Injection moulding mould for automobile steering lamp holder

A technology for injection molds and lamp holders, which is applied to household appliances, other household appliances, and household components. It can solve problems such as partial precision failure, production difficulties of enterprises, and inability to produce qualified products. It achieves a high product qualification rate, The effect of high cavity precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described below in conjunction with accompanying drawing.

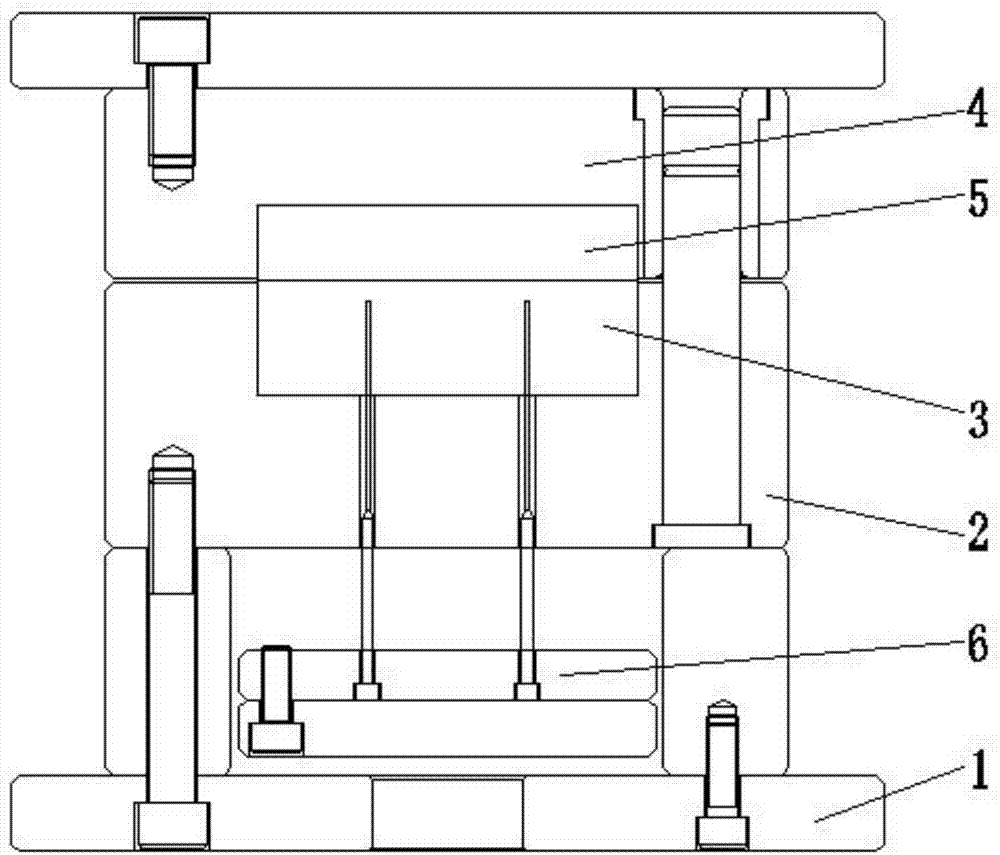

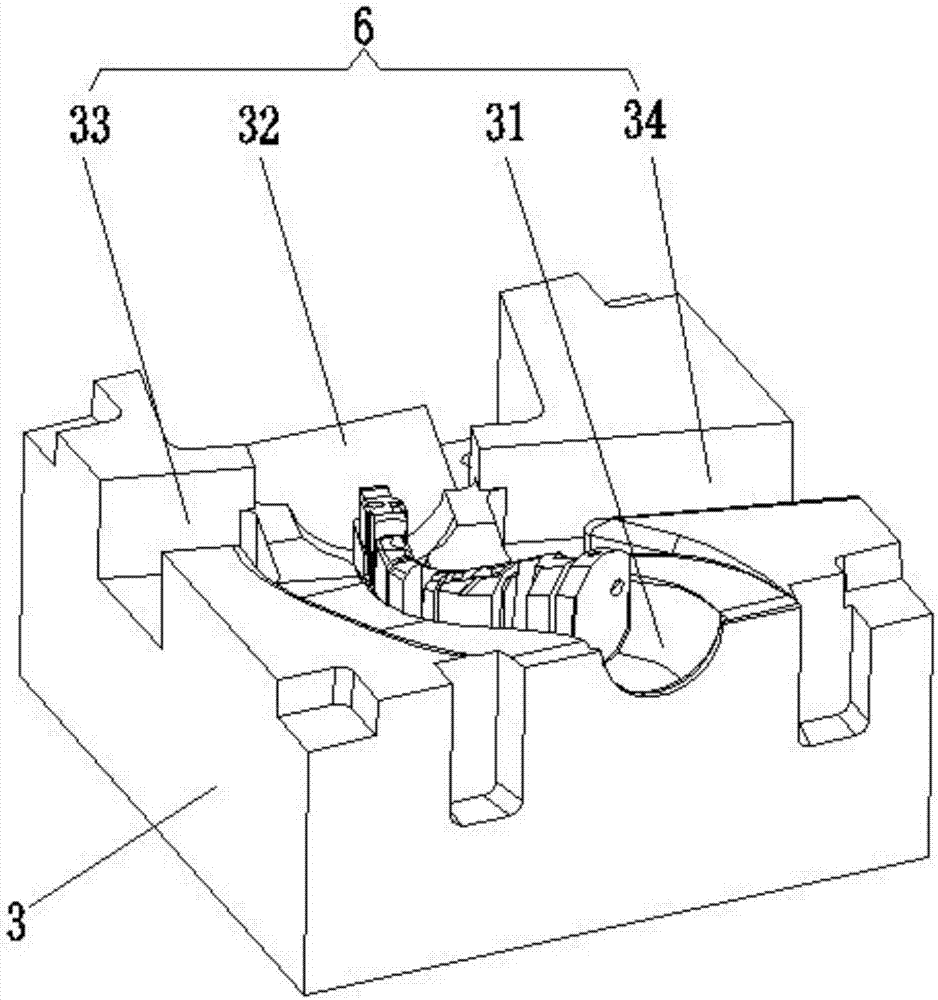

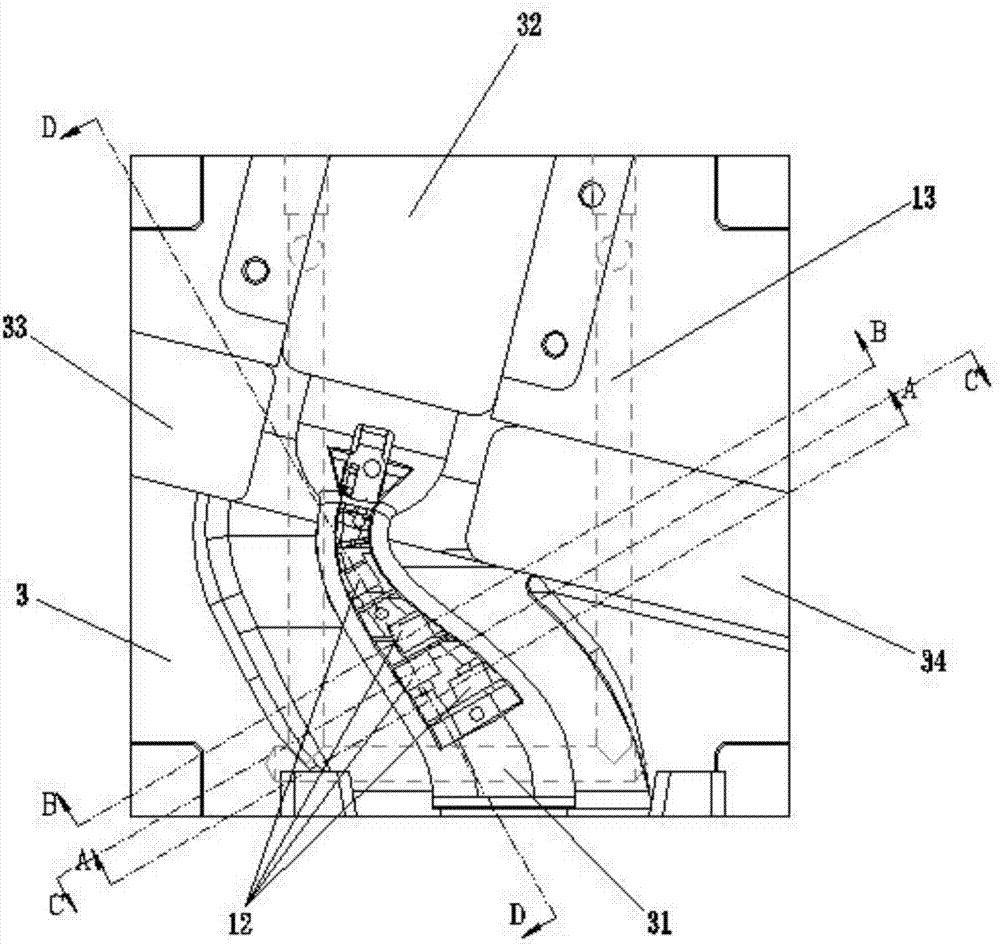

[0036] A kind of injection mold of automobile turning lamp holder of the present invention, as attached figure 1 - As shown, it includes a mold base 1, a male mold base 2, a male mold core 3, a female mold base 4, a female mold core 5 and an ejection mechanism 6; the female mold base 4 and the male mold base 2 are matched up and down , the male mold core 3 is installed in the male mold base 2, and the female mold core 5 is installed in the female mold base 4; between the male mold core 3 and the female mold core 5, there are four Slider chamber 6; said four slider chambers 6 are respectively front slider chamber 31, rear slider chamber 32, left slider chamber 33 and right slider chamber 34; said front slider chamber 31, rear slider chamber Cavity 32, left slider cavity 33 and right slider cavity 34 are respectively provided with front slider assembly 7, rear slider assembly 8, left sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com