Injection mold device

An injection mold and corresponding position technology, which is applied in the field of injection molding equipment, can solve the problems of reducing injection molding precision, inconvenient mold opening, and unfavorable production efficiency of enterprises, so as to achieve the effect of improving injection molding precision, increasing production efficiency, and reducing reprocessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

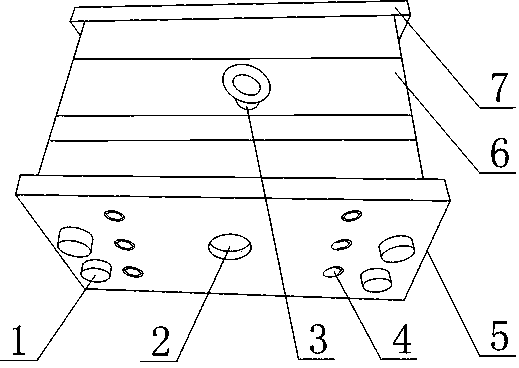

[0022] Such as figure 1 As shown, a kind of injection mold device comprises front baffle 5, a plurality of cavity plates 6 and rear baffle 7 with cavities inside, and a plurality of said cavity plates 6 are located at front baffle 5 and rear baffle. Between the plates 7, and a plurality of the cavity plates 6 are arranged sequentially, the sides of the adjacent two cavity plates 6, the front baffle plate 5 and the cavity plate 6, the cavity plate 6 and the rear baffle plate 7 are mutually Fitting, the front baffle 5 is also provided with an injection hole 2, and the rear baffle 7 is also provided with an exhaust hole.

[0023] The set front baffle 5, multiple cavity plates 6 and rear baffle 7 are combined to form the cavity of the injection mold, and the cavity part is composed of front baffle 5, multiple cavity plates 6 and rear baffle 7. Composition, this structure allows the cavity of the above structure to be set into a more complex structure, that is, at the structure wh...

Embodiment 2

[0025] This embodiment is further improved on the basis of embodiment 1, as figure 1 As shown, at least two through holes are provided at corresponding positions on the front baffle plate 5, a plurality of cavity plates 6 and the rear baffle plate 7, and at least two guide posts 1 are also included, each of the guide posts 1 and the through hole in the corresponding position form a clearance fit.

[0026] The provided through holes and the guide column 1 facilitate positioning when the front baffle 5 , multiple cavity plates 6 and the rear baffle 7 are connected.

[0027] It also includes lifting lugs 3 which are fixedly connected to the cavity plate 6 .

[0028] The set lug 3 facilitates the convenience of moving the present invention.

[0029] The two adjacent cavity plates 6, the front baffle plate 5 and the cavity plate 6, the cavity plate 6 and the rear baffle plate 7 are all provided with bolt holes, and also include connecting bolts 4. The cavity plate 6, the front b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com