Insertion opening crack resisting structure for prestressed concrete cylinder pipes and manufacturing method of structure

A technology for concrete pipes and prestressed steels, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of reducing the service life of pipes, corrosion of steel cylinders and steel wires, pipe bursting, etc., and reduce valgus deformation. , The effect of improving bending resistance and improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

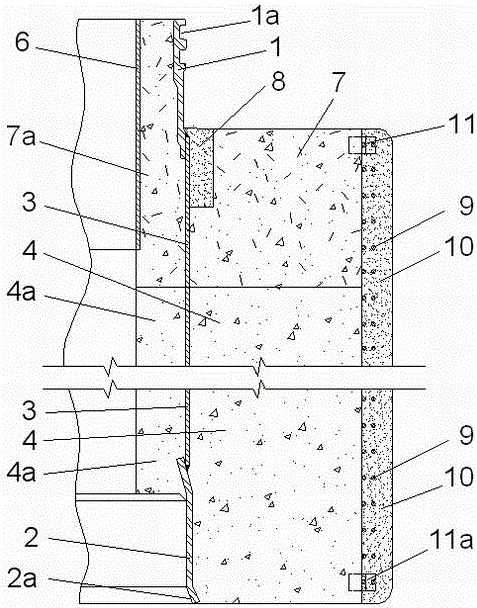

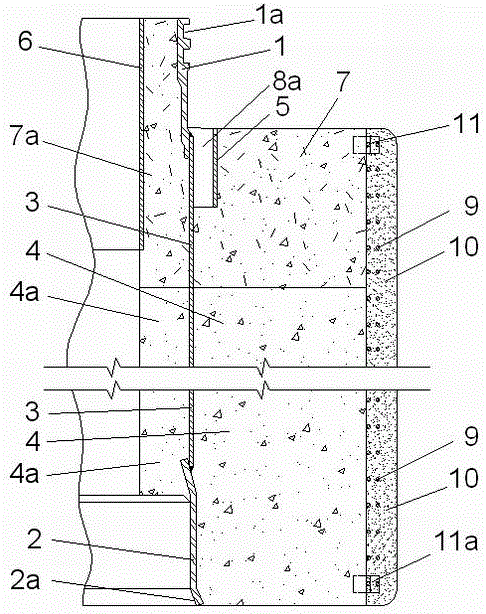

[0024] figure 1 It shows a crack-resistant structural diagram of a socket of a prestressed steel cylinder concrete pipe. In the figure, the anti-cracking structure of the socket of the prestressed steel cylinder concrete pipe includes a tubular steel structure in which the socket special-shaped steel ring 1, the steel cylinder 3, and the socket special-shaped steel ring 2 are sequentially welded together and poured on the outer surface of the tubular steel structure. The outer pipe core concrete 4 and the inner pipe core concrete 4a poured on the inner surface of the tubular steel structure. The pouring height of the outer pipe core concrete 4 and the inner pipe core concrete 4a is 568 mm from the top of the special-shaped steel ring 1 of the socket, and the outer steel fiber concrete 7 poured on the outer pipe core concrete 4 is higher than the middle steel cylinder 3 of the tubular steel structure The top welding seam is 15mm, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com