Blunt trailing edge type wind turbine blade as well as implementing device and method thereof

A wind turbine and blunt trailing edge technology is applied in the field of lamination design and process realization of wind turbine blades, can solve the problems of low constitutive strength bonding interface strength, increased trailing edge strength, etc., and achieves compact trailing edge structure, The effect of small additional bending moment and improved bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make the objectives, technical methods and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

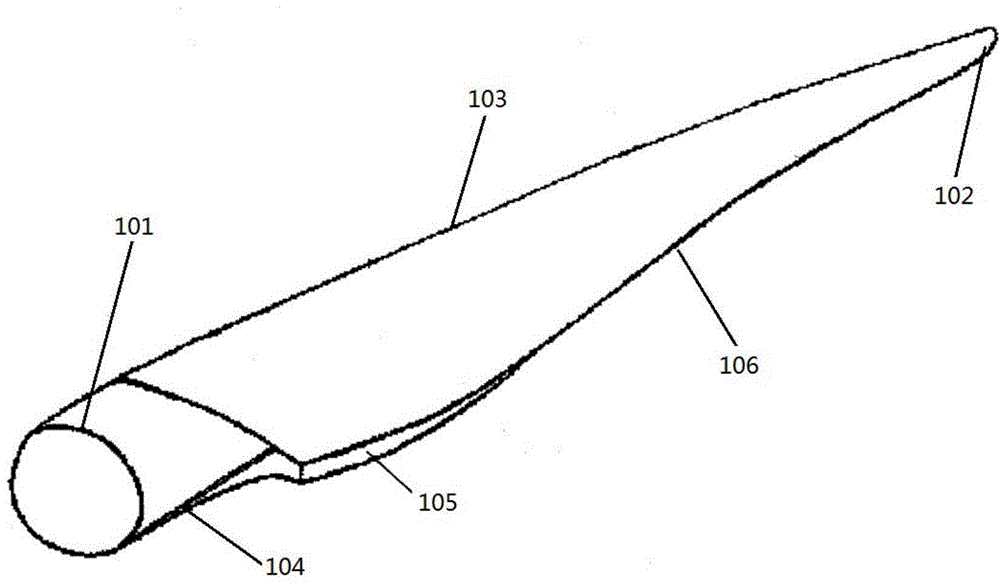

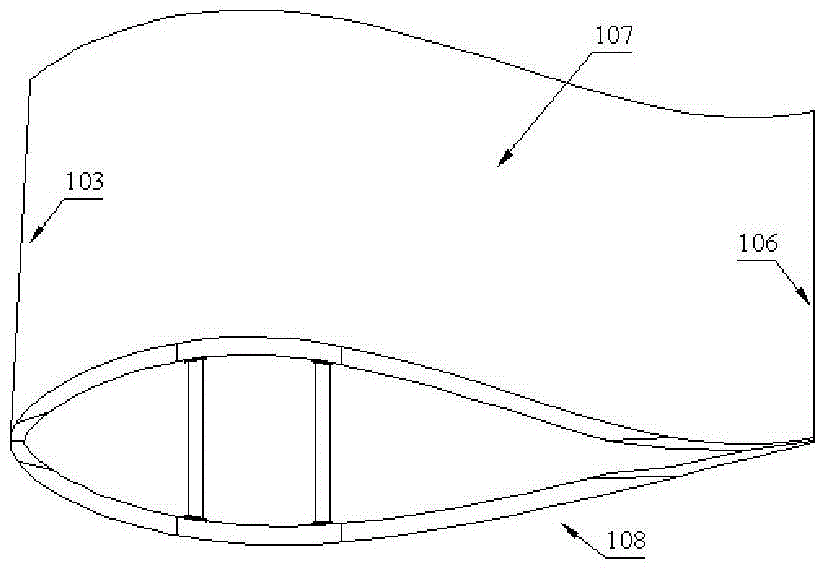

[0058] like figure 1 , 2 As shown, the fiber-reinforced composite material wind turbine blunt trailing edge blade of the present invention includes a blade leading edge 103, a pressure side shell 107 and a suction side shell 108, such as figure 1 As shown, the blade trailing edge includes a cylindrical trailing edge 104 of the root section, a pointed trailing edge 106 of the tip section, and a blunt trailing edge 105 in the middle.

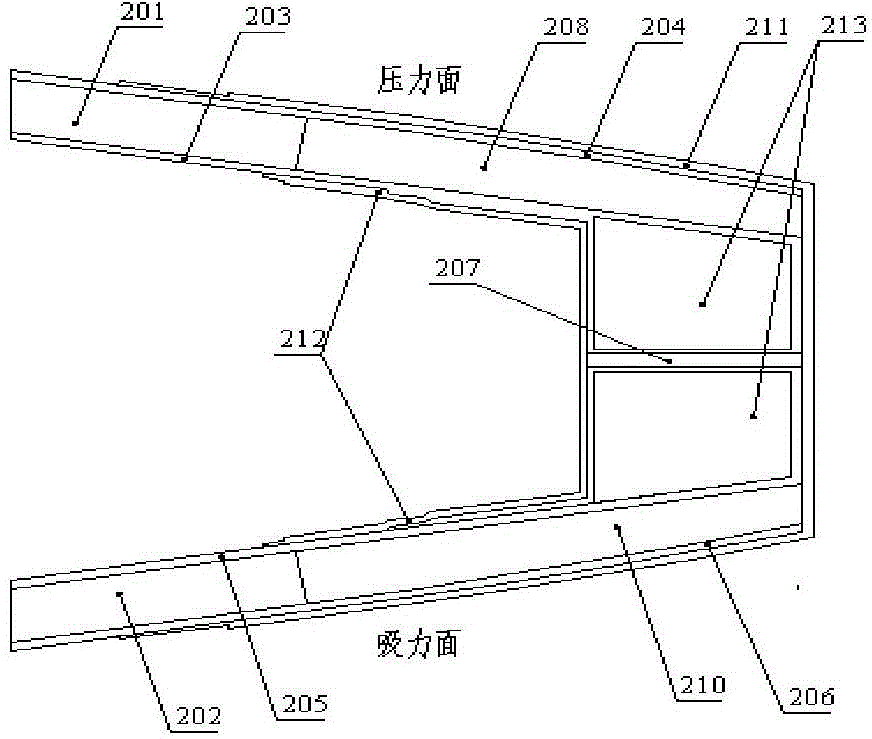

[0059] like image 3 As shown, the blunt trailing edge of the existing blunt trailing edge blade includes a pressure surface part, a suction surface part and a vertical part structure, and the pressure surface part includes a trailing edge core material 201, an inner skin 203, an oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com