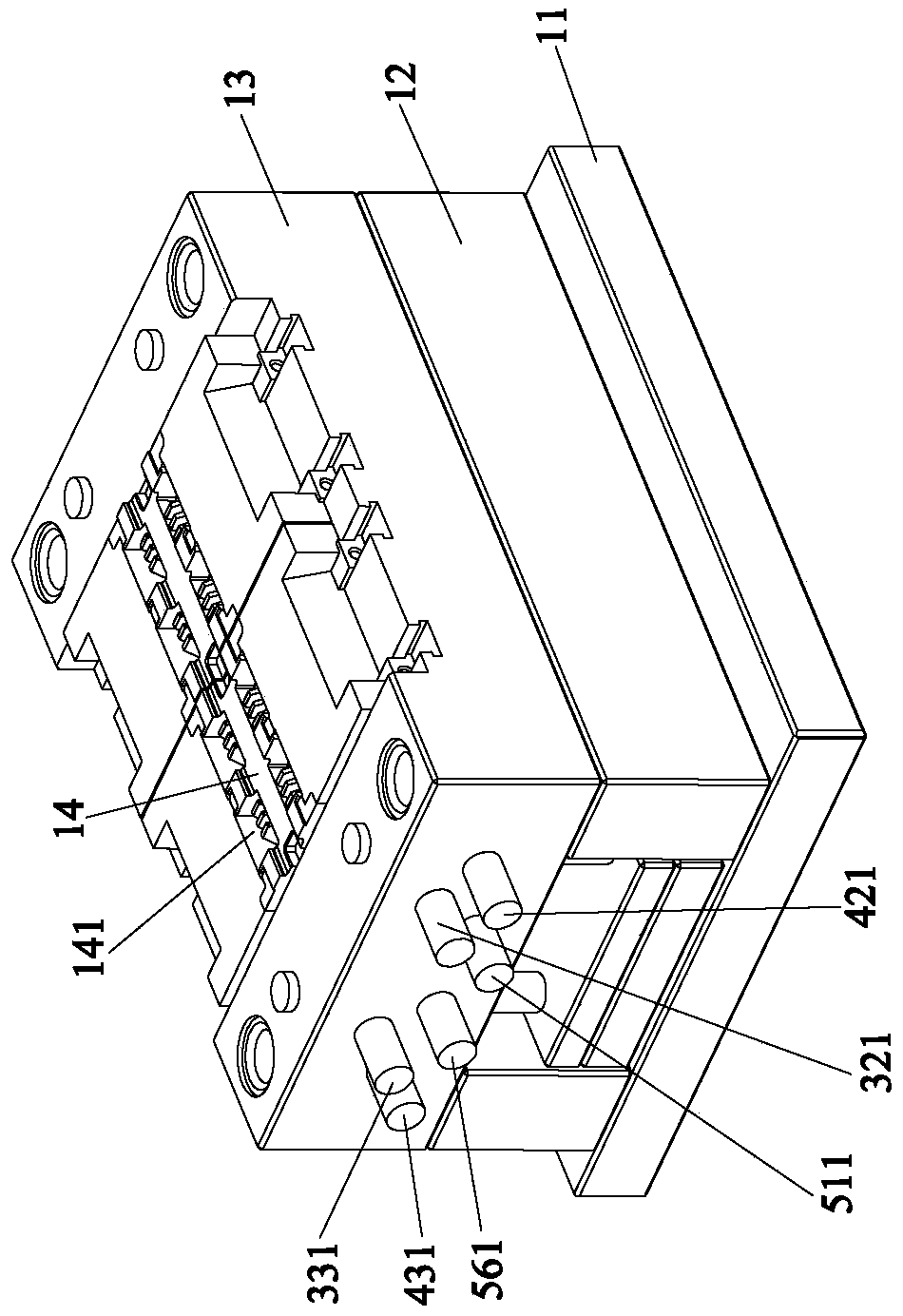

Machining mold device

PendingCN113001896AReduce replacement costsPrevent movementMechanical engineeringIndustrial engineering

The invention relates to the field of dies, in particular to a machining mold device. According to the machining mold device, an injection mold body can be rapidly replaced, the injection mold body can rapidly slide into / out of a mounting interval through a slide way mechanism arranged on a mold assembly, the mold replacement time is greatly shortened, the production efficiency is improved, only the injection mold body needs to be replaced without replacing the whole set of mold assembly, the mold replacement cost is greatly saved, the production cost is reduced, meanwhile, the injection mold body can be locked and fixed in the mounting interval through a locking mechanism, the injection mold body is effectively prevented from moving relatively, operation is easy, production is safe and stable, rapid mold replacement is achieved, and the injection molding precision is higher.

Owner:迪恩易模具科技(深圳)有限公司

Double-layer sliding type terminal cover injection mold

Owner:WUHU WANHUA PLASTIC PROD

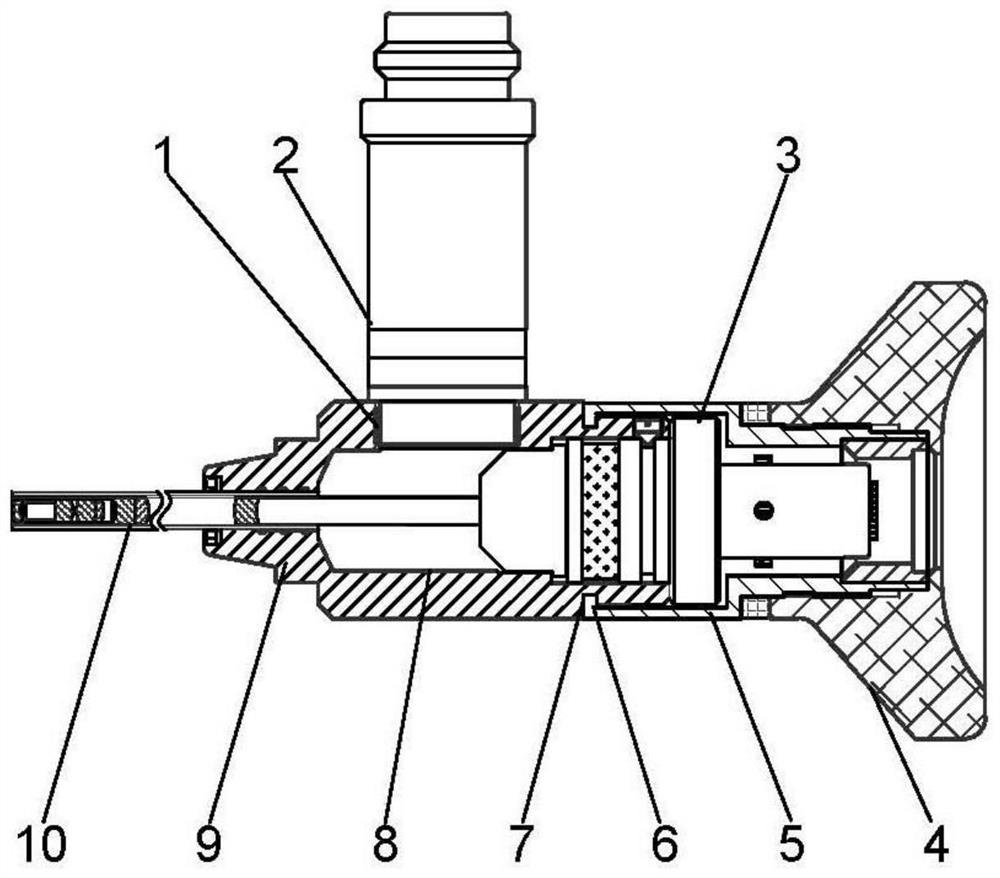

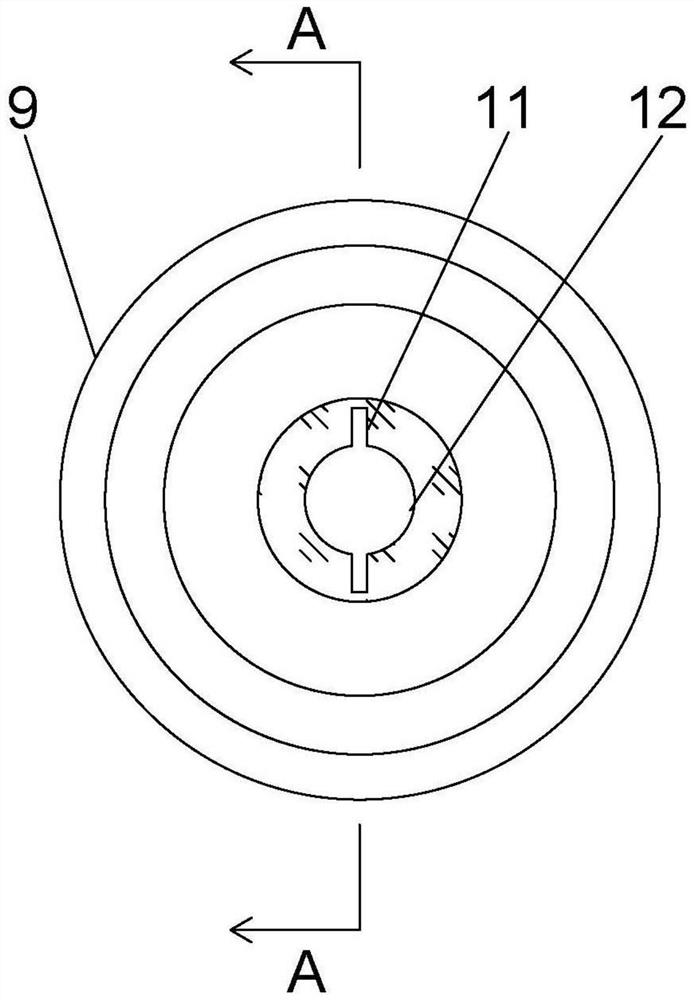

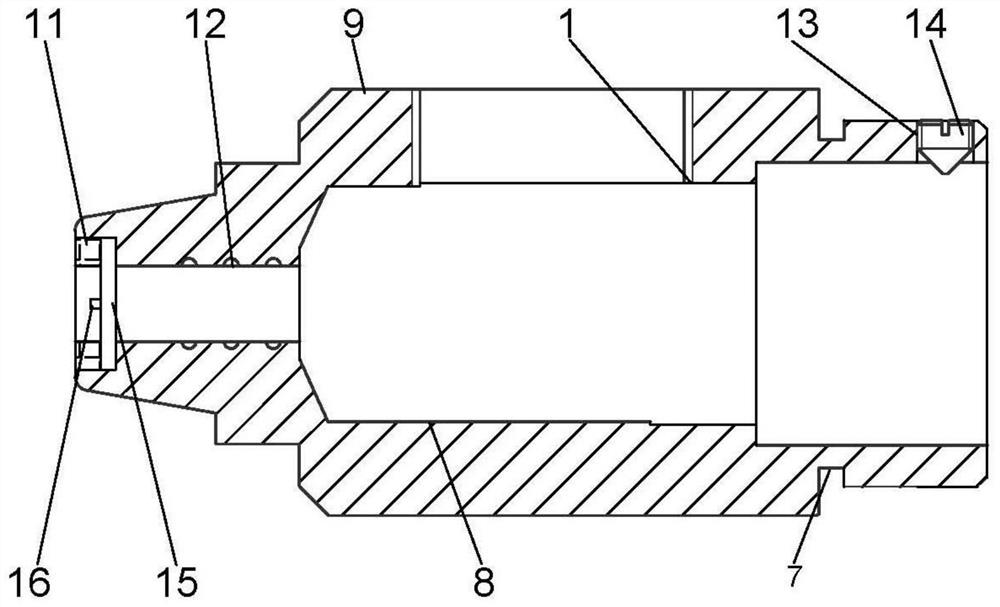

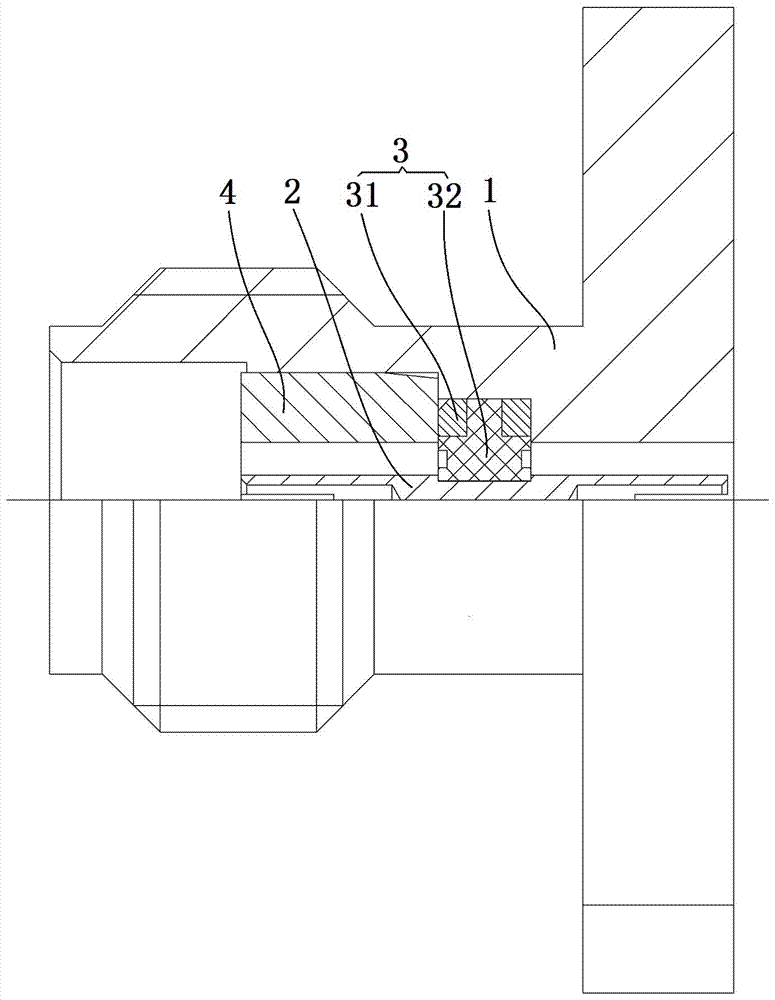

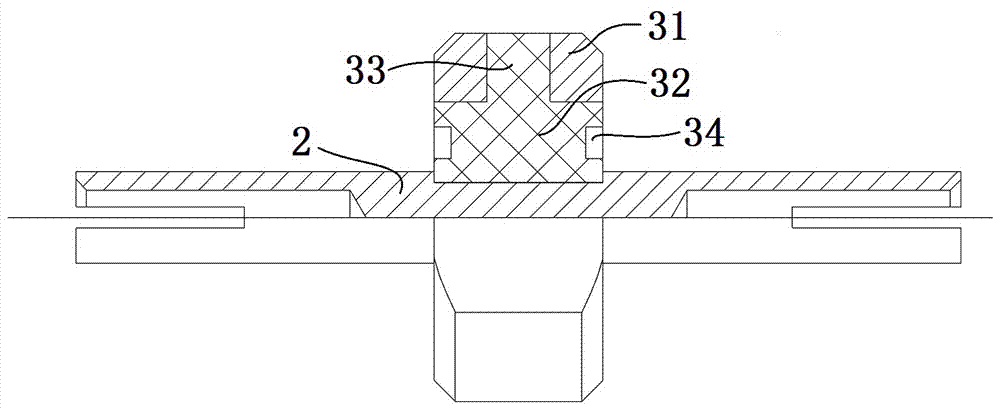

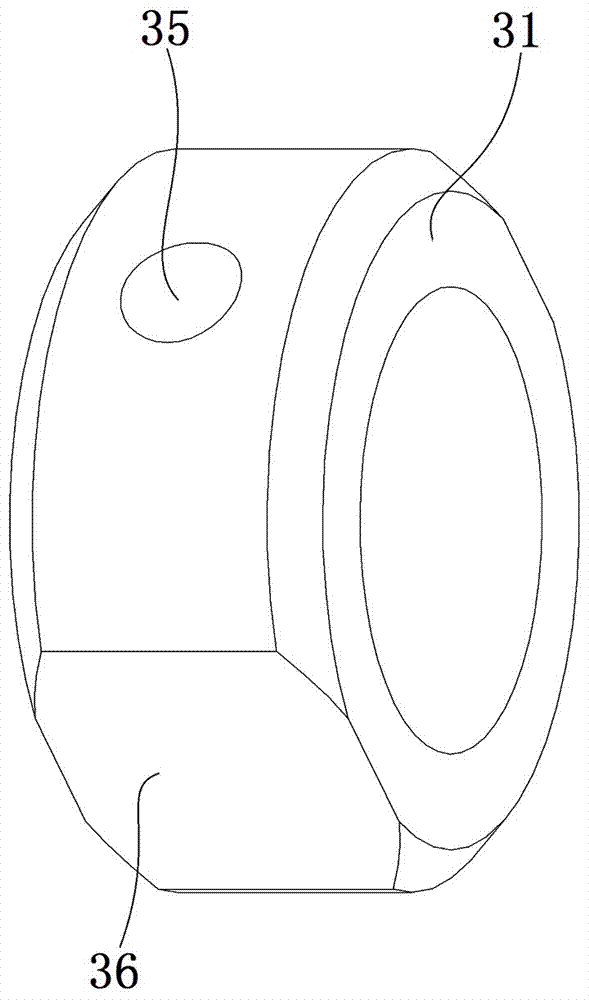

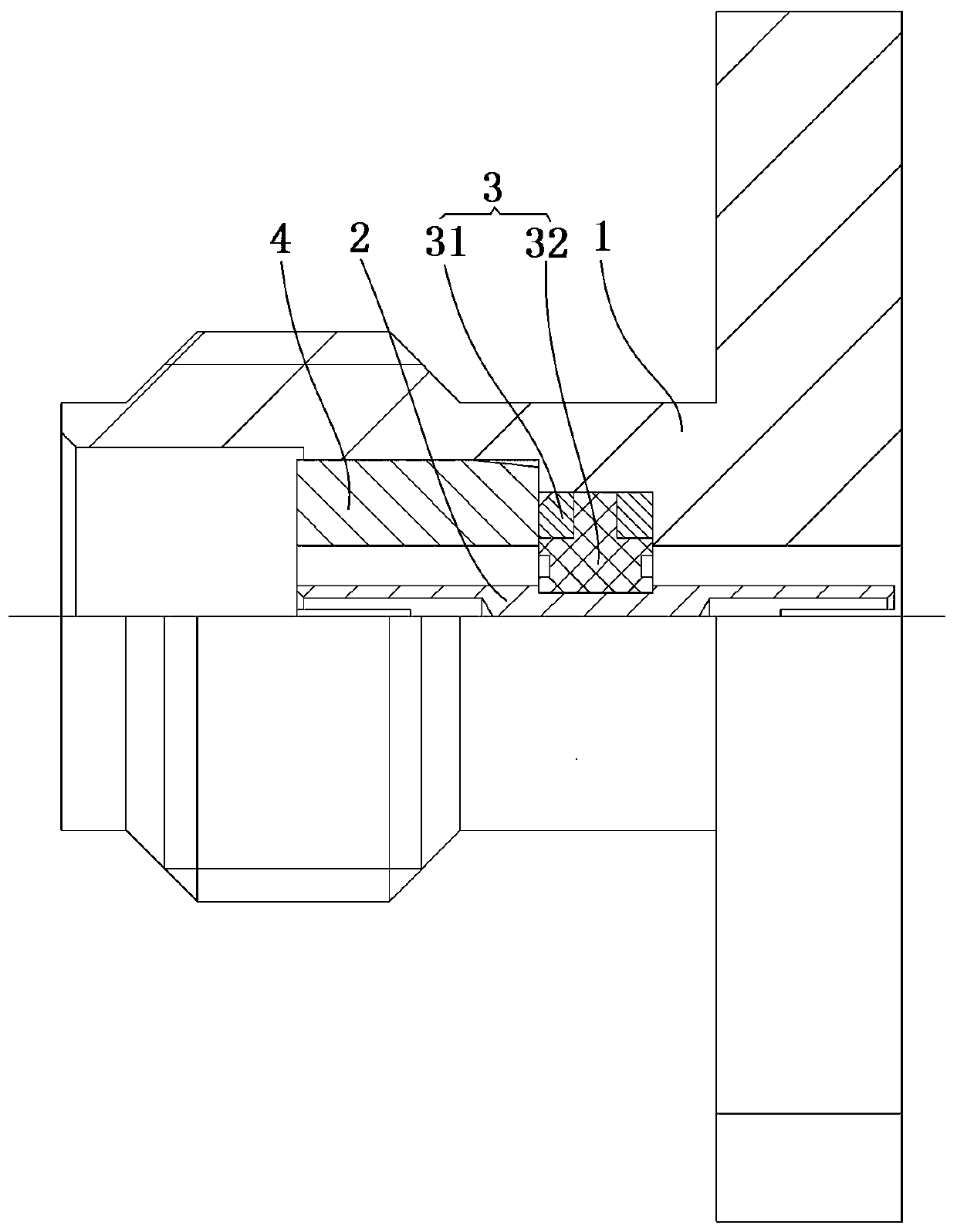

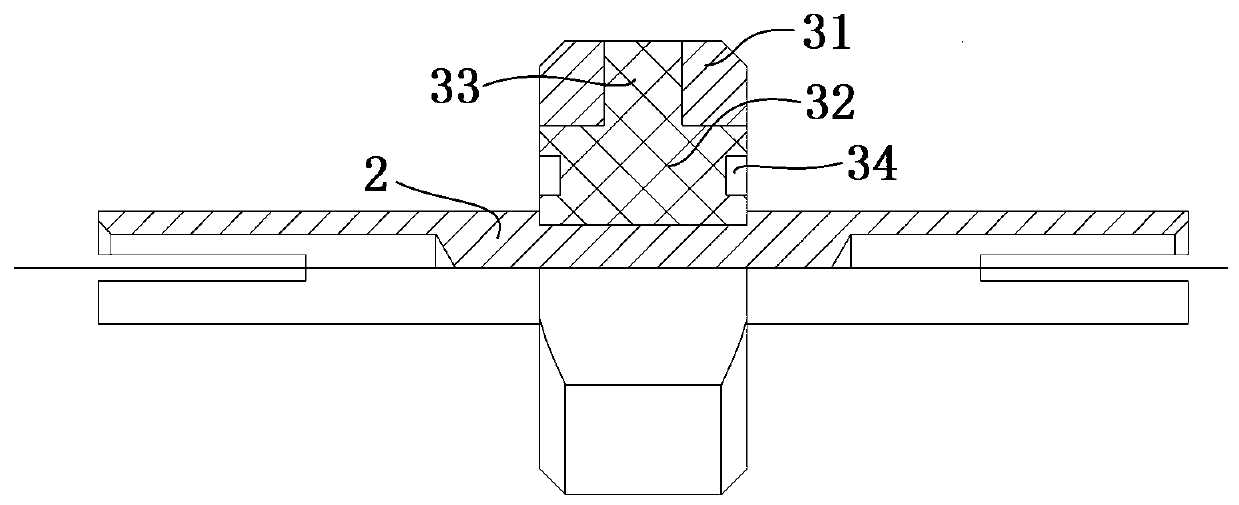

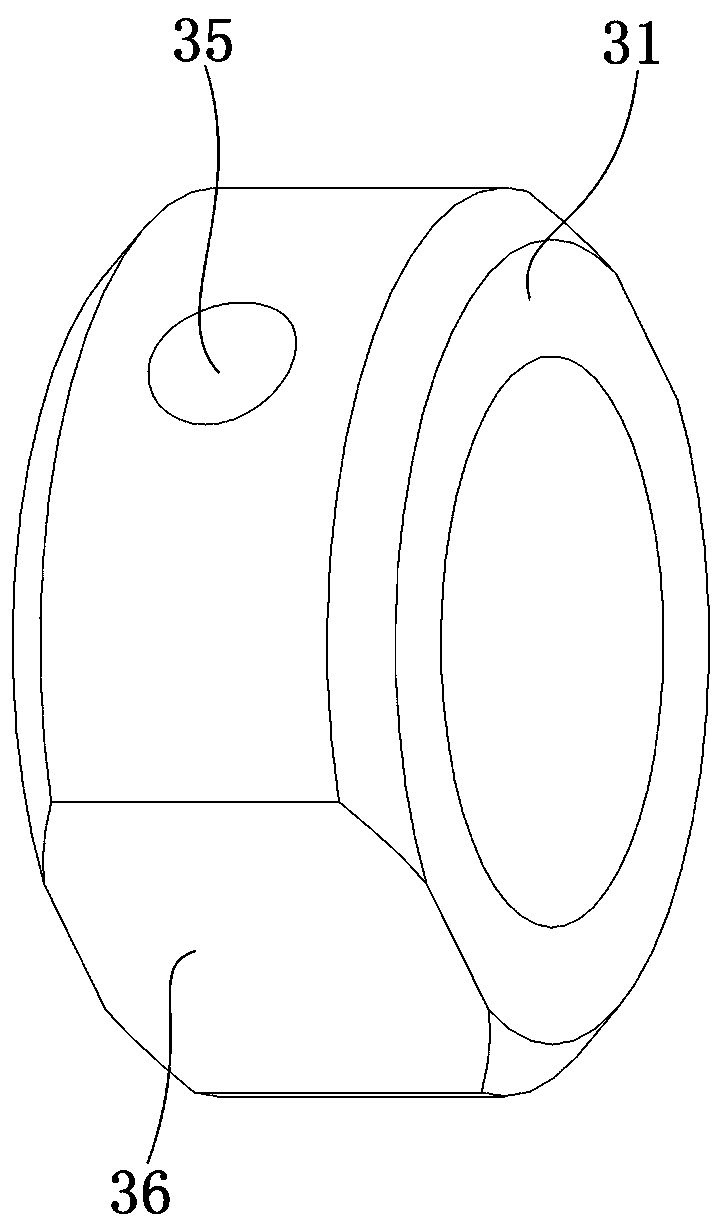

Radio-frequency connector and insulating support thereof

ActiveCN106887742AHigh precisionEasy to assembleSecuring/insulating coupling contact membersTwo-part coupling devicesElectrical conductorInjection moulding

The present invention relates to a radio-frequency connector and an insulating support thereof. The radio-frequency connector comprises an internal conductor, an external conductor, and an insulating support. The internal conductor and the external conductor are coaxially mounted. The insulating support is used for supporting the internal conductor inside the inner hole of the external conductor. The insulating support comprises an annular base body and an insulator integrally injected and molded inside the inner hole of the annular base body. During assembly, the insulating support is sleeved onto the internal conductor through the installation hole of the insulator. After that, the internal conductor is installed inside the external conductor together with the insulating support. Therefore, the assembly is simple and convenient. The insulator is formed through the injection molding process. The surface precision of the installation hole of the insulator is guaranteed by a core shaft. Therefore, the precision of the installation hole of the insulator is improved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

An injection molding device for educational toy processing

Owner:狼伙伴(苏州)影视产业有限公司

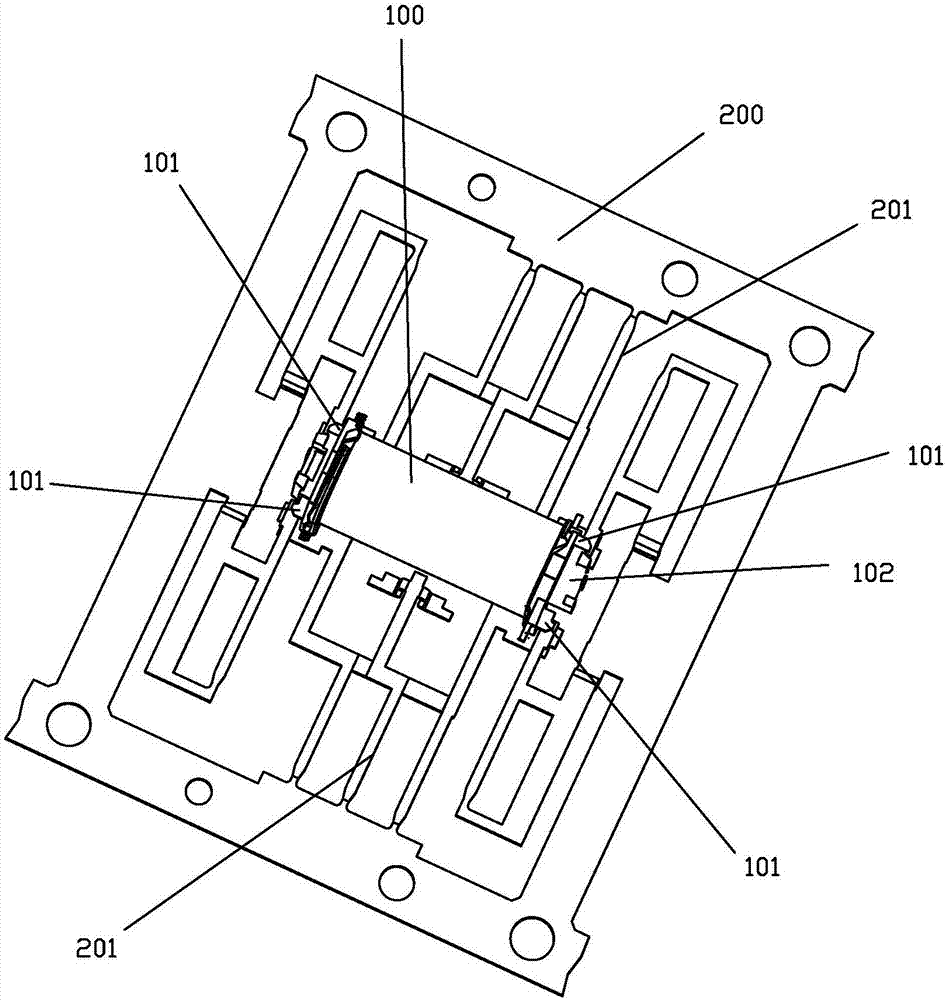

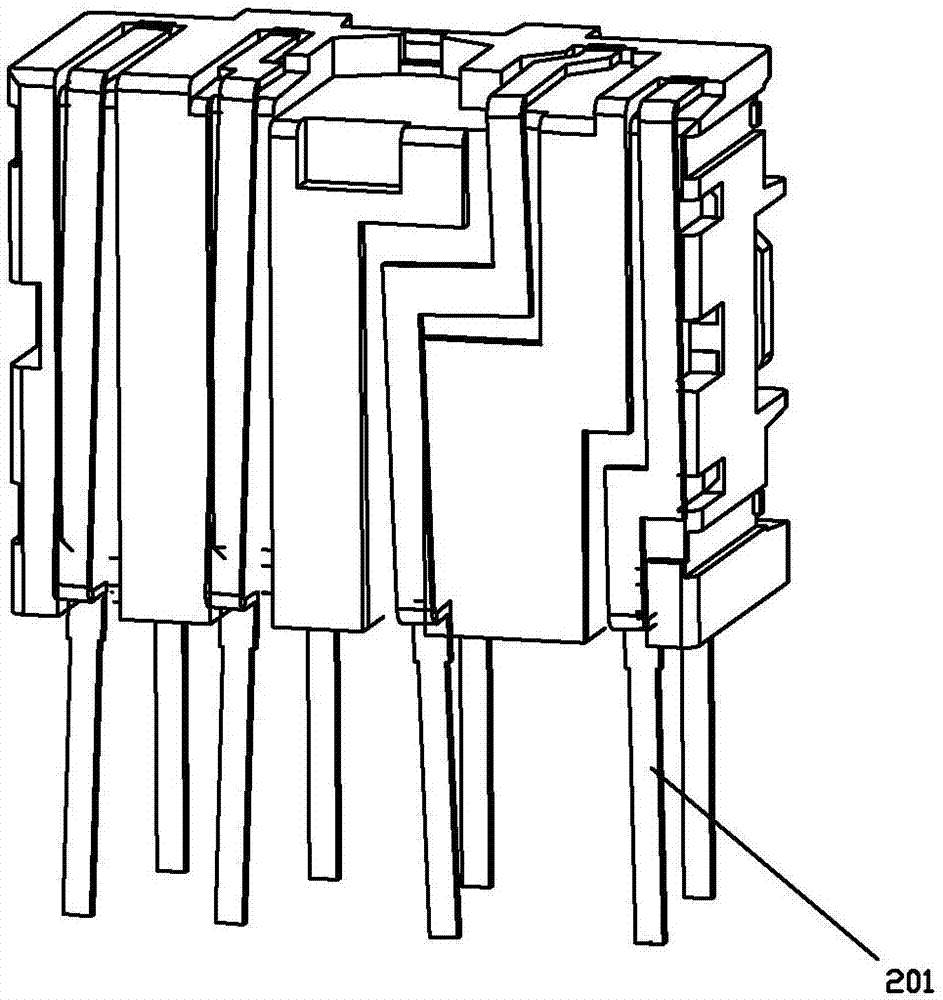

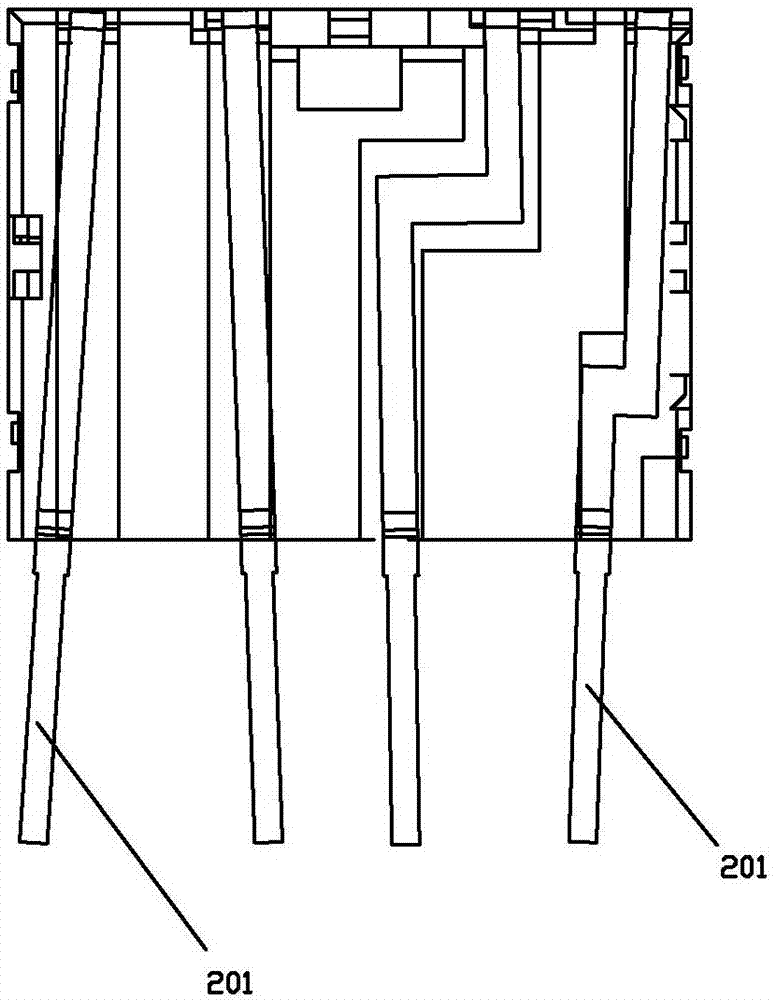

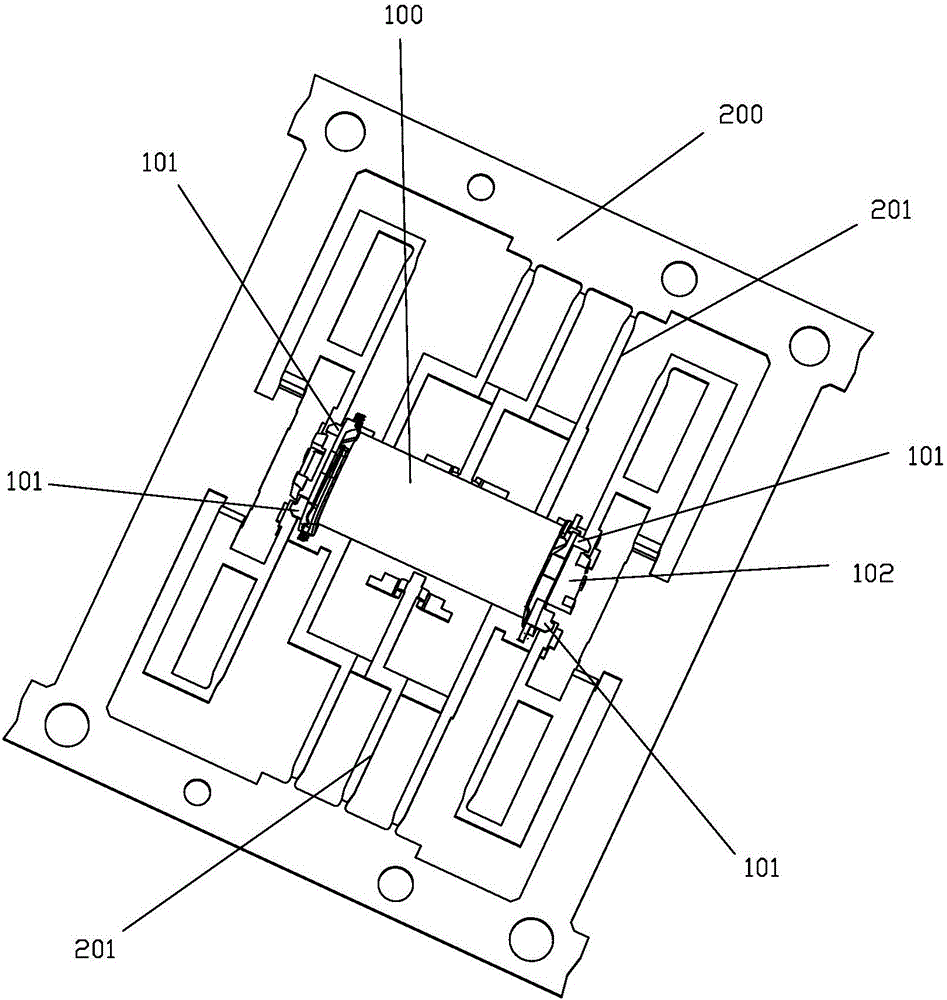

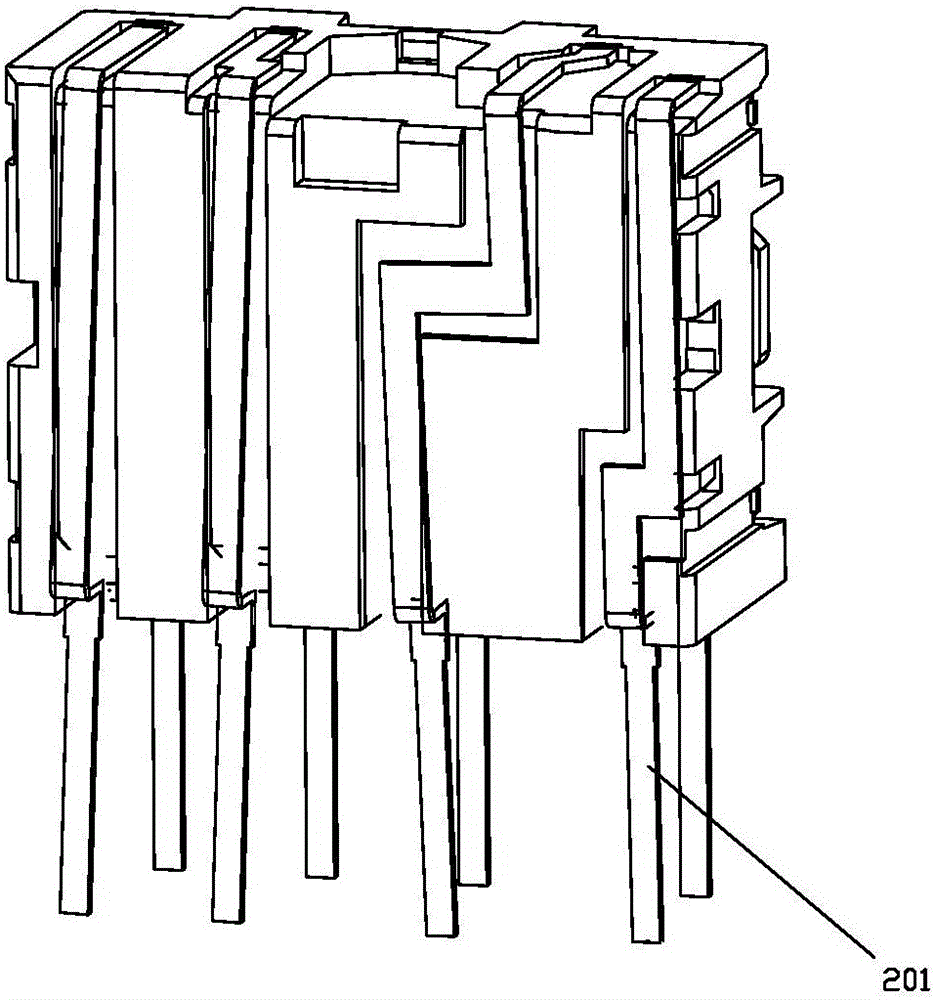

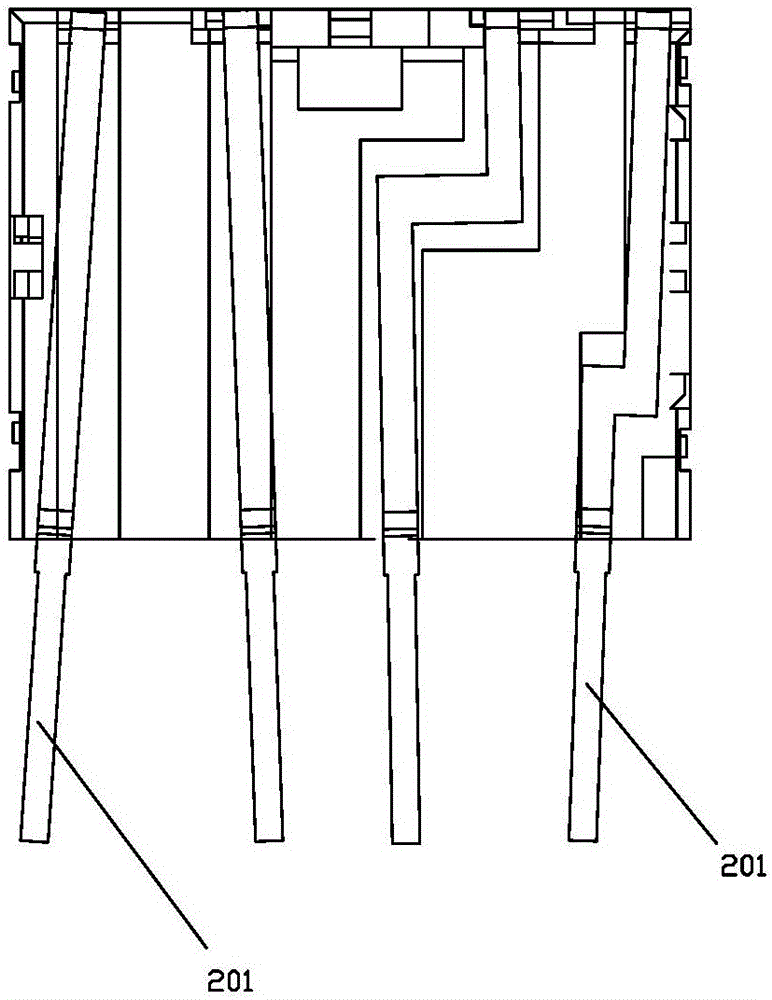

A relay base structure with stable positioning and good consistency can be achieved during secondary injection molding

ActiveCN105826132BAchieve positioningRealize the positioning of the positioningElectromagnetic relay detailsCopperInternal stress

The invention discloses a relay base structure capable of realizing positioning stability and good consistency during secondary injection molding. The relay base structure includes a coil rack and two copper leading-out sheets which are formed on one end of the coil rack during primary injection molding and serve as coil leading-out pins, and the other end of the coil rack is not provided with copper leading-out sheets, but the other end of a coil component is provided with a positioning part used for realizing positioning with an injection mold during secondary injection molding, so that when corresponding positions of the two copper leading-out sheets of the one end of the coil rack and a static spring belt adopt laser welding positioning, the positioning part can enable the coil component to realize positioning in a preset direction. Through improvement of a relay base structure, internal stress generated after integral injection molding of a coil due to deformation of the static spring belt can be eliminated, leading-out terminals of a relay can be guaranteed to be straight after integral injection molding, and thus efficient automated production can be realized and performance can be guaranteed.

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

Relay base structure capable of realizing positioning stability and good consistency during secondary injection molding

ActiveCN105826132APrevent vertical and lateral offsetThe position of the iron core end face is reliableElectromagnetic relay detailsInternal stressCopper

The invention discloses a relay base structure capable of realizing positioning stability and good consistency during secondary injection molding. The relay base structure includes a coil rack and two copper leading-out sheets which are formed on one end of the coil rack during primary injection molding and serve as coil leading-out pins, and the other end of the coil rack is not provided with copper leading-out sheets, but the other end of a coil component is provided with a positioning part used for realizing positioning with an injection mold during secondary injection molding, so that when corresponding positions of the two copper leading-out sheets of the one end of the coil rack and a static spring belt adopt laser welding positioning, the positioning part can enable the coil component to realize positioning in a preset direction. Through improvement of a relay base structure, internal stress generated after integral injection molding of a coil due to deformation of the static spring belt can be eliminated, leading-out terminals of a relay can be guaranteed to be straight after integral injection molding, and thus efficient automated production can be realized and performance can be guaranteed.

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

RF connector and its insulating support

ActiveCN106887742BHigh precisionEasy to assembleSecuring/insulating coupling contact membersTwo-part coupling devicesElectrical conductorEngineering

The present invention relates to a radio-frequency connector and an insulating support thereof. The radio-frequency connector comprises an internal conductor, an external conductor, and an insulating support. The internal conductor and the external conductor are coaxially mounted. The insulating support is used for supporting the internal conductor inside the inner hole of the external conductor. The insulating support comprises an annular base body and an insulator integrally injected and molded inside the inner hole of the annular base body. During assembly, the insulating support is sleeved onto the internal conductor through the installation hole of the insulator. After that, the internal conductor is installed inside the external conductor together with the insulating support. Therefore, the assembly is simple and convenient. The insulator is formed through the injection molding process. The surface precision of the installation hole of the insulator is guaranteed by a core shaft. Therefore, the precision of the installation hole of the insulator is improved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

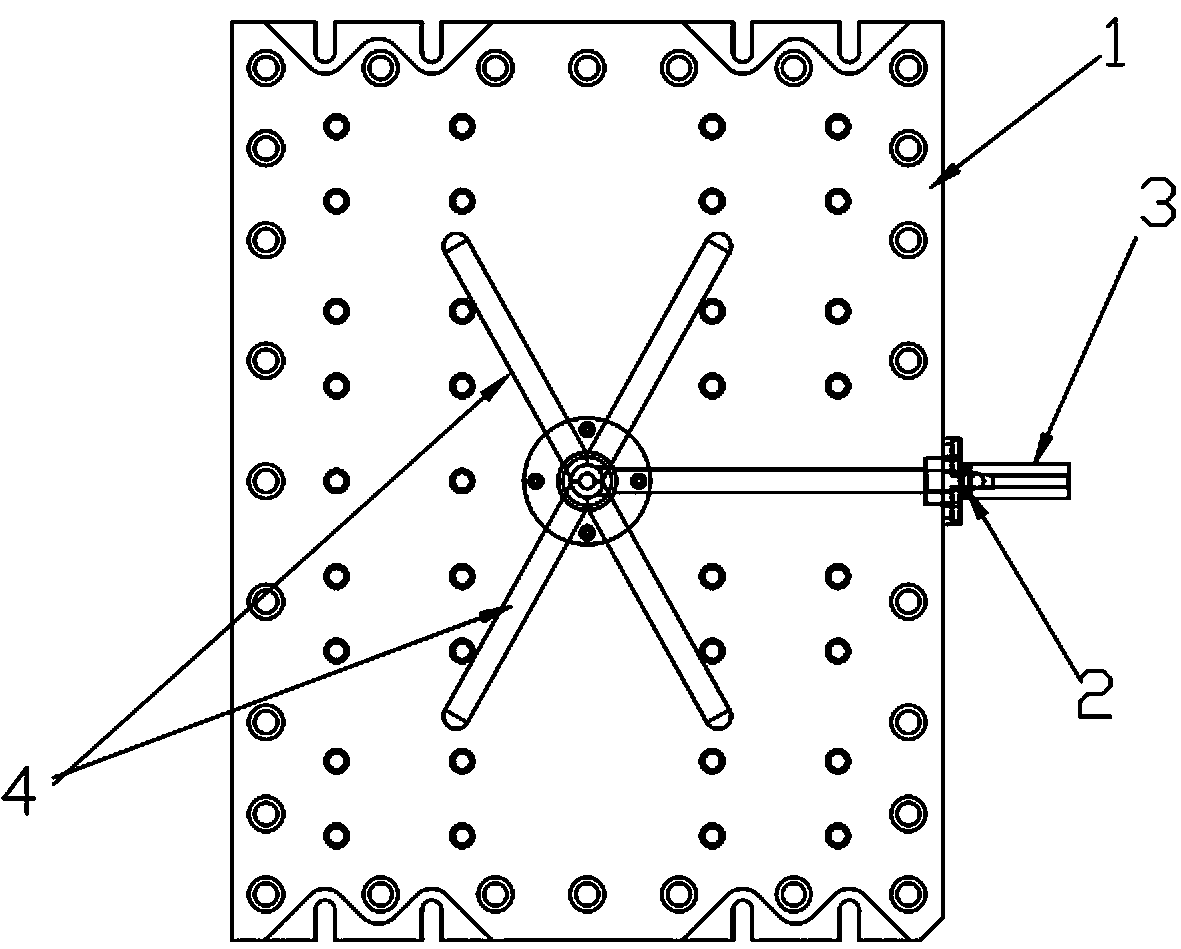

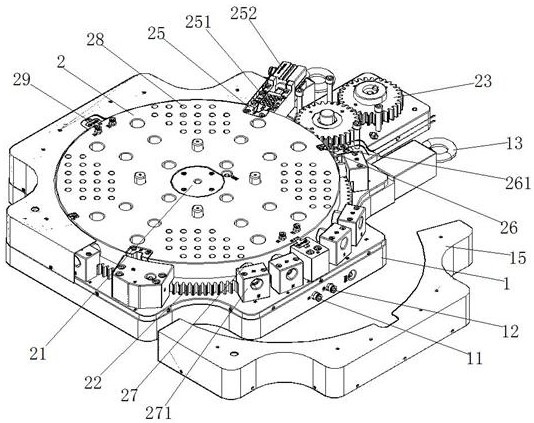

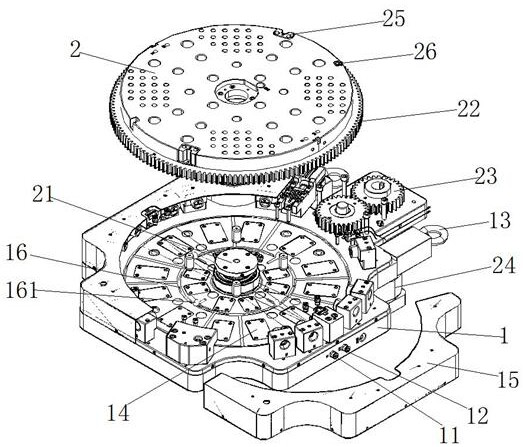

Auxiliary rotary table for forming multi-color mold by single-color machine

The invention discloses an auxiliary rotary table for forming a multi-color mold by a single-color machine. The rotary table comprises a base, a horizontally arranged rotary table is arranged at the upper end of the base, a central rotating shaft is arranged at the upper end of the rotary table, teeth are arranged at the lower end of the peripheral edge of the rotary table, the teeth are meshed with a correspondingly matched driving gear set, and the driving gear set is fixedly arranged at the upper end of the base. The driving gear set is connected with a driving motor, a plurality of concave positioning concave blocks and sensor contact blocks are arranged at the upper end of the edge of the periphery of the rotary table, positioning convex blocks correspondingly matched with the positioning concave blocks are arranged at the upper end of the base, the positioning convex blocks are connected with positioning air cylinders, and sensors corresponding to the sensor contact blocks are arranged at the upper end of the base. A plurality of pressing wheels are arranged at the side end of the periphery of the rotary table, arranged on the upper end faces of the teeth and arranged at the upper end of the base through pressing wheel fixing seats. The auxiliary rotary table has the advantages of being novel in design, simple in structure, accurate in positioning, capable of being used for multi-color mold injection molding, low in cost and good in injection molding effect.

Owner:东莞市凯誉塑胶模具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com