Patents

Literature

106results about How to "With electromagnetic shielding function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method for fiberboard with electromagnetic shielding function

ActiveCN104690804ARealize industrial productionSimple manufacturing processFlat articlesDomestic articlesMassive gravityFiber

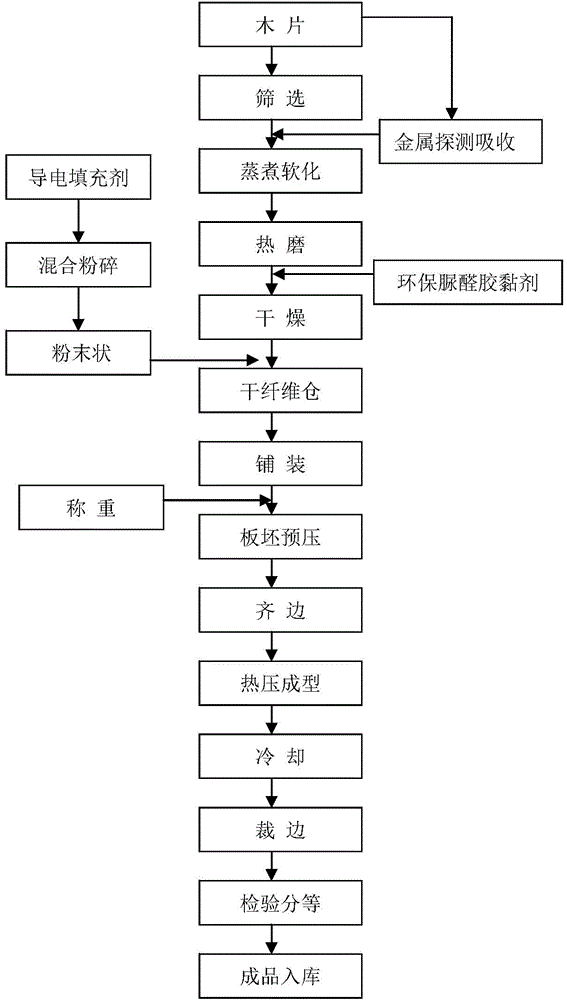

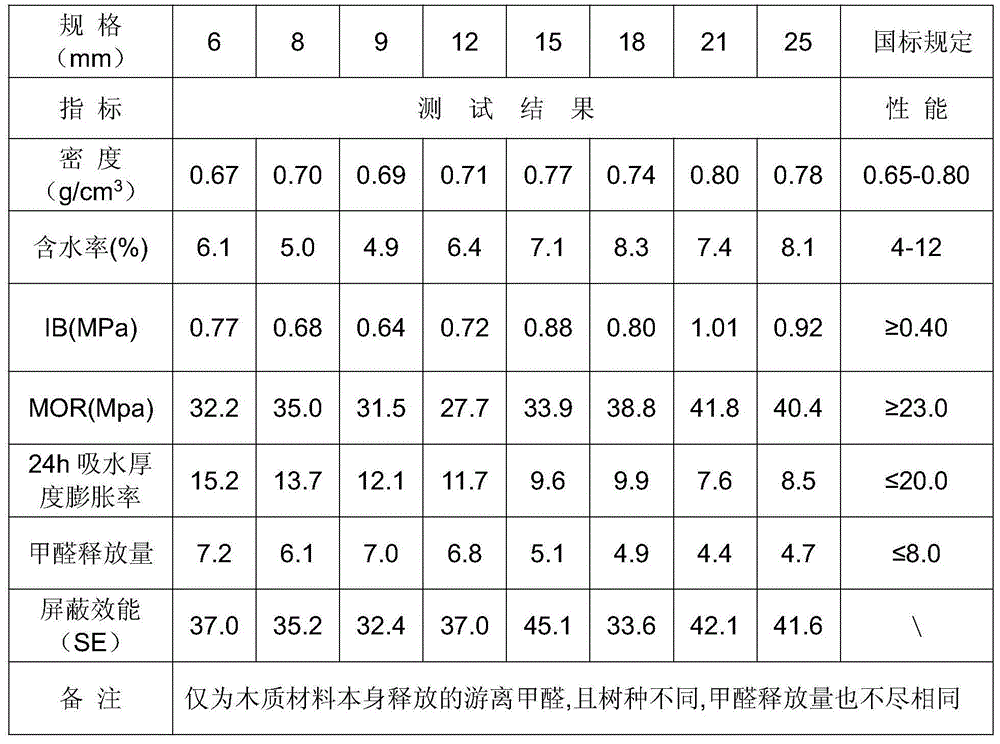

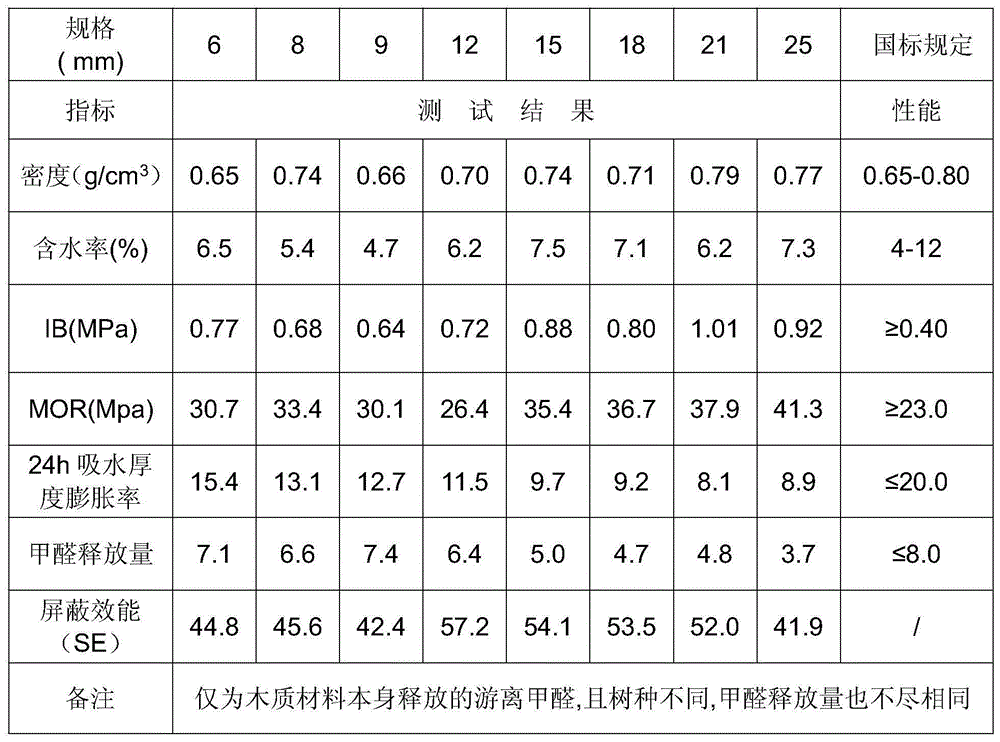

The invention provides a manufacturing method for a fiberboard with an electromagnetic shielding function. The manufacturing method comprises the following technical steps: timber chipping, screening, steaming, fiber separating, adhesive preparing and applying, dry separating, mat forming, pre-pressing, hot pressing, reversing cooling, sanding, detecting, storing and packaging. The manufacturing method for the fiberboard with the electromagnetic shielding function is characterized in that an environmental-friendly series of timber adhesives are applied in the adhesive preparing and applying step; a composite conducting filler is applied in the drying separating step, and is subjected to application measurement by a device at a position with 1.0-1.2 m distance between the front part of a drying pipeline discharging fan and a fan, so that the conducting filler is sucked and uniformly distributed into a fiber bin under the action of an attractive force negative pressure of the fan. By aims at the bottleneck problems in the prior art, an industrial manufacturing method for the fiberboard with the electromagnetic shielding function is provided, and the influence of electromagnetic radiation on the human lives and environments is reduced.

Owner:GUANGXI FENGLIN WOOD IND GRP CO LTD

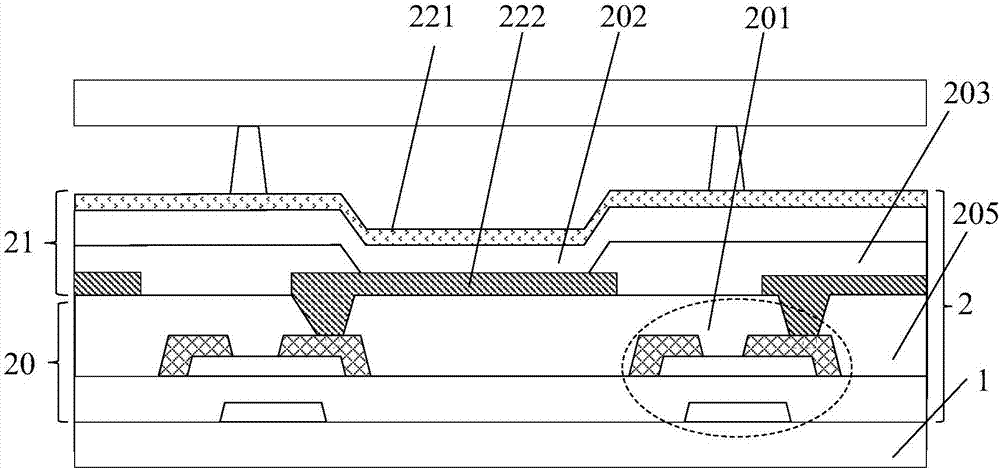

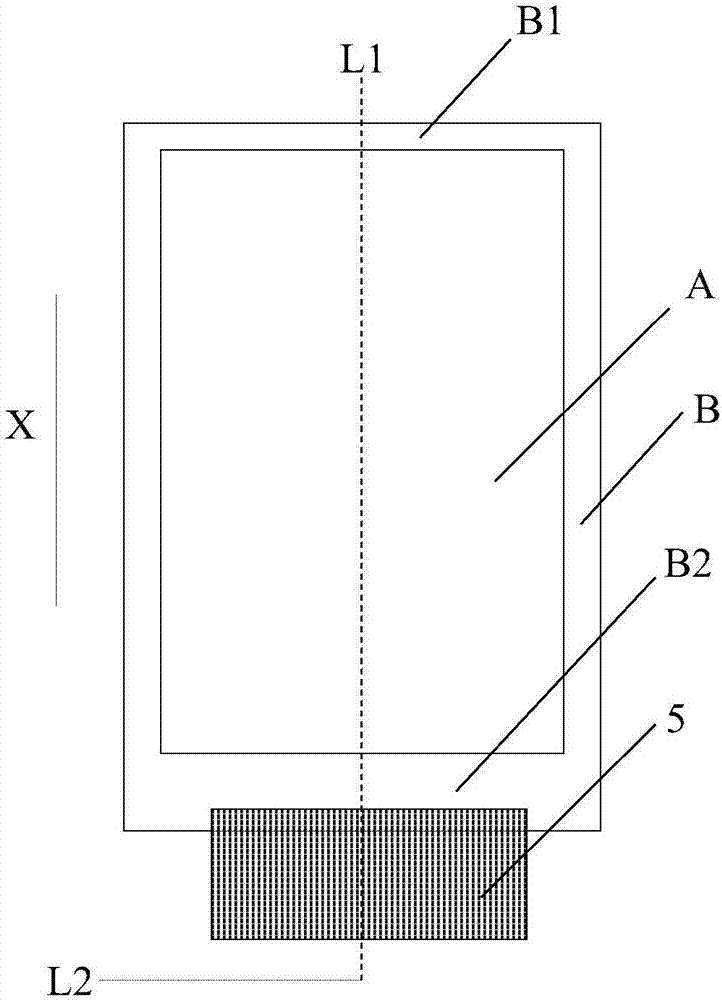

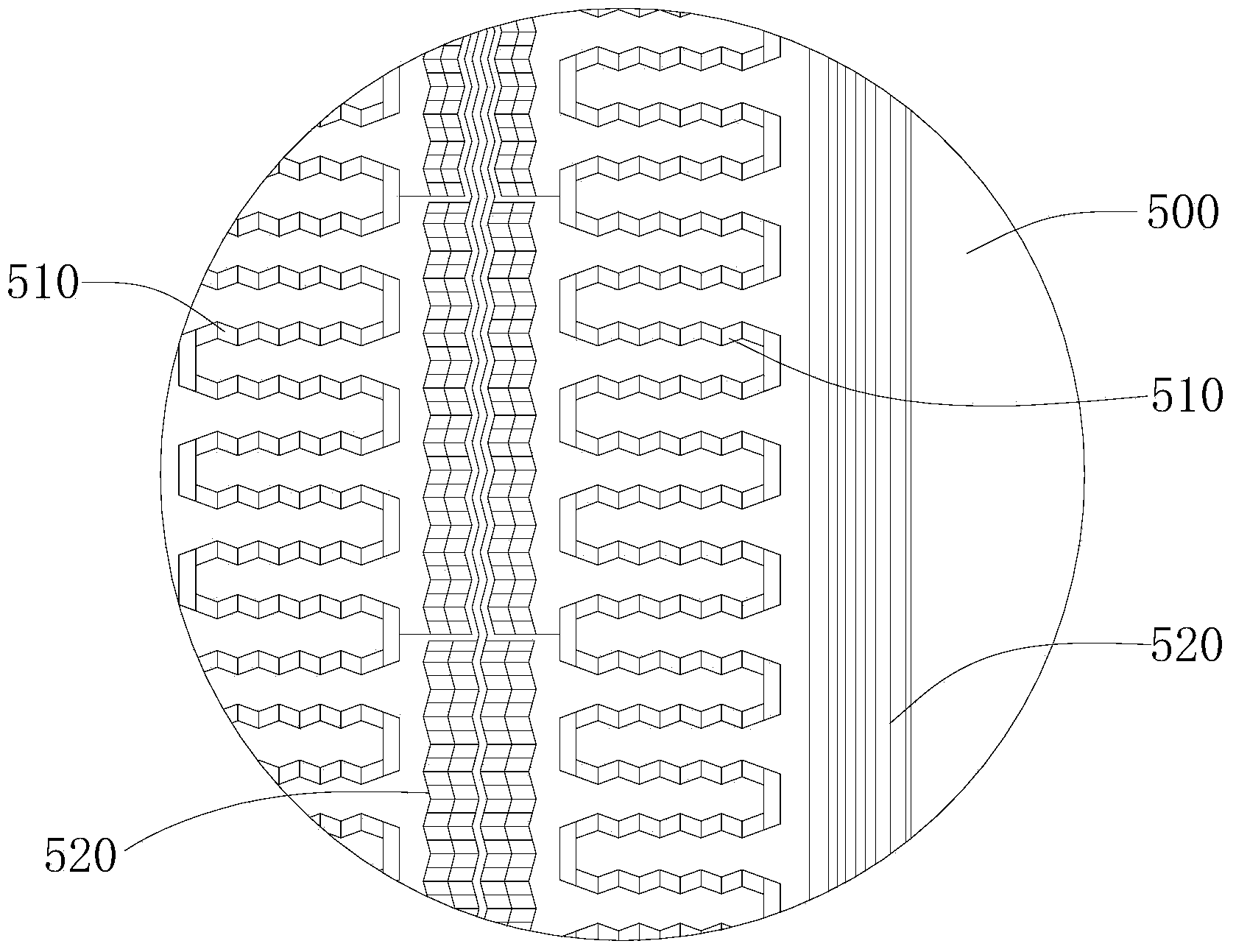

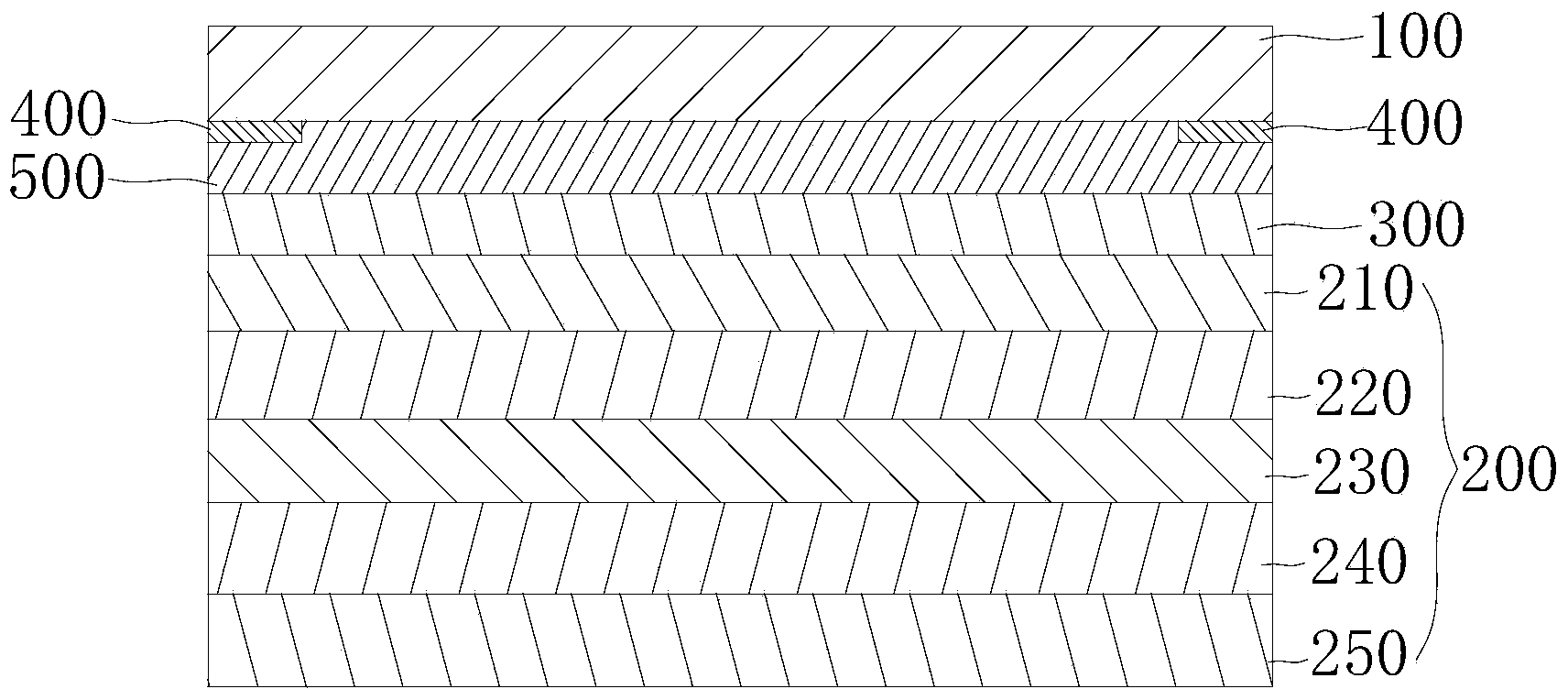

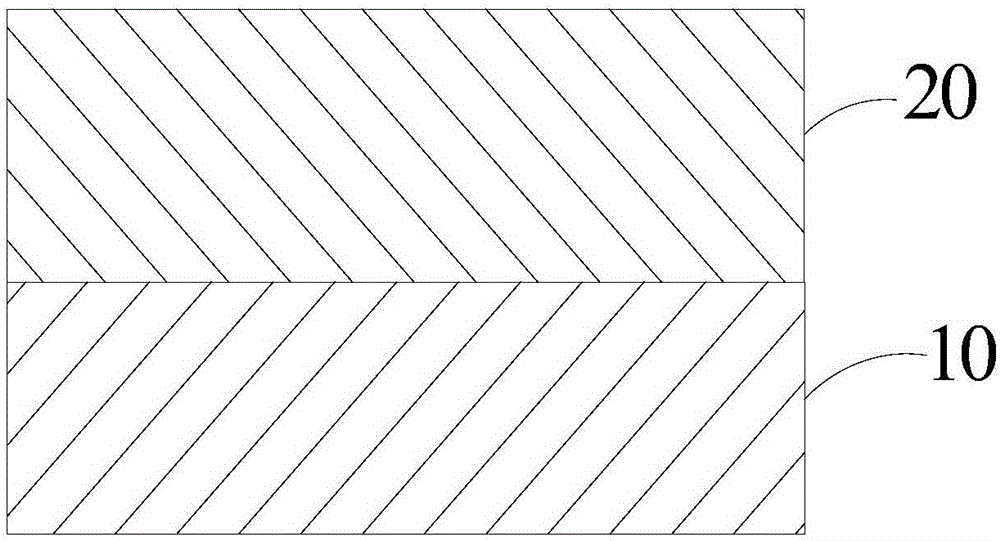

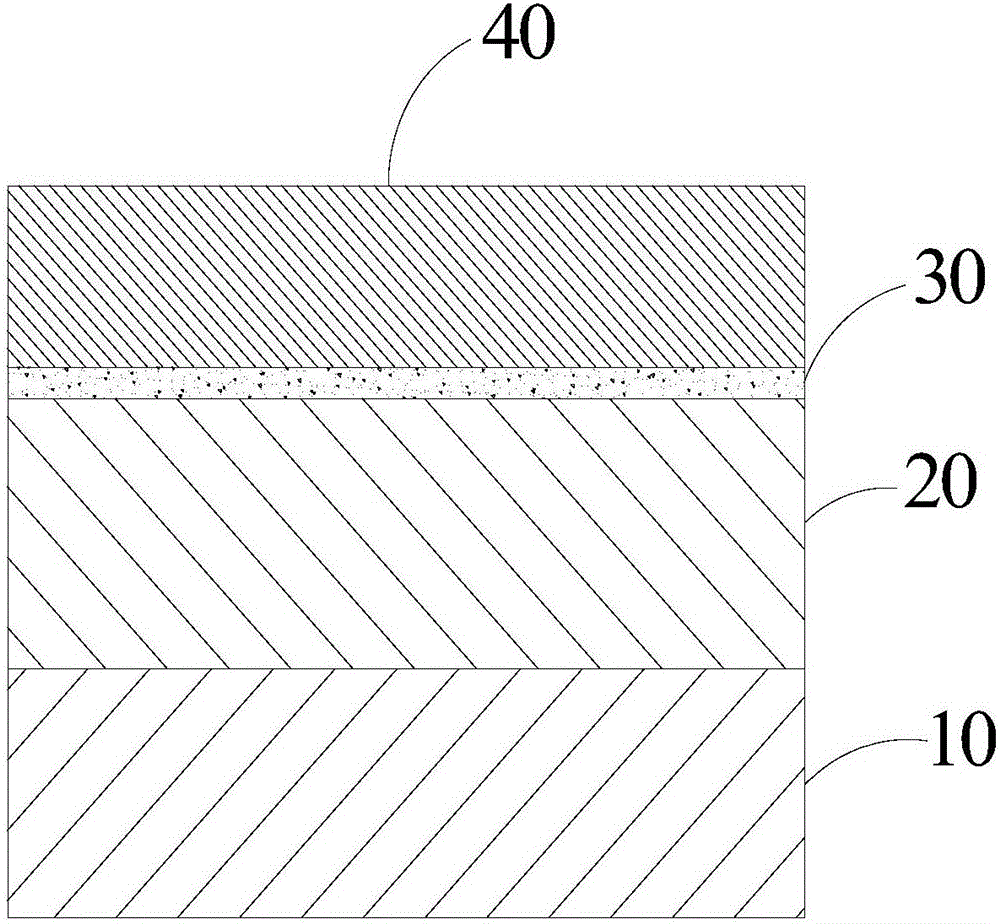

Flexible display panel and flexible display device

ActiveCN107482041AWith electromagnetic shielding functionShield interferenceNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsEngineeringFlexible display

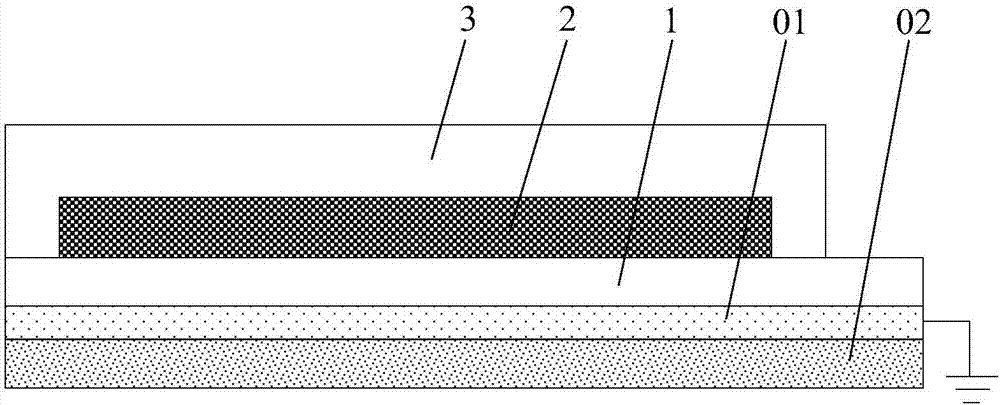

The present invention provides a flexible display panel and a flexible display device comprising the same. The flexible display panel comprises: a flexible substrate; a luminescent device layer located at one side of the flexible substrate; an encapsulation layer located at one side, far away from the flexible substrate, of the luminescent device layer; and a conductive bonding layer located at one side, far away from the encapsulation layer, of the flexible substrate, wherein the conductive bonding layer is an adhesive layer with conductivity and is connected with an external potential. The conductive bonding layer can shield the interference of external electromagnetic signals on a circuit in the luminescent device layer while having a dual-face bonding function so as to improve the display frame scintillation phenomenon caused by the external electromagnetic signals, improve the display effect of the flexible display device and reduce the module thickness of the flexible display device.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

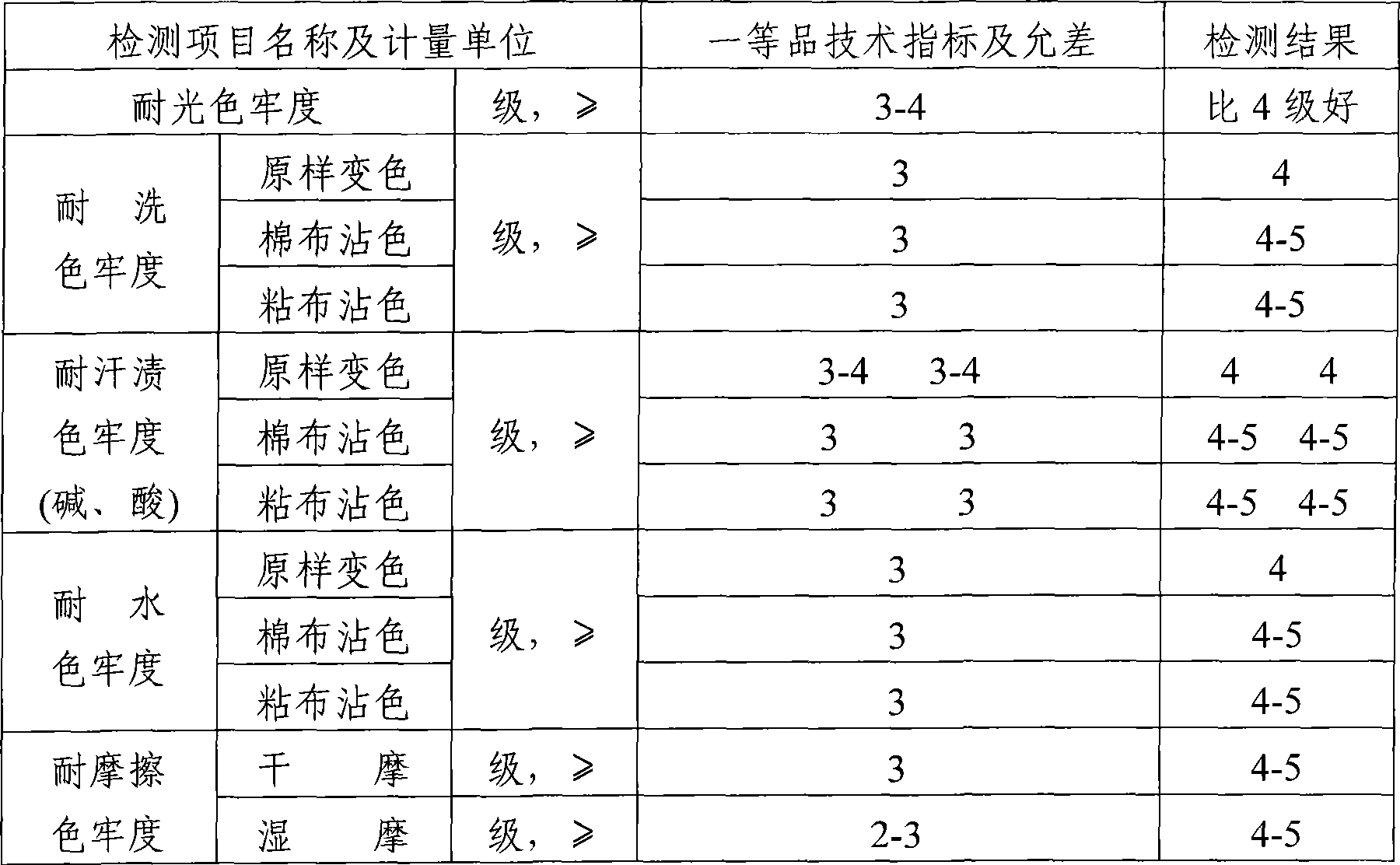

Antistatic blended yarn and application thereof

The invention provides an antistatic blended yarn, which is prepared from 20 to 45 percent of polyester fiber, 35 to 70 percent of cotton fiber and 10 to 30 percent of stainless steel fiber by weight percentage through blended spinning. The invention also provides an antistatic sweater produced by adopting the antistatic blended yarn and a method for producing the same. The product of the antistatic blended yarn has antistatic and electromagnetic shielding functions, does not have special requirement on washing, is not influenced by the environment, has complete colors and solid texture, is sweat-resistant and corrosion-resistant, can be applied to special industries such as anti-microwave clothes and radiation-resistant clothes, can effectively prevent human body from being radiated by computers and the like, and particularly protect pregnant women. The antistatic blended yarn can be processed into clothes worn in spring, autumn and winter and the clothes are comfortable to wear with excellent performance.

Owner:JIANGYIN XIANGFEI APPAREL

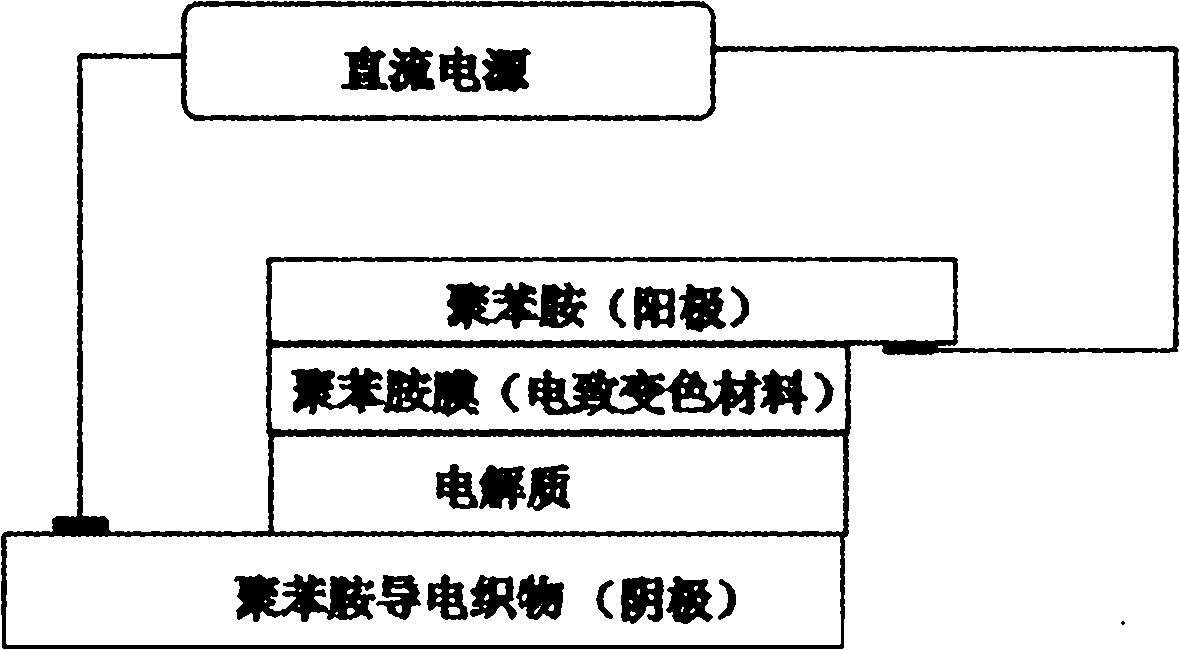

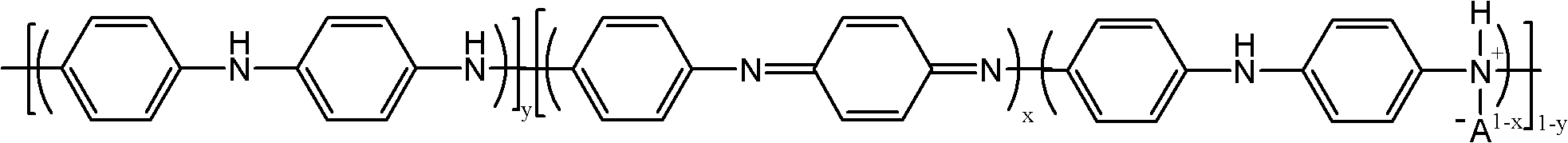

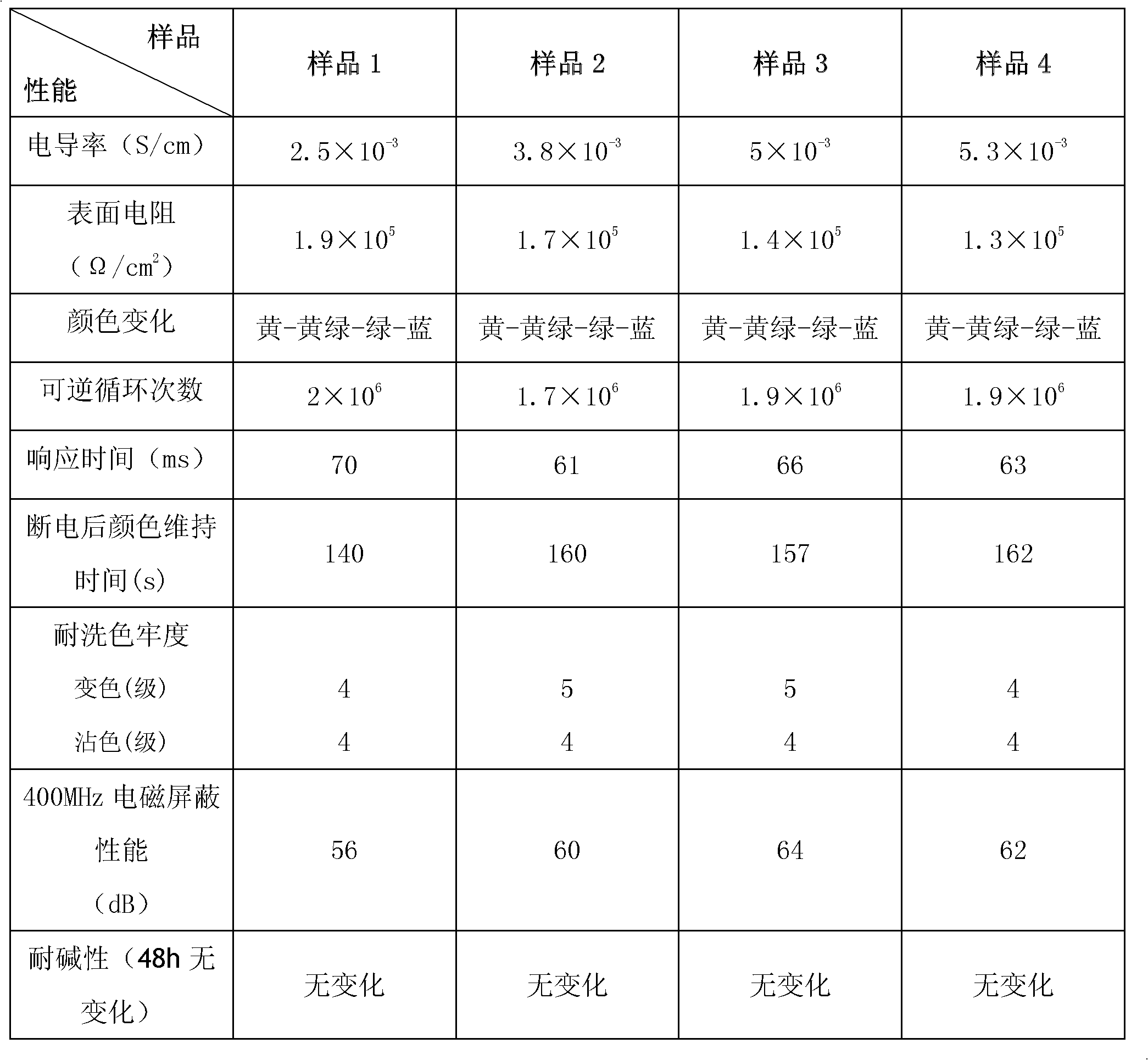

Polymer electrochromic fabric and preparation method thereof

InactiveCN102135692AUniform growthUniform film thicknessFibre treatmentNon-linear opticsFiberConductive polymer

The invention provides an electrochromic fabric and a preparation method thereof, relates to an electrochromic material, and aims at synthesizing an electrochromic fabric with low cost, controllable discoloration and reversible circulation by using an in-situ chemical method. The electrochromic fabric is a sandwich type electrochromic device consisting of a direct current power supply, positive and negative electrodes, an electrolyte solution, an electrochromic material and the like, has the alert inducing characteristic of a conductive polymer, has the physical mechanical performance and soft comfort of matrix fiber, and has the advantages that a polyaniline film formed on the surface of the fiber has uniform thickness; the defects of easy leakage and uneven discoloration of the traditional electrolyte are overcome; and the conductive performance is excellent; the color is controllable, the circulation is reversible, and the material maintains longer after power off. Furthermore, thefabric has static resistance, corrosion prevention and an excellent electromagnetic shielding function, is an environmentally friendly product, and has simple process flows, low production cost and excellent product performance.

Owner:QUANZHOU JIANENG MACHINERY MFG

Electromagnetic shielding nylon 66 material and preparation process thereof

InactiveCN101717577AGood physical and mechanical propertiesWith electromagnetic shielding functionMagnetic/electric field screeningCarbon fibersNylon 66

The invention relates to an organic polymer composite material, in particular to an electromagnetic shielding nylon 66 material and a preparation process thereof. The material comprises the following components in percentage by weight: 49.5-90 percent of nylon 66, 0-45 percent of metal fiber, 0-35 percent of carbon fiber, 0-30 percent of conductive graphite, 2-5 percent of heat stabilizer, 0.2-1.0 percent of coupling agent and 0.3-5.5 percent of other auxiliary agents. The electromagnetic shielding nylon 66 material can replace metal raw materials to produce parts or shells, and has higher physical and mechanical properties of the nylon 66 and the electromagnetic shielding function of the metal materials, thereby being convenient to produce and purchase, greatly reducing relevant cost and comprehensively improving the competitiveness.

Owner:KECHUANG POLYMER SUZHOU

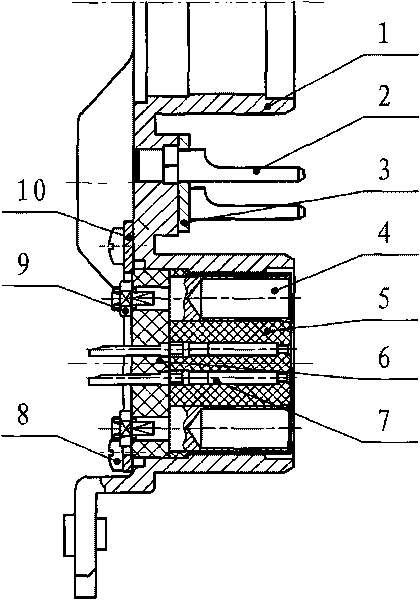

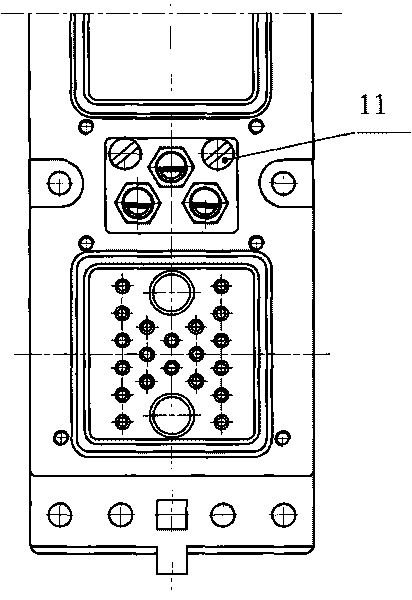

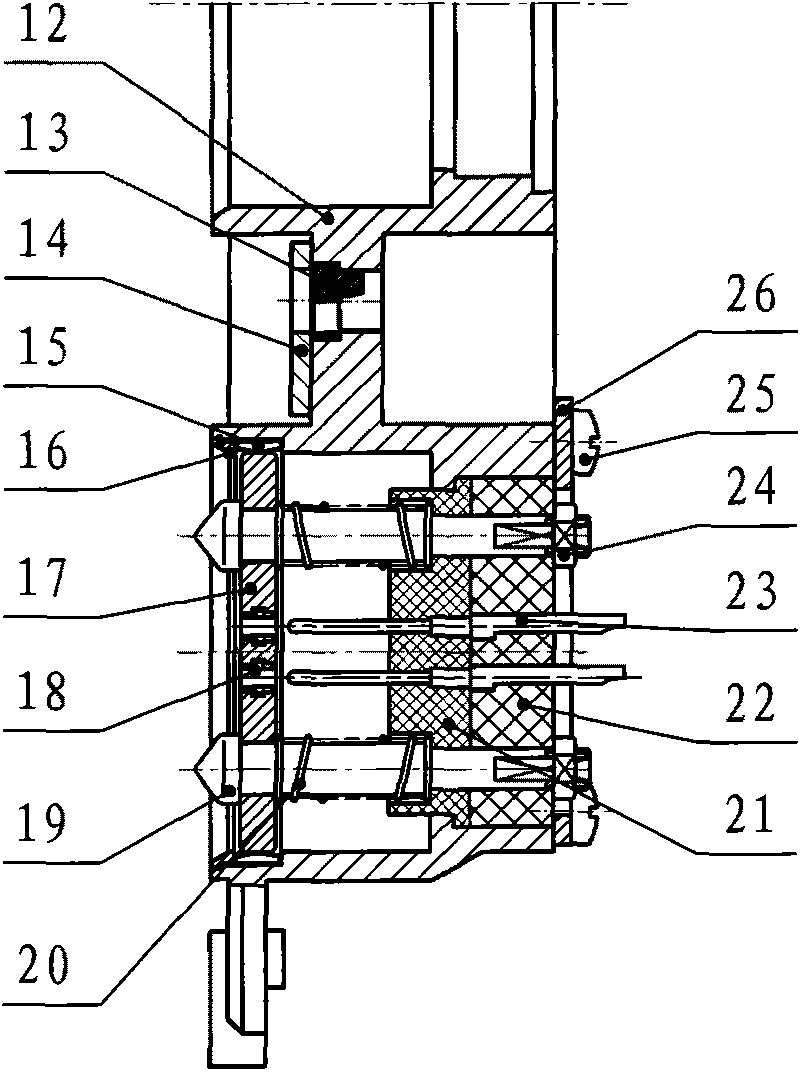

Cabinet-type electric connector

ActiveCN101714727AMeet the needs of the applicationWith electromagnetic shielding functionCoupling protective earth/shielding arrangementsElectricityEngineering

A cabinet-type electric connector consists of a plug and a socket; the plug and a shell of the socket are provided with a plurality of cavities for mounting a plurality of corresponding functional modules; and the abutting end of each functional module is provided with a mobile electromagnetic shielding device and a guide positioning device, wherein the mobile electromagnetic shielding device consists of a shielding plate, an elastic shielding reed, an insulating sleeve and a spring. By using a matching form of the mobile shielding plate and the elastic shielding reed, the electromagnetic shielding function after the connector is plugged and separated is well implemented; meanwhile, the arranged guide positioning device can well implement guiding and positioning when the plug is plugged in the socket so as to realize automatic alignment of the connector; and the cabinet-type electric connector has higher mounting error compensation capability, meets the requirements of cabinet-type application occasions, and has stronger practicability.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

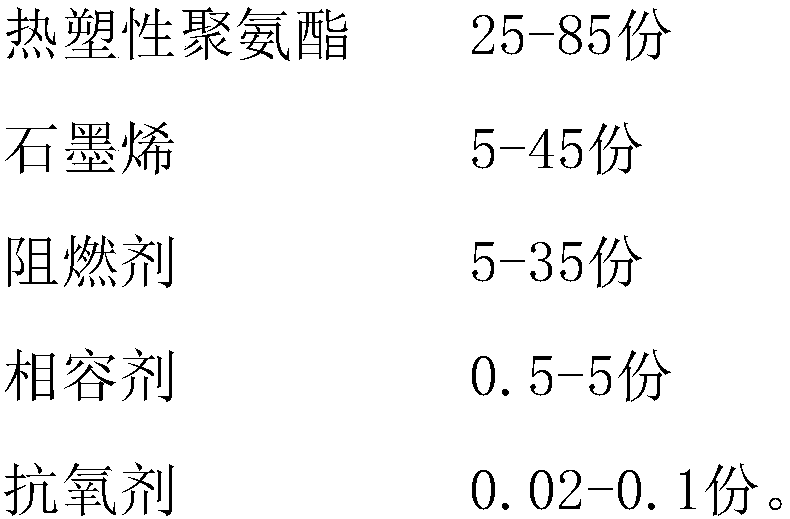

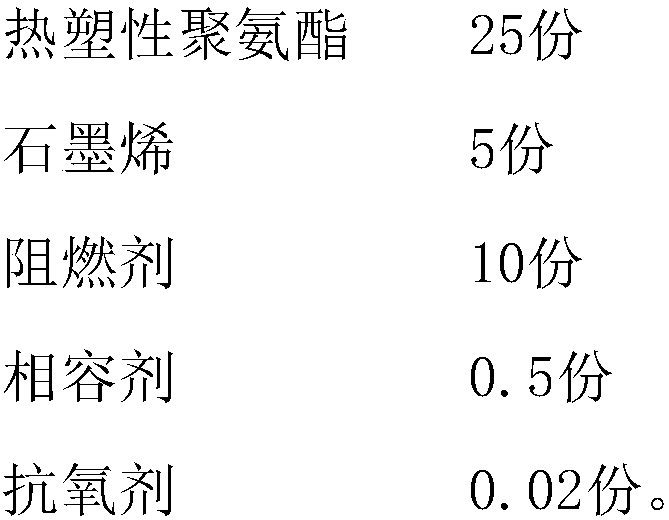

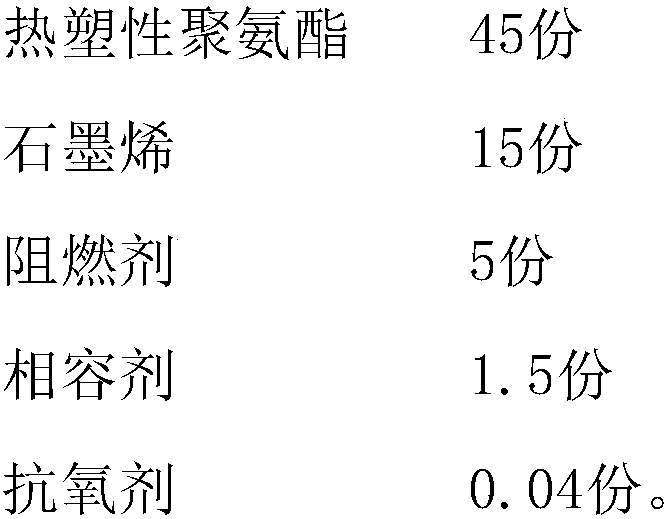

Flame-retardant TPU cable sheathing material with electromagnetic shielding function and preparation method of TPU cable sheathing material

InactiveCN108410161AReduce usageEffect on mechanical propertiesPlastic/resin/waxes insulatorsAntioxidantPliability

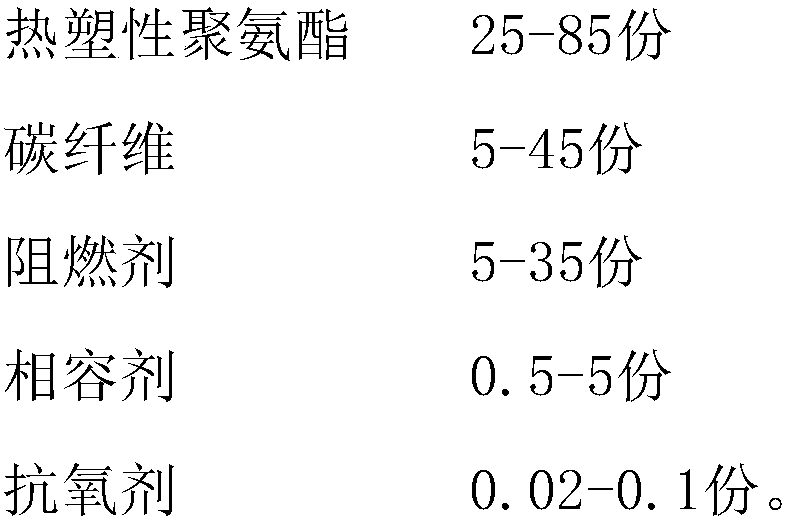

The invention relates to the technical field of cable materials, and in particular relates to a flame-retardant thermoplastic polyurethane (TPU) cable sheathing material with an electromagnetic shielding function and a preparation method of the TPU cable sheathing material. The TPU cable sheathing material comprises the following raw materials in parts by weight: 25-85 parts of thermoplastic polyurethane, 5-45 parts of graphene, 5-35 parts of a flame retardant, 0.5-5 parts of a compatibilizer, and 0.02-0.1 part of an antioxidant. The TPU cable sheathing material provided by the invention has the electromagnetic shielding function, the shielding effectiveness (SE) value can reach 17-50 db, and the flame-retardant effect is excellent; and a single vertical burning test can reach a V0 level,the strength is high, the tensile strength can reach 25.2 MPa or more, the flexibility is good, the elongation at break is high and can reach 405% or more, and the mechanical properties are excellent.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

Flame-resistant TPU (thermoplastic polyurethane) cable sheath material with electromagnetic shielding function as well as preparation method thereof

InactiveCN108250726AWith electromagnetic shielding functionImprove flame retardant performancePlastic/resin/waxes insulatorsFiberCarbon fibers

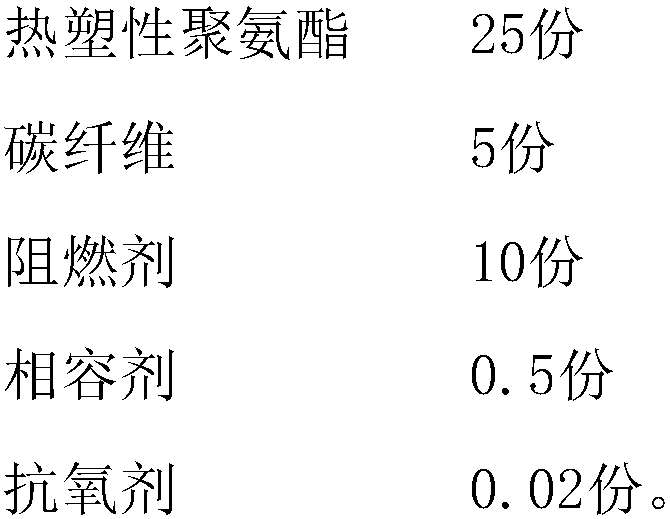

The invention relates to the technical field of a cable material, in particular to a flame-resistant TPU (thermoplastic polyurethane) cable sheath material with an electromagnetic shielding function as well as a preparation method thereof. The TPU cable sheath material comprises the following raw materials in parts by weight: 25 to 85 parts of TPU, 5 to 45 parts of carbon fiber, 5 to 35 parts of flame retardant, 0.5 to 5 parts of compatilizer and 0.02 to 0.1 part of antioxidant. The TPU cable sheath material provided by the invention has the electromagnetic shielding function, the shielding efficacy SE value can reach to 17 to 50 db, the flame-resistant effect is excellent, the flame-resistant effect of single cable sheath cable through vertical combustion test can reach to Level V0, the strength is high, the tensile strength can reach to above 25.5 MPa, the flexibility is high, the breaking elongation is high and can reach to above 410 percent and the mechanical property is excellent.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

Electromagnetic shielding polyethylene material and preparation process thereof

InactiveCN101701083AEasy to produce and purchaseLow costMagnetic/electric field screeningThermoplasticCorrosion

The invention relates to an organic polymer composite material, in particular to a polyethylene material capable of electromagnetic shielding and a preparation method thereof. The polyethylene material comprises the following components in percentage by weight: 49.5-90 percent of polyethylene, 5-35 percent of carbon fiber, 2-30 percent of conductive graphite, 0.2-1.0 percent of antioxidant, 0.2-2.0 percent of coupling agent and 0.3-5.5 percent of other auxiliary agent. The electromagnetic shielding polyethylene material can replace metal raw materials to produce spare and accessory parts or casings, and combines the favorable performance of thermoplastic plastics which can be processed easily and the electromagnetic shielding function of metal materials, therefore, the production purchasing of the electromagnetic shielding polyethylene material can be realized conveniently, and the relevant cost can be greatly reduced. The electromagnetic shielding polyethylene material also has the advantages of acid-resistant and alkali-resistant corrosion, certain mechanical strength and temperature toleration, thereby comprehensively improving the competitiveness.

Owner:KECHUANG POLYMER SUZHOU

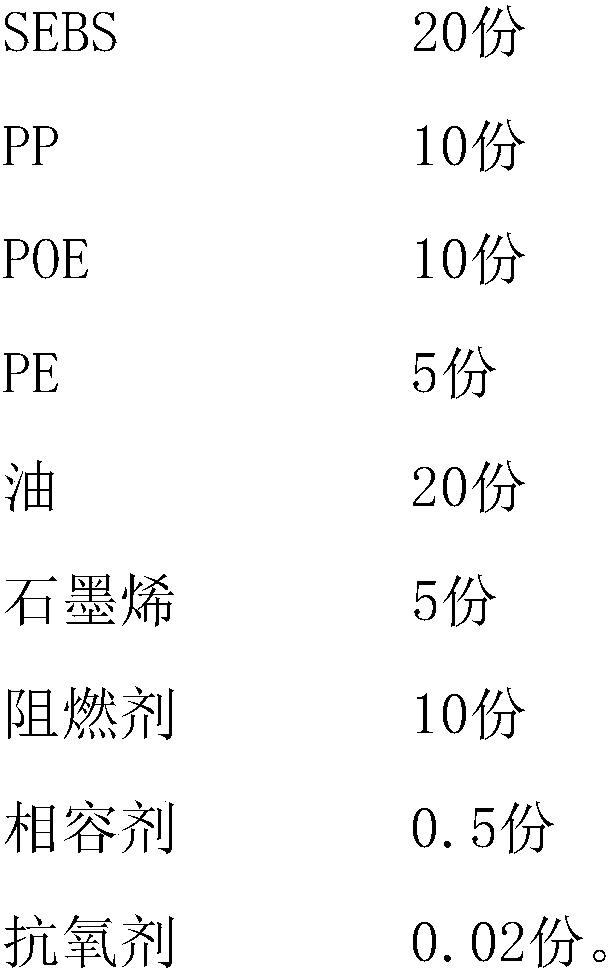

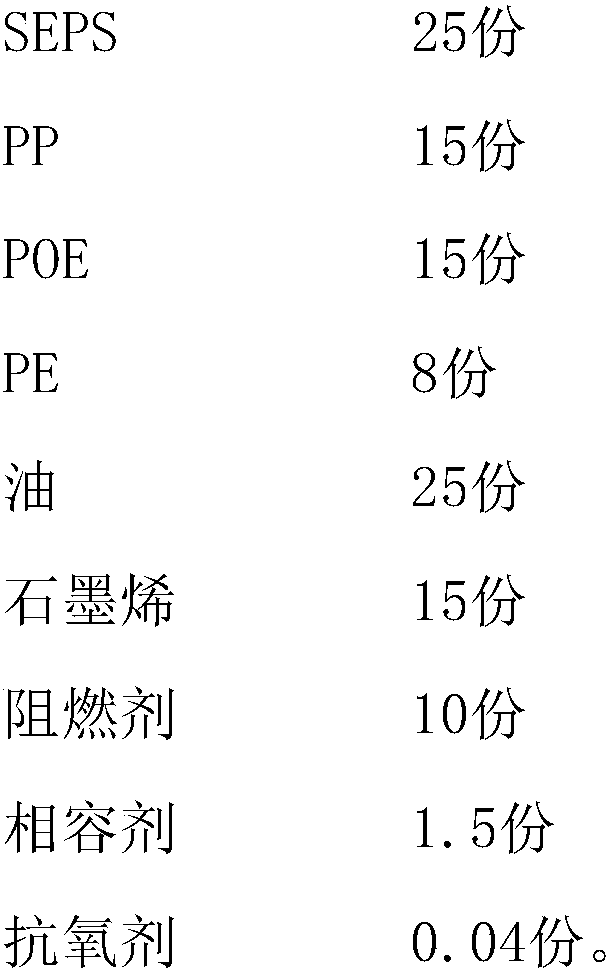

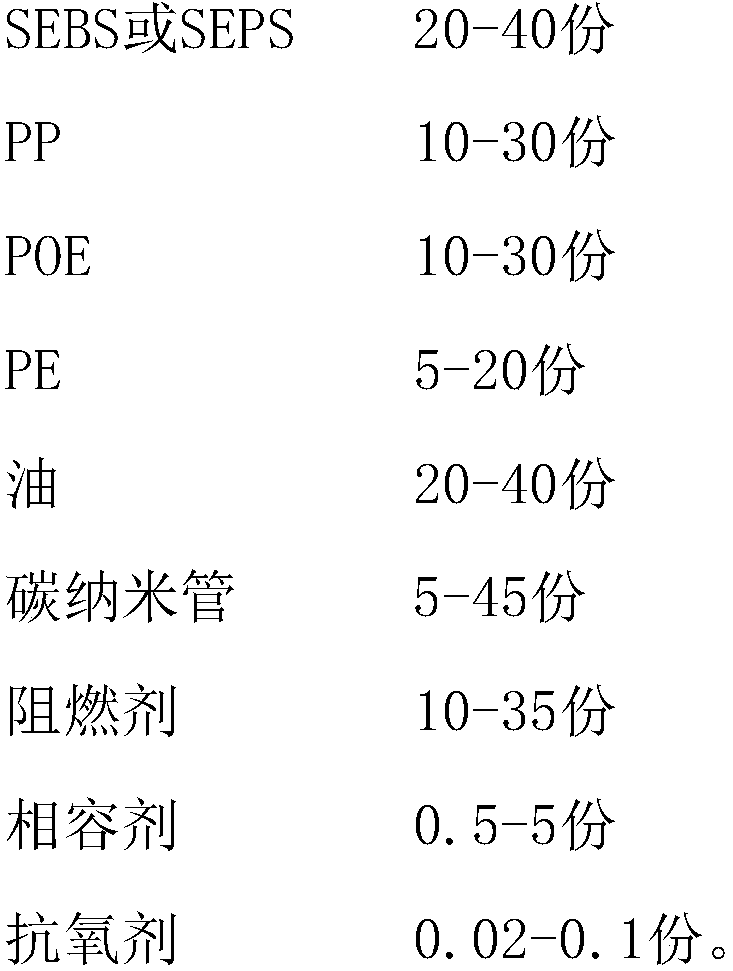

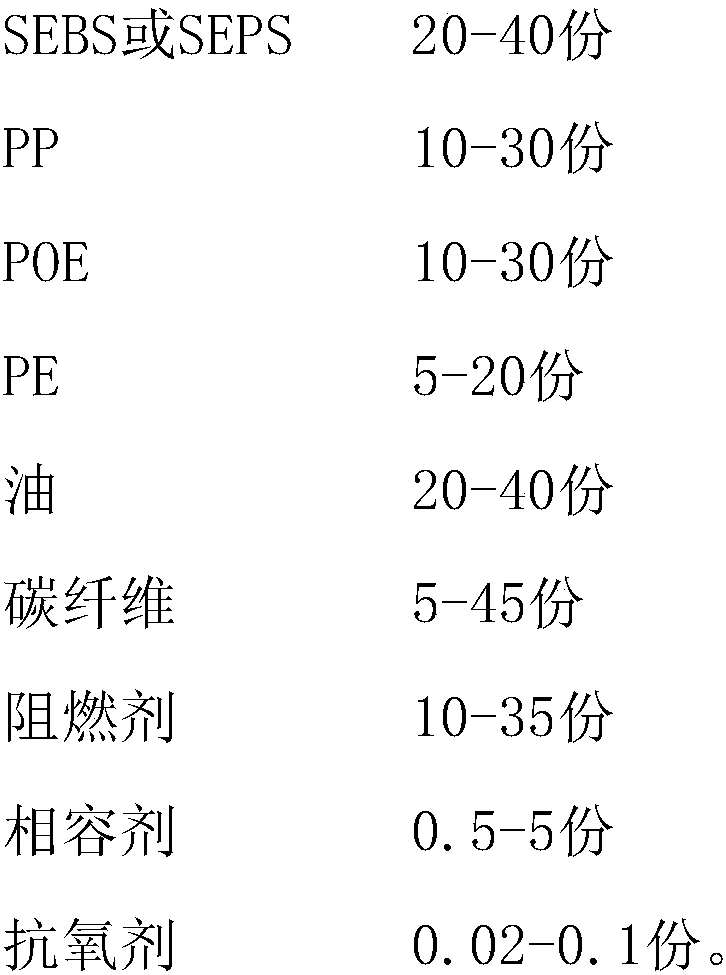

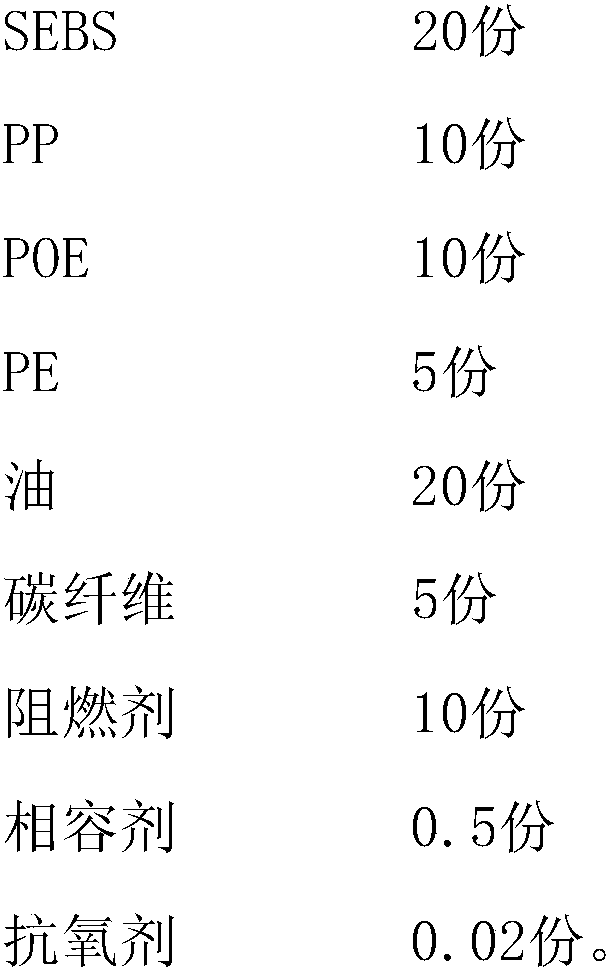

Flame-retardant TPE cable insulation material or sheathing material with electromagnetic shielding function and preparing method thereof

InactiveCN108456394AImprove low temperature toughnessImprove impact performancePlastic/resin/waxes insulatorsMagnetic/electric field screeningPliabilityEngineering

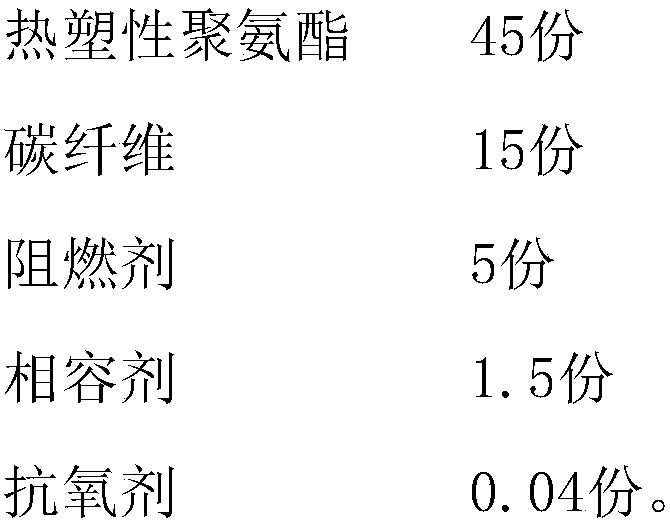

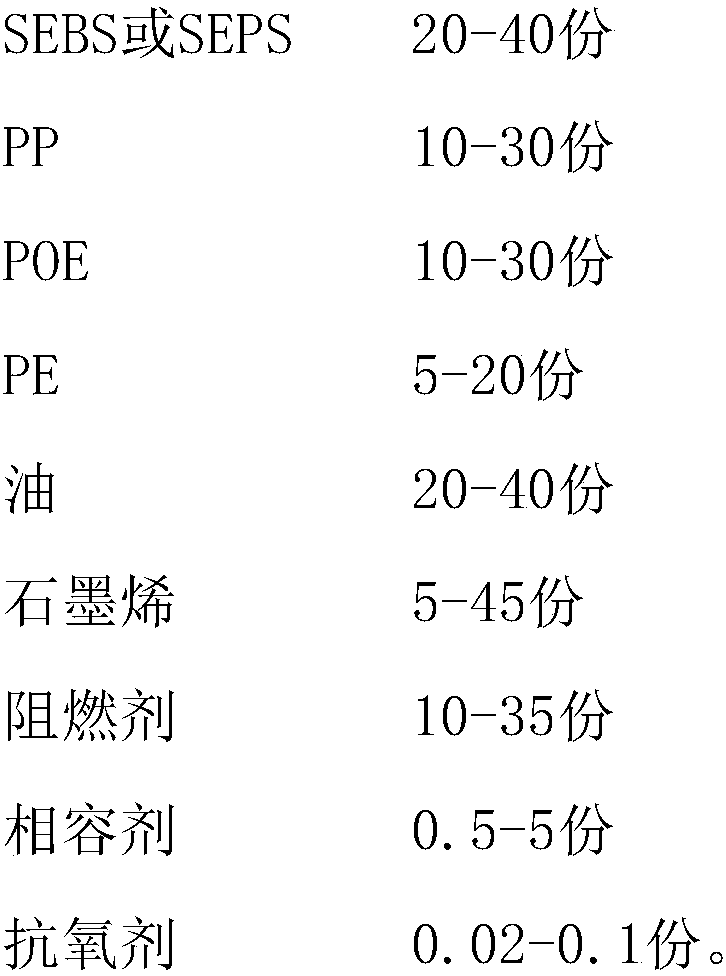

The invention relates to the technical field of cable materials, in particular to a flame-retardant TPE cable insulation material or sheathing material with an electromagnetic shielding function and apreparing method thereof. The TPE cable insulation material or sheathing material is prepared from, by weight, 20-40 parts of SEBS or SEPS, 10-30 parts of PP, 10-30 parts of POE, 5-20 parts of PE, 20-40 parts of oil, 5-45 parts of graphene, 5-35 parts of flame retardant, 0.5-5 parts of compatilizer, and 0.02-0.1 part of antioxygen. The flame-retardant PVC cable insulation material or sheathing material has the electromagnetic shielding function, the shielding effectiveness (SE) value of the flame-retardant PVC cable insulation material or sheathing material can reach 17-50 db, the flame-retardant effect is excellent, the vertical burning test of a single cable can reach V0 level, the strength is high, the tensile strength can reach 17 MPa or above, the flexibility is good, the elongationat break is high and can reach 470% or above, and the mechanical performance is excellent.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

Composite fireboard with electromagnetic shielding function and preparation method thereof

ActiveCN105082314AWith electromagnetic shielding functionLight in massWood working apparatusDomestic articlesFiberAdhesive

The invention provides a composite fireboard with the electromagnetic shielding function and a preparation method of the composite fireboard. The composite fireboard is mainly prepared by compositing nickel zinc ferrite expanded graphite and wood fibers in mass ratio of 2-7: 3; the composite fiberboard is 2-5mm in thickness, and 0.7-1.0g / cm<3> in density. The preparation method comprises the following steps: respectively weighing the wood fibers and nickel zinc ferrite expanded graphite, and uniformly mixing to obtain a first mixture; adding a certain amount of isocyanate adhesives to the first mixture, and uniformly stirring to obtain raw materials for being pressed to prepare the board, wherein the dosage of the isocyanate adhesives is 8 to 16% of the total mass of the wood fibers and nickel zinc ferrite expanded graphite; uniformly paving the obtained raw materials for being pressed to prepare the board, and then prepressing and thermally pressing to obtain the composite fireboard with the electromagnetic shielding function. According to the composite fireboard, the electromagnetic shielding effect can be more than 50dB averagely within the range from 0.3 to 1500MHz, and the bandwidth is 11-17GHz when the electromagnetic wave reflection coefficient reaches -5dB within the range from 2 to 18GHz.

Owner:GUANGXI UNIV

Heat-dissipating pouring sealant for packaging electronic devices

InactiveCN105969277AImprove cooling effectImprove electromagnetic shielding efficiencyNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyHeat conducting

This case discloses a heat-dissipating encapsulant for encapsulating electronic devices. The encapsulant includes component A and component B, and the mass ratio of component A to component B is (8-10): (4~8), wherein, the A component includes the following materials: epoxy resin, mixed diluent, inorganic mixed thermally conductive filler, spherical silica powder, and the B component includes the following materials: composite curing agent, plasticizer , Epoxy accelerator. The invention provides a heat-dissipating potting glue for encapsulating electronic devices. By adding inorganic mixed heat-conducting fillers and spherical silicon micropowder with a suitable particle size to epoxy resin, a compound with uniform structure, high light transmittance and large refractive index can be obtained. , a potting compound with good elongation, tensile strength, and bonding strength, as well as excellent thermal conductivity and dielectric properties.

Owner:苏州市奎克力电子科技有限公司

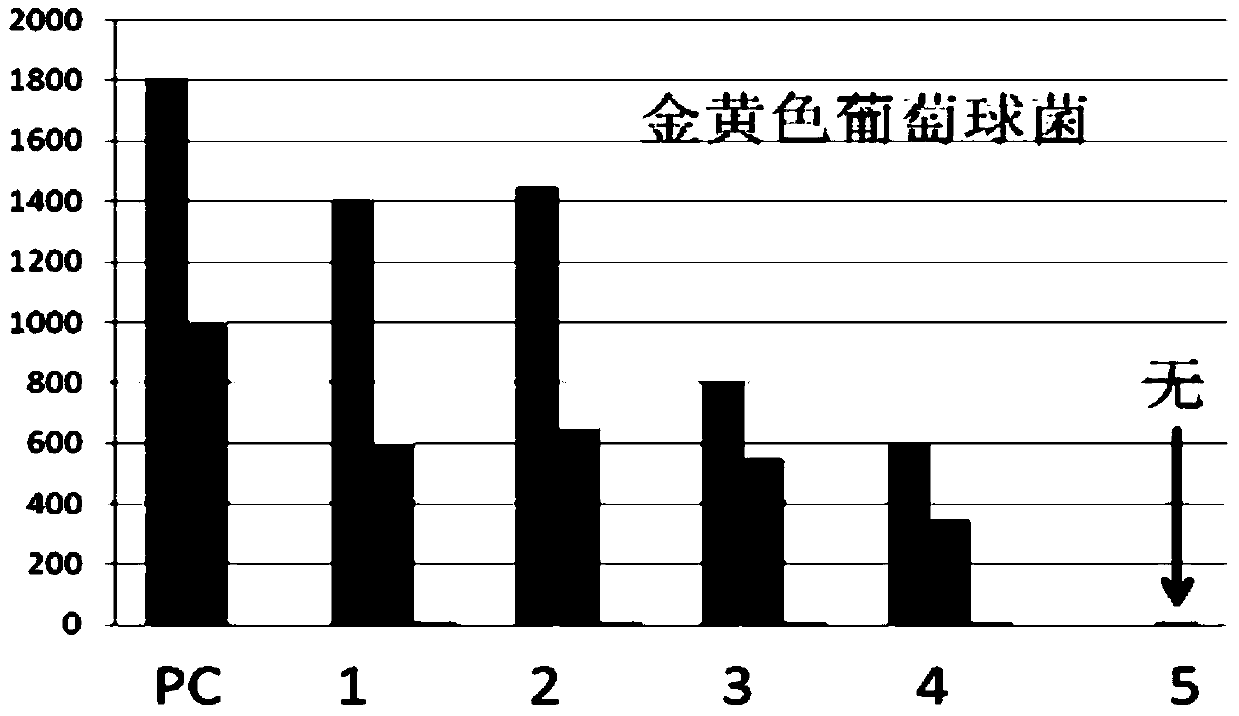

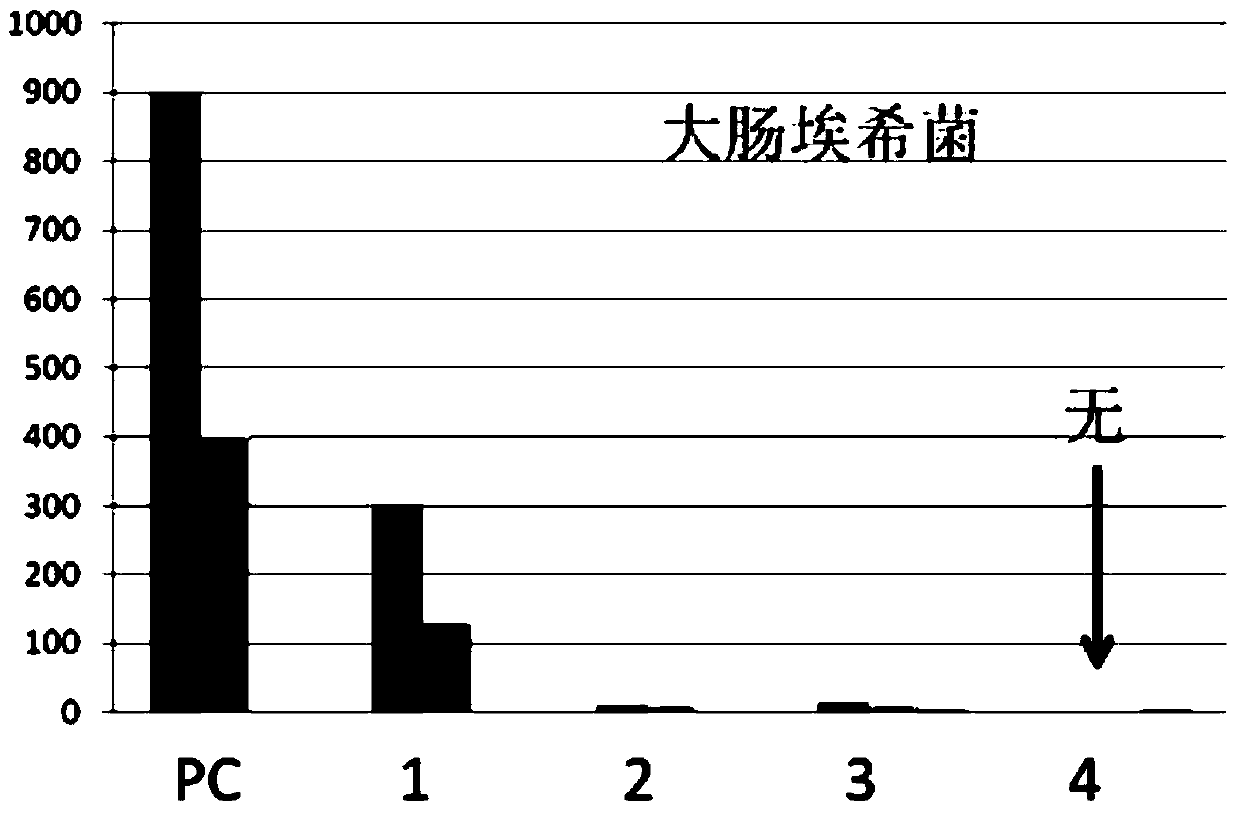

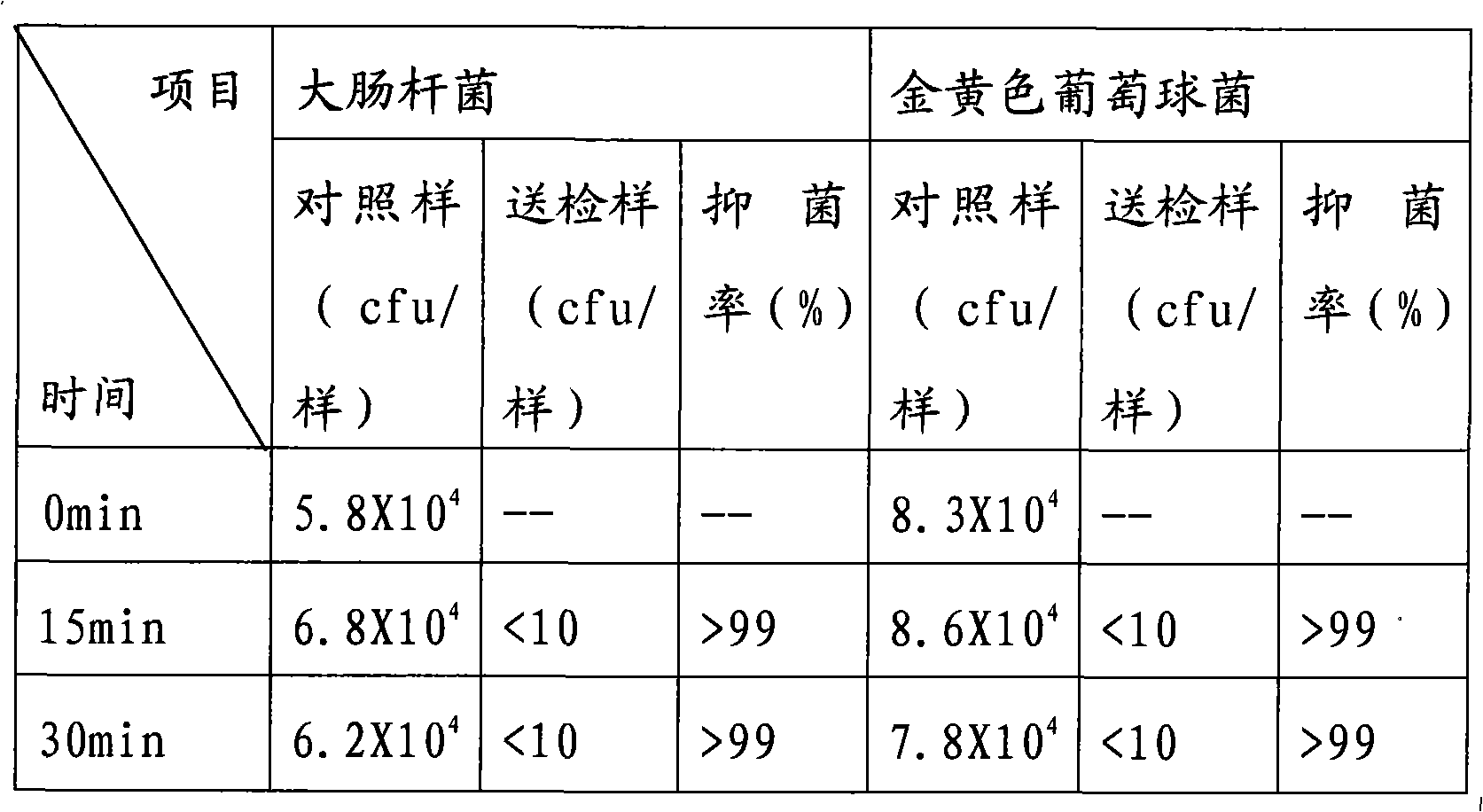

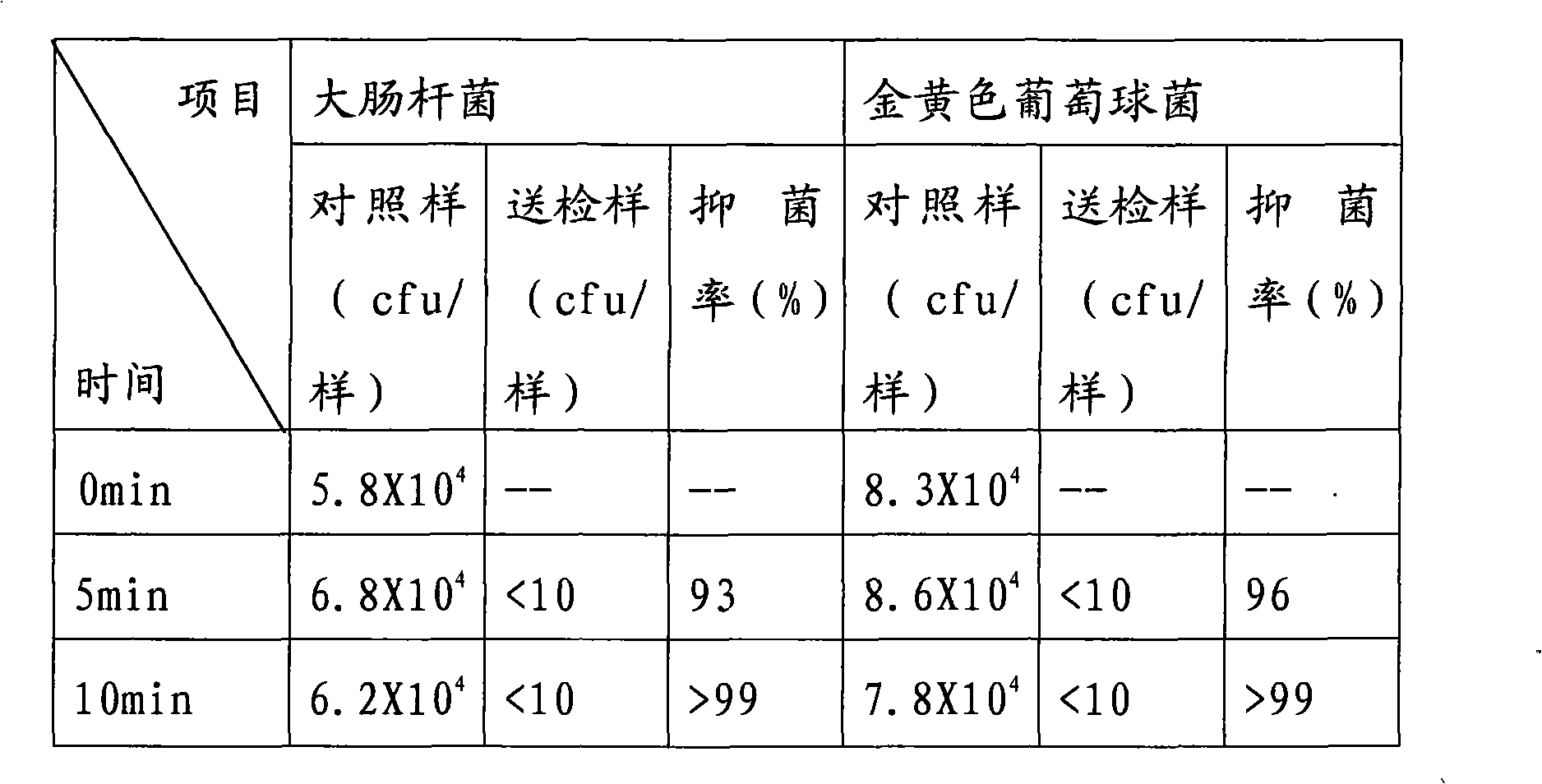

Method for manufacturing fabric with antibacterial and electromagnetic shielding functions

The invention relates to a method for manufacturing a fabric with antibacterial and electromagnetic shielding functions. The method is characterized by comprising steps of (1), respectively sealing two ends of each hollow fiber in containers which are not communicated with each other, placing one end of each hollow fiber in AgNO<3> solution, placing the other end of each hollow fiber in the corresponding empty container, filling compressed air into the container with the AgNO<3> solution, vacuumizing the empty container with the other ends of the hollow fibers, adding ammonium hydroxide solution and acetaldehyde into the container with the AgNO<3> solution, placing the hollow fibers in water bath to heat the hollow fibers and generating silver particles on the inner walls of the hollow fibers to obtain hollow silver-plated fibers; (2), weaving the hollow silver-plated fibers and common fibers to obtain a fabric; (3), preparing quaternary ammonium salt solution with the mass percentage concentration of 10-20%, soaking the fabric obtained in the step (2) into the quaternary ammonium salt solution and then drying the soaked fabric at the temperature of 60-80 DEG C for 20-40 minutes. The method has the advantage that the fabric has conductive, antistatic and electromagnetic radiation protection functions.

Owner:WUXI TAIBO GARMENT

Composite material panel with electromagnetic shielding function

InactiveCN105774095AWith electromagnetic shielding functionReduce weightDomestic containersGlass/slag layered productsMetallurgyHoneycomb

The invention provides a composite material panel with the electromagnetic shielding function.The composite material panel comprises at least three composite material layers and at least two metal wire mesh layers.The metal wire mesh layers include at least one 120-200-mesh metal wire mesh layer.At least one composite material layer is arranged between every adjacent metal wire mesh layers.The outmost layer and the innermost layer of the panel are the composite material layers.The composite material panel with the electromagnetic shielding function has the electromagnetic shielding function, is low in weight and is not likely to be debonded with foams or honeycombs or the like, and the electromagnetic shielding effectiveness within the range from 100 kHz to 10 GHz is larger than 40 dB.A deck is easy to install, and metal wire meshes are convenient and reliable to connect.

Owner:HENGSHEN

Artificial plate with electromagnetic shielding function and manufacturing method thereof

ActiveCN103978524AWith electromagnetic shielding functionLow costWood veneer joiningPressure impregnationFiberSurface layer

The invention discloses an artificial plate with an electromagnetic shielding function and a manufacturing method thereof. The artificial plate is prepared from a wooden / bamboo single plate and an aniline prepolymer, wherein the aniline prepolymer is subjected to in-situ polymerization in a wooden / bamboo single plate substrate to form conductive polyaniline macromolecules and adopts a double-layer structure; a surface layer is a polyaniline-containing wooden / bamboo single plate, and a bottom layer adopts a wooden plywood, a medium (high)-density fiber plate or a chipboard. The artificial plate has the advantages that characteristics of wood and polyaniline are fully used; the wooden artificial plate is used as a base material, and a wooden / bamboo material with the polyaniline is laminated on the surface layer of the base material, so that the novel wooden artificial plate with a conductive function is prepared. The artificial plate has the self performance feature of the wooden material, and the electromagnetic shielding efficiency of the artificial plate is up to 32.78-49.35dB under a shielding efficiency test within a frequency range of 5-1,500KHz according to a military standard (GB-SJ20524-1995) of the electronic industry in China.

Owner:JIANGSU SHENGYU FLOORING

Antibacterial antiviral non-woven fabric with electromagnetic shielding function and production method and device

InactiveCN102154815AWith electromagnetic shielding functionAntibacterialFibre treatmentDiluentElectromagnetic shielding

The invention relates to an antibacterial antiviral non-woven fabric with an electromagnetic shielding function, a production method and a device. The antibacterial antiviral non-woven fabric with the electromagnetic shielding function is manufactured in a way that a common non-woven fabric is put into an antibacterial antiviral solution, wherein the antibacterial antiviral solution comprises the following components by weight ratio: 35%-45% of composite antibacterial material of silica-coated tourmaline and titanium dioxide particles, 30%-45% of coated composite carbon-based electromagnetic shielding material, 10%-35% of foam additive and 10%-20% of diluent. The antibacterial antiviral non-woven fabric with the electromagnetic shielding function has antibacterial, antiviral, electromagnetic-shielding and anti-penetration functions.

Owner:BEIJING MEGACESS NON WOVEN TECH

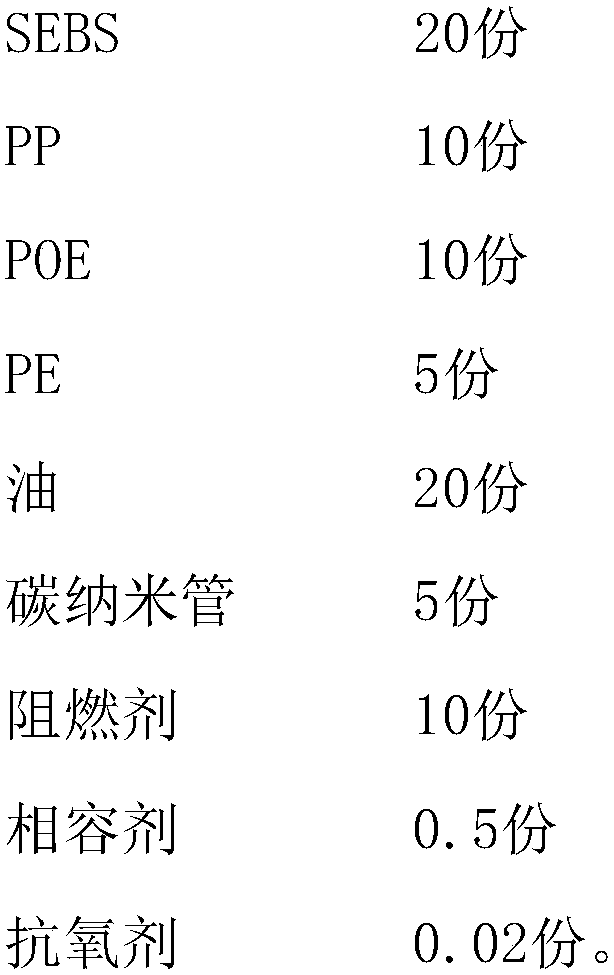

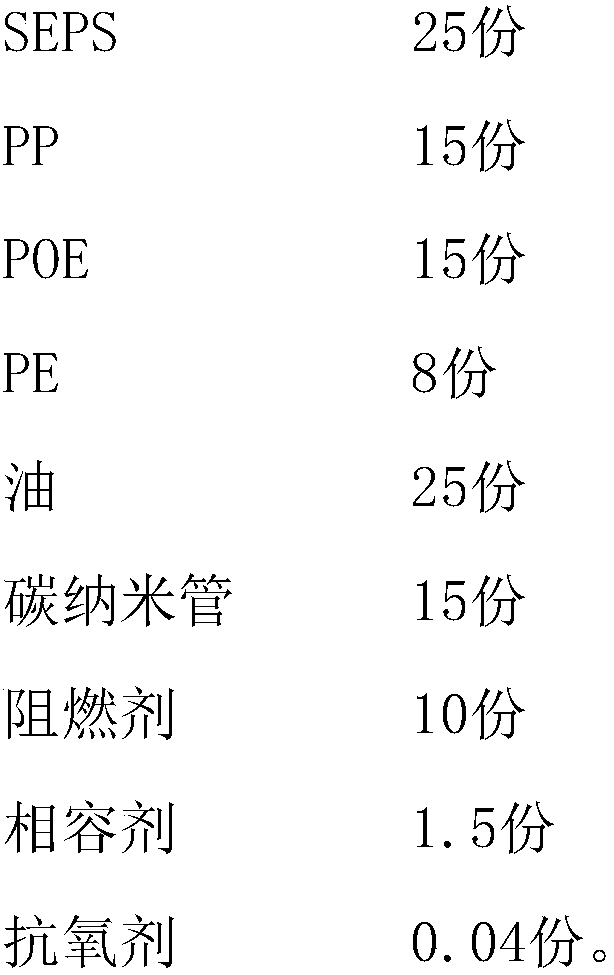

Flame-retardant TPE cable insulation material or sheathing material with electromagnetic shielding function and preparation method of TPE cable insulation material or sheathing material

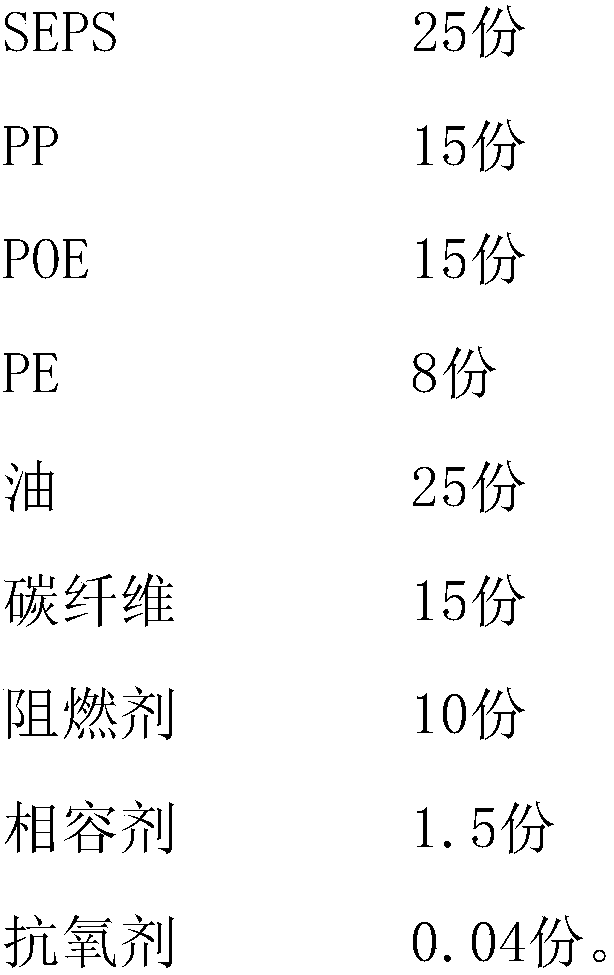

InactiveCN108410112AImprove low temperature toughnessImprove impact performancePlastic/resin/waxes insulatorsLiquid organic insulatorsAntioxidantThermoplastic elastomer

The invention provides a flame-retardant thermoplastic elastomer (TPE) cable insulation material or sheathing material with an electromagnetic shielding function and a preparation method of the TPE cable insulation material or sheathing material. The TPE cable insulation material or sheathing material comprises the following raw materials in parts by weight: 20-40 parts of SEBS or SEPS, 10-30 parts of PP, 10-30 parts of POE, 5-20 parts of PE, 20-40 parts of oil, 5-45 parts of carbon nanotubes, 5-35 parts of a flame retardant, 0.5-5 parts of a compatibilizer, and 0.02-0.1 part of an antioxidant. The TPE cable insulation material or sheathing material provided by the invention has the electromagnetic shielding function, the shielding effectiveness (SE) value can reach 17-50 db, and the flame-retardant effect is excellent; and a single vertical burning test can reach a V0 level, the strength is high, the tensile strength can reach 15 MPa or more, the flexibility is good, the elongation atbreak is high and can reach 450% or more, and the mechanical properties are excellent.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

Flame-retardant TPU cable sheathing material with electromagnetic shielding function and preparation method of TPU cable sheathing material

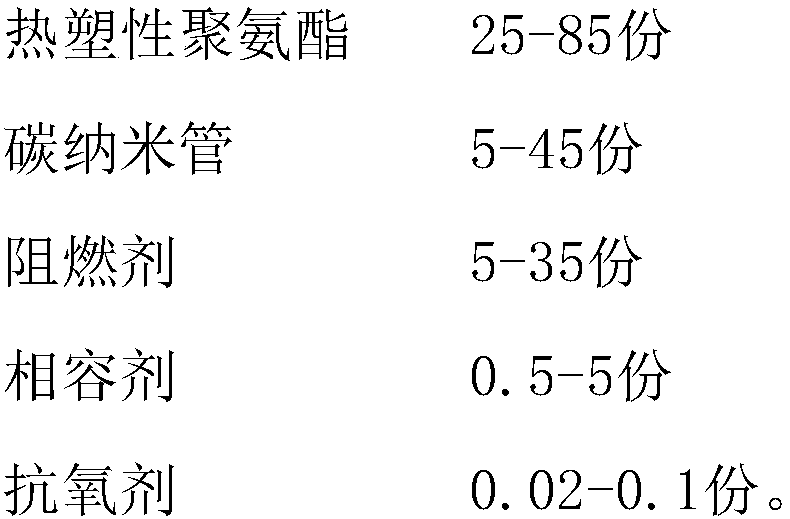

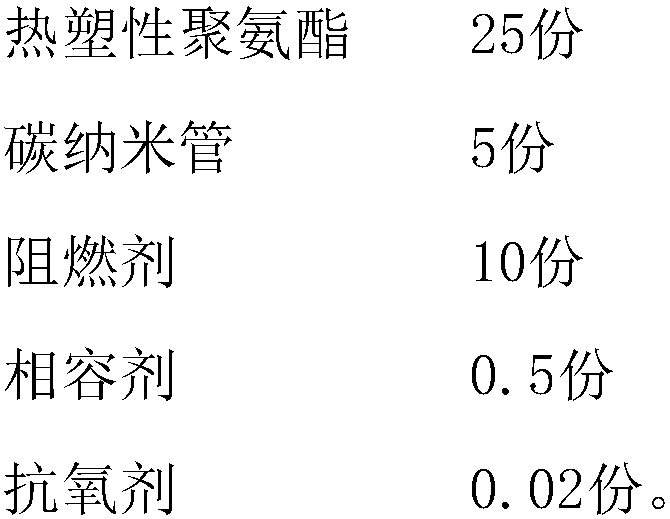

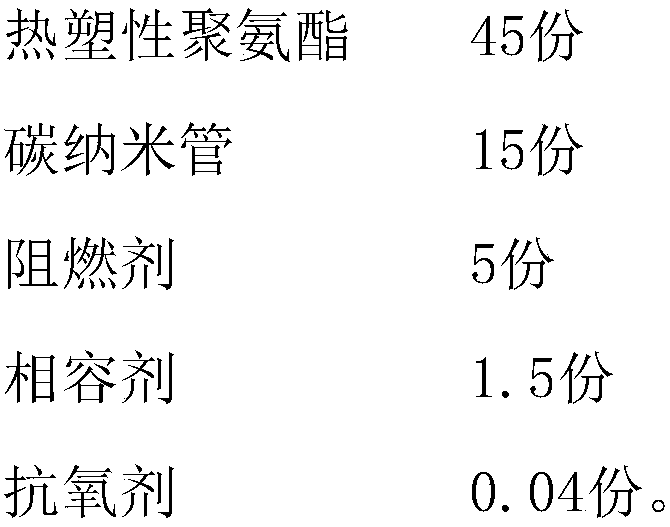

InactiveCN108410160AReduce usageEffect on mechanical propertiesPlastic/resin/waxes insulatorsCarbon nanotubeThermoplastic polyurethane

The invention relates to the technical field of cable materials, and in particular relates to a flame-retardant thermoplastic polyurethane (TPU) cable sheathing material with an electromagnetic shielding function and a preparation method of the TPU cable sheathing material. The TPU cable sheathing material comprises the following raw materials in parts by weight: 25-85 parts of thermoplastic polyurethane, 5-45 parts of carbon nanotubes, 5-35 parts of a flame retardant, 0.5-5 parts of a compatibilizer, and 0.02-0.1 part of an antioxidant, wherein the carbon nanotubes are surface-acidified single-walled carbon nanotubes or multi-walled carbon nanotubes. The TPU cable sheathing material provided by the invention has the electromagnetic shielding function, the shielding effectiveness (SE) value can reach 17-50 db, and the flame-retardant effect is excellent; and a single vertical burning test can reach a V0 level, the strength is high, the tensile strength can reach 25 MPa or more, the flexibility is good, the elongation at break is high and can reach 400% or more, and the mechanical properties are excellent.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

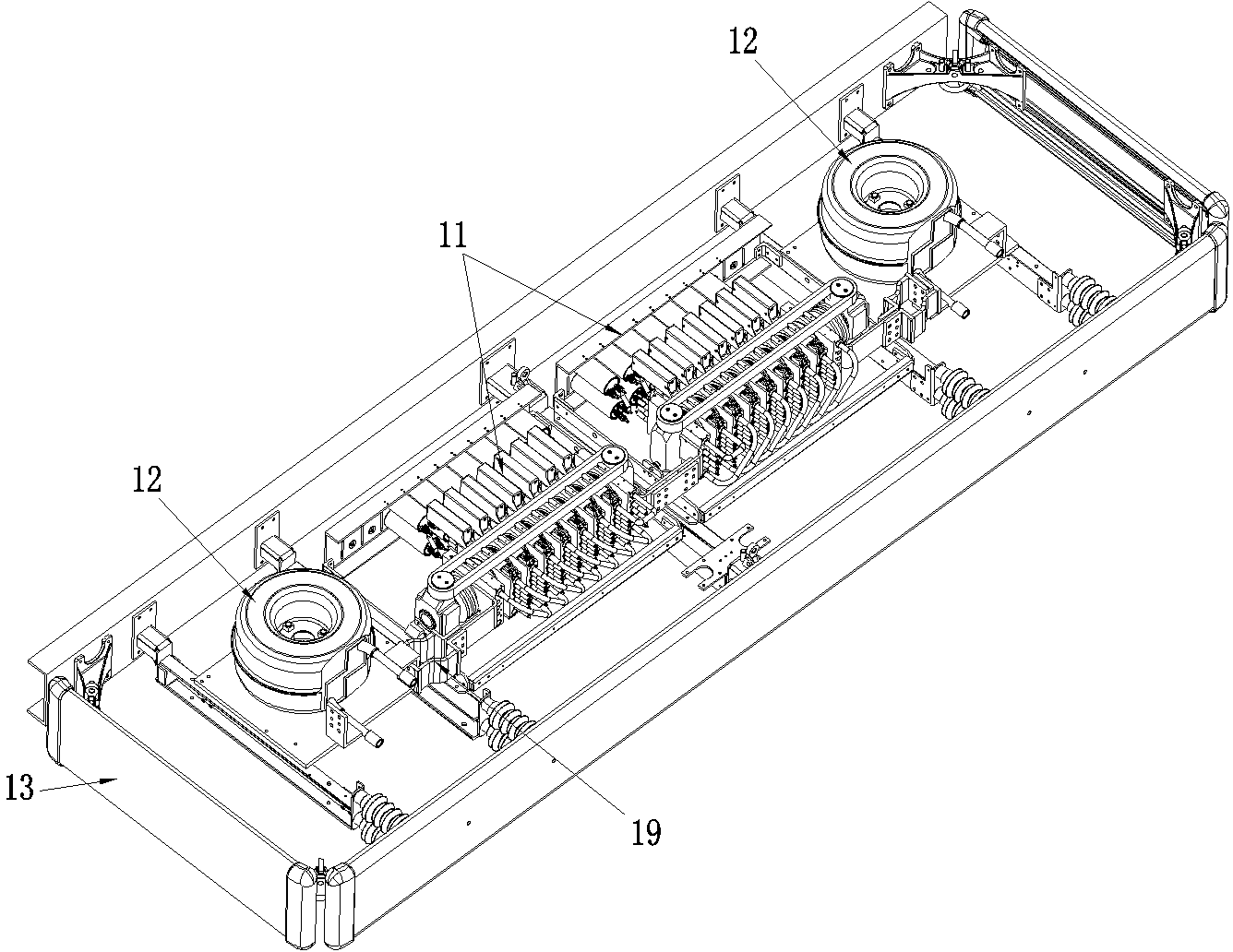

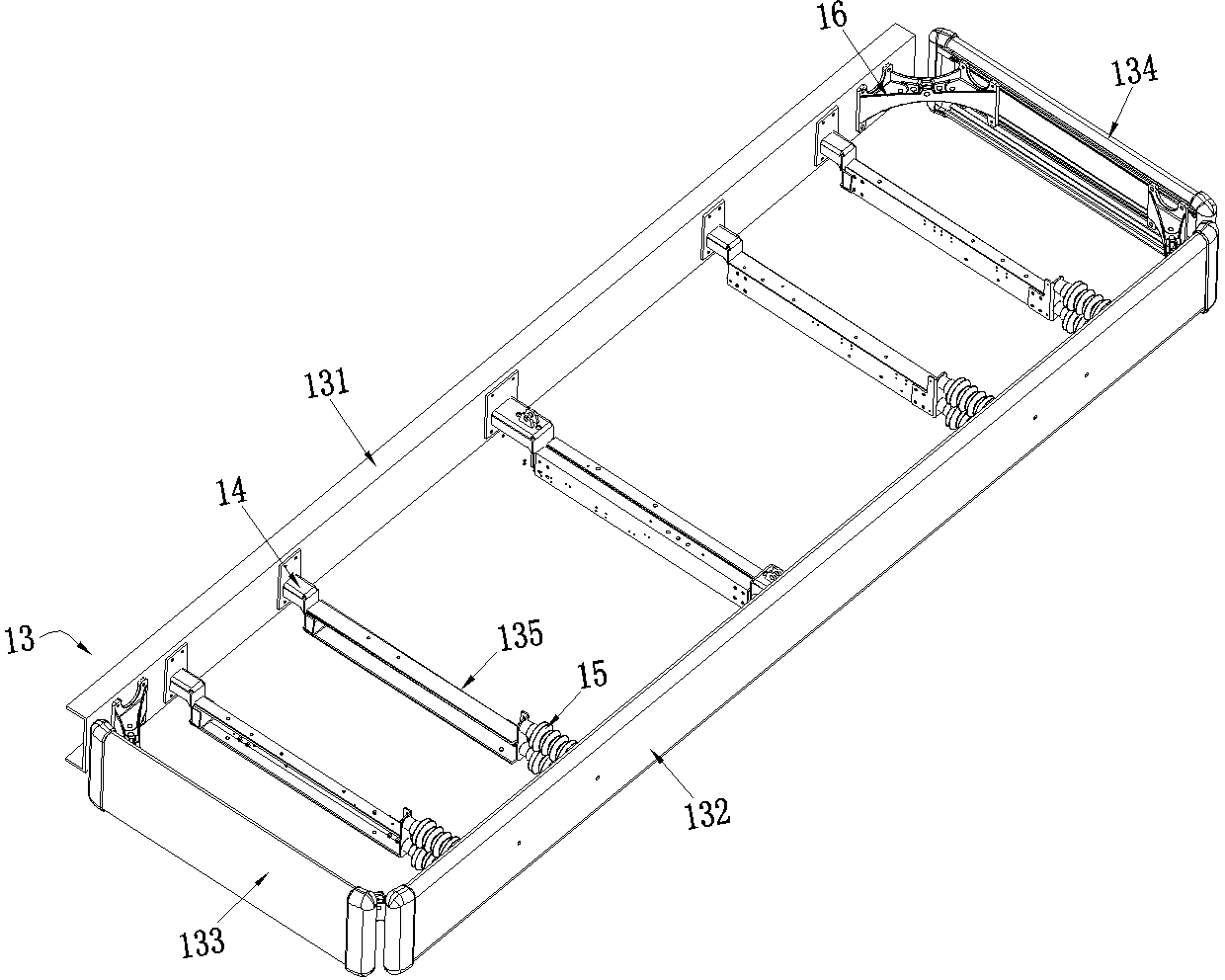

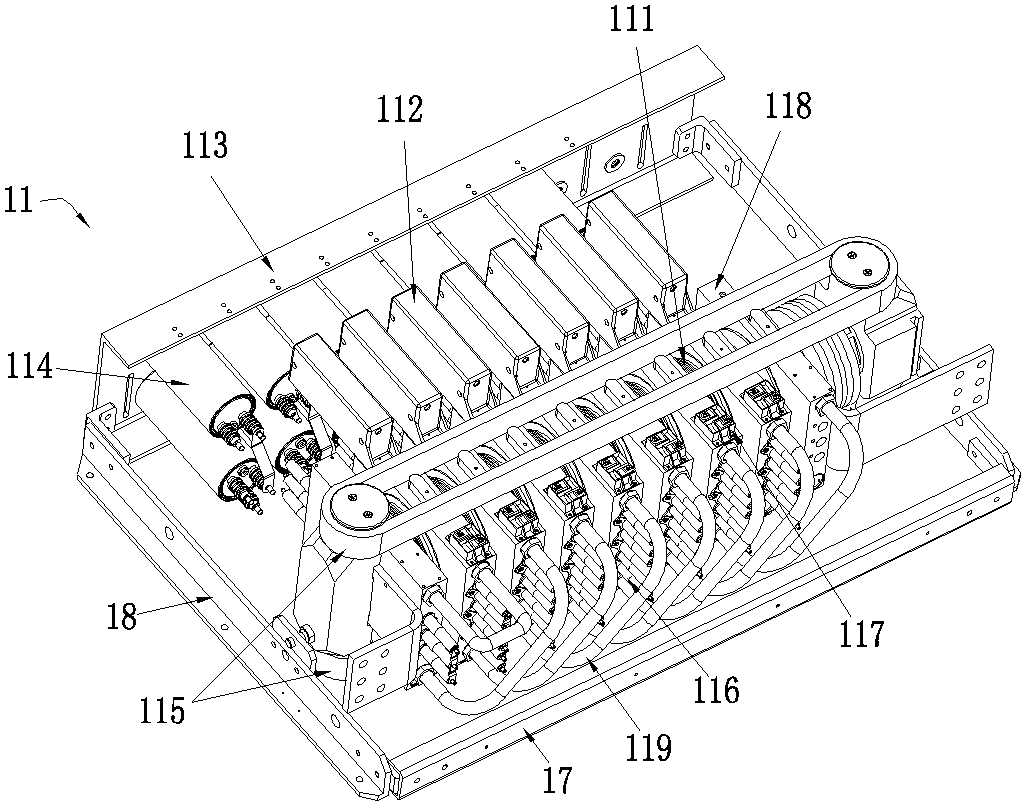

Thyristor converter valve assembly

ActiveCN103354235AReduce volumeEasy to transportSemiconductor/solid-state device detailsSolid-state devicesComputer moduleHigh-voltage direct current

The invention relates to a high-power electrical electronic rectification and inversion apparatus, and specifically relates to a thyristor converter valve assembly applicable in high-voltage direct-current power transmission, direct-current ice melting equipment, SVC, etc. The thyristor converter valve assembly comprises valve modules and corresponding reactors. The valve module includes a frame. The valve modules and the reactors are fixedly mounted on a rectangular frame-type base in a detachable manner and distributed along the left-right direction of the base. The base includes a front border, a rear border, a left border, a right border and supporting beams bridging the front border and the rear border. The lengths of the left and right borders are smaller than that of the front and rear borders. The left and right borders are made of aluminium section material. One of the front and rear borders is made of aluminium section material, while the other one is made of insulation material. The thyristor converter valve assembly has the advantages of convenience for both transport and on-site assembly.

Owner:XJ ELECTRIC

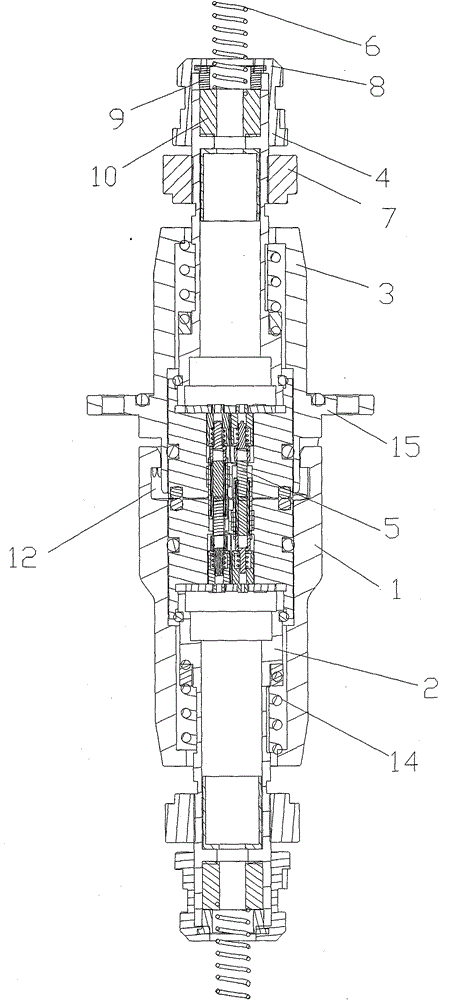

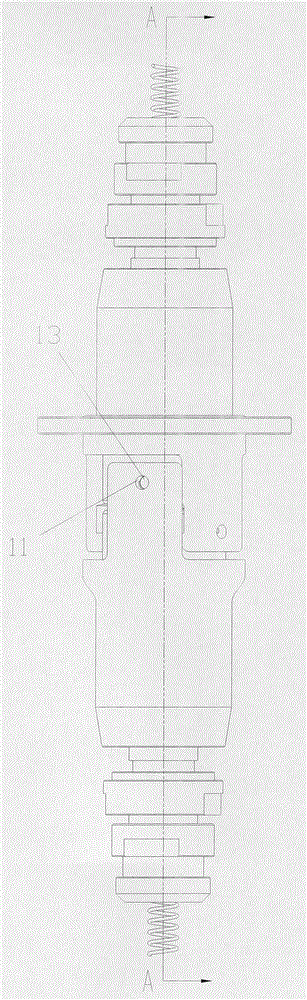

Pluggable electromagnetic shielding optical fiber connector

ActiveCN104035164AImprove stabilityWith electromagnetic shielding functionCoupling light guidesElectromagnetic shieldingEngineering

The invention relates to a pluggable electromagnetic shielding optical fiber connector. The pluggable electromagnetic shielding optical fiber connector comprises a plug and a socket which are connected with each other, wherein the plug comprises a plug shell and a plug core main body arranged in the plug shell; the socket comprises a socket shell and a socket core main body arranged in the socket shell; the two ends of the plug core main body and the socket core main body are provided with optical fiber connecting assemblies and cable protection springs respectively; the joints of the plug shell and the socket shell are provided with anti-slip pin outlet holes; the plug shell and the socket shell are provided with butt joint guide grooves close to the anti-slip pin outlet holes; one end of the optical fiber connecting assembly is connected with a travel spring; the optical fiber connecting assembly is provided with a bolt; the plug and the socket are connected with each other through the anti-slip pin outlet holes and the bolt. The pluggable electromagnetic shielding optical fiber connector has the beneficial effects that the connector is firm, durable and resistant to impact, vibration, dust and water by adopting a high-strength metal shell, and has an electromagnetic shielding function; the plug and the socket can be optionally connected with each other, and the function of preventing blind insertion and wrong insertion is realized.

Owner:河北长飞优创科技有限公司

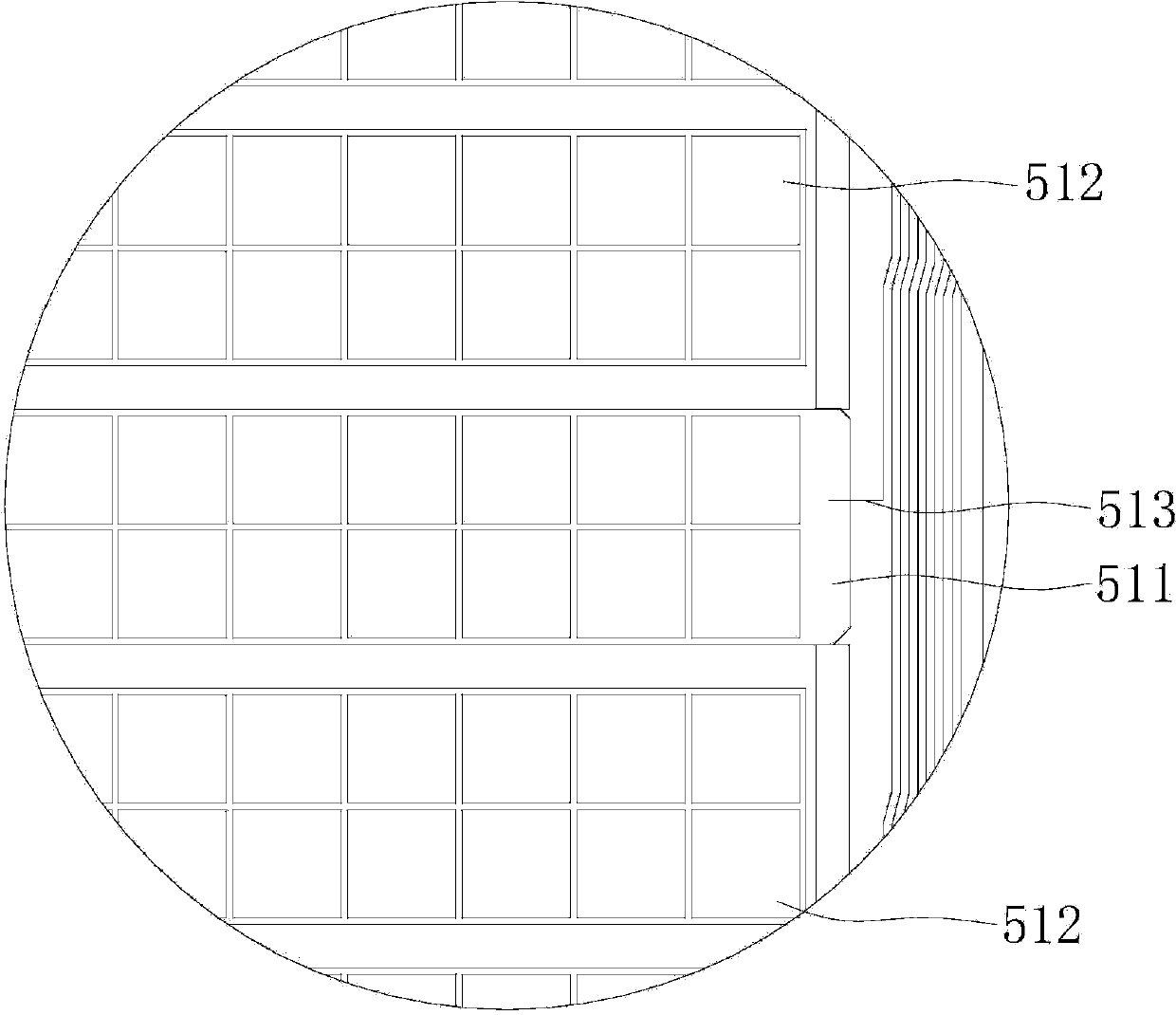

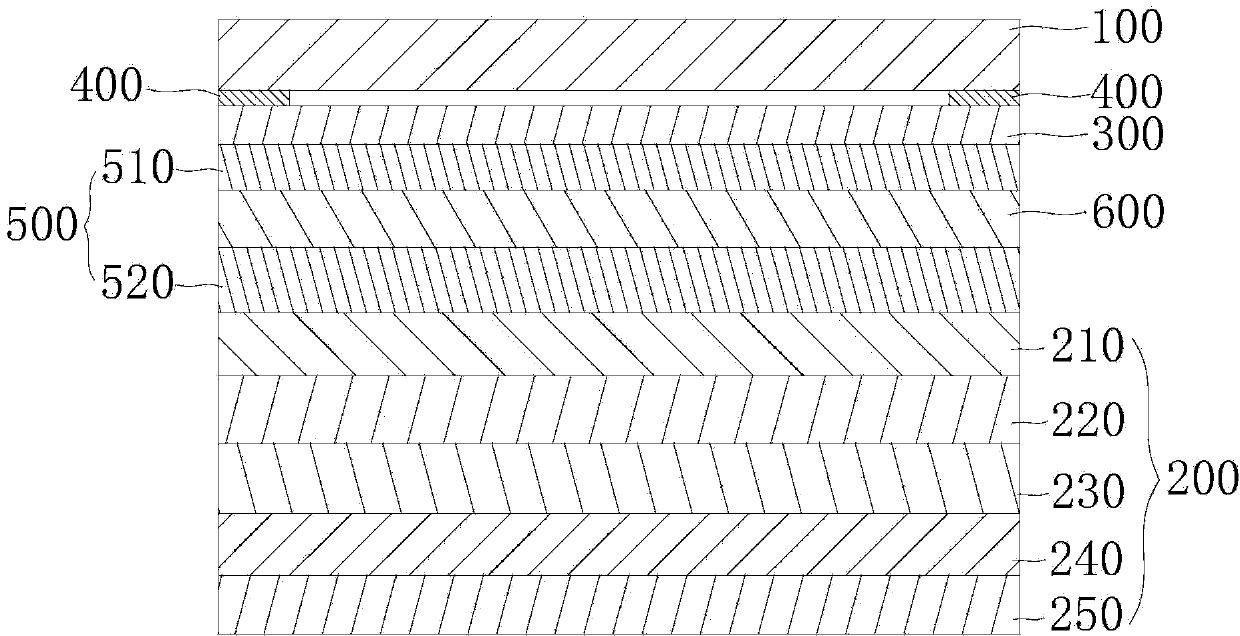

Electronic equipment and manufacturing method for single-layered multipoint capacitive touch screen and touch layer

InactiveCN103761017AImprove accuracyExpand the range of speciesInput/output processes for data processingEngineeringTouchscreen

The invention discloses electronic equipment and a manufacturing method for a single-layered multipoint capacitive touch screen and a touch layer thereof. The single-layered multipoint capacitive touch screen comprises a panel and a screen module, wherein a transparent optical adhesive layer is arranged between the panel and the screen module; a BM (basement membrane) frame layer is arranged on the frame of the panel; the screen module comprises an upper polaroid, an upper glass substrate, a lower glass substrate, a lower polaroid and a backlight plate which are sequentially arranged in a stacked manner from top to bottom and are adhered to one another; a metal conductive ink circuit layer is arranged between the panel and the screen module or in the screen module and comprises a plurality of touch units which are arranged in parallel; and each touch unit is independently provided with a lead connected with a processor. The single-layered multipoint capacitive touch screen is sensitive in touch, high in accuracy and wide in application range; the manufacturing method for the touch layer of the single-layered multipoint capacitive touch screen is simple; the touch layer is low in cost, and is energy-saving and environment-friendly; and the using convenience and the reliability of the electronic equipment with the touch screen are improved.

Owner:SHENZHEN SUCCESS ELECTRONICS LTD

Method for manufacturing capacitive touch screen and touch-control layer, and electronic device

InactiveCN103744567AImprove accuracyImprove finenessInput/output processes for data processingControl layerEngineering

The invention is suitable for the technical field of touch screen structures, and discloses a method for manufacturing a capacitive touch screen and a touch-control layer, and an electronic device. The capacitive touch screen comprises a panel and a screen module, wherein an optical adhesive layer and a BM border layer are arranged between the panel and the screen module; the screen module comprises an upper polarizer, an upper glass substrate, a lower glass substrate, a lower polarizer and a backlight board which are sequentially arranged in a cascade manner from top to bottom, wherein a first metal conductive ink circuit layer is arranged on the panel, a second metal conductive ink circuit layer is arranged in the screen module, or both the first metal conductive ink circuit layer and the second metal conductive ink circuit layer are arranged in the screen module; each of the first metal conductive ink circuit layer and the second metal conductive ink circuit layer comprises a plurality of touch units, and each of the touch units is provided with a lead wire connected with a processor. The capacitive touch screen is sensitive in touch control and high in accuracy degree; the production method for the touch-control layer is simple, low in cost, energy-saving and environment-friendly, and capable of improving the use convenience and reliability of the electronic device with the touch screen.

Owner:SHENZHEN SUCCESS ELECTRONICS LTD

Flame-retardant TPE (thermoplastic elastomer) cable insulation material or sheath material with electromagnetic shielding function and preparation method of flame-retardant TPE cable insulation material or sheath material

InactiveCN108299782AImprove low temperature toughnessImprove impact performancePlastic/resin/waxes insulatorsLiquid organic insulatorsElastomerFiber

The invention provides a flame-retardant TPE (thermoplastic elastomer) cable insulation material or sheath material with an electromagnetic shielding function and a preparation method of flame-retardant TPE cable insulation material or sheath material. The TPE cable insulation material or sheath material is prepared from the following raw materials in parts by weight: 20-40 parts of SEBS (styrene-ethylene-butylene-styrene) or SEPS (styrene-ethylene / propylene-styrene block copolymer), 10-30 parts of PP (polypropylene), 10-30 parts of POE (polyolefin elastomer), 5-20 parts of PE (polyethylene),20-40 parts of oil, 5-45 parts of carbon fiber, 5-35 parts of a flame retardant, 0.5-5 parts of a compatibilizer and 0.02-0.1 parts of an antioxidant. The TPE cable insulation material or sheath material has the electromagnetic shielding function, and the shielding efficiency SE value can reach 17-50 db; the flame retardant effect is excellent, the single vertical combustion test can reach V0 grade, strength is high, the tensile strength can reach 16 MPa or higher, flexibility is good, the elongation at break is high, the elongation at break can reach 460% or higher, and the mechanical property is excellent.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

Preparation method for polyimide three-layer composite film with electromagnetic shielding function

InactiveCN106939518AWith electromagnetic shielding functionReduce agglomeration effectFilament/thread formingNon-woven fabricsComposite filmElectrospinning

The invention provides a preparation method for a polyimide three-layer composite film with an electromagnetic shielding function. When carbon nanotubes are employed for modification of a polyimide film, the resistivity of the polyimide film can be effectively reduced; however, with increase of the content of the carbon nanotubes, the carbon nanotubes are substantially agglomerate in polyimide, which leads to drastic decrease of the mechanical properties of the polyimide film. The preparation method provided by the invention comprises the following steps: (1) preparation of a carbon nanotube-modified polyamide acid solution; (2) preparation of a carbon nanotube-modified polyamide acid microporous film by using an electrostatic spinning method; (3) preparation of a polyamide acid solution; (4) coating of two sides of the microporous film with the polyamide acid solution; and (5) thermal imidization of a prepared carbon nanotube-modified polyimide acid three-layer composite film. The polyimide three-layer composite film prepared in the invention is mainly applied to broaden the application scope of polyimide films in the field of electromagnetic shielding materials.

Owner:HARBIN UNIV OF SCI & TECH

Radiation crosslinked polyethylene foam as well as preparation method and application thereof

PendingCN111592706ALow equipment requirementsGood environmental performancePelletizingPolymer chemistry

The invention discloses radiation crosslinked polyethylene foam as well as a preparation method and application thereof. The radiation cross-linked polyethylene foam is mainly prepared from low-density polyethylene, azodicarbonamide, conductive powder, a foaming aid and a compatilizer as raw materials through mixing granulation, extrusion molding, radiation cross-linking and foaming, and the weight ratio of the conductive powder to the foaming aid to the compatilizer is (8-10): (0.3-1): (1-5). The problems that in the prior art, a radiation cross-linked polyethylene foam product with the electromagnetic shielding function and the wave absorbing function causes large pollution to the environment, and the technical problems of complex process, low production efficiency, high process cost, high foam foaming density and poor electromagnetic shielding performance and wave-absorbing performance of foam products are solved, and the radiation crosslinked polyethylene foam products are better in wave-absorbing performance, better in electromagnetic shielding performance, more environment-friendly, higher in production efficiency and lower in foaming density.

Owner:SHENZHEN CHANGYUAN TEFA TECH CO LTD

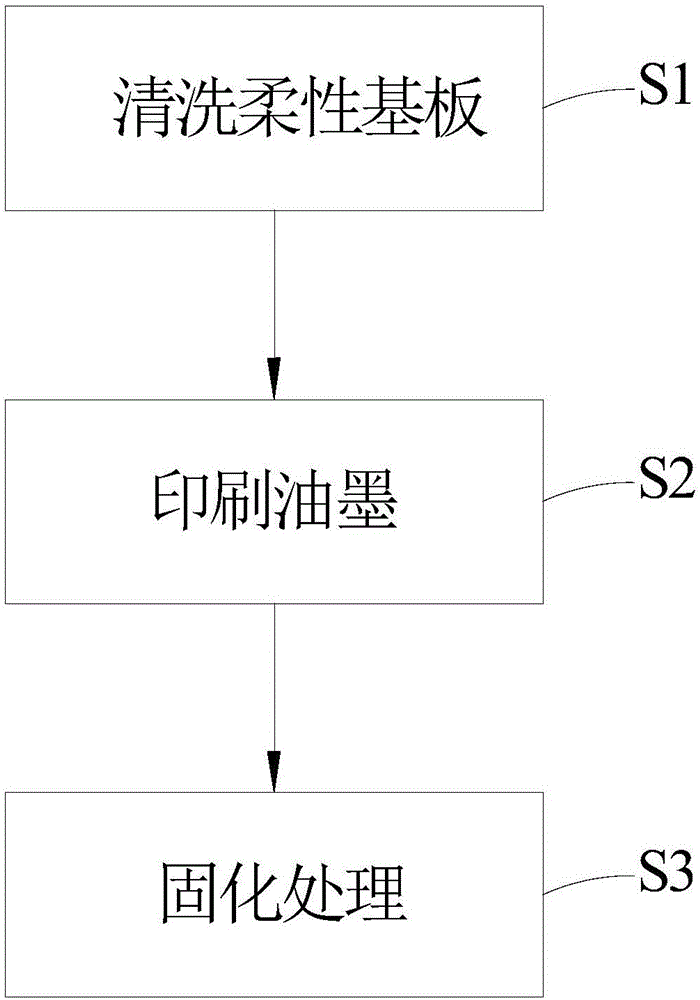

Flexible capacitive touch screen and manufacturing method thereof

PendingCN106371686ALarge touch precision requirementsHigh touch precision requirementsInput/output processes for data processingCooking & bakingHigh density

The invention is applicable to the technical field of capacitive touch screens, and provides a method for manufacturing a flexible capacitive touch screen. The method comprises the following steps: cleaning of a flexible substrate: cleaning the flexible substrate with a cleaning machine; ink printing: printing a metal conductive ink on the surface of the flexible substrate with printing equipment, and forming a conductive circuit layer on the surface of the flexible substrate, wherein the conductive circuit layer comprises an X-direction induction module and a Y-direction induction module; curing treatment: baking the flexible substrate printed with the metal conductive ink. In the method, the printing equipment is used to print the metal conductive ink on the surface of the flexible substrate, so as to form the conductive circuit layer; the baking-curing treatment is performed to form the flexible capacitive touch screen; in the whole manufacturing process, only the cleaning machine, the printing equipment and baking equipment are used, so that the method greatly reduces equipment costs, has an electromagnetic shielding function, effectively reduces the signal interference, and can be used for producing circuits with high touch accuracy requirements and high density, such as the capacitive touch screen with narrow border and high touch accuracy.

Owner:SHENZHEN YUSHUN IND INTELLIGENT TECH CO LTD +3

Electromagnetic shielding marble-imitated coating and producing method thereof

InactiveCN104559496AWith electromagnetic shielding functionElectrically-conductive paintsCelluloseEmulsion

Electromagnetic shielding marble-imitated coating and a producing method thereof are disclosed. The coating comprises following components by weight: 0.08-0.8 part of cellulose, 0.1-2 parts of a pH conditioner, 100-450 parts of an emulsion, 3-5 parts of an electrically conductive filling material, 5-32 parts of a film coalescing aid, 500-900 parts of quartz sand, 0.1-8 parts of a thickening agent, 0.1-5 parts of a defoaming agent and 50-100 parts of water. After a wall is brushed with the coating, the coating has functions of beautification and decoration to allow the wall to have beauty and texture which are same as that of marble, and also can shield electromagnetic signals, thus achieving two former steps of wall coating decoration and electromagnetic shielding device installation only by performing the one step of coating brushing, and saving time and labor.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

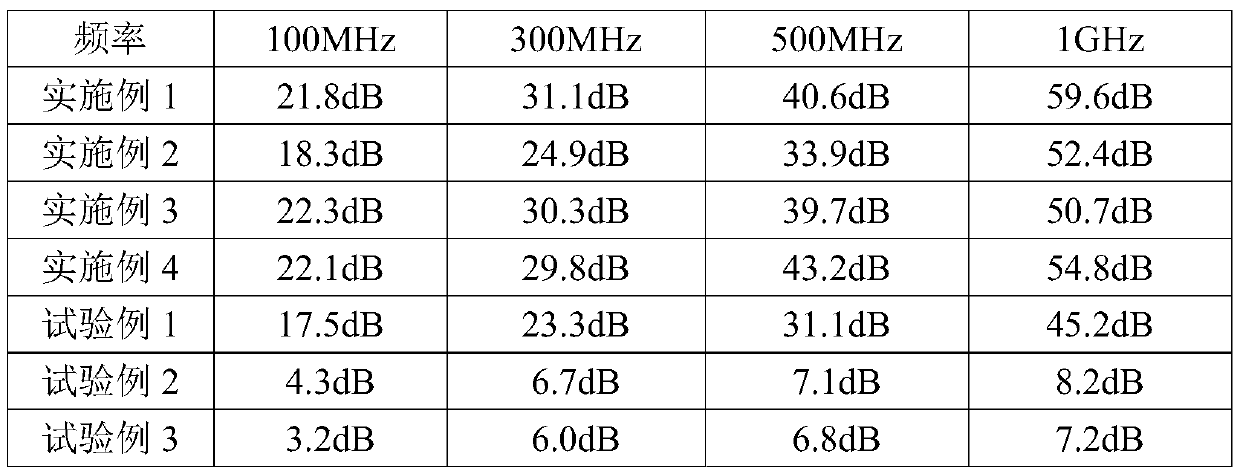

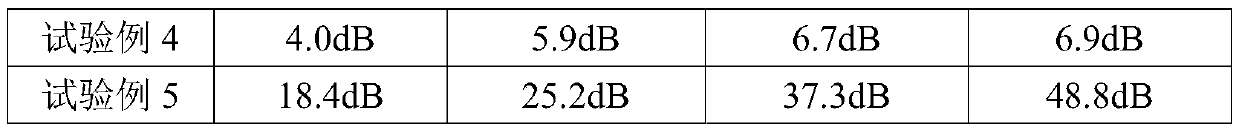

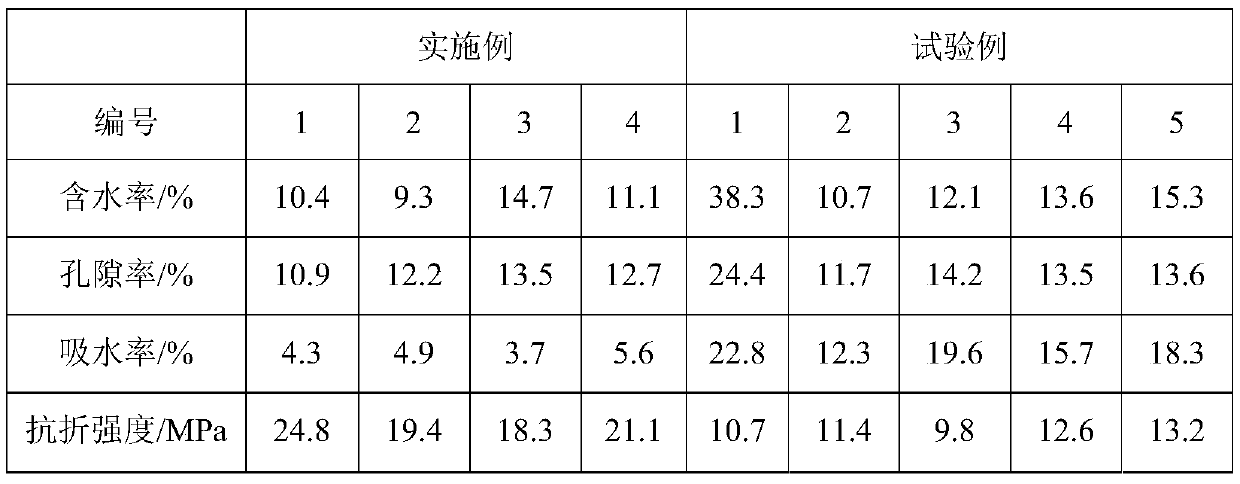

Electromagnetic shielding cement board and semi-dry preparation process thereof

The invention belongs to the technical field of production of a cement board, and particularly relates to a cement board which has an electromagnetic shielding function and is prepared by adopting a semi-dry method. The electromagnetic shielding cement board comprises a material A and a solution B, wherein the material A comprises the following raw materials in parts by weight: 5-70 parts of cement, 5-10 parts of glass fibers, 3-7 parts of silica fume, 5-15 parts of fly ash and 0.3-1.5 parts of polyvinylpyrrolidone. The solution B is prepared from the following raw materials in parts by weight: 90 to 98 parts of water, 1 to 6 parts of silane coupling agent and 0.05 to 0.15 part of Fe3O4-modified graphene oxide. The cement board is low in water content, high in density, low in porosity, lowin water absorption rate, excellent in breaking strength and good in anti-freezing performance, and has good mechanical properties and excellent shielding performance. The product can completely meetthe performance requirements when the cement board is used as a decorative board and an external wall board, and has wide application potential.

Owner:UNIV OF JINAN

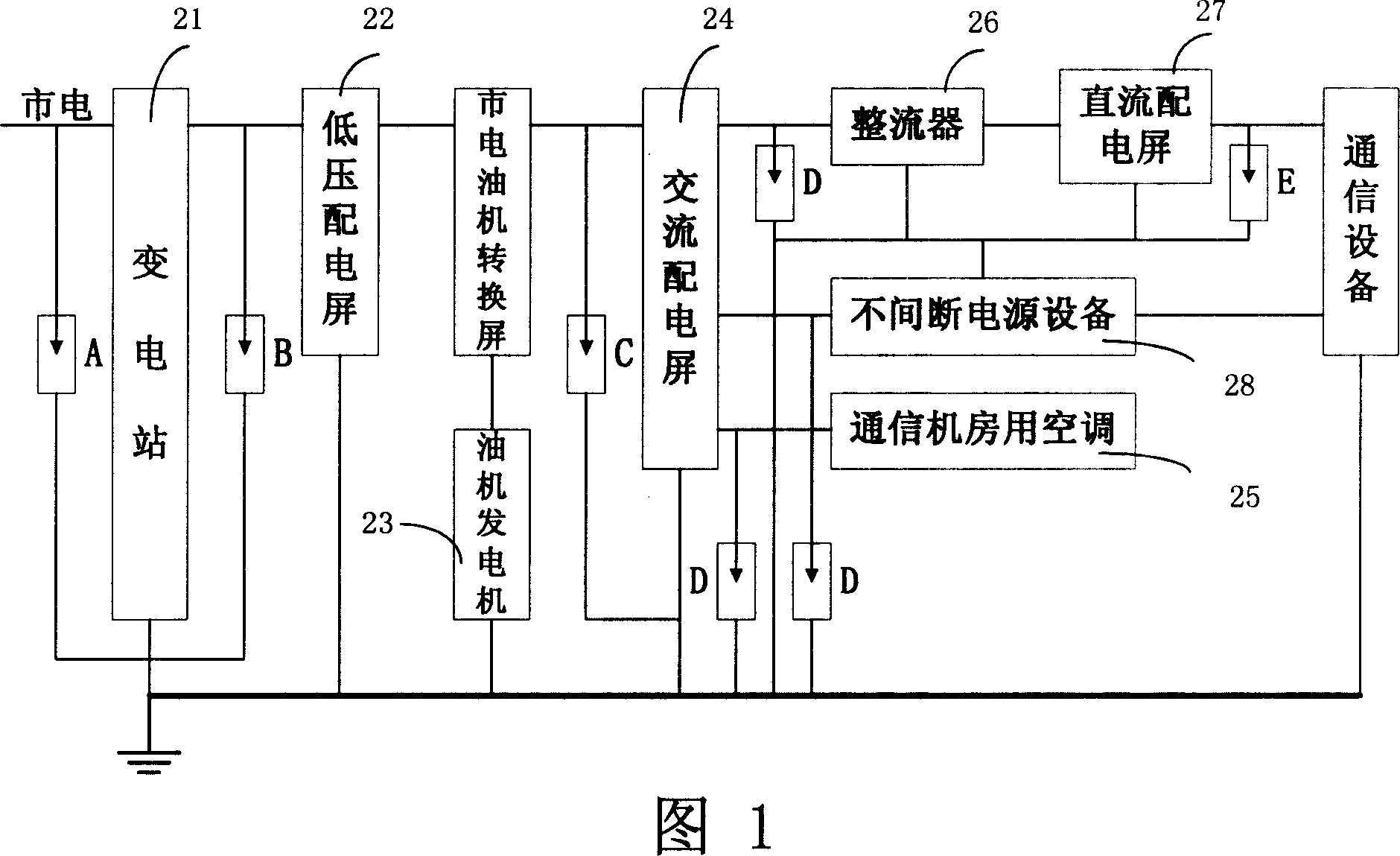

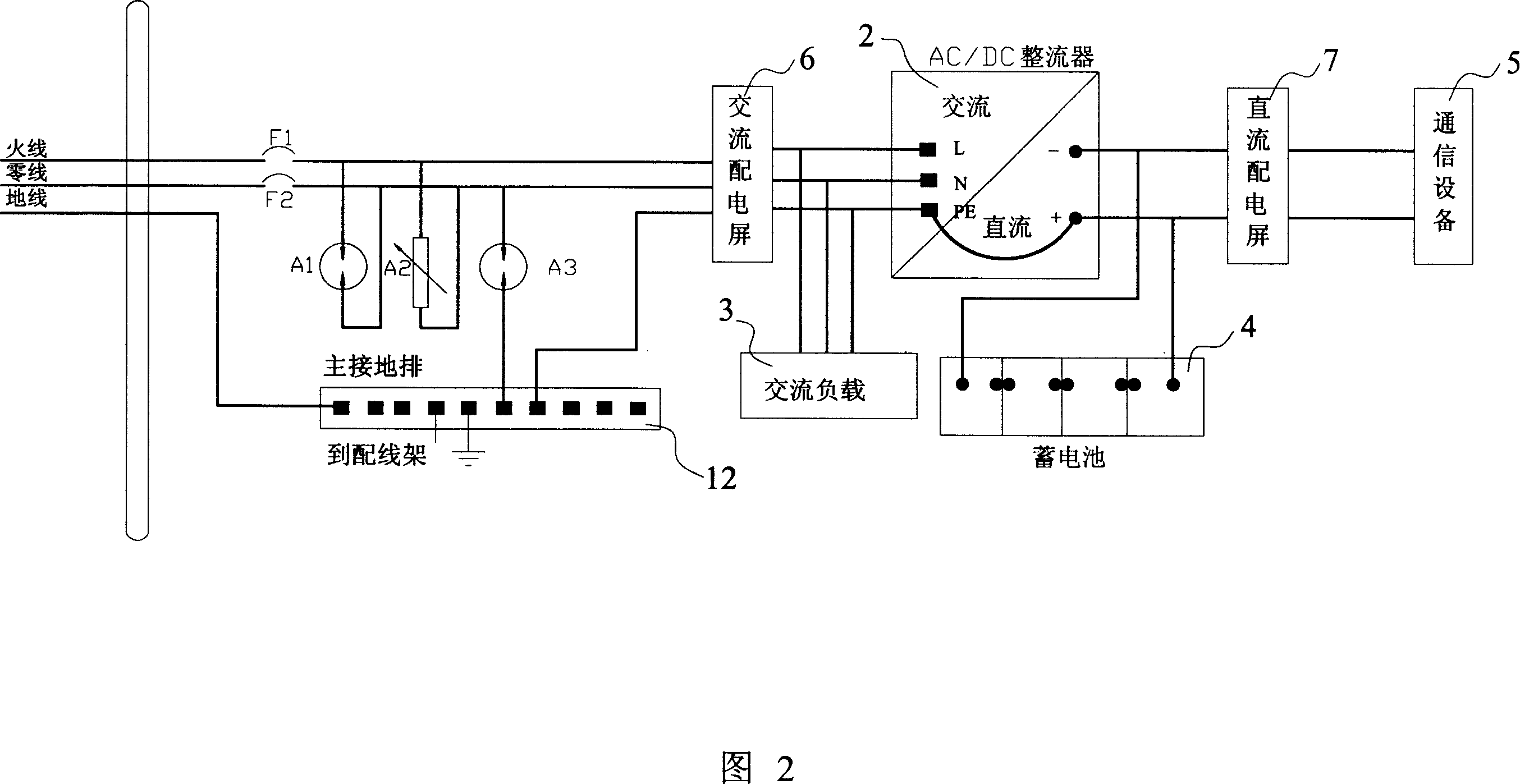

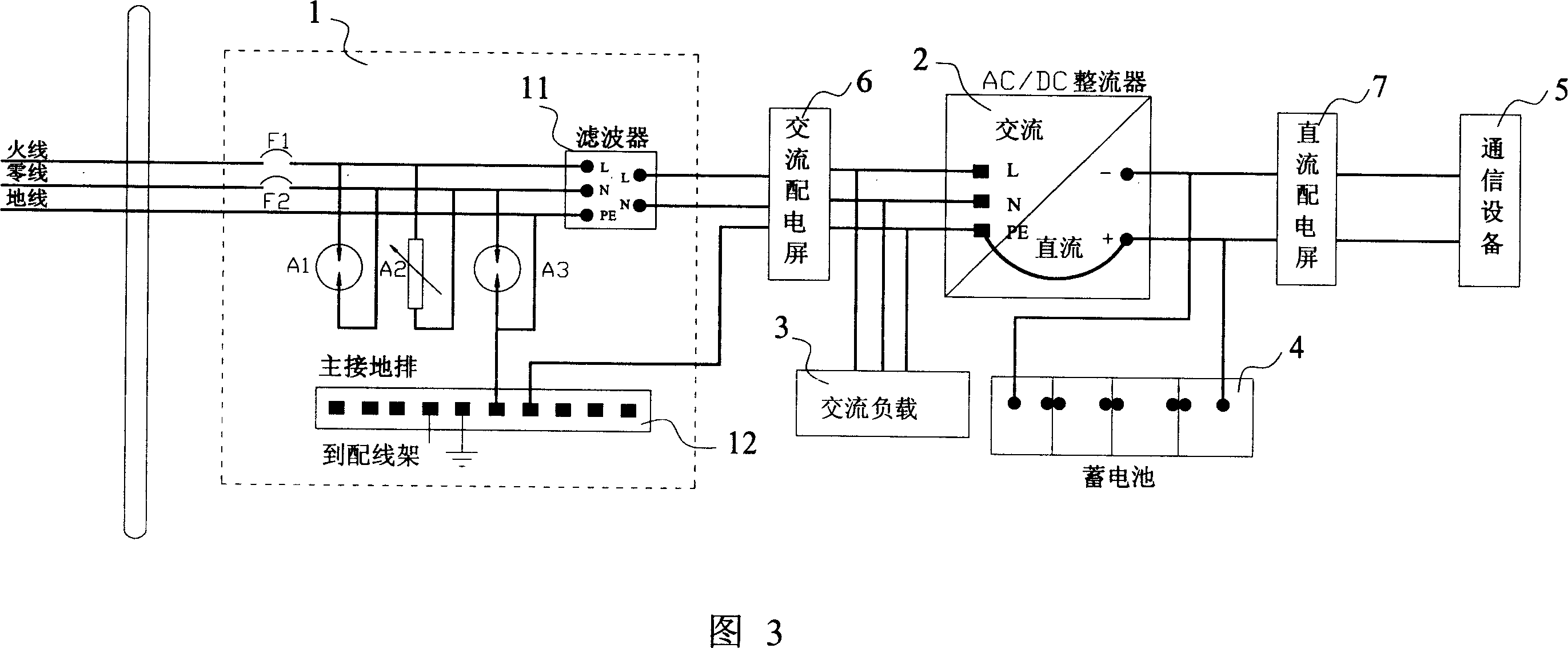

Outdoor type lightning protection communication electric power system

InactiveCN1921256AWith electromagnetic shielding functionImprove reliabilityEmergency protective arrangements for limiting excess voltage/currentElectric power systemEngineering

The invention relates to an outdoor anti-thunder communication power system, which comprises alternative-current distributing screen, AC / DC rectifier and accumulator. Wherein, the input of screen has one anti-thunder system, ground array and one filter for absorbing the alternative-current load transmission interference, to be contained by one electric box. The invention combines the anti-thunder, ground, filter and power functions together, with small volume, to improve the system reliability. The invention reduces the number of lightning arrester, to reduce cost and save space. It can realize IEC61643-1 class I+II lightning arrest in small volume, while its nominal current can reach 50KA (10 / 350us), and protective voltage Up is under 1.5KV. The invention can directly replace present power module.

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD

Heat-curable magnetic epoxy resin powder and inductor packaging method thereof

InactiveCN106010124AReduce wasteStorage time exceededTransformers/inductances casingsEncapsulation/impregnationEpoxyFerrite powder

The invention discloses a heat-curable magnetic epoxy resin powder coating and an inductor packaging method thereof. The heat-curable magnetic epoxy resin powder coating is characterized by containing the following substances in percentage by weight: 30 to 50 percent of epoxy resin, 20 to 50 percent of soft magnetic ferrite powder, 10 to 20 percent of a composite curing agent, 5 to 8 percent of a filler and 3 to 8 percent of an assistant. The method comprises the following steps: proportionally mixing the epoxy resin, the soft magnetic ferrite powder, the composite curing agent, the filler and the assistant, performing uniform stirring by virtue of stirring equipment, preparing a flaky dry material, crushing the flaky dry material, impregnating a preheated inductor in obtained powder by virtue of fluidized coating equipment, and performing baking, cooling and packaging. The heat-curable magnetic epoxy resin powder coating and the inductor packaging method thereof have the advantages that the powder has high flowability under the driving of airflow, so that packaging is facilitated without adhesion; the material cost is reduced, and the prepared coating can be easily stored for long; the production efficiency can be improved, the coating can be kept uniform, and the product is stable in inductance and small in error change; the inductance can be increased, the coating can be endowed with an electromagnetic shielding function, and flux leakage is avoided; the saturation resistance of current is improved; the heat-curable magnetic epoxy resin powder coating and the inductor packaging method thereof are applied to improvement of packaging of a vertical plug-in inductor and a packaging material.

Owner:王强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com