Flame-retardant TPU cable sheathing material with electromagnetic shielding function and preparation method of TPU cable sheathing material

A cable sheathing material, electromagnetic shielding technology, applied in circuits, electrical components, organic insulators, etc., can solve problems such as abnormal use, instrument and instrument interference, etc., to reduce usage, low production costs, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

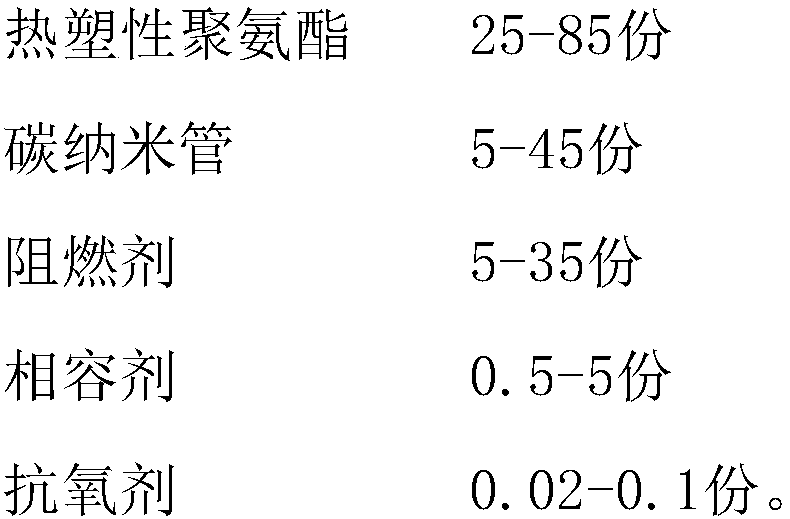

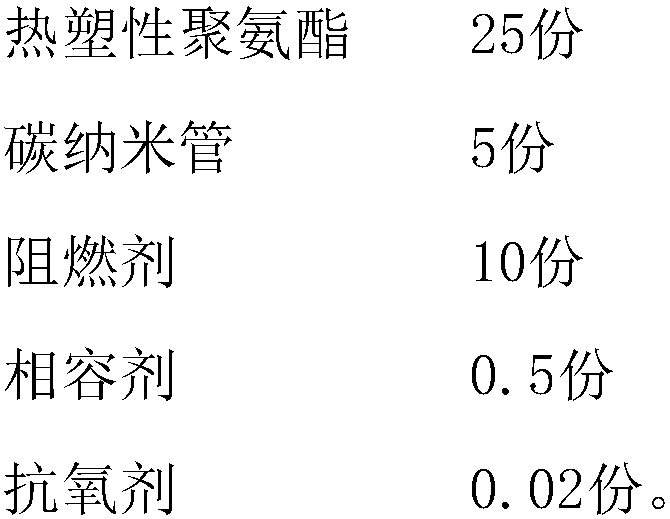

[0047] A flame-retardant TPU cable sheath material with electromagnetic shielding function, comprising the following raw materials in parts by weight:

[0048]

[0049] The thermoplastic polyurethane is polyether polyurethane.

[0050] The carbon nanotubes are single-walled carbon nanotubes whose surfaces have been acidified.

[0051] The carbon nanotubes have a diameter of 10 nm and an aspect ratio of 100.

[0052] The flame retardant is a halogen-free flame retardant; the halogen-free flame retardant is ammonium phosphate, ammonium polyphosphate, modified ammonium polyphosphate, aluminum hypophosphite or melamine and compounds thereof.

[0053] The compatibilizer is polyurethane prepolymer modified maleic anhydride grafted polyethylene.

[0054] The antioxidant is tetrakis[methylene-3,5-(di-tert-butyl-4-hydroxy-phenyl)propionate]pentaerythritol ester.

[0055] It also includes 1 part of smoke suppressant and 0.02 part of antihydrolysis agent; the smoke suppressant is m...

Embodiment 2

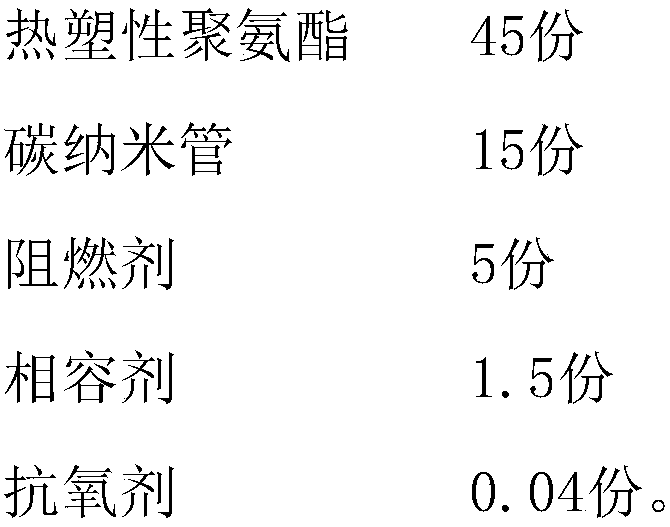

[0061] A flame-retardant TPU cable sheath material with electromagnetic shielding function, comprising the following raw materials in parts by weight:

[0062]

[0063] The thermoplastic polyurethane is polyester polyurethane.

[0064] The carbon nanotubes are multi-walled carbon nanotubes whose surfaces have been acidified.

[0065] The carbon nanotubes have a diameter of 20 nm and an aspect ratio of 200.

[0066] The flame retardant is a mixture of a halogen-containing flame retardant and a synergistic flame retardant in a weight ratio of 4:1; the halogen-containing flame retardant is 2,6-dibromophenylene ether, tetrabromobisphenol A , hexabromocyclododecane, octabromoether, decabromodiphenylethane or polypentabromophenol-based acrylate; the synergistic flame retardant is antimony trioxide, bismuth trioxide, molybdenum trioxide or three ferric oxide.

[0067] The compatibilizer is divinyltetramethyldisiloxane, vinyltriethoxysiloxane, vinyltrichlorosilane or vinyltris(β...

Embodiment 3

[0075] A flame-retardant TPU cable sheath material with electromagnetic shielding function, comprising the following raw materials in parts by weight:

[0076]

[0077] The thermoplastic polyurethane is polycarbonate polyurethane.

[0078] The carbon nanotubes are single-walled carbon nanotubes whose surfaces have been acidified.

[0079] The carbon nanotubes have a diameter of 50 nm and an aspect ratio of 500.

[0080] The flame retardant is a halogen-free flame retardant; the halogen-free flame retardant is zinc borate, montmorillonite, clay or metal hydroxide.

[0081] The compatibilizer is γ-glycidyl etheroxypropyl trimethoxysilane, γ-methacryloxypropyl-trimethoxysilane or N-(β-aminoethyl)-γ-aminopropyl -Methyl-trimethoxysilane.

[0082] The antioxidant is tris[2,4-di-tert-butylphenyl]phosphite.

[0083] It also includes 5 parts of smoke suppressant and 0.06 part of anti-hydrolysis agent; said smoke suppressant is metal oxide; said anti-hydrolysis agent is polycarbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com