Laser engraving machine and operating method thereof

A laser engraving machine and visual positioning technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of low positioning accuracy of parts, unsuitable for diversified production, low utilization rate of laser engraving machines, etc., to achieve Improve the utilization rate, improve the quality and product qualification rate, and protect the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

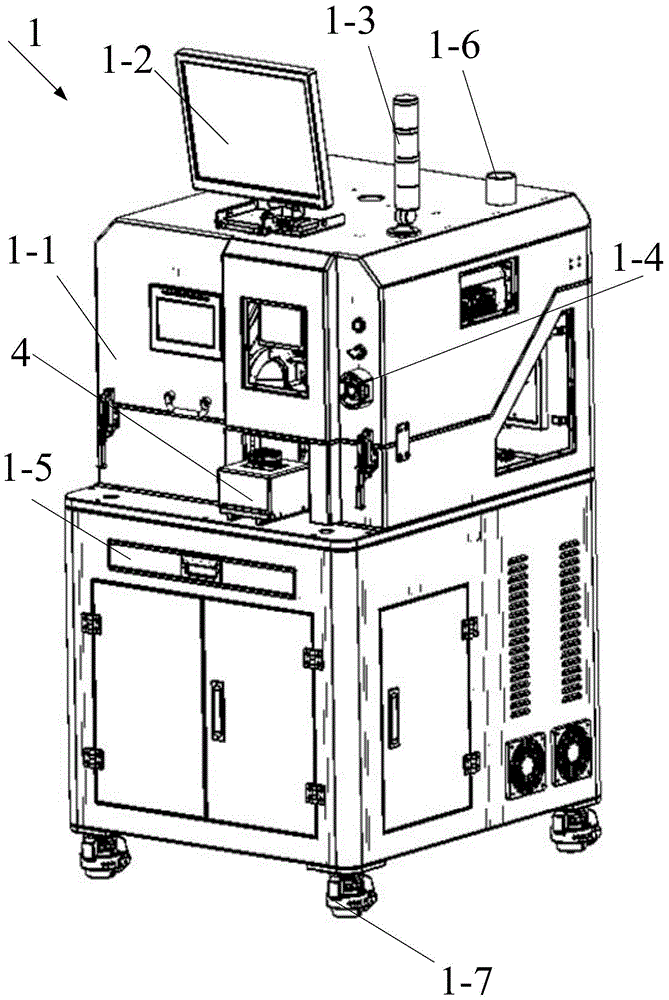

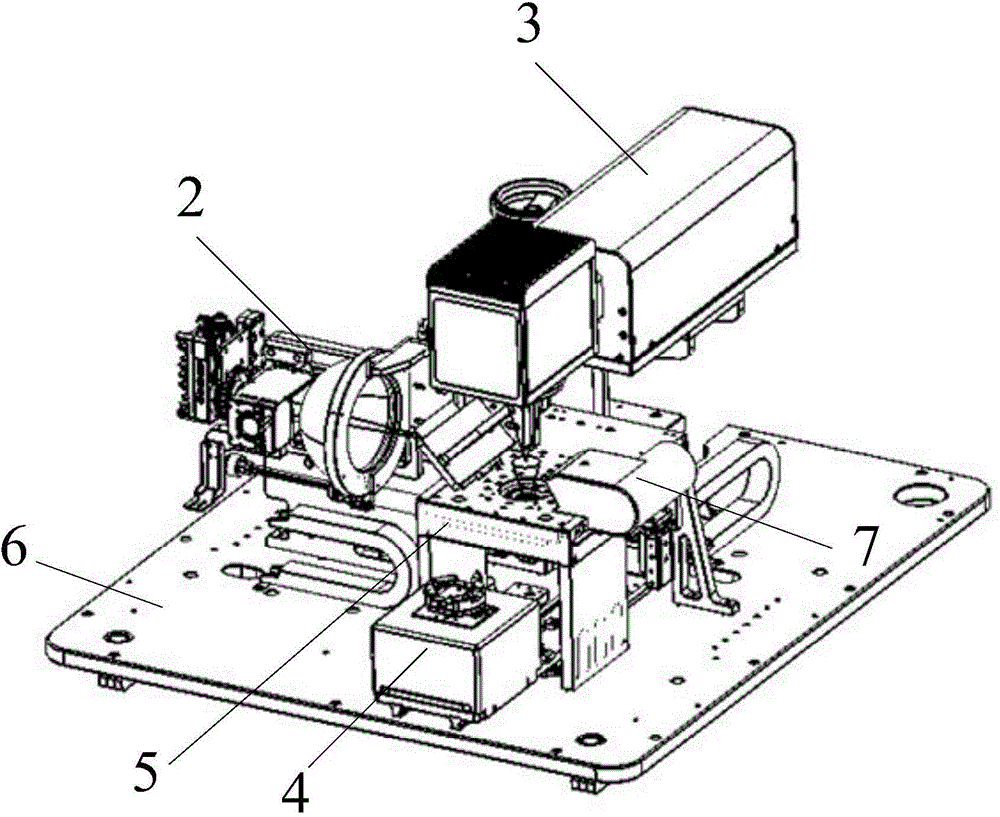

[0036] Please refer to Figure 1a and Figure 1b , a laser engraving machine, comprising a box 1,

[0037] AC voltage stabilizer, after the power is turned on, the AC voltage stabilizer can provide a stable voltage for the laser engraving machine;

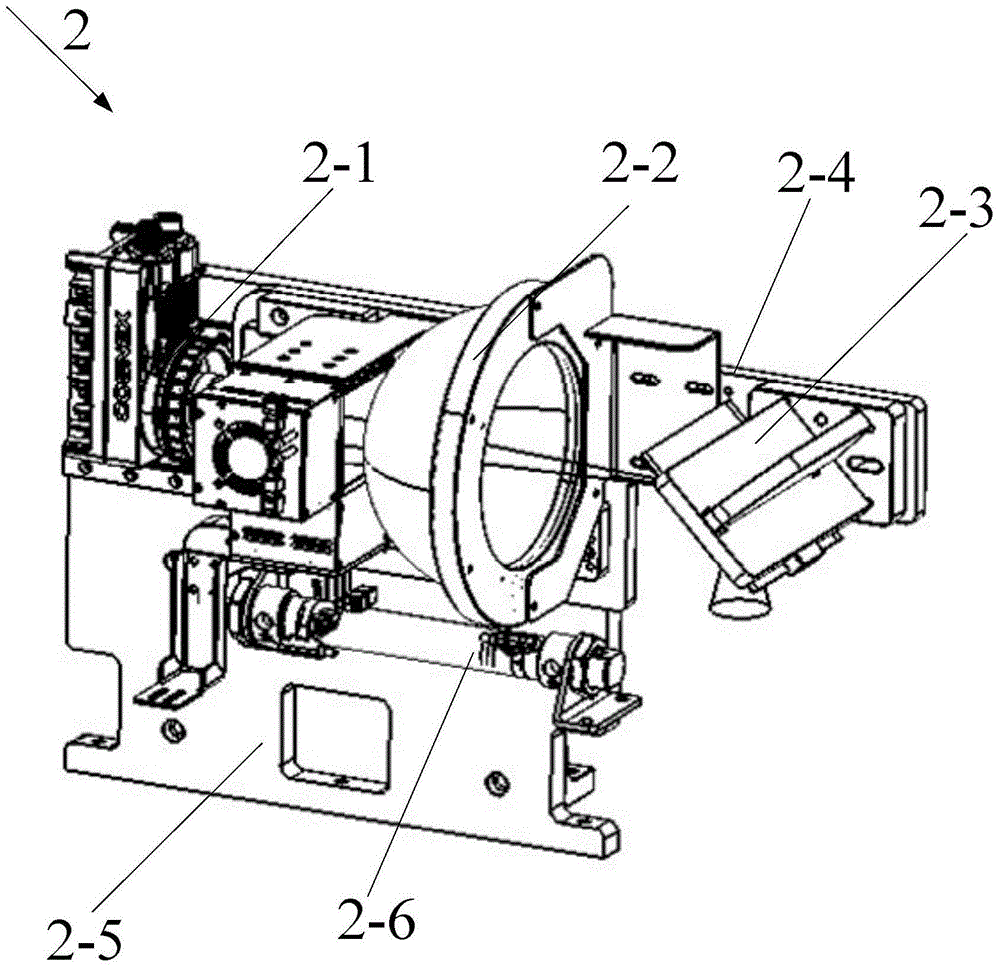

[0038] Visual positioning system 2, said visual positioning system 2 is slidably connected with the visual positioning system motion guide rail arranged on said support platform 6, and said visual positioning system makes X along the visual positioning system motion guide rail on said support platform 6 direction movement; visual positioning system 2 is used to take pictures and locate the parts to be processed;

[0039] The height-adjustable laser engraving machine system 3 is used for l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com