Injection mold device with heating device

A technology of injection mold and heating device, applied in the field of injection molding equipment, can solve the problems of reducing injection molding precision, inconvenience, and adversely affecting the production efficiency of enterprises, and achieves the effects of good sealing performance, convenient extraction and insertion, and reliable connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

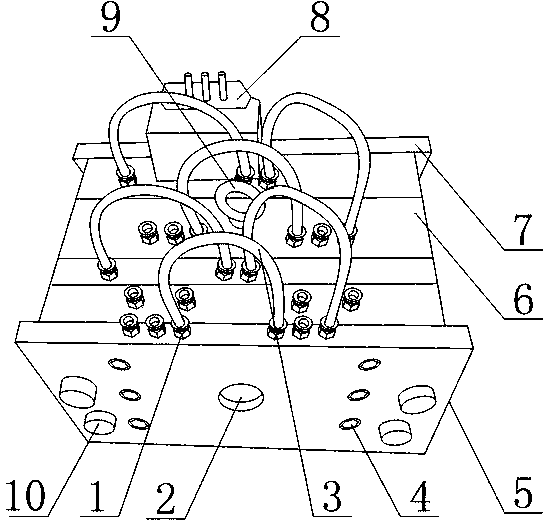

[0026] Such as figure 1 As shown, a kind of injection mold device with heating device comprises front baffle plate 5, a plurality of cavity plates 6 with cavities inside, rear baffle plate 7 and electric heater 8, and a plurality of said cavity plates 6 is located between the front baffle 5 and the rear baffle 7, and the front baffle 5, a plurality of the cavity plates 6, and the rear baffle 7 are stacked in sequence, and the front baffle 5, the plurality of cavity plates 7 Both the cavity plate 6 and the rear baffle 7 are provided with a plurality of flow passages communicating up and down, the front baffle 5 is also provided with injection holes 2, and the rear baffle 7 is also provided with exhaust holes. The electric heater 8 is arranged on the cavity plate 6 .

[0027] The set front baffle 5, multiple cavity plates 6 and rear baffle 7 are combined to form the cavity of the injection mold, and the cavity part is composed of front baffle 5, multiple cavity plates 6 and rea...

Embodiment 2

[0029] This embodiment is further defined on the basis of embodiment 1, as figure 1 As shown, it also includes drainage tube interfaces 1 whose number is twice the number of flow channels, and the drainage tube interfaces 1 are respectively arranged at the inlet and outlet of each flow channel.

[0030] The provided drainage tube interface 1 facilitates the connection between the flow channel and the external pipeline in the present invention.

[0031] It also includes a drainage tube 3, the drainage tube interface 1 is a common quick connector for gas and liquid, the drainage tube 3 is a plastic hose, and the free ends of the drainage tube 3 are fixedly connected to any two drainage tube interfaces 1 .

[0032] The set plastic hose and the gas-liquid shared quick connector are easy to pull out and insert, and the connection is reliable, and the sealing performance of the connection surface is good.

[0033] The front baffle plate 5, the plurality of cavity plates 6 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com