Method for making paper for used in embossed and patterned gold porcelain

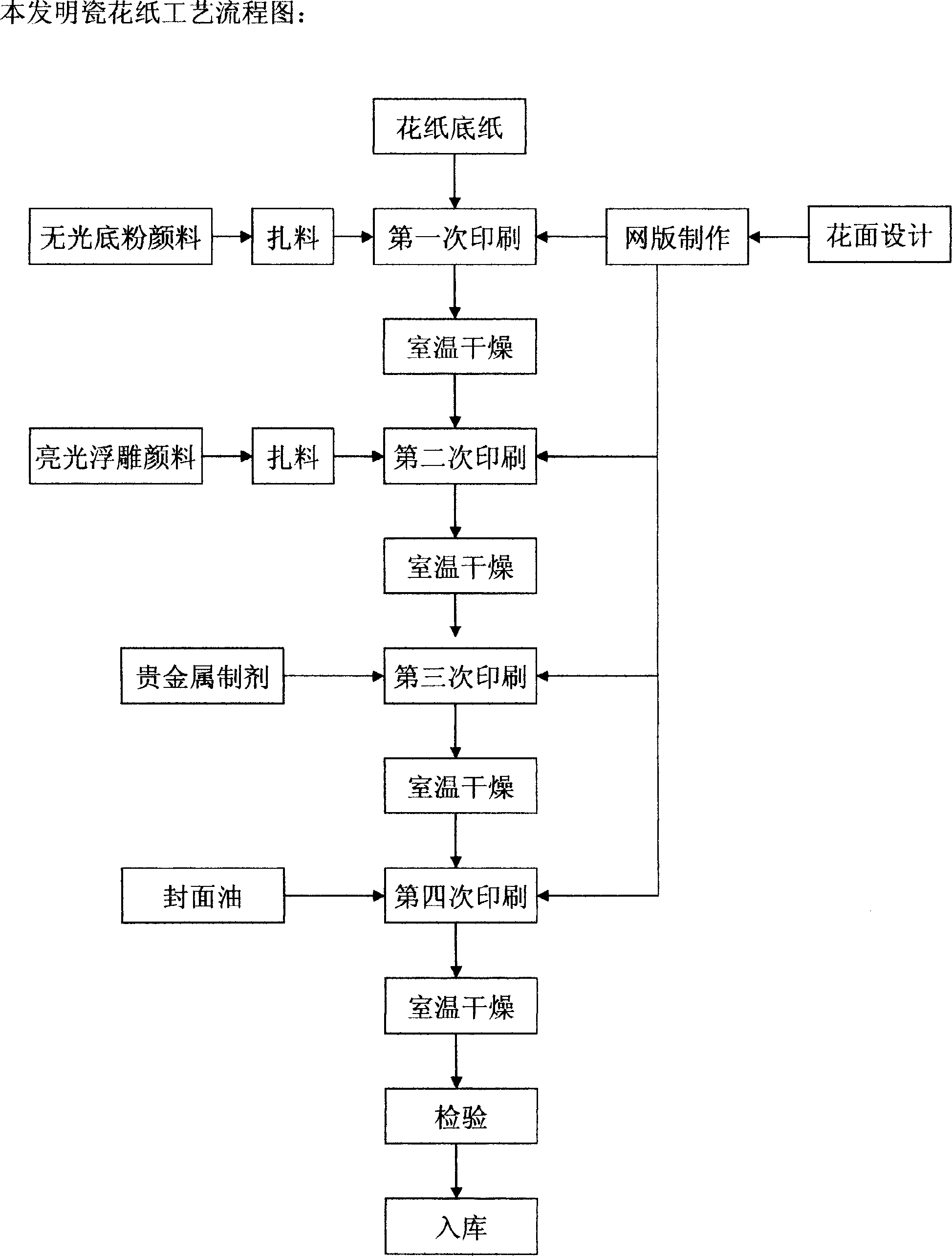

A manufacturing method and decal paper technology, applied to patterned paper, special paper, paper, etc., can solve the problems of manual gold painting, low production efficiency, long process flow, etc., achieve a strong three-dimensional effect, improve production efficiency, and improve product quality. The effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] Example 1: the manufacture of porcelain flower paper of the present invention

[0019] (1) Take 40 kg of titanium dioxide, 18 kg of boron oxide, and 20 kg of zirconia, mix them, put them into a container made of quartz, calcinate them in a kiln at 1280°C, add 23.4 kg of flux block for ball milling, and add 10.1 kg of edible alcohol Grind, dry at 32°C, and crush with a 300-mesh grinder to make a matte base powder pigment for subsequent use.

[0020] (2) Take 10 kg of lead oxide, 22 kg of silicon dioxide, 15 kg of zirconia, and 30 kg of alumina, mix them, put them into a container made of quartz, calcinate them in a kiln at 1280 ° C, and add 23.1 kg of flux block Ball milling, adding 10 kg of alcohol for grinding, drying at 32°C, and crushing with a 300-mesh grinder to make bright relief pigments for future use.

[0021] (3) Get 38 kilograms of pine oil, 17 kilograms of hydrodesulfurized heavy oil, 17 kilograms of 2-butoxyethyl acetate, 6.2 kilograms of heavy aromatics c...

example 2

[0027] Example 2: the manufacture of porcelain flower paper of the present invention

[0028] In the step (7) of example 1, the bright platinum paste is printed, and the other steps are the same as in example 1, that is, the porcelain decal paper of the present invention whose precious metal preparation is platinum paste is prepared.

example 3

[0029] Example 3: Porcelain flower paper of the present invention is used to decorate daily porcelain

[0030] (1) Before decals, clean the surface of daily-use porcelain (green body) without oil or dust.

[0031] (2) Send the porcelain pasted with porcelain decals to the kiln for firing, and the temperature is controlled between 810-830°C. At the same time, note that the top cover of the kiln before 300°C cannot be closed tightly, and sufficient oxygen in the furnace must be ensured.

[0032] (3) When roasting, the temperature should not rise too quickly, and the solvent of the cover oil should be completely evaporated before entering the high temperature section. The temperature of film discharge should be controlled between 500-550°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com