Rapid cooling type injection molding device

A cooling and fast technology, applied in the field of injection molding equipment, can solve problems such as poor effect, achieve novel design, strong practicability, and increase the effect of injection molding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

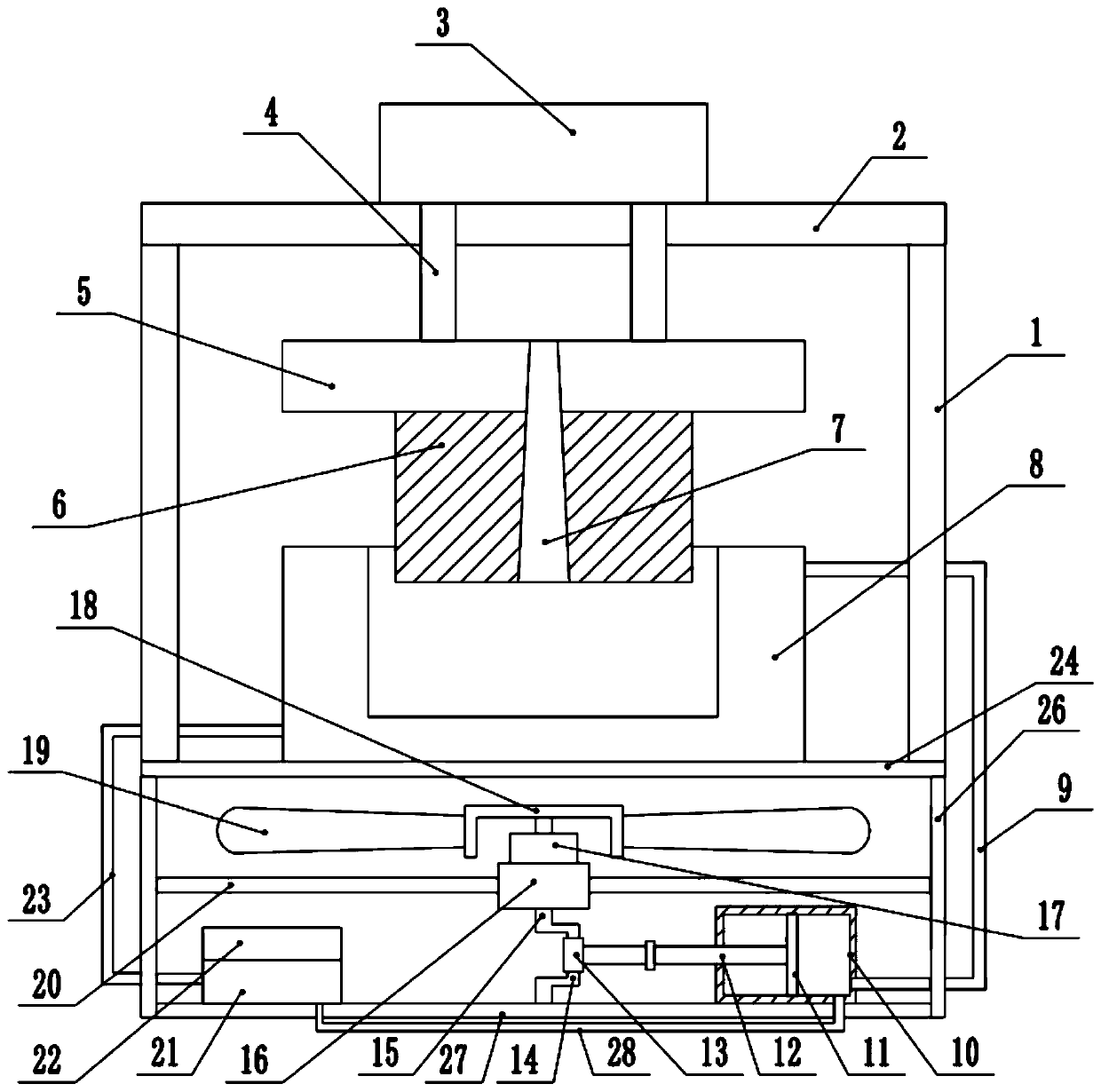

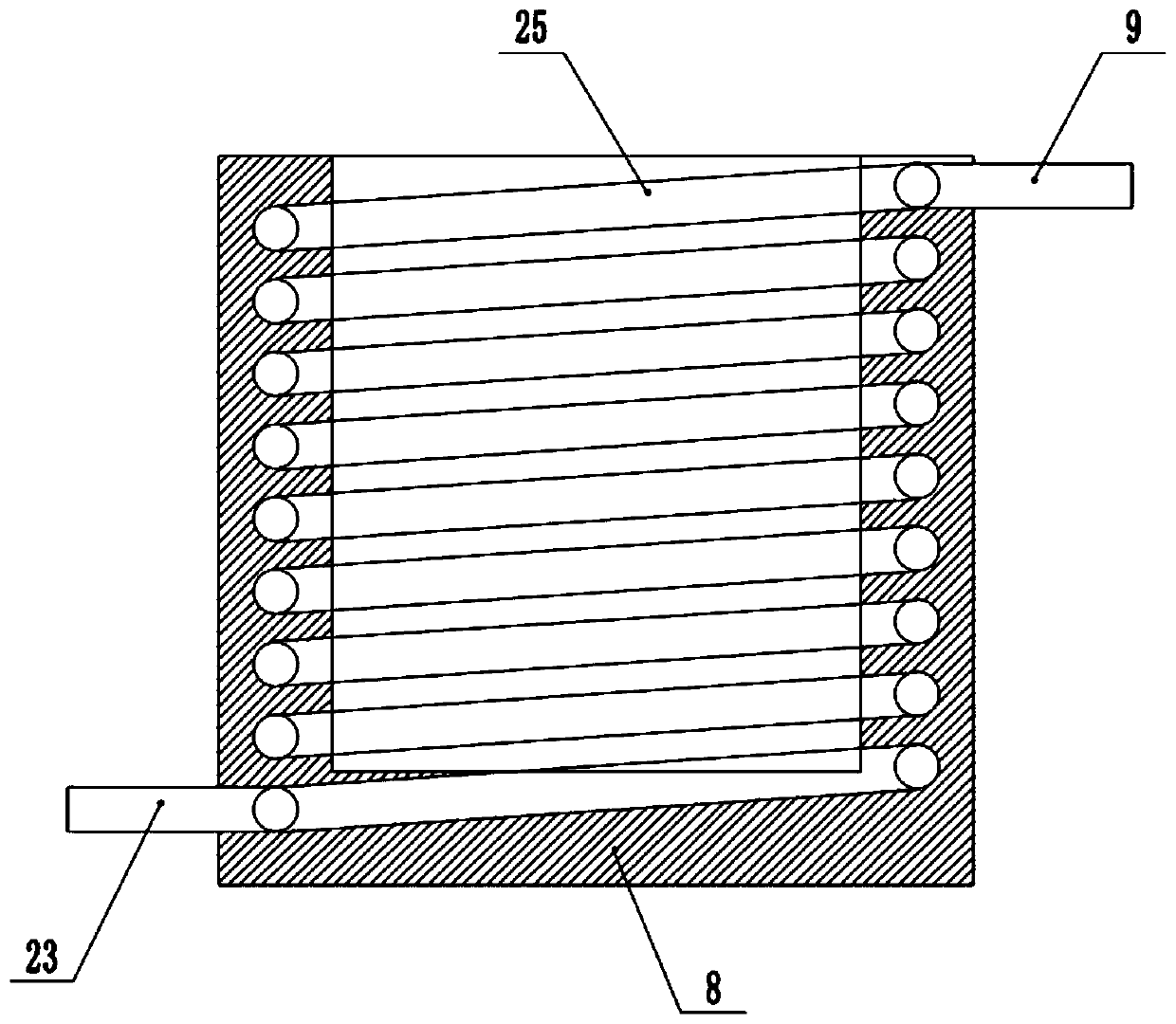

[0029] refer to Figure 1~3 , in an embodiment of the present invention, a rapid cooling injection molding device includes a support frame 1, a top plate 2 is installed on the upper end of the support frame 1, and a power unit 3 is installed on the upper end of the top plate 2, and the power unit 3 is a hydraulic cylinder or an air cylinder. The power shaft 4 is installed at the lower end of the part 3, and the mold seat 5 is installed at the bottom end of the power shaft 4, so that the upper mold 6 can move up and down under the action of the power part 3, and an injection channel is provided between the mold seat 5 and the interior of the upper mold 6 7. To meet the needs of injection molding materials, the upper mold 6 is installed at the lower end of the mold base 5, the support plate 24 is installed at the bottom end of the support frame 1, the lower mold 8 is installed at the middle of the upper end of the support plate 24, and the upper mold 6 and the lower mold 8 are in...

Embodiment 2

[0031] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that a refrigeration mechanism 22 is installed on the upper end of the refrigeration box 21, and the refrigeration mechanism 22 includes a refrigeration plate 221, and the lower end of the refrigeration plate 221 is provided with a The cold end 223, the cold end 223 is located inside the refrigeration box 21, the upper end of the refrigerating sheet 221 is provided with a hot end 222, and the refrigerating sheet 221 is a semiconductor refrigerating sheet, which can realize rapid cooling.

[0032] The present invention, when working, first injects materials into the injection channel 7, and realizes the opening and closing of the upper mold 6 and the lower mold 8 through the power part 3. During this process, the drive motor 17 is started to make the drive shaft 15 rotate. On the one hand, the rotary blade 19 is rotated to realize air cooling and heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com