Manufacturing method of waistband buckle and waistband buckle manufactured by manufacturing method

A production method and technology of belt buckles, which are applied to belt buckles, fasteners, clothing, etc., can solve the problems of restricting the development of belt product refinement, lower product grade and taste, and different product quality, so as to achieve beautiful appearance and improve The effect of high taste and product fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

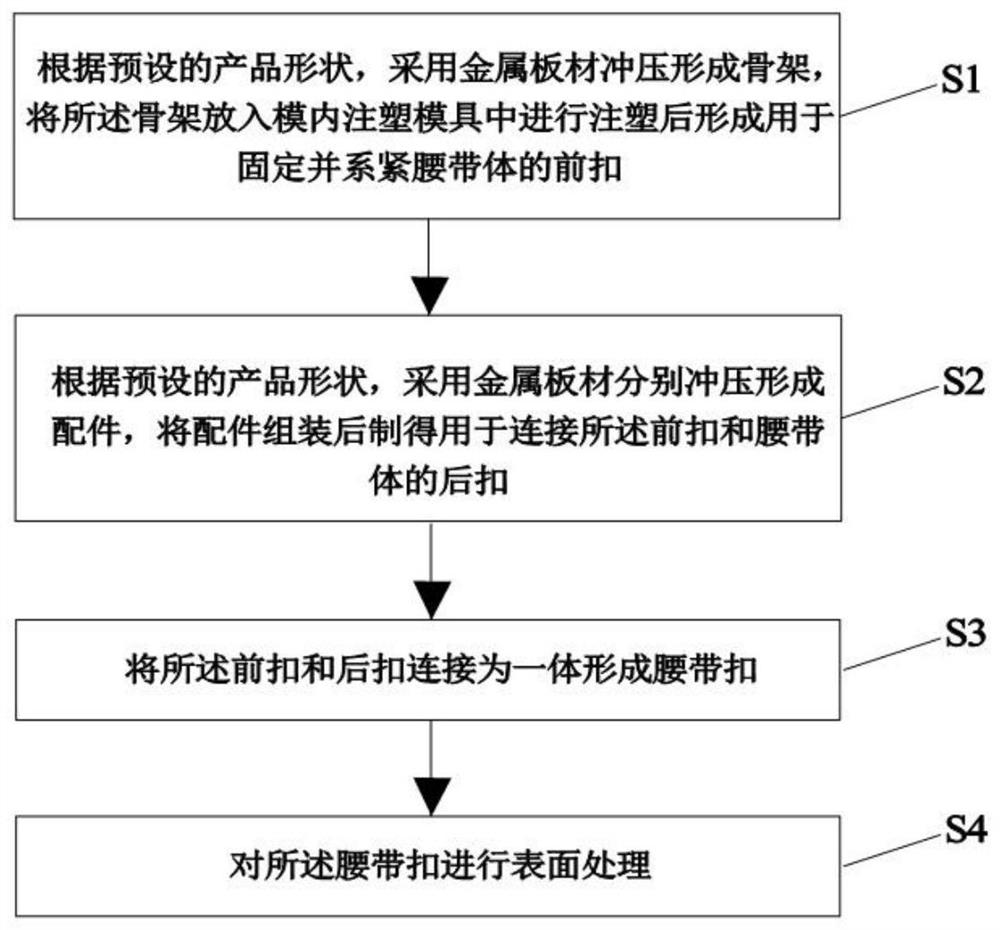

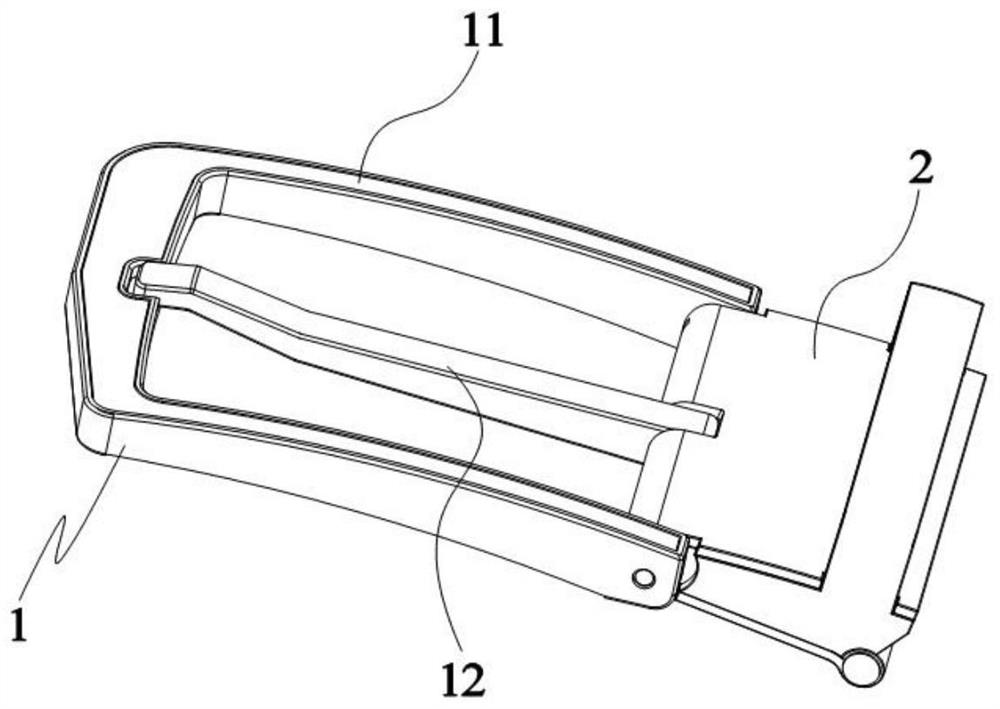

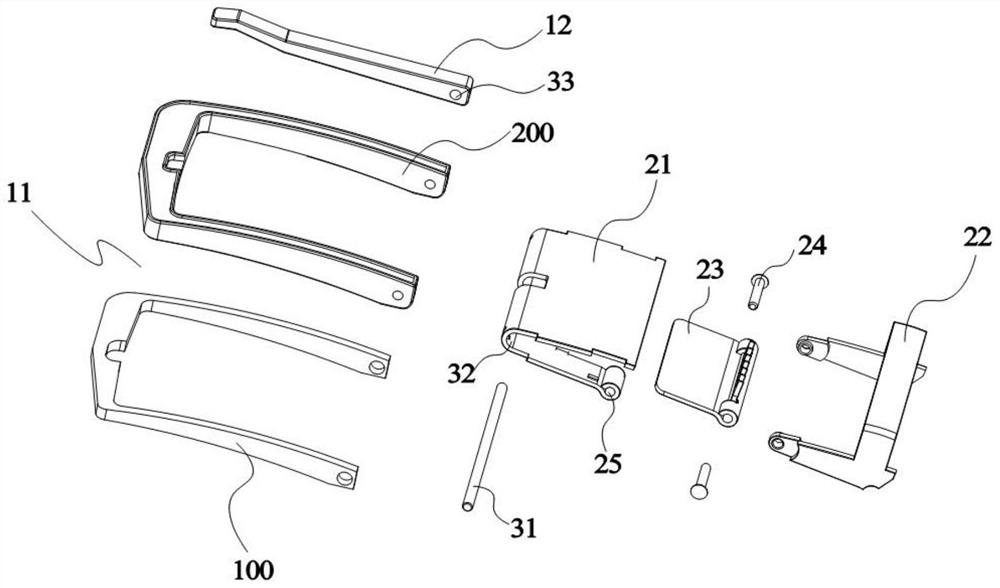

[0034] like Figure 2 ~ Figure 3 As shown, the present embodiment provides a method for manufacturing a pin-type belt buckle, the pin-type belt buckle includes a front buckle 1 and a rear buckle 2, and the method includes the following steps:

[0035] S101: According to the shape of the front buckle 1, use 1-2mm metal plate to form a metal stamping skeleton 100 by precision stamping, put the skeleton 100 into an in-mold injection mold for injection molding and a partial appearance surface 200 to form the front buckle body 11. The front buckle pin 12 is formed by precision stamping of a metal plate, the front buckle body 11 and the front buckle pin 12 constitute the front buckle 1, and the front buckle 1 is used to fix and fasten the belt body;

[0036] S102: According to the shape of the back buckle 2, the back buckle body 21, the back buckle crossing bridge 22 and the back buckle pressing plate 23 are formed by punching metal plates respectively, and the back buckle body 21 a...

specific Embodiment 2

[0042] like Figure 4 ~ Figure 5 As shown, the present embodiment provides a method for manufacturing a plate-type belt buckle, the plate-type belt buckle includes a front buckle 1 and a rear buckle 2, and the method includes the following steps:

[0043] S201: According to the shape of the front buckle 1, the metal stamping skeleton 100 is formed by precise stamping of a metal plate of 1-2 mm, and the skeleton 100 is put into an in-mold injection mold for injection molding and a partial appearance surface 200 to form the front buckle body 11. The front buckle nail 12 is formed by precise stamping of metal sheet, the front buckle body 11 and the front buckle nail 12 form the front buckle 1, and the front buckle 1 is used to fix and fasten the belt body;

[0044] S202: According to the shape of the back buckle 2, the back buckle body 21, the back buckle crossing bridge 22 and the back buckle pressing plate 23 are formed by punching metal plates respectively, and the back buckle...

specific Embodiment 3

[0050] like Figure 6 ~ Figure 7 As shown, the present embodiment provides a method for manufacturing an automatic gusset type belt buckle, the automatic gusset type belt buckle includes a front buckle 1 and a rear buckle 2, and the method includes the following steps:

[0051] S301: According to the shape of the front buckle 1, a metal stamping skeleton 100 is formed by precise stamping of a 1-2mm metal plate, and the skeleton 100 is put into an in-mold injection mold for injection molding and a partial appearance surface 200 to form the front buckle body 11. The front buckle automatic buckle 12 is formed by precise stamping of metal plates, the front buckle body 11 and the front buckle automatic buckle 12 form the front buckle 1, and the front buckle 1 is used to fix and fasten the belt body;

[0052] S302: According to the shape of the back buckle 2, the back buckle body 21, the back buckle crossing bridge 22 and the back buckle pressing plate 23 are formed by punching meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com