Method for manufacturing fabric with antibacterial and electromagnetic shielding functions

An electromagnetic shielding, fabric technology, applied in the direction of textiles and paper, textiles, fabrics, etc., to prevent accumulation, prevent and kill bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

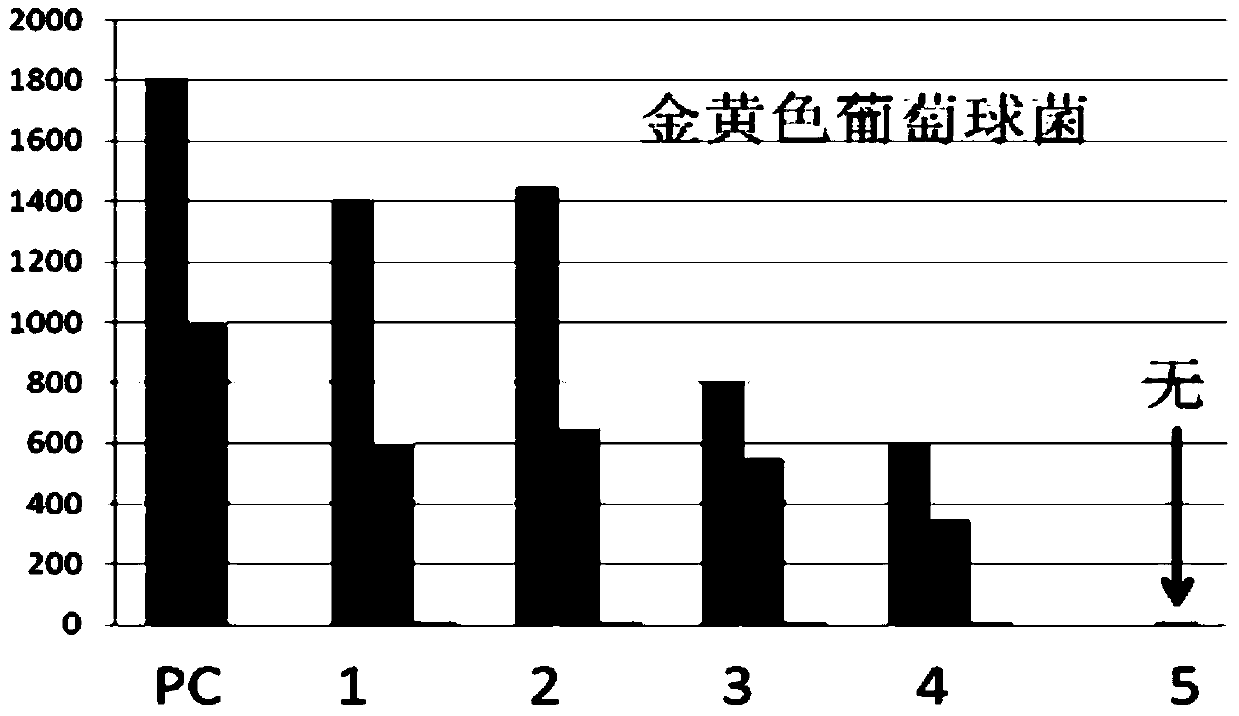

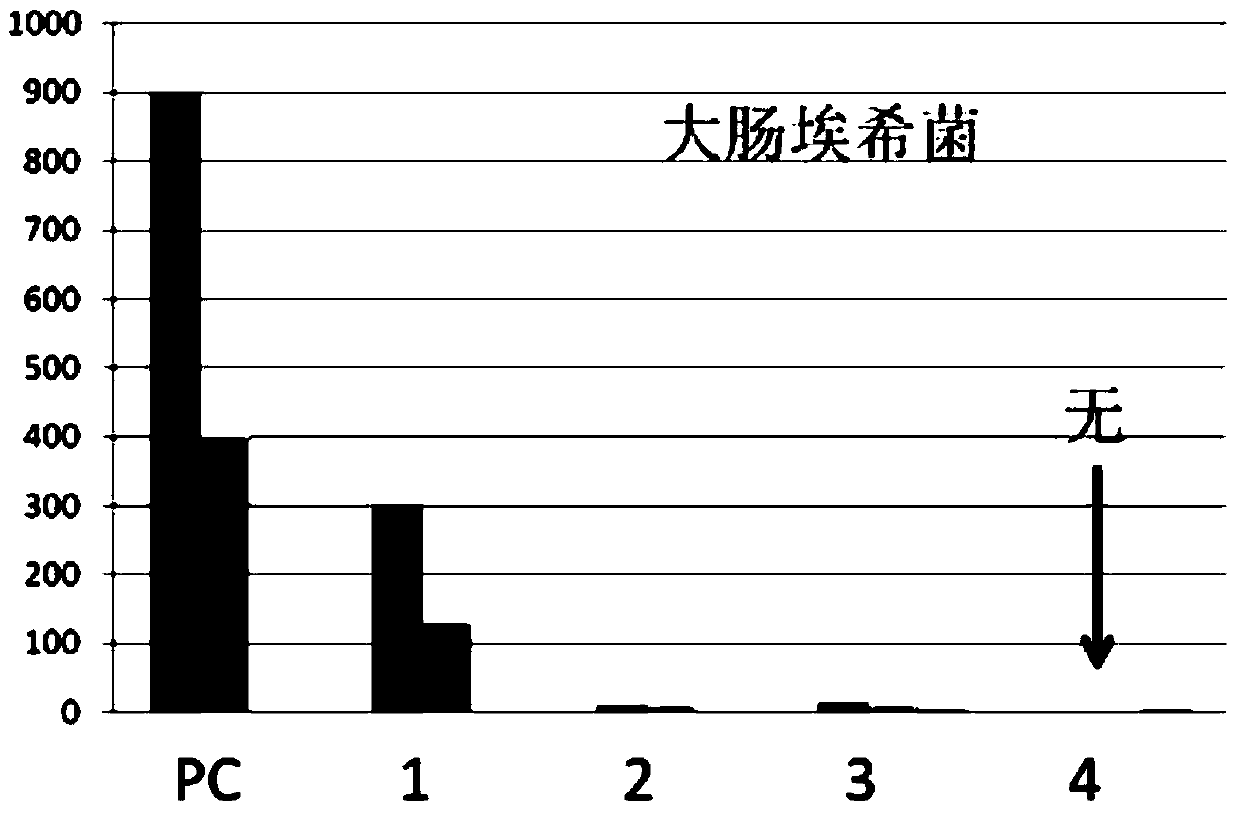

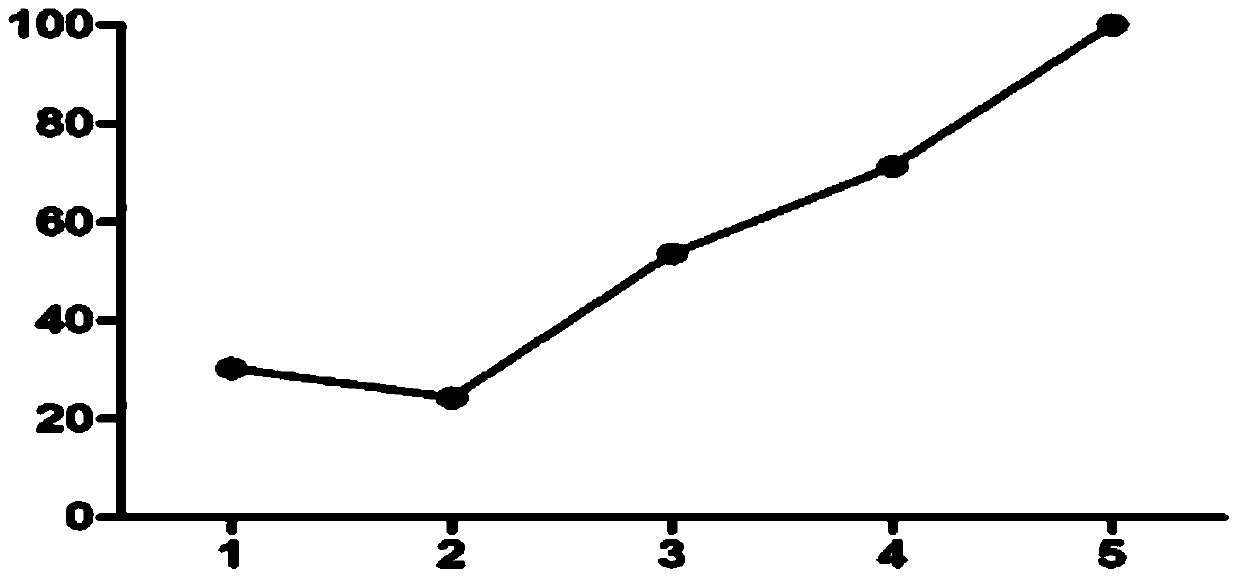

Embodiment 1

[0021] Embodiment one: a kind of preparation method of fabric with antibacterial and electromagnetic shielding function, comprises the following steps:

[0022] (1) Preparation of hollow silver-plated fiber:

[0023] a. Seal both ends of the polyester hollow fiber in disconnected containers, and place one end of the polyester hollow fiber in AgNO 3 solution, the other end of the polyester hollow fiber was placed in an empty container; the AgNO 3 The mass percentage concentration of solution is 1.5%;

[0024] b. Xiang Shengyou AgNO 3 Compressed air is passed through the container of the solution, and the empty container at the other end of the polyester hollow fiber is evacuated, and a pressure difference of 24 atm is generated at both ends of the polyester hollow fiber, so that the AgNO 3 The solution is poured into the inner cavity of the polyester hollow fiber from one end of the hollow fiber;

[0025] c. Keep the pressure difference between the two ends of the polyester...

Embodiment 2

[0028] Embodiment two: a kind of preparation method of fabric with antibacterial and electromagnetic shielding function, comprises the following steps:

[0029] (1) Preparation of hollow silver-plated fiber:

[0030] a. Seal both ends of the polyester hollow fiber in disconnected containers, and place one end of the polyester hollow fiber in AgNO 3 solution, the other end of the polyester hollow fiber was placed in an empty container; the AgNO 3 The mass percentage concentration of solution is 3%;

[0031] b. Xiang Shengyou AgNO 3 Compressed air is passed through the container of the solution, and the empty container at the other end of the polyester hollow fiber is evacuated, and a pressure difference of 28atm is generated at the two ends of the polyester hollow fiber, so that the AgNO 3 The solution is poured into the inner cavity of the polyester hollow fiber from one end of the hollow fiber;

[0032] c. Keep the pressure difference between the two ends of the polyester...

Embodiment 3

[0035] Embodiment three: a kind of preparation method of fabric with antibacterial and electromagnetic shielding function, comprises the following steps:

[0036] (1) Preparation of hollow silver-plated fiber:

[0037] a. Seal both ends of the polyester hollow fiber in disconnected containers, and place one end of the polyester hollow fiber in AgNO 3 solution, the other end of the polyester hollow fiber was placed in an empty container; the AgNO 3 The mass percentage concentration of solution is 2%;

[0038] b. Xiang Shengyou AgNO 3 Compressed air is passed through the container of the solution, and the empty container at the other end of the polyester hollow fiber is evacuated, and a pressure difference of 26 atm is generated at the two ends of the polyester hollow fiber, so that the AgNO 3 The solution is poured into the inner cavity of the polyester hollow fiber from one end of the hollow fiber;

[0039] c. Keep the pressure difference between the two ends of the polyes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com