Flame-retardant TPE cable insulation material or sheathing material with electromagnetic shielding function and preparation method of TPE cable insulation material or sheathing material

A cable insulation and electromagnetic shielding technology, applied in the direction of organic insulators, organic liquid insulators, insulators, etc., can solve problems such as instrument and instrument interference, abnormal use, etc., to reduce usage, improve compatibility, and improve processing rheology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

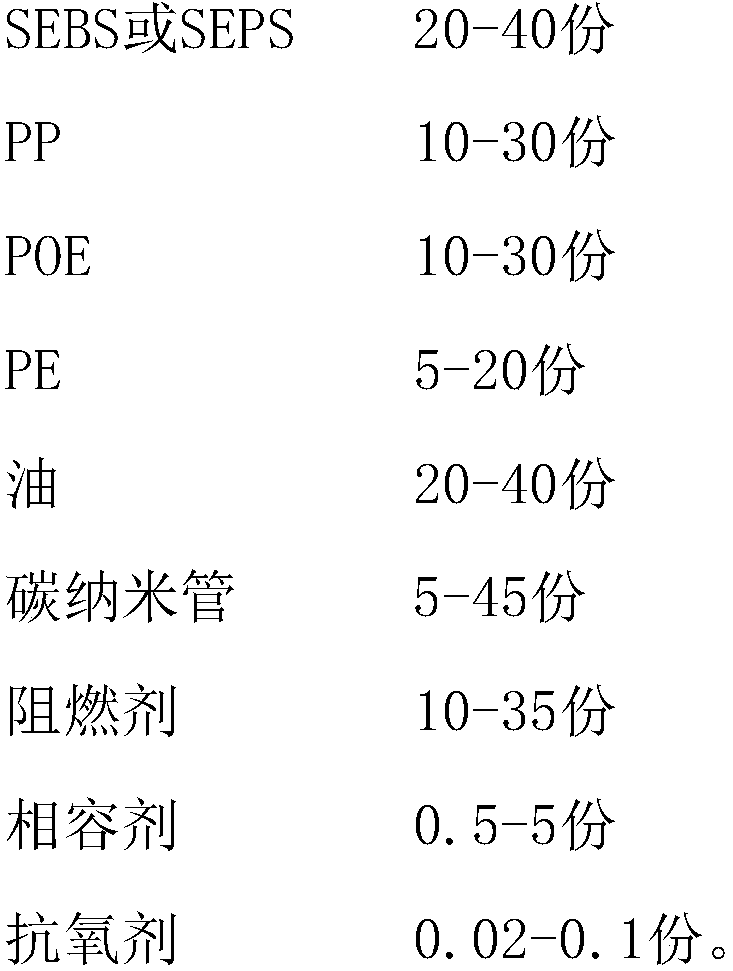

[0052] A flame-retardant TPE cable insulation material or sheath material with electromagnetic shielding function, comprising the following raw materials in parts by weight:

[0053]

[0054] The SEBS is a styrene-ethylene-butylene-styrene block copolymer with a styrene unit content of 40%, an ethylene unit content of 30%, and a butene unit content of 30%.

[0055] The PP is a homopolypropylene with a Rockwell hardness of 90 and a melt index of 5g / 10min at a temperature of 230°C; the POE is an ethylene-octene copolymer with a hardness of 70A and an octene unit content of 20%; the The PE is low-density polyethylene; the oil is white oil with a flash point of 200°C.

[0056] The carbon nanotubes are single-arm carbon nanotubes whose surfaces have been acidified.

[0057] The carbon nanotubes have a diameter of 10 nm and an aspect ratio of 100.

[0058] The flame retardant is a halogen-free flame retardant; the halogen-free flame retardant is ammonium phosphate, ammonium pol...

Embodiment 2

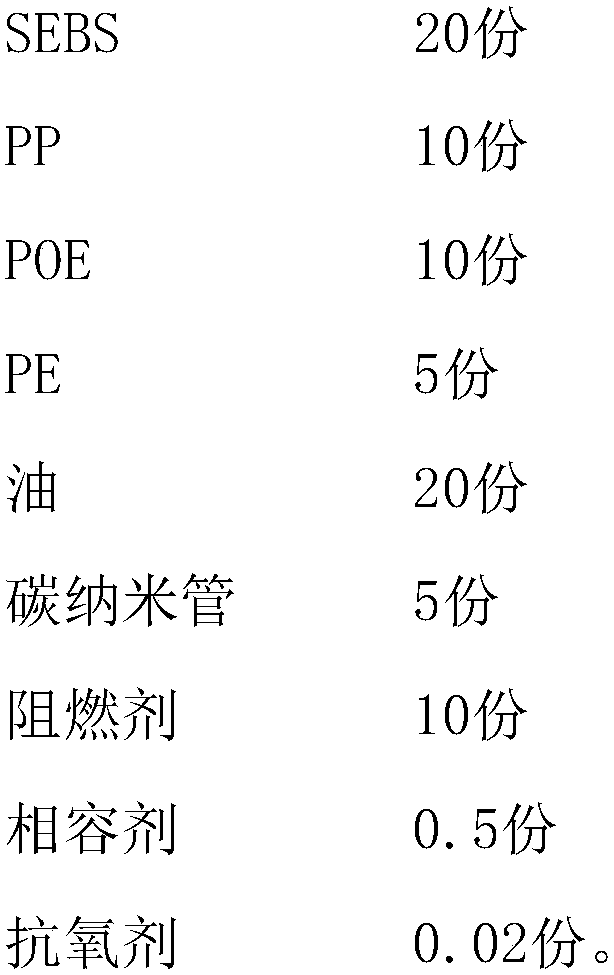

[0067] A flame-retardant TPE cable insulation material or sheath material with electromagnetic shielding function, comprising the following raw materials in parts by weight:

[0068]

[0069] The SEPS is a styrene-ethylene-propylene-styrene block copolymer with a styrene unit content of 40%, an ethylene unit content of 30%, and a propylene unit content of 30%.

[0070] The PP is a block copolymer polypropylene with a Rockwell hardness of 100 and a melt index of 8g / 10min at a temperature of 230°C; the POE is an ethylene-octene copolymer with a hardness of 75A and an octene unit content of 22%; The PE is linear low-density polyethylene; the oil is naphthenic oil with a flash point of 220°C.

[0071] The carbon nanotubes are multi-walled carbon nanotubes whose surfaces have been acidified.

[0072] The carbon nanotubes have a diameter of 20 nm and an aspect ratio of 200.

[0073] The flame retardant is a mixture of a halogen-containing flame retardant and a synergistic flame...

Embodiment 3

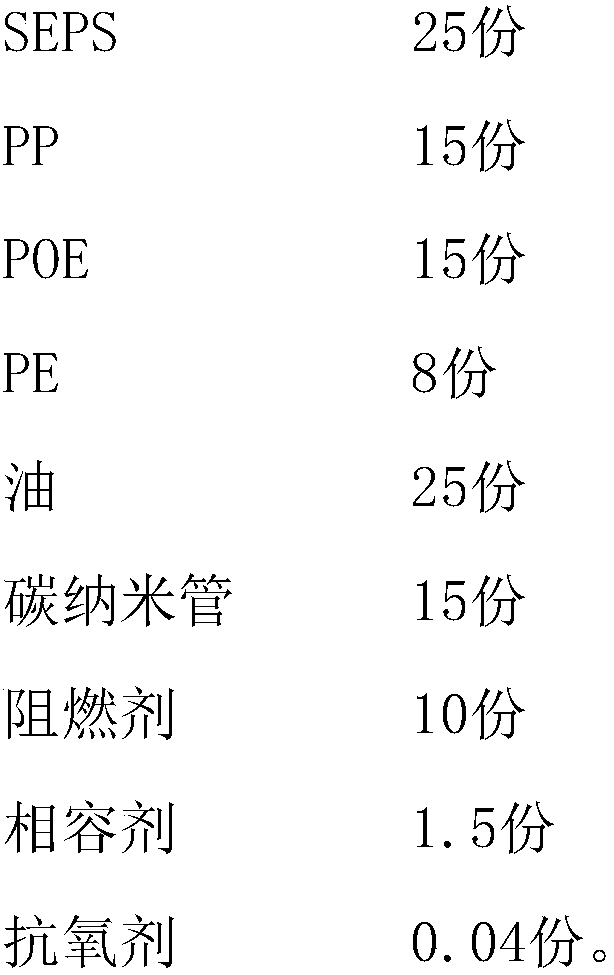

[0082] A flame-retardant TPE cable insulation material or sheath material with electromagnetic shielding function, comprising the following raw materials in parts by weight:

[0083]

[0084]

[0085] The SEBS is a styrene-ethylene-butylene-styrene block copolymer with a styrene unit content of 50%, an ethylene unit content of 25%, and a butene unit content of 25%.

[0086] The PP is a random copolymerized polypropylene with a Rockwell hardness of 105 and a melt index of 12g / 10min at a temperature of 230°C; the POE is an ethylene-octene copolymer with a hardness of 78A and an octene unit content of 25%; The PE is metallocene linear low-density polyethylene; the oil is white mineral oil with a flash point of 250°C.

[0087] The carbon nanotubes are single-arm carbon nanotubes whose surfaces have been acidified.

[0088] The carbon nanotubes have a diameter of 50 nm and an aspect ratio of 500.

[0089] The flame retardant is a halogen-free flame retardant; the halogen-fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com