An injection molding device for educational toy processing

A technology of toys and injection molding machines, which is applied in the field of injection molding machines, can solve problems such as shortening the injection molding production cycle of a single product, difficulty in quick installation and disassembly, and errors in plastic viscosity, so as to facilitate timely maintenance and cleaning, reduce waste, and guarantee The effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

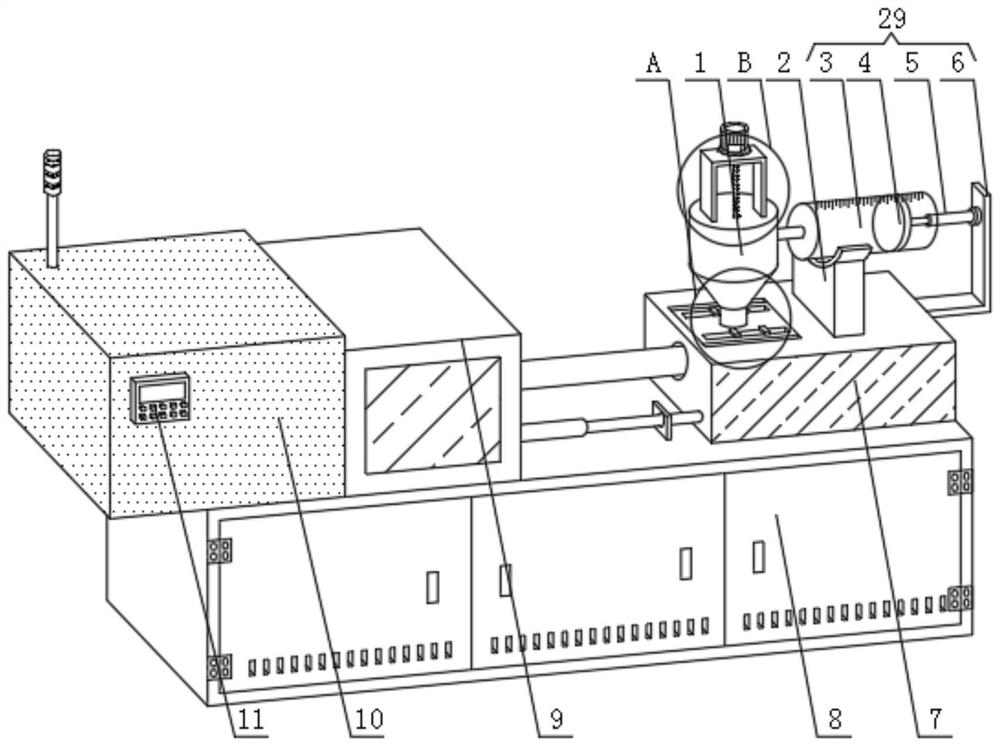

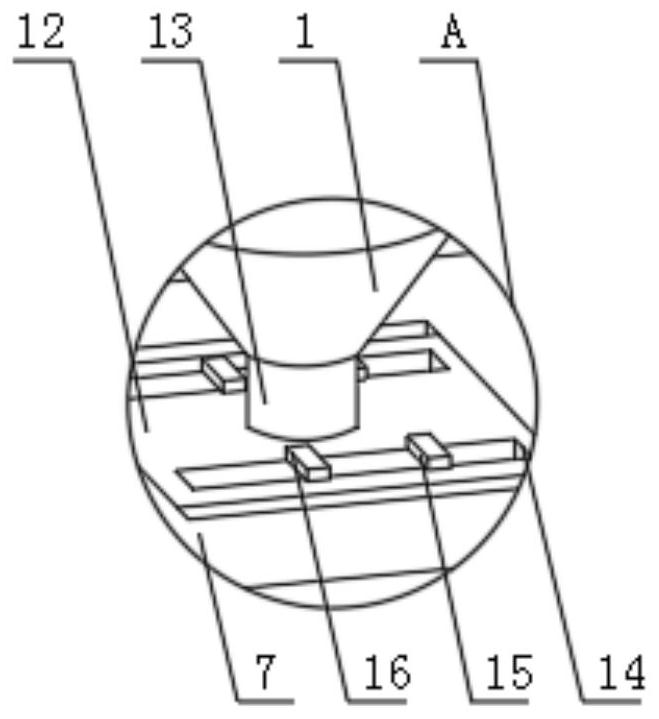

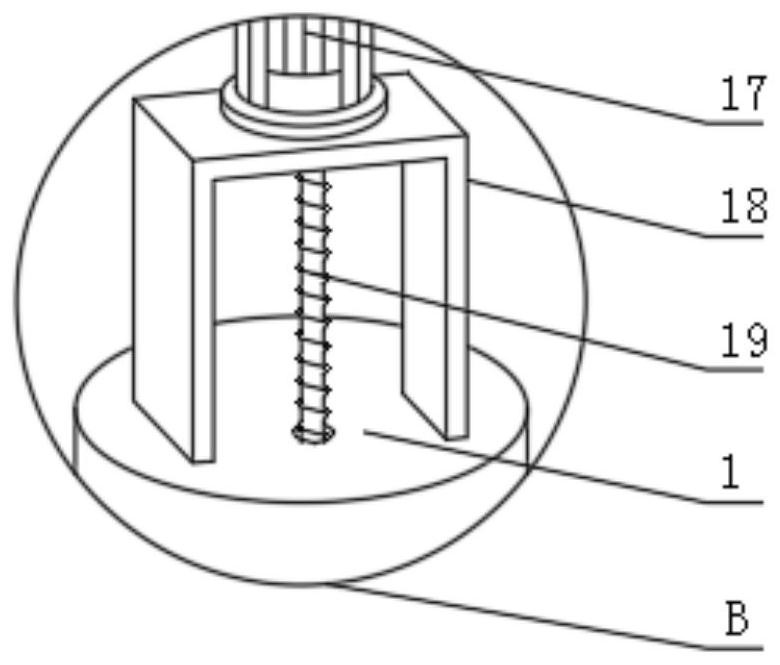

[0023] see Figure 1-5, in an embodiment of the present invention, an injection molding device for educational toy processing includes an injection molding machine body 8 and a collecting bucket 1, a mold box 9 is fixedly installed on the top of the injection molding machine body 8, and the top of the injection molding machine body 8 is close to the mold A working box 7 is fixedly installed at one side of the box 9, a mold clamping box 10 is fixedly installed on the side wall of the mold box 9, a control switch 11 is fixedly installed on the front surface of the mold clamping box 10, and a DKC- Y110 controller, the top of the working box 7 is fixedly installed with a fixed seat 2, and the top of the working box 7 is embedded with a cover plate 12 near the side of the fixed seat 2, and the top of the cover plate 12 is provided with a chute 14, and The bottom of the cover plate 12 is fixedly equipped with a support rod 24 near the rear side of the chute 14, the top of the cover ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com