Auxiliary rotary table for forming multi-color mold by single-color machine

A turntable, monochrome technology, applied in the field of auxiliary turntables, can solve the problems of slow rotation, only 180 degrees of reciprocating rotation, uneven acceleration and deceleration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described below in conjunction with specific embodiments.

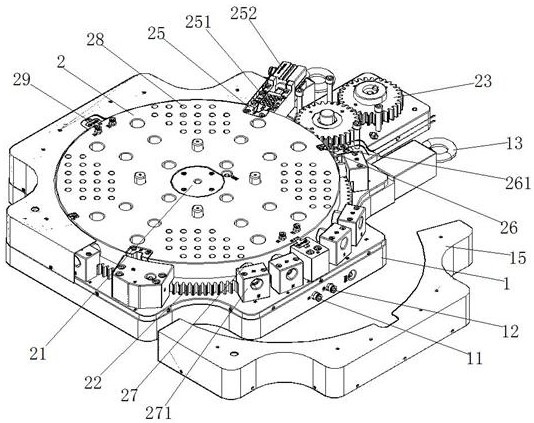

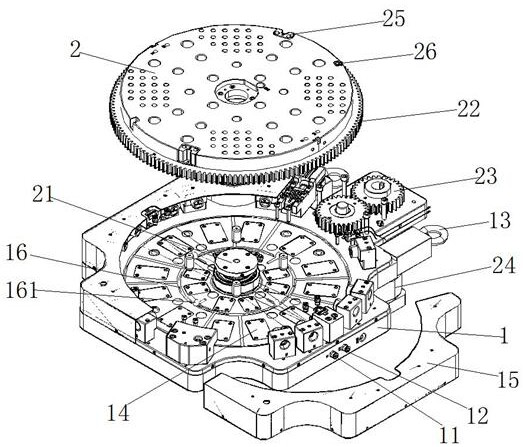

[0016] Such as Figure 1-2 As shown, an auxiliary turntable for forming a multi-color mold by a single-color machine includes a base 1, a turntable 2 arranged horizontally is installed on the upper end of the base 1, and a central rotating shaft 21 is arranged on the upper end of the turntable 2, and the lower end of the turntable 2 is arranged on the periphery. There are teeth 22, and the teeth 22 are engaged with a corresponding matching driving gear set 23, the driving gear set 23 is fixedly installed on the upper end of the base 1, and the driving gear set 23 is connected with a driving motor 24, and the upper end of the surrounding edge of the turntable 2 is equipped with Several concave positioning concave blocks 25 and sensor contact blocks 26, and the positioning concave blocks 25 corresponding matching positioning bumps 251 are installed on the upper end of the base 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com