High-speed low-inertia structure applied to injection molding machine and injection molding machine with high-speed low-inertia structure

An injection molding machine, low inertia technology, applied in the field of high-speed and low-inertia structure and injection molding machine with this structure, can solve the problems of reducing machine use accuracy, large moving inertia, increasing machine power consumption, etc., to prevent excessive wear and reduce Small moving inertia, the effect of preventing the backflow of molten plastic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

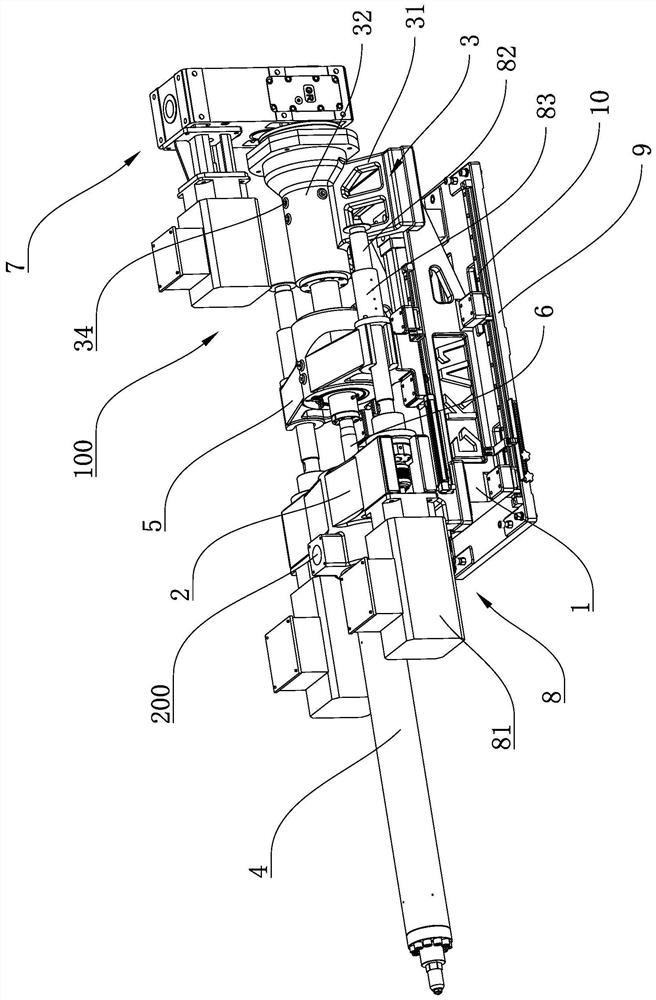

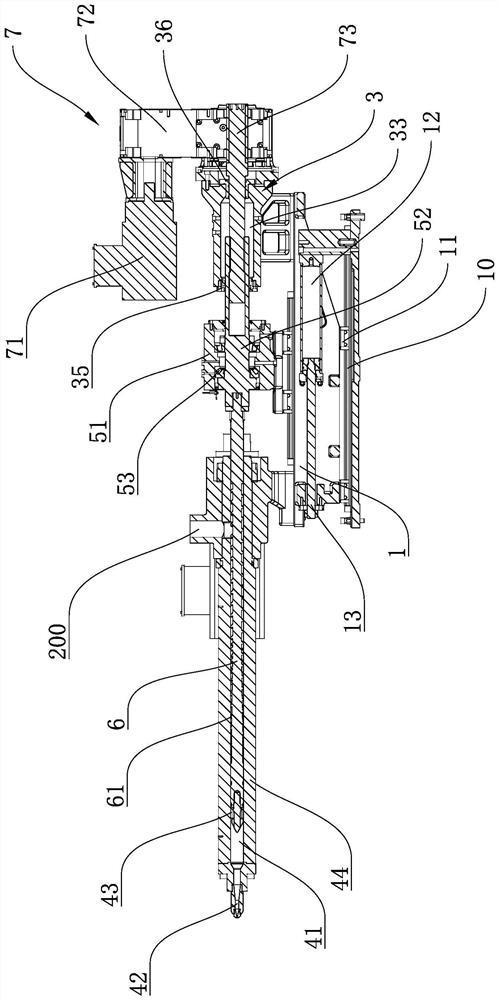

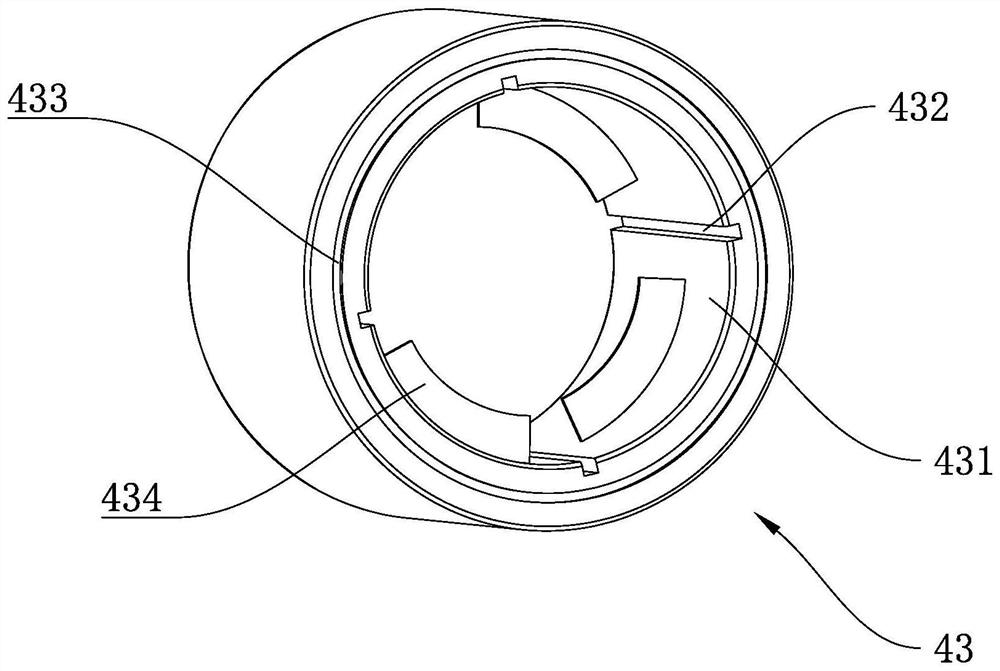

[0030] This embodiment provides a high-speed low-inertia structure applied to injection molding machines, combined with figure 1 with figure 2 As shown, it includes a base 1, including a base 1, a front plate 2 and a rear plate 3 are fixedly arranged on the base 1, and an injection plastic cylinder 4 is connected to the front plate 2, and the front plate 2 and the rear plate 3 are provided with There is a moving assembly 5 that can slide relative to the base 1, and a drive mechanism 100 for driving the moving assembly 5 to move close to the front plate 2 or the rear plate 3 is arranged on the front plate 2, the rear plate 3 and / or the base 1, that is, the drive The mechanism 100 can be arranged in at least one of the three positions of the front plate 2, the rear plate 3 and the base 1, and of course it can also be arranged in multiple places. The storage drive mechanism 7 of the plate 3 and the injection drive mechanism 8 that can drive the mobile assembly 5 close to the fr...

Embodiment 2

[0046] This embodiment provides an injection molding machine, combined with Figure 1-3 As shown, it includes an injection molding machine casing, and the injection molding machine casing is provided with the high-speed and low-inertia structure applied to the injection molding machine described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com