Machining mold device

A technology for processing molds and molds, which is applied in the field of molds, can solve the problems of insufficient processing accuracy, short service life, and high production costs, and achieve the effects of high injection molding accuracy, reduced production costs, and safe and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

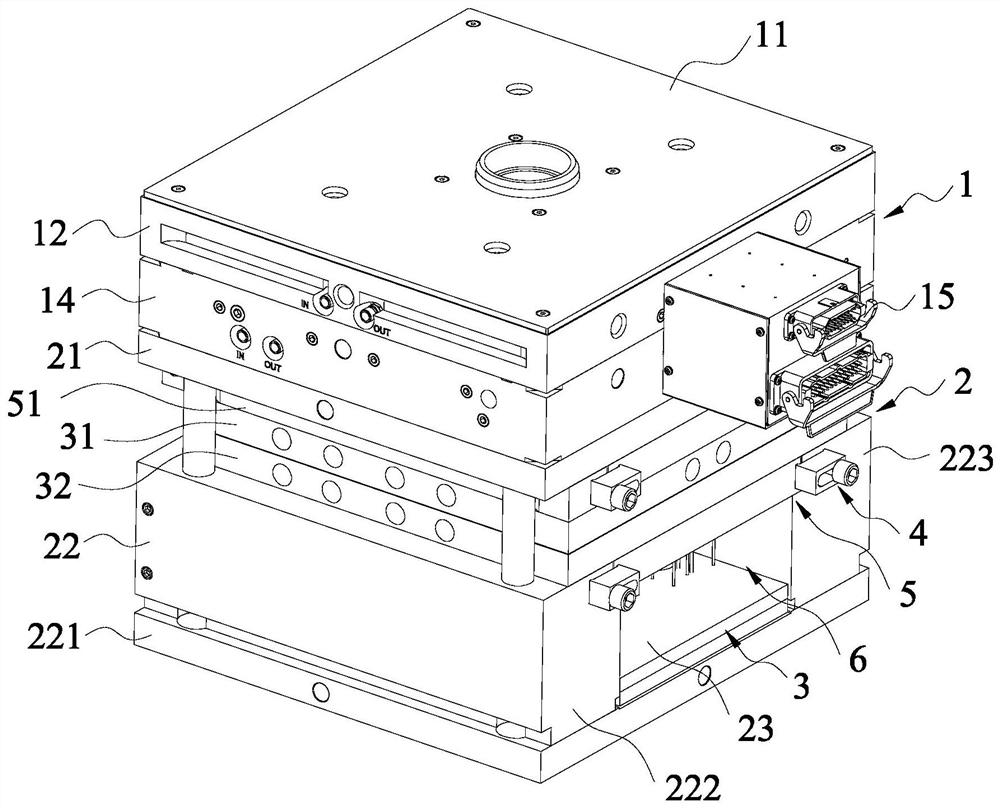

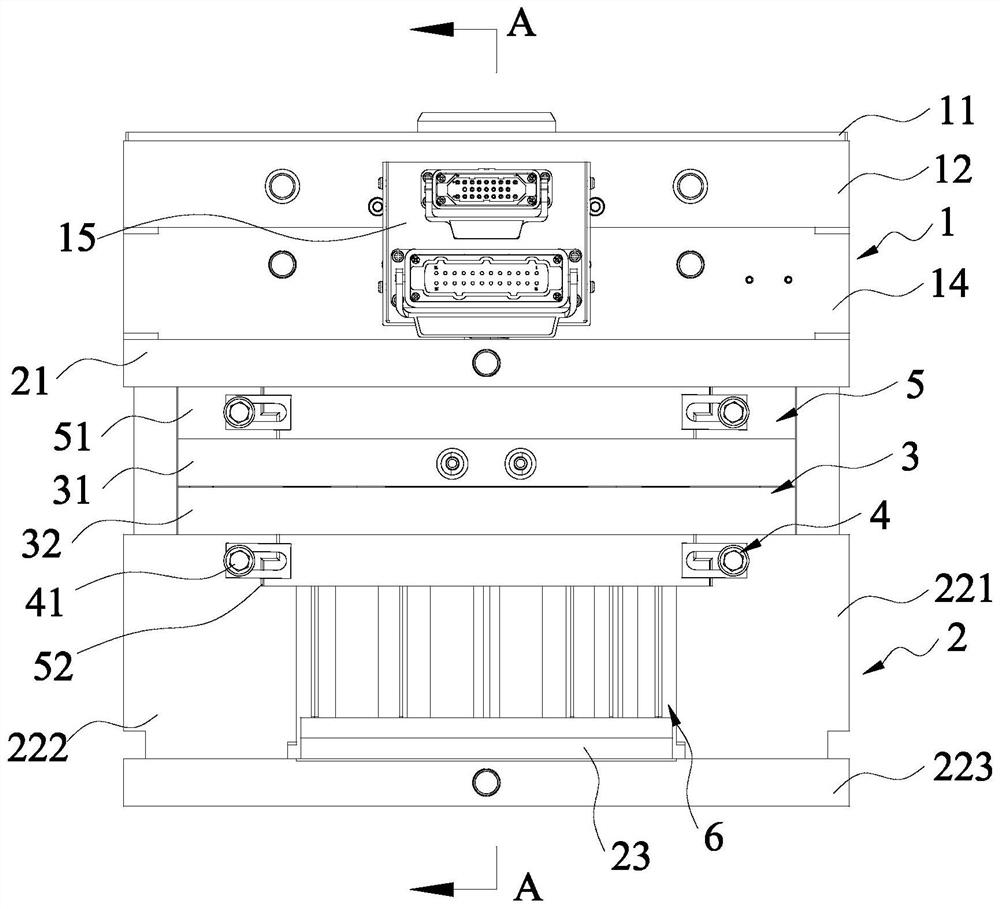

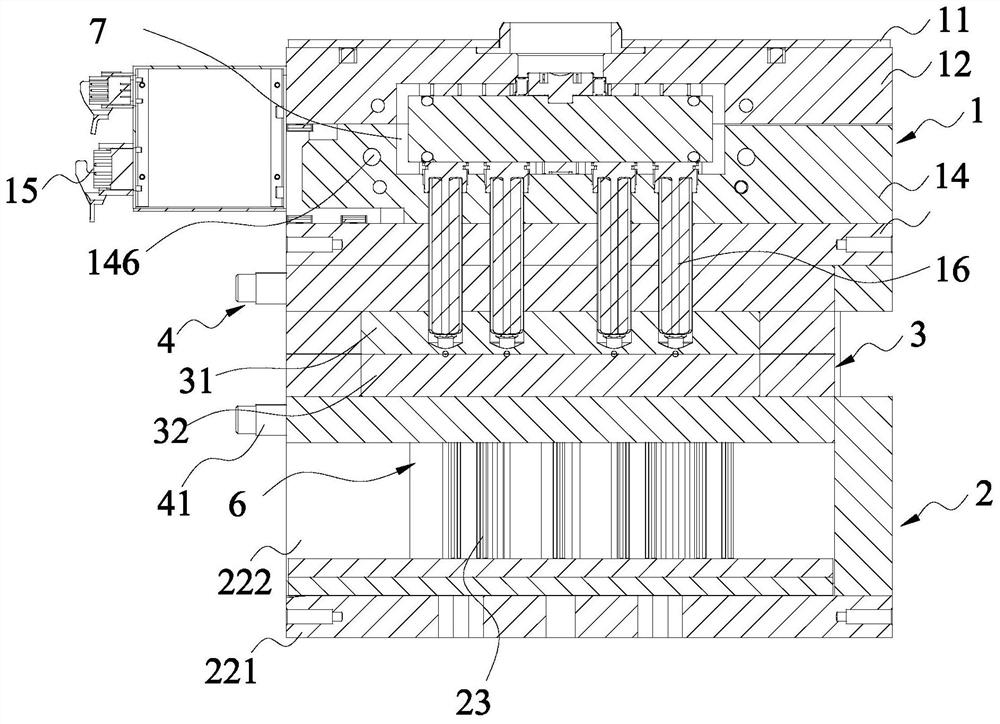

Embodiment 1

[0025] see Figure 1-6 As shown, the present invention relates to a processing mold device, including a hot runner assembly 1 and a mold assembly 2, the hot runner assembly 1 and the mold assembly 2 are arranged up and down and form a heat flow for molten liquid to inject into the mold assembly 2 Runner 7, the mold assembly 2 is provided with a first mold frame body 21, an injection mold body 3, a locking mechanism 4, a slideway mechanism 5, a needle plate group 23 and a second mold frame body 22, the first mold frame body 21 and the second mold frame body 22 are arranged up and down to form an installation section 6 for loading the injection molding body 3, the slideway mechanism 5 is installed in the installation section 6, and the injection molding body 3 and the The slideway mechanism 5 is suitable for installation, and the injection mold body 3 slides into the installation section 6 through the slideway mechanism 5 and is locked in the installation section 6 by the lockin...

Embodiment 2

[0035] see Figure 1-6 As shown, the present invention relates to a processing mold device, including a hot runner assembly 1 and a mold assembly 2, the hot runner assembly 1 and the mold assembly 2 are arranged up and down and form a heat flow for molten liquid to inject into the mold assembly 2 Runner 7, the mold assembly 2 is provided with a first mold frame body 21, an injection mold body 3, a locking mechanism 4, a slideway mechanism 5, a needle plate group 23 and a second mold frame body 22, the first mold frame body 21 and the second mold frame body 22 are arranged up and down to form an installation section 6 for loading the injection molding body 3, the slideway mechanism 5 is installed in the installation section 6, and the injection molding body 3 and the The slideway mechanism 5 is suitable for installation, and the injection mold body 3 slides into the installation section 6 through the slideway mechanism 5 and is locked in the installation section 6 by the lockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com