Rotor of haymaking machine provided with arms in two parts connected by an improved connecting device

一种连接装置、制作机的技术,应用在杆的连接、干草摊晒机、连接构件等方向,能够解决机器使用复杂等问题,达到防止意外松脱、保证使用安全性和持久操作、增强使用安全性和持久性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

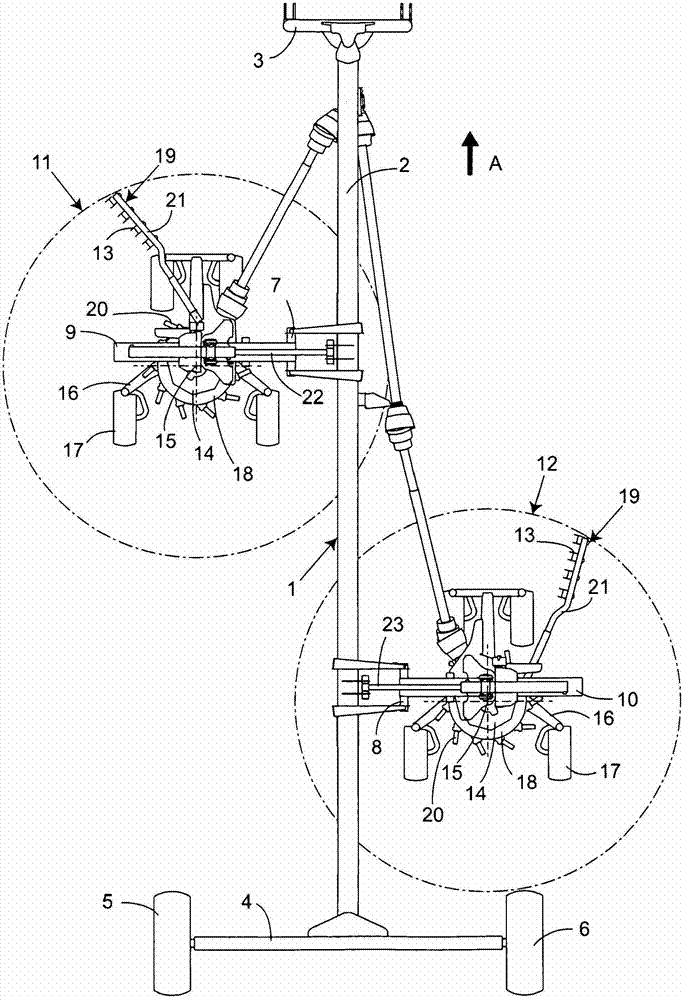

[0020] Such as figure 1 As shown, the machine according to the invention is a crop windrower placed on the ground. It comprises a support structure 1 comprising a central beam 2 with connecting means 3 at its front end for hooking the central beam to a tractor (not shown) so that the machine can be moved in an advancing direction A. In the remainder of the description, the term "front" is defined in terms of the direction of travel A.

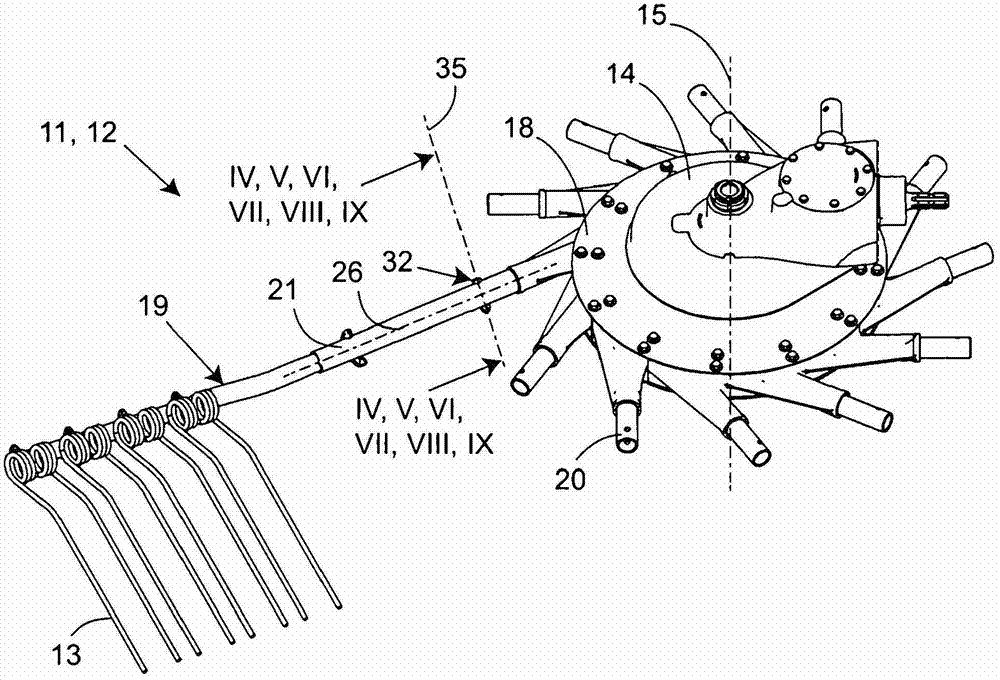

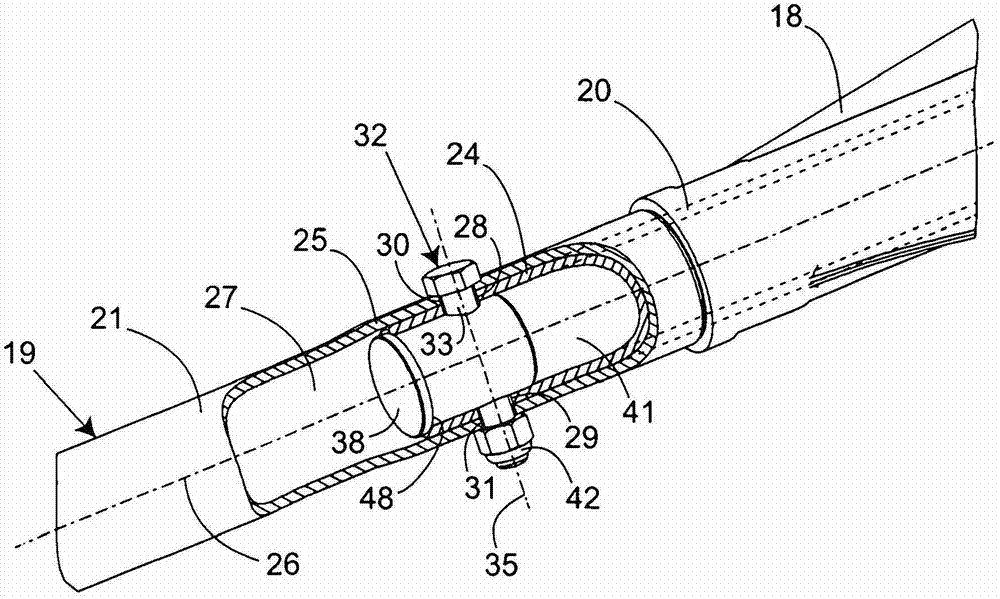

[0021] The rear end of the central beam 2 has a crossbar 4 provided with wheels 5, 6 rolling on the ground. Each side of the central beam 2 is articulated via substantially horizontal shafts 7, 8 with arms 9, 10 carrying rotors 11, 12 having work implements 13 intended to heap crops such as grass Or cut straw lying on the ground. In the example shown, the arms 9 , 10 and the corresponding rotors 11 , 12 are biased in the advancing direction A. As shown in FIG. The crops piled by the frontmost rotor 11 can be processed again by the rearmost ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com