Antibacterial antiviral non-woven fabric with electromagnetic shielding function and production method and device

A non-woven fabric, electromagnetic shielding technology, used in textiles, papermaking, fiber processing, etc., can solve the problems of products that cannot meet the requirements of use, intensified competition, and reduced product added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

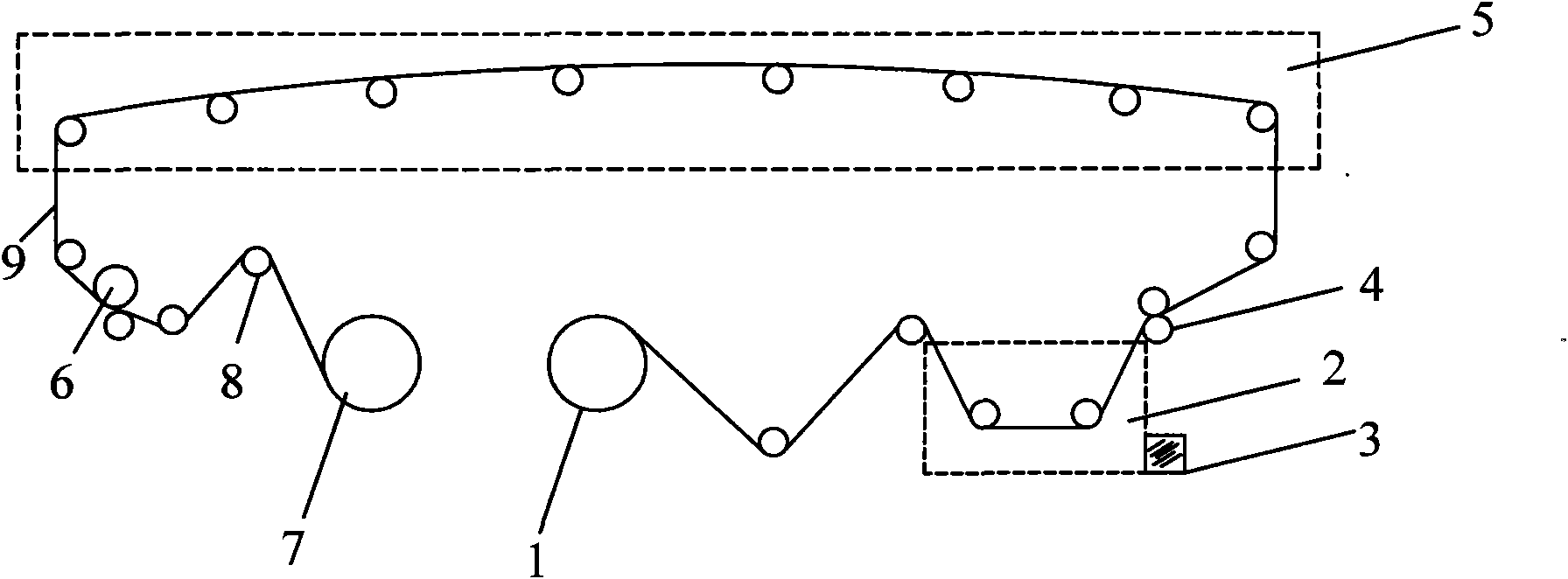

Method used

Image

Examples

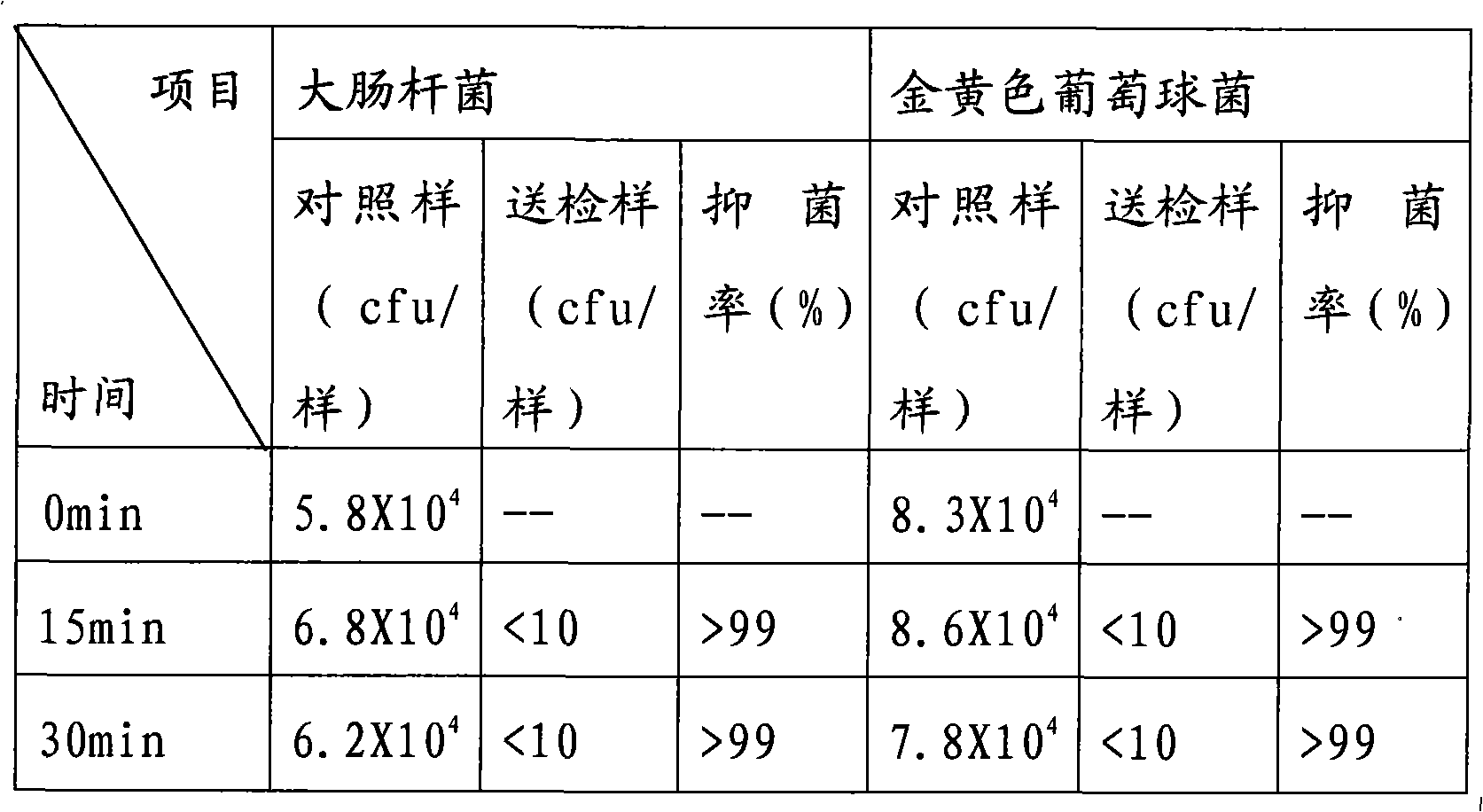

Embodiment 1

[0021] In this example, the spun-bonded nonwoven fabric is prepared by putting it into an antibacterial and antiviral solution, which comprises 35% by weight of a composite of silica-coated tourmaline and titanium dioxide particles. Antibacterial material, 45% coated composite carbon-based electromagnetic shielding material and 20% foam additive, said coated composite carbon-based electromagnetic shielded material is mixed with iron pentacarbonyl and graphite powder in a ratio of 90:10 It is obtained by stirring and suspending with an electromagnetic levitation stirrer, reacting at 35°C under an inert gas atmosphere, and then heat-treating at 100°C under an inert gas atmosphere; the raw materials included in the foam aid And the corresponding weight components are: 1 part of hydroxyethyl cellulose, 0.1 part of fatty alcohol polyoxyethylene ether, 2 parts of sodium lauryl sulfate, 0.4 part of γ-aminopropyl triethoxysilane, hexadecane 3 parts of trimethylammonium chloride, 12 pa...

Embodiment 2

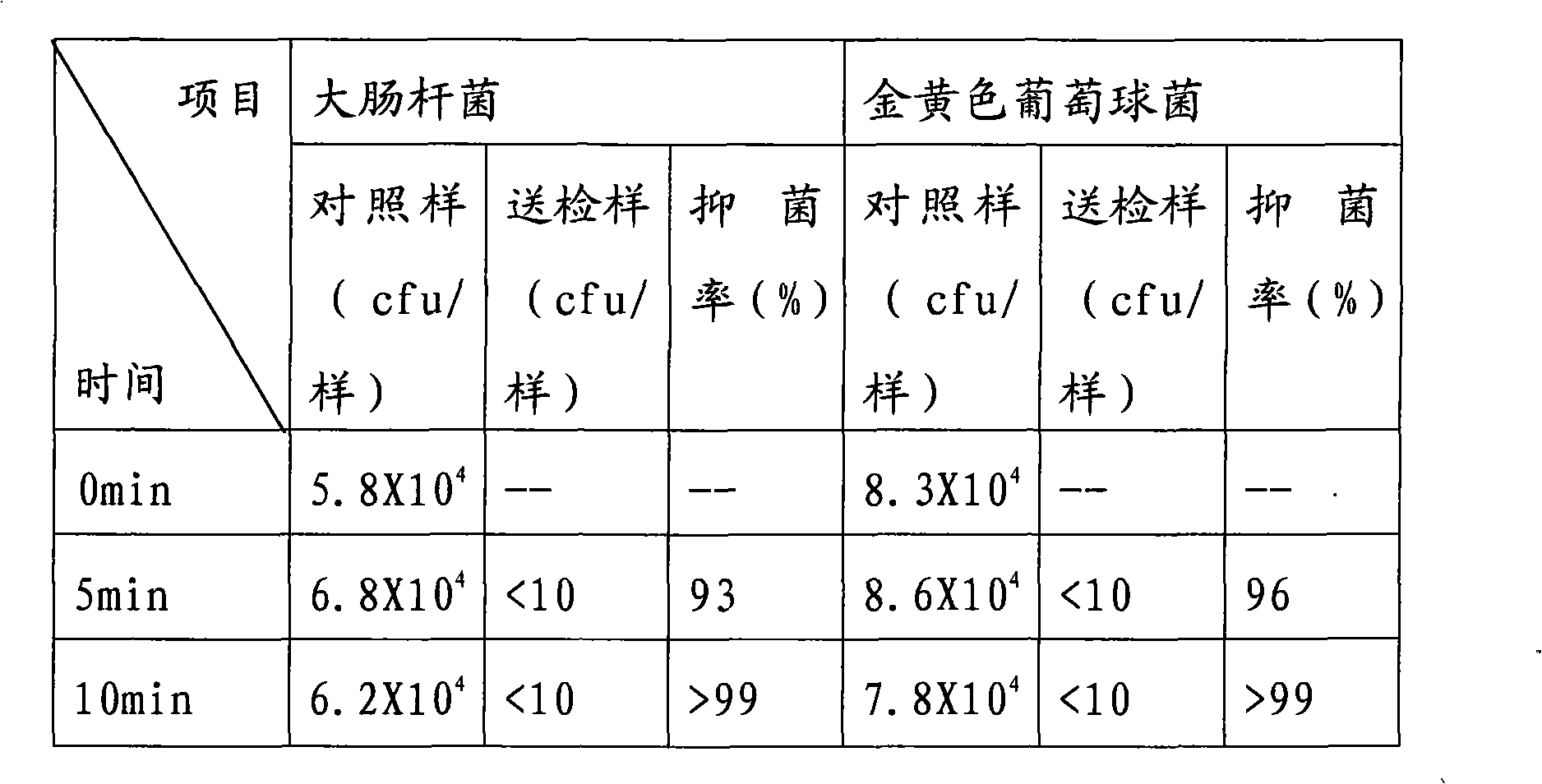

[0025] In this example, the melt-blown nonwoven fabric is made by putting it into an antibacterial and antiviral solution, and the antibacterial and antiviral solution includes 45% by weight percentage of a composite of silica-coated tourmaline and titanium dioxide particles. Antibacterial material, 30% coated composite carbon-based electromagnetic shielding material and 25% foam additives, the coated composite carbon-based electromagnetic shielded material is mixed by nickel tetracarbonyl and carbon fiber in a ratio of 50:50 and It is obtained by stirring and suspending with an electromagnetic levitation stirrer, reacting at 103°C under an inert gas atmosphere, and then heat-treating at 450°C under an inert gas atmosphere; the raw materials included in the foam aid and The corresponding weight components are: 2 parts of hydroxyethyl cellulose, 0.3 parts of fatty alcohol polyoxyethylene ether, 3 parts of sodium lauryl sulfate, 0.6 parts of γ-aminopropyl triethoxysilane, cetyl ...

Embodiment 3

[0029] In this embodiment, the viscous melt-blown composite non-woven fabric is put into an antibacterial and antiviral solution, and the antibacterial and antiviral solution includes 30% of silica-coated tourmaline and titanium dioxide particles by weight percentage Composite antibacterial material, 35% coated composite carbon-based electromagnetic shielding material and 35% foam additive, said coated composite carbon-based electromagnetic shielded material is made by iron pentacarbonyl and carbon nanotube with 70:30 Proportionally mixed and stirred and suspended using an electromagnetic suspension stirrer, reacted at 85°C under an inert gas atmosphere, and then heat-treated at 250°C under an inert gas atmosphere; the foam aid includes The raw materials and corresponding weight components are: 1.5 parts of hydroxyethyl cellulose, 0.2 parts of fatty alcohol polyoxyethylene ether, 2.5 parts of sodium lauryl sulfate, 0.5 parts of γ-aminopropyl triethoxysilane, ten 5 parts of hex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com