Patents

Literature

264results about "Rakes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

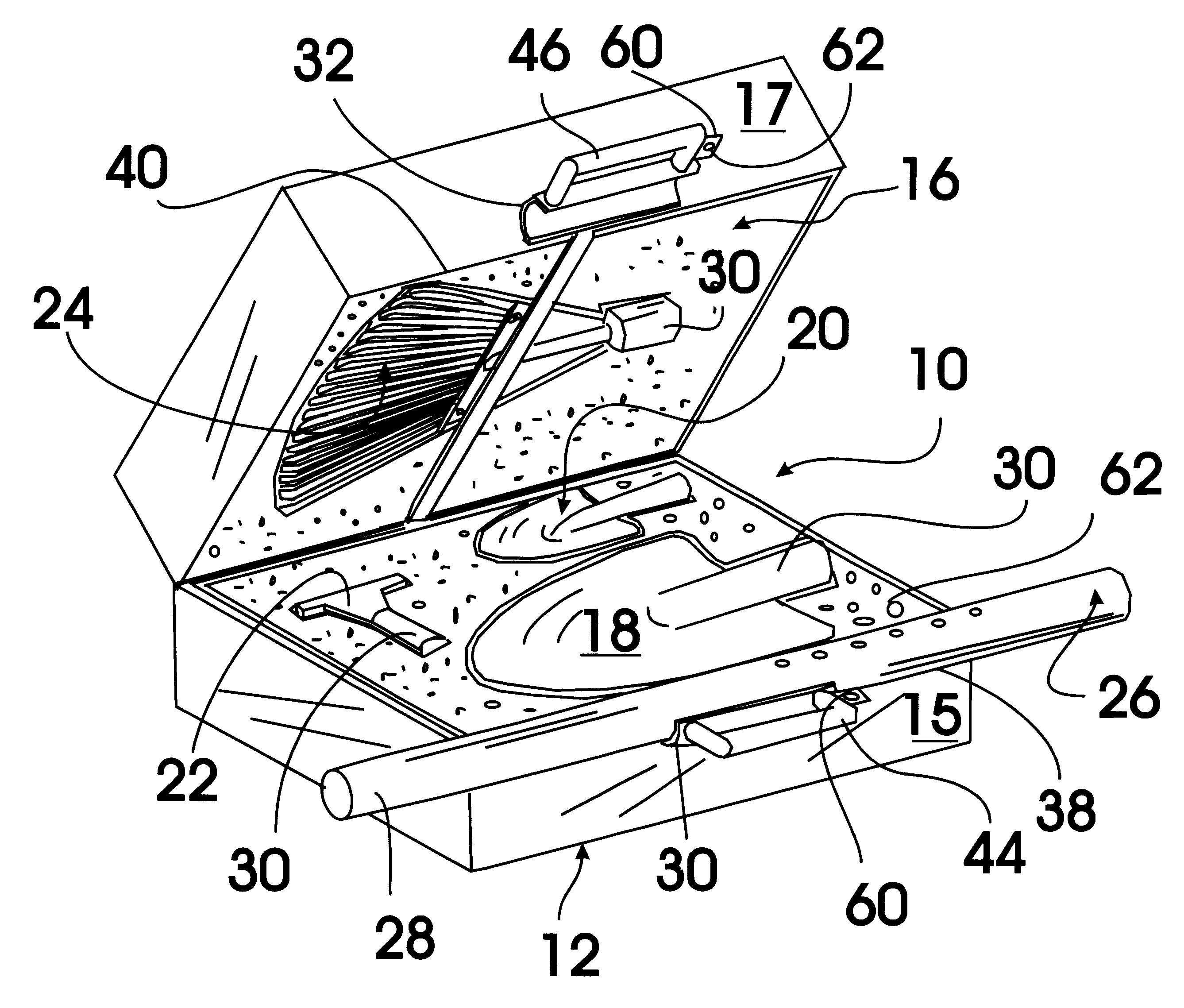

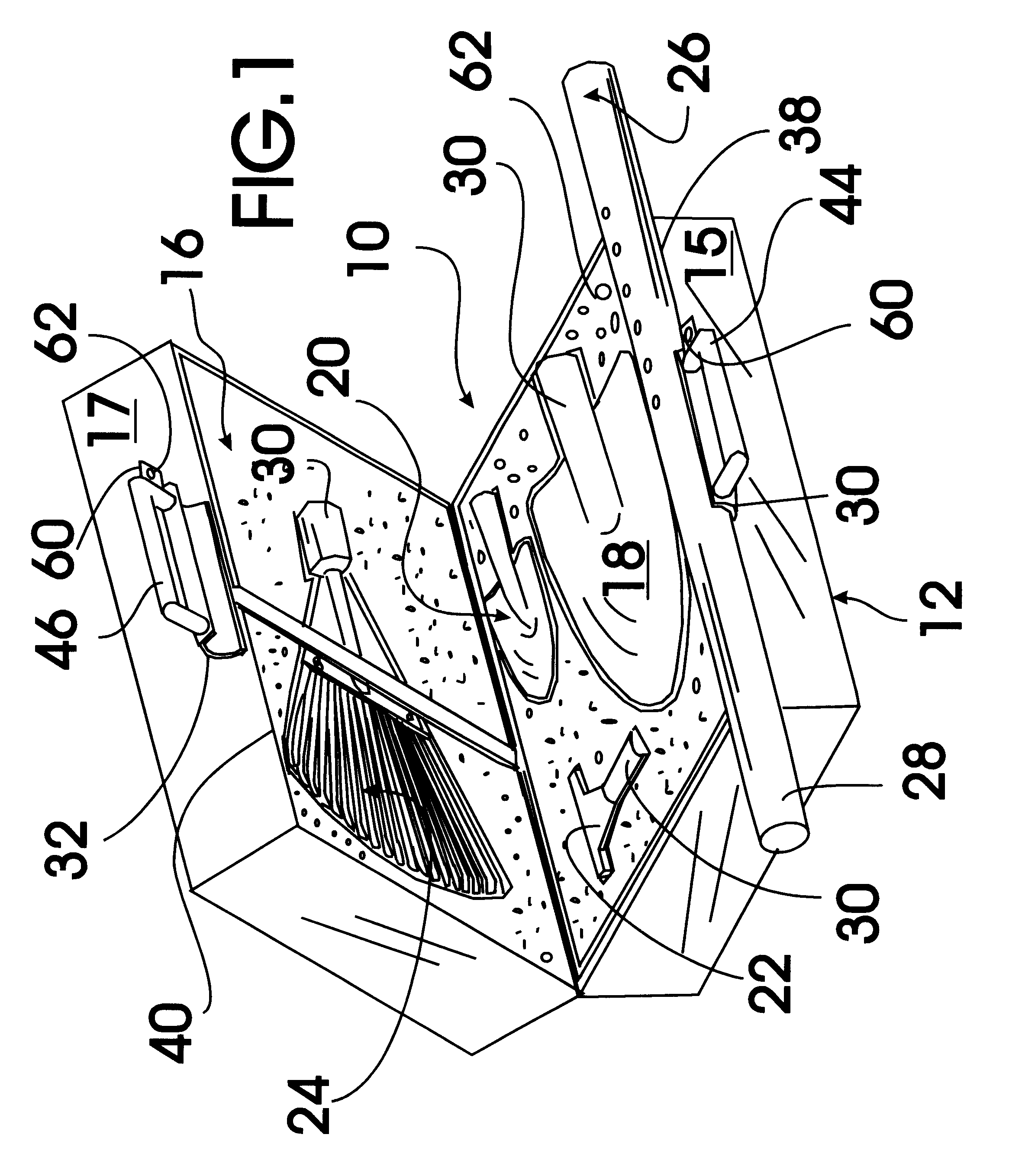

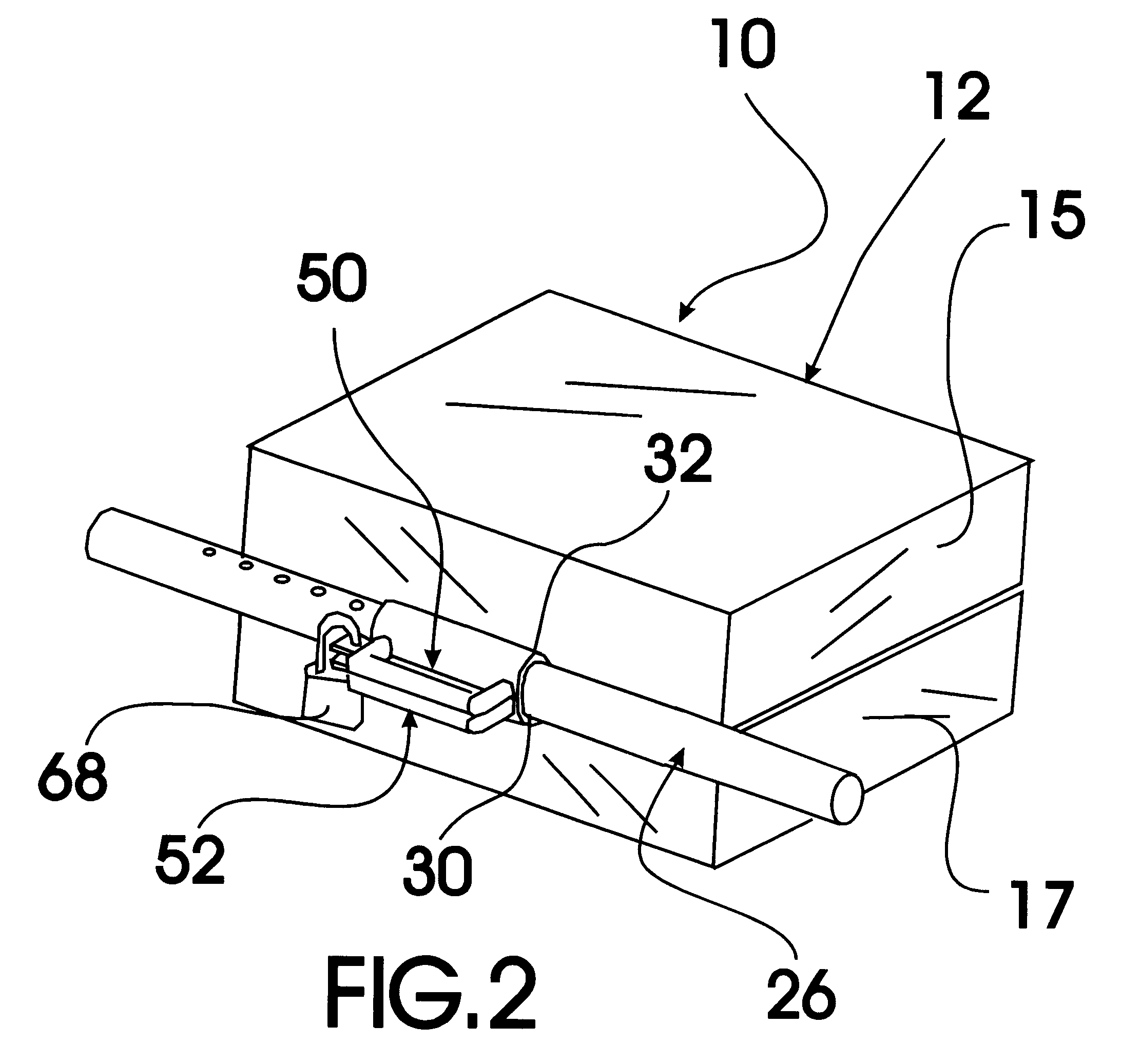

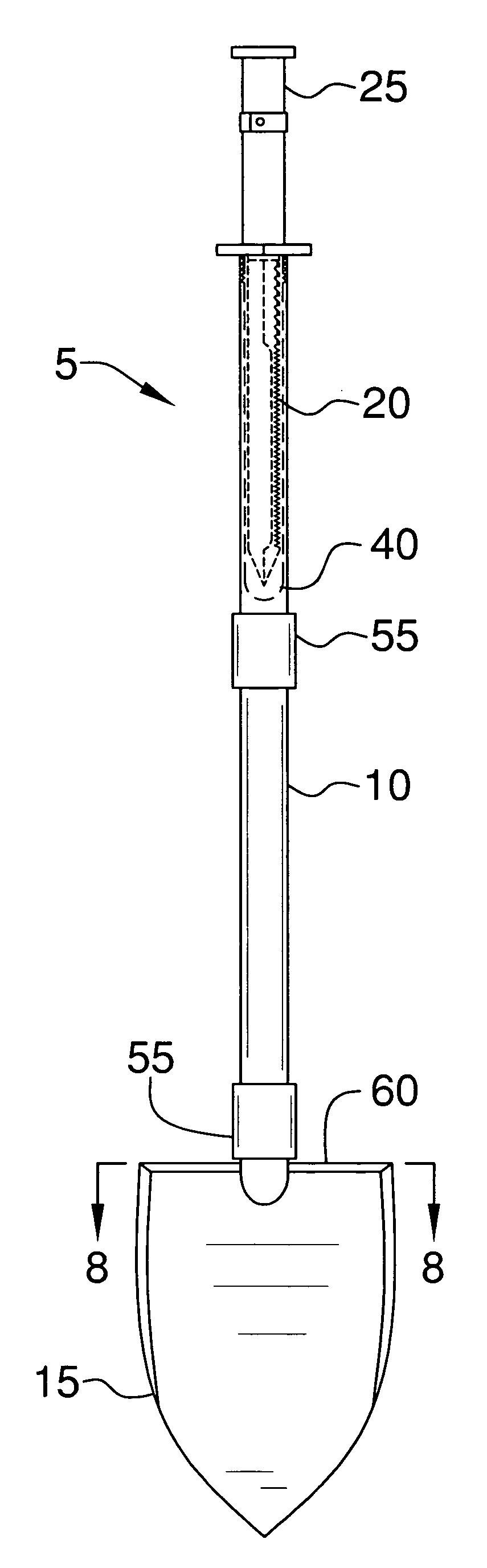

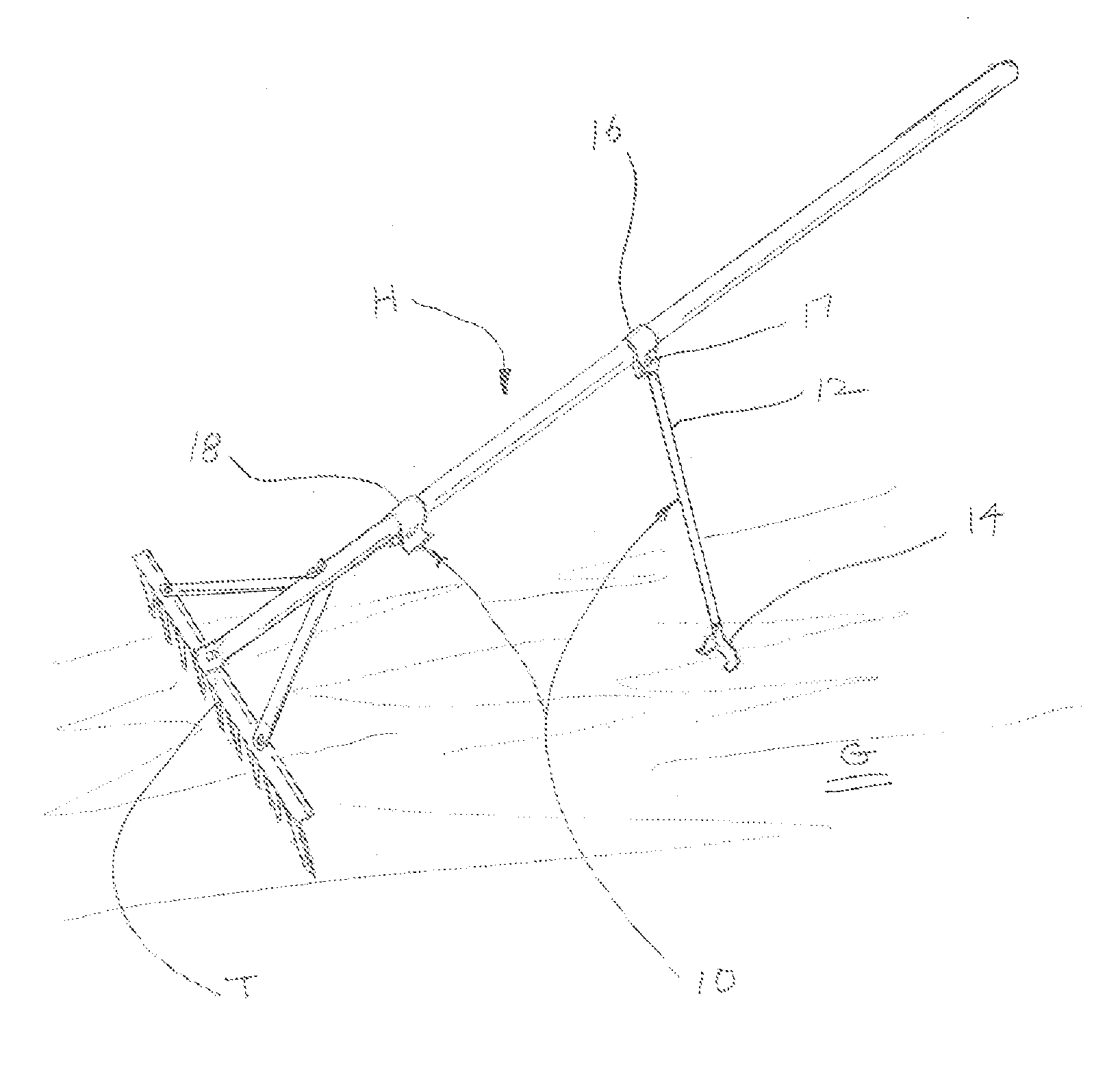

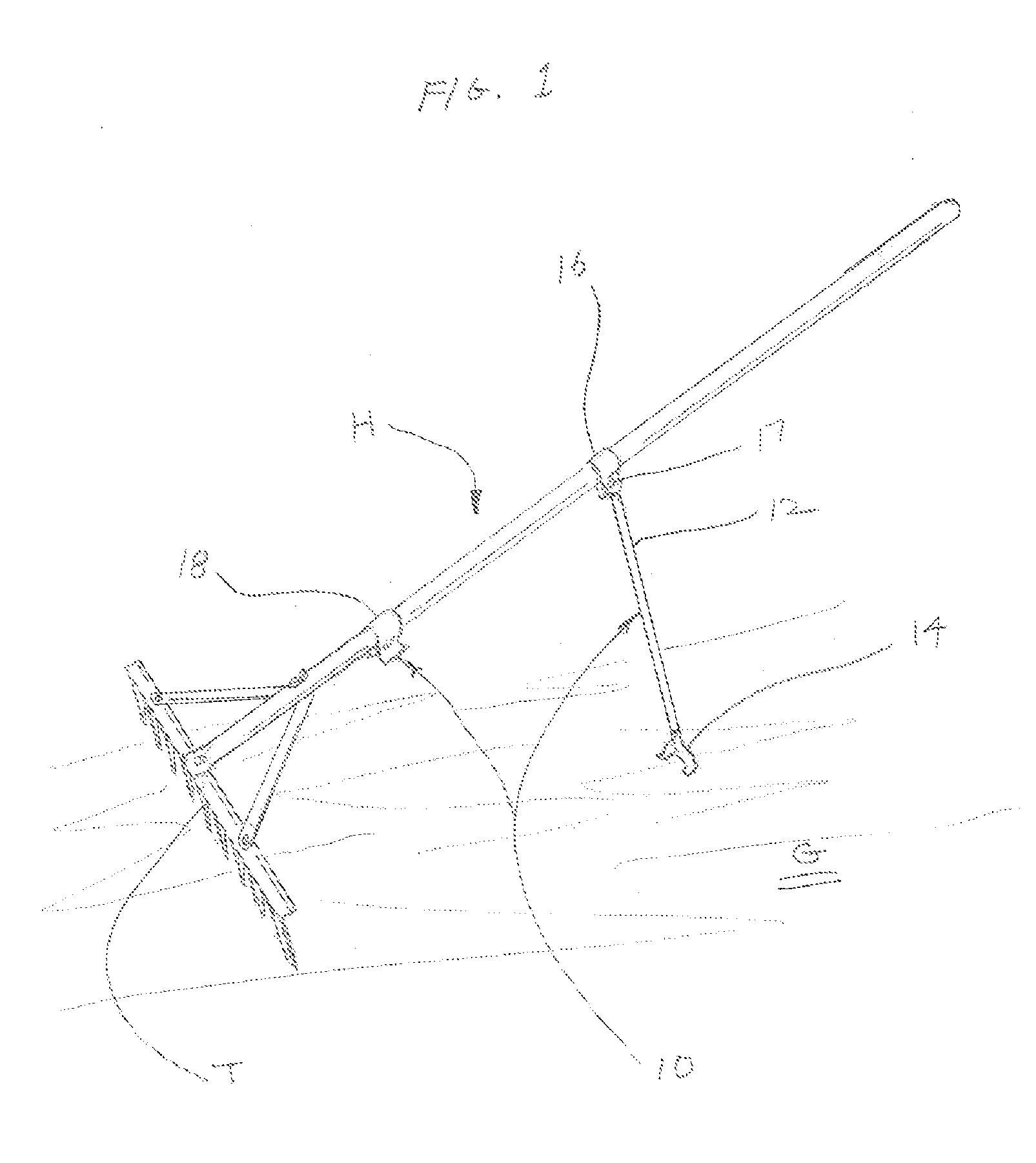

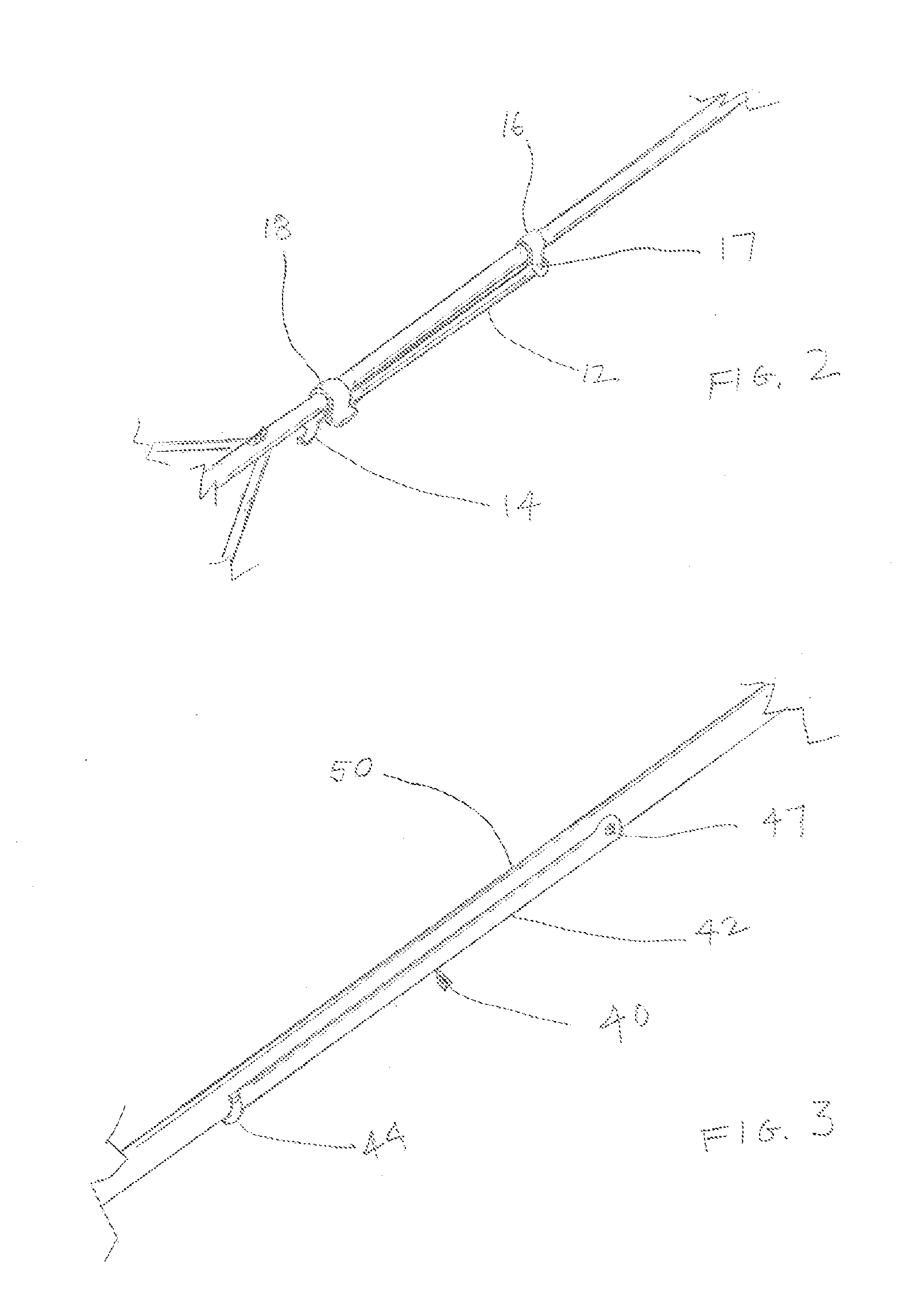

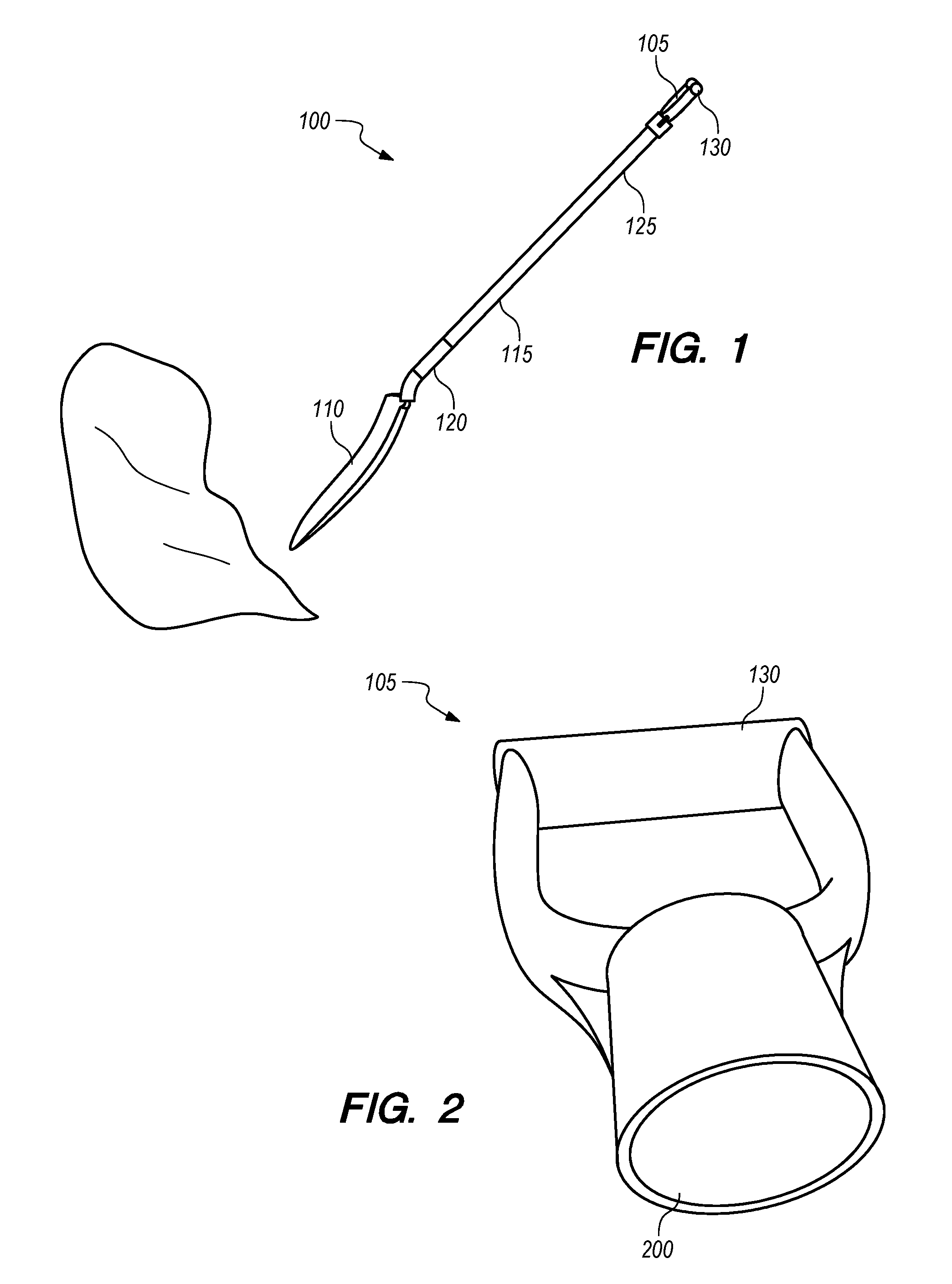

Garden implement system

A garden implement system that includes a case for storing and transporting various garden implements needed at various times while gardening. The garden implement system includes a two-part, hingedly connected, foam-lined container; a garden trowel; a number of garden implement heads including a shovel head, a hoe head, and a rake head; and a telescoping handle having a bottom end that is securable to an attachment fitting provided on the shovel head, the hoe head, and the rake head.

Owner:EATMON DELTON R

All in one home and yard maintenance tool package and method therefor

A home and yard maintenance tool for performing a plurality of different task is disclosed. The home and yard maintenance tool has a handle section. A plurality of different home and yard accessory attachments are further provided. Each of the different attachments may be removably coupled to the handle for performing the plurality of different task.

Owner:HUGHES DAVID P

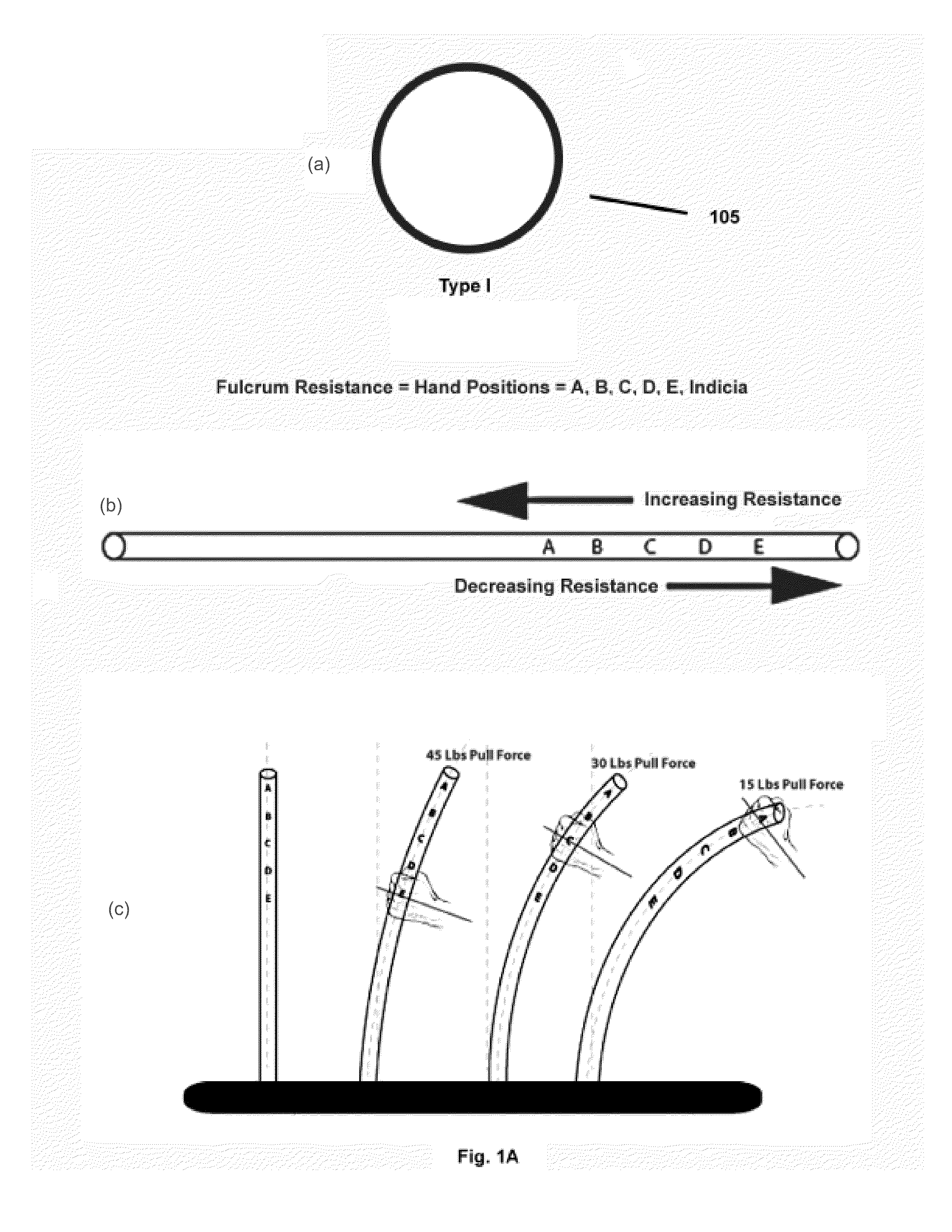

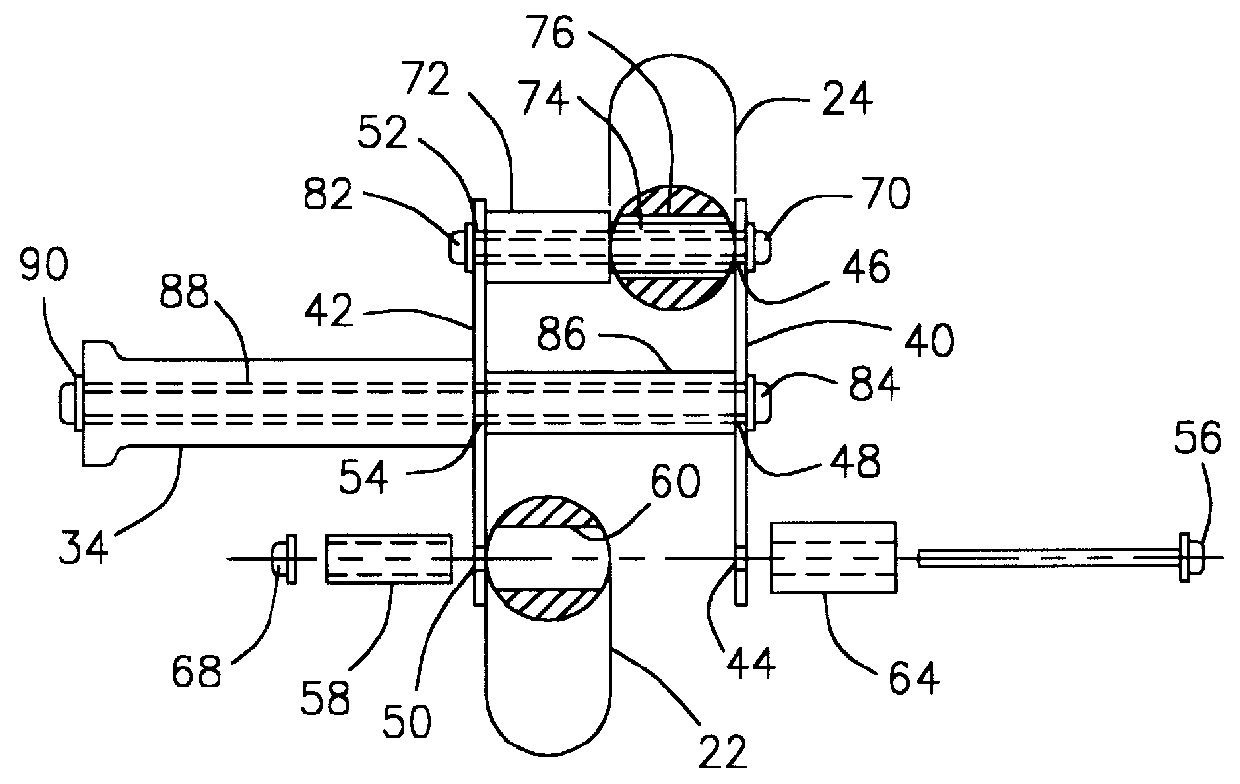

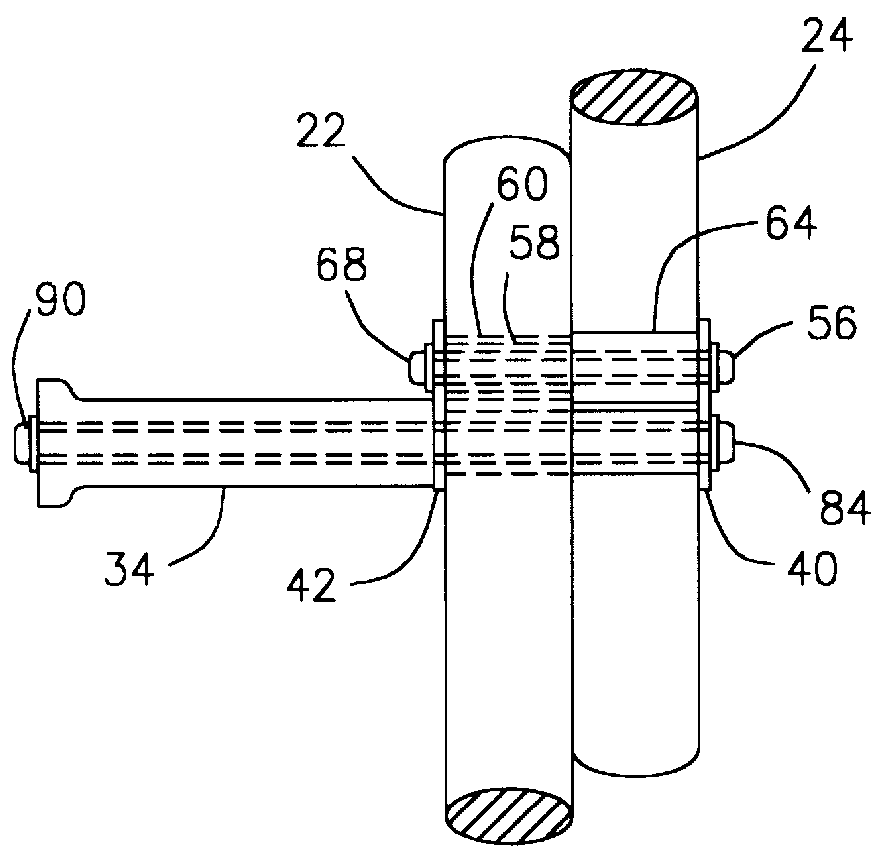

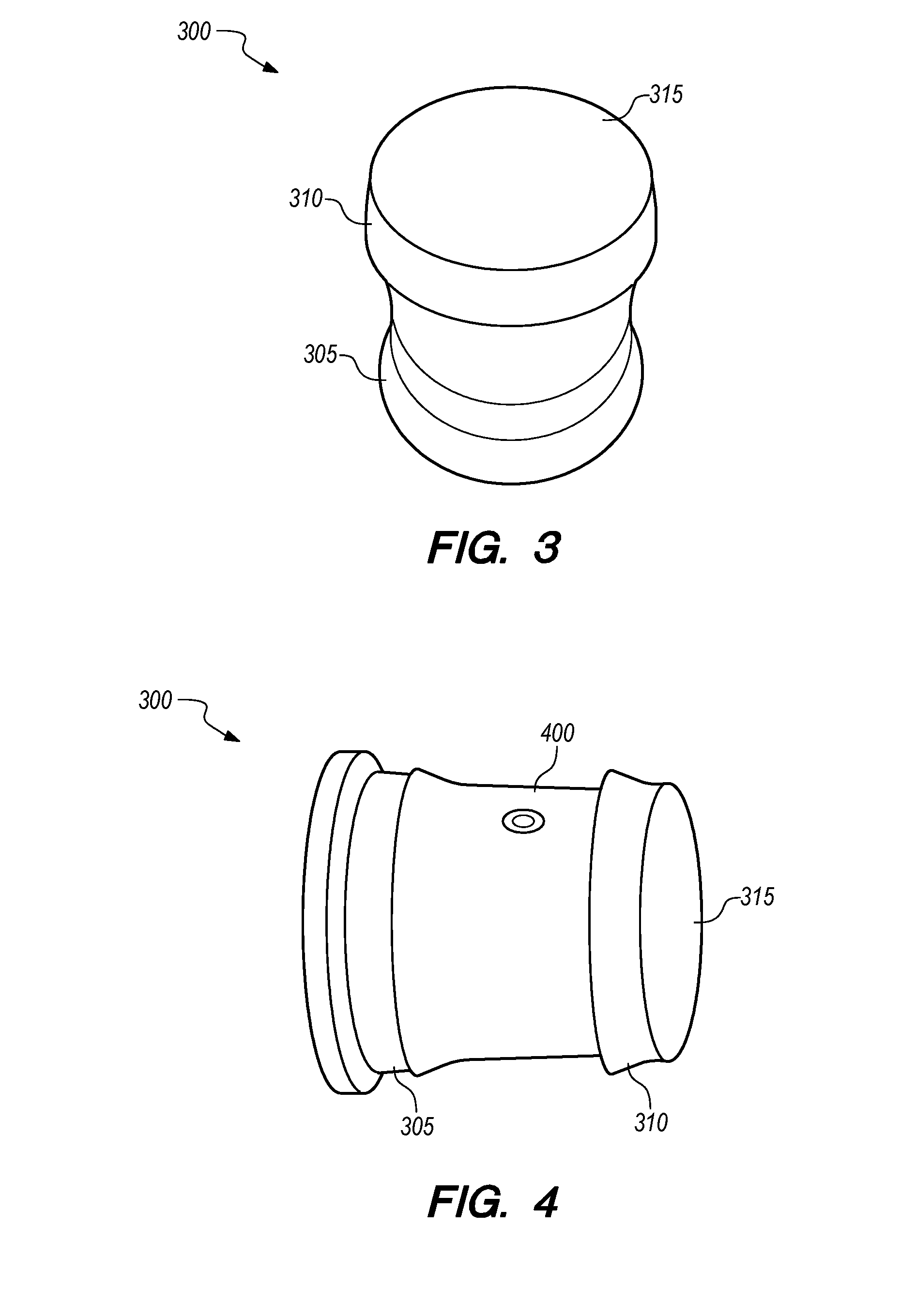

Methods for Adjusting Stiffness and Flexibility in Devices, Apparatus and Equipment

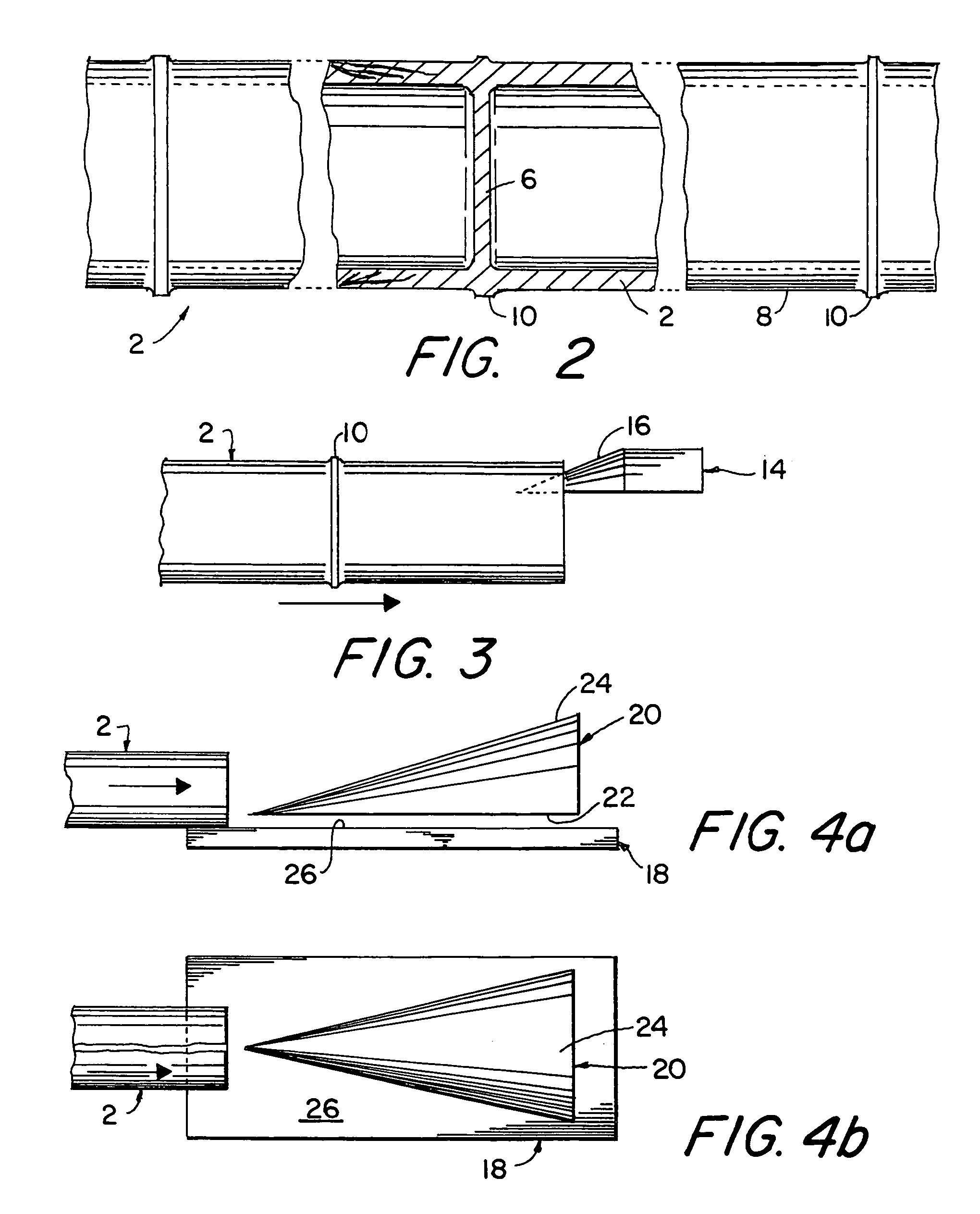

InactiveUS20130178344A1Constant and consistent flex adjustmentRodsRakesMedical deviceBiomedical engineering

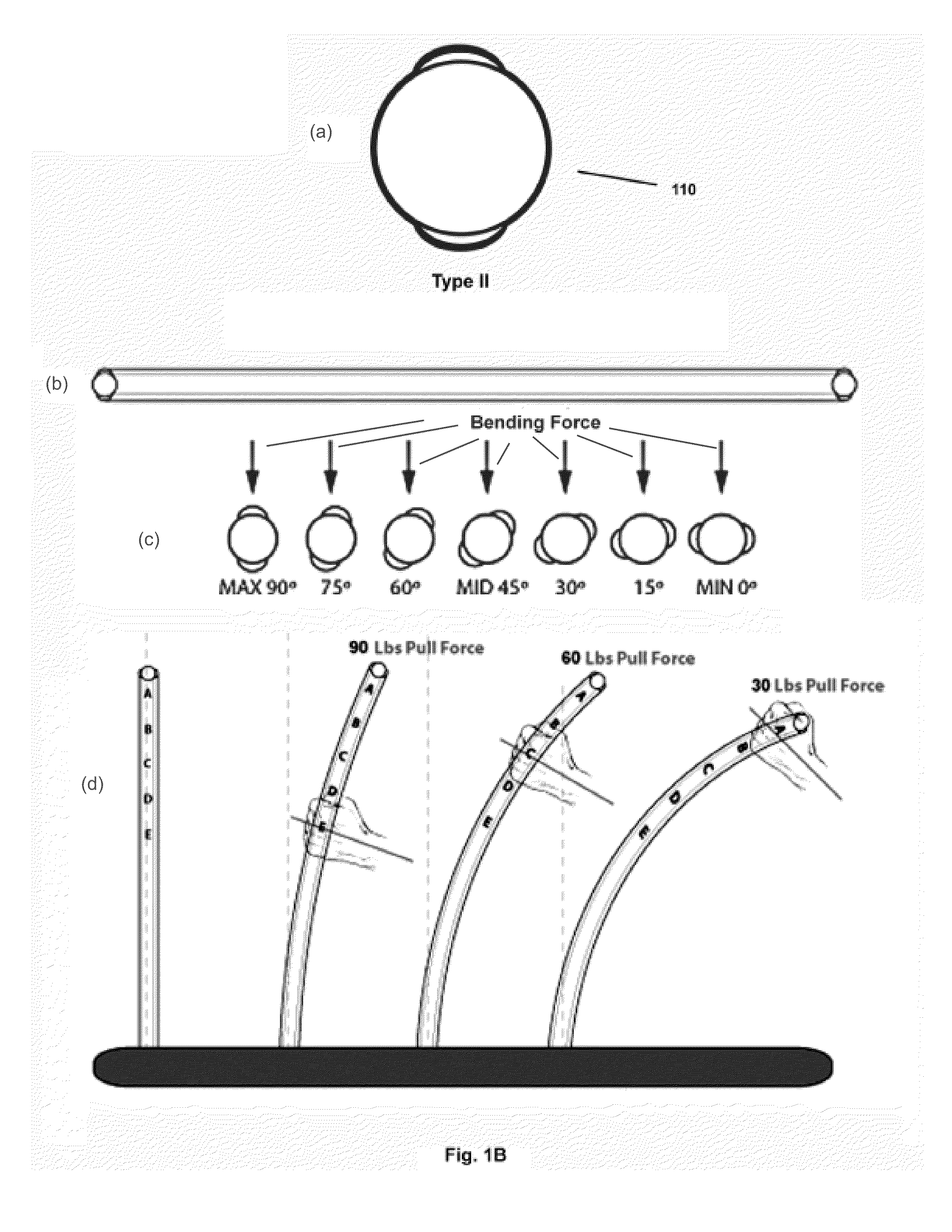

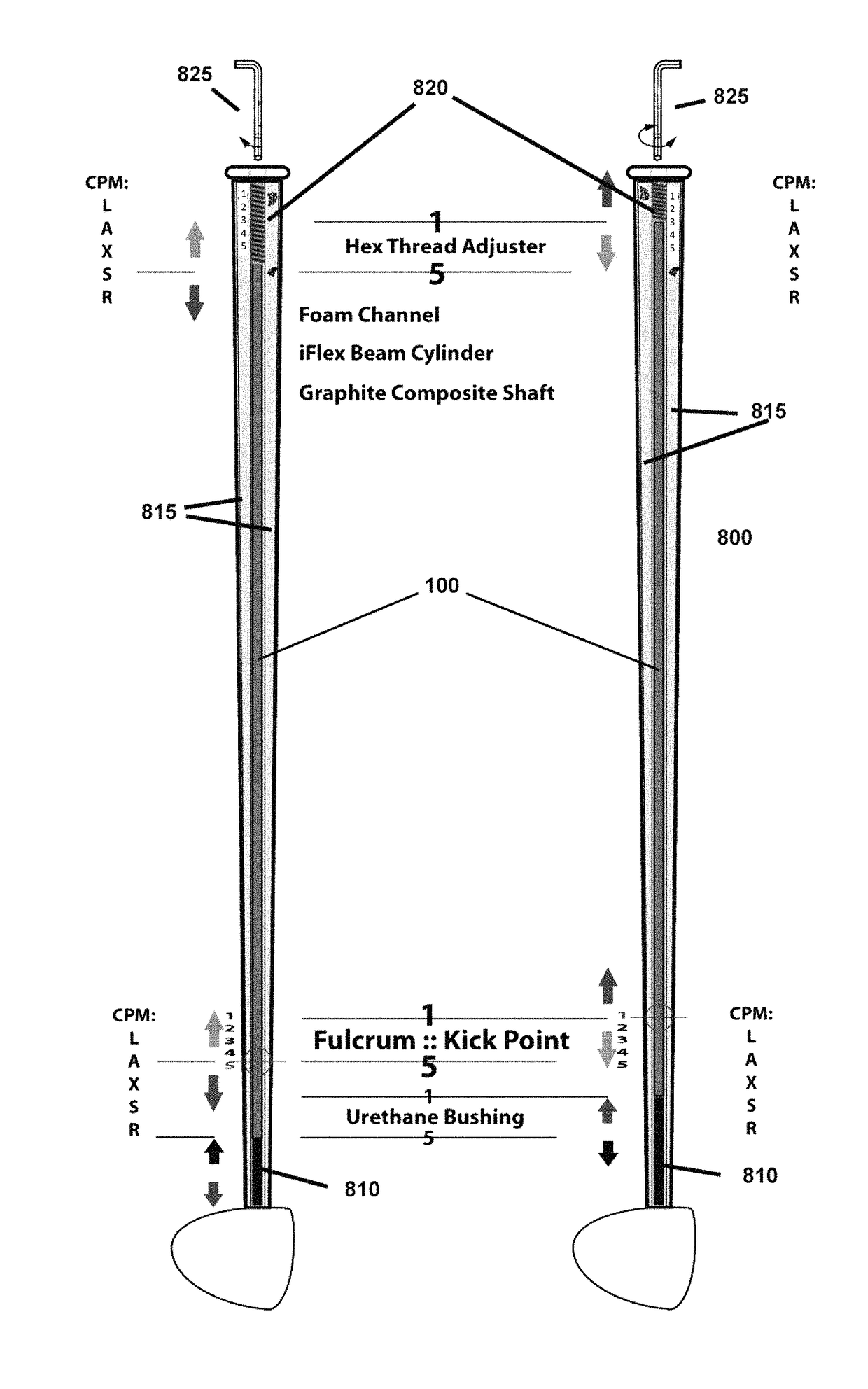

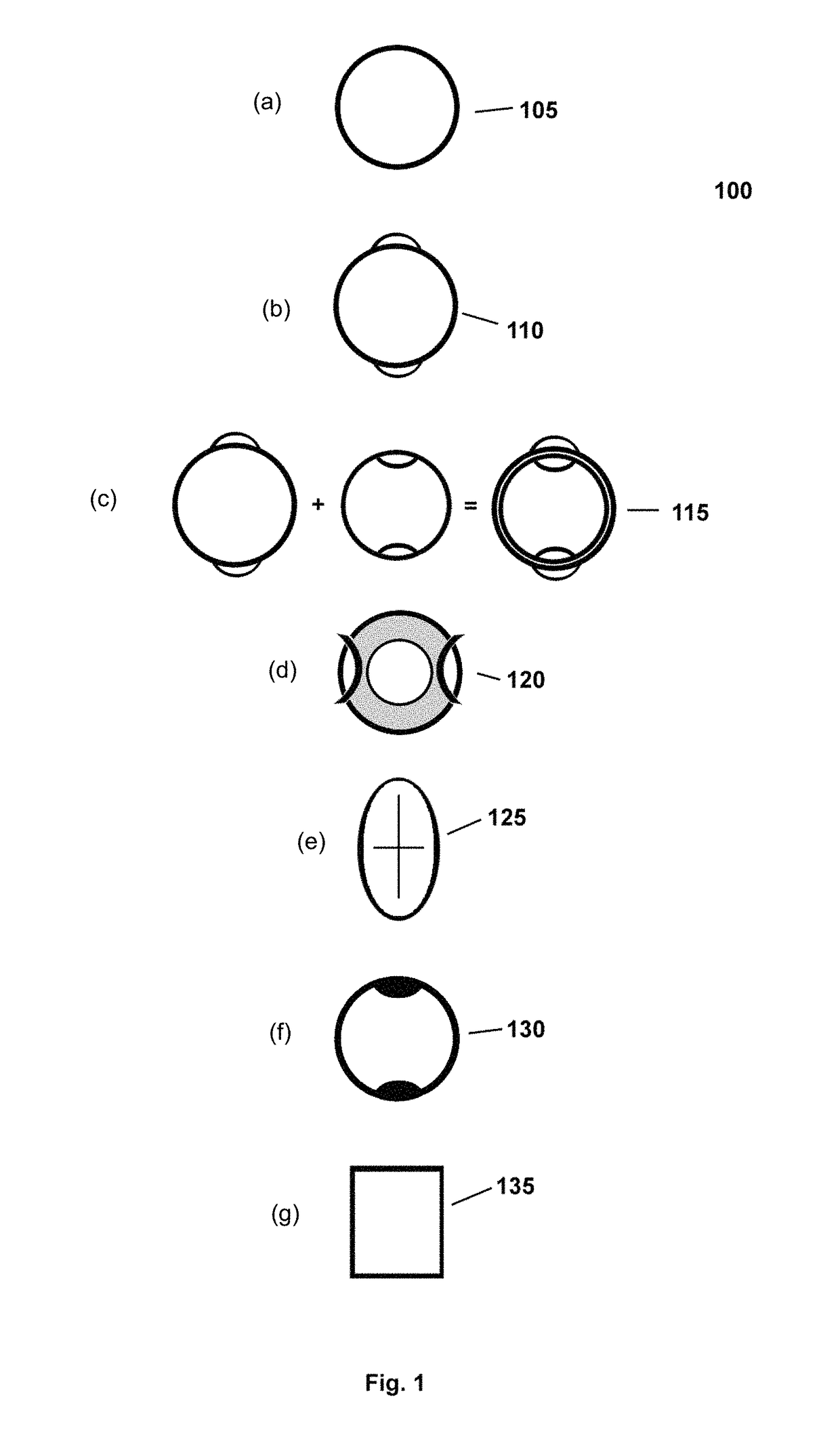

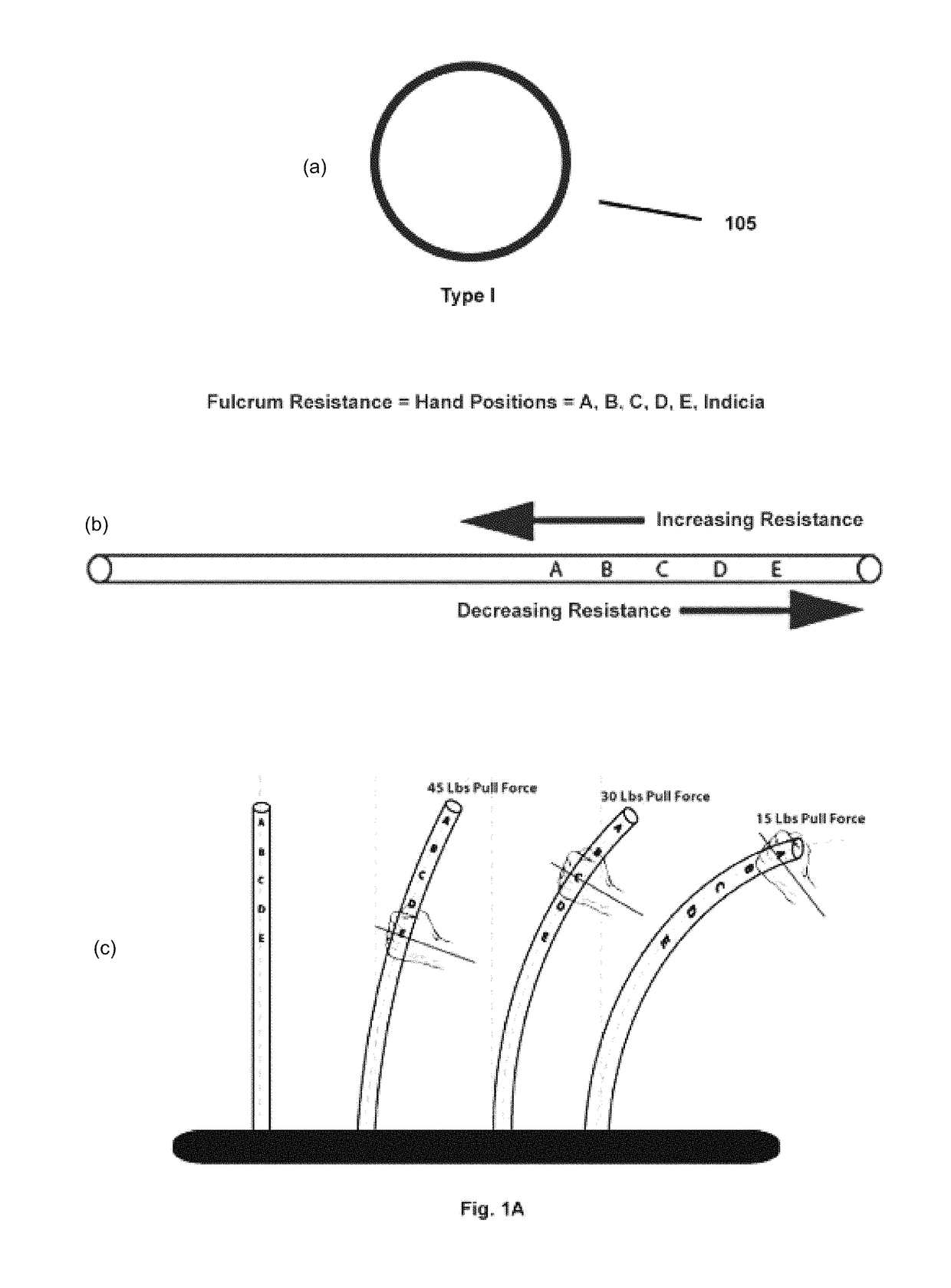

A resilient rod that provides adjustable directional resistance is disclosed. In one aspect of the invention, a resistance level may be determined based on a thickness of the rod and a position of an applied force with respect to a fulcrum point. In another aspect of the invention, at least one spine may be attached to the beam to increase a diameter of the beam along one axis. A resistance level may be determined based on a thickness of the rod, a position of an applied force and an orientation of the at least one spine with regard to the direction of the applied force. In other aspects of the invention, the resilient rods may be incorporated into various equipment that provide for adjustable resistance levels. In still other aspects of the invention, the resilient rod may be incorporated into medical devices that provide adjustable support for injured limbs or joints.

Owner:ALLIANCE DESIGN & DEVMENT GROUP

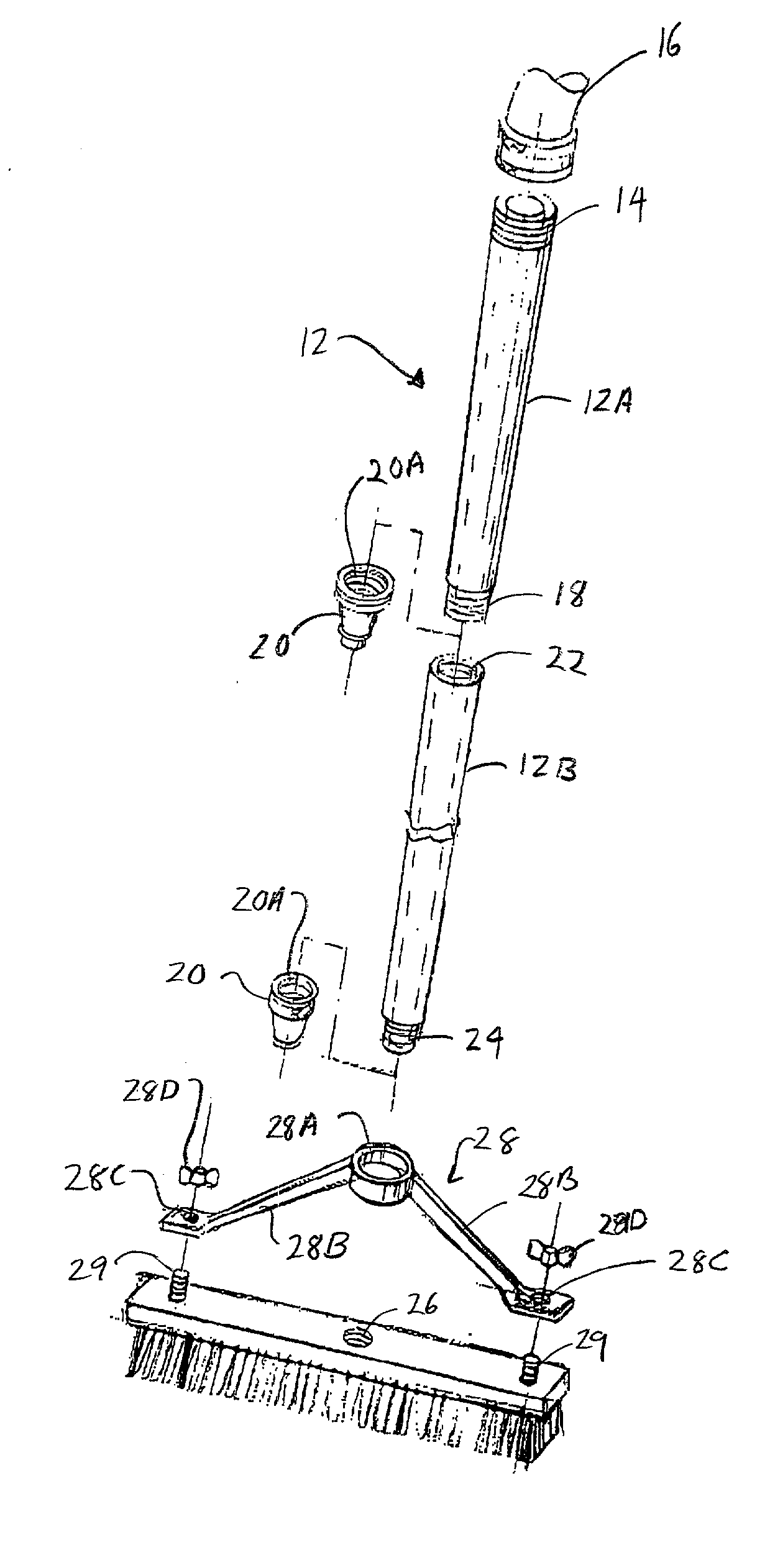

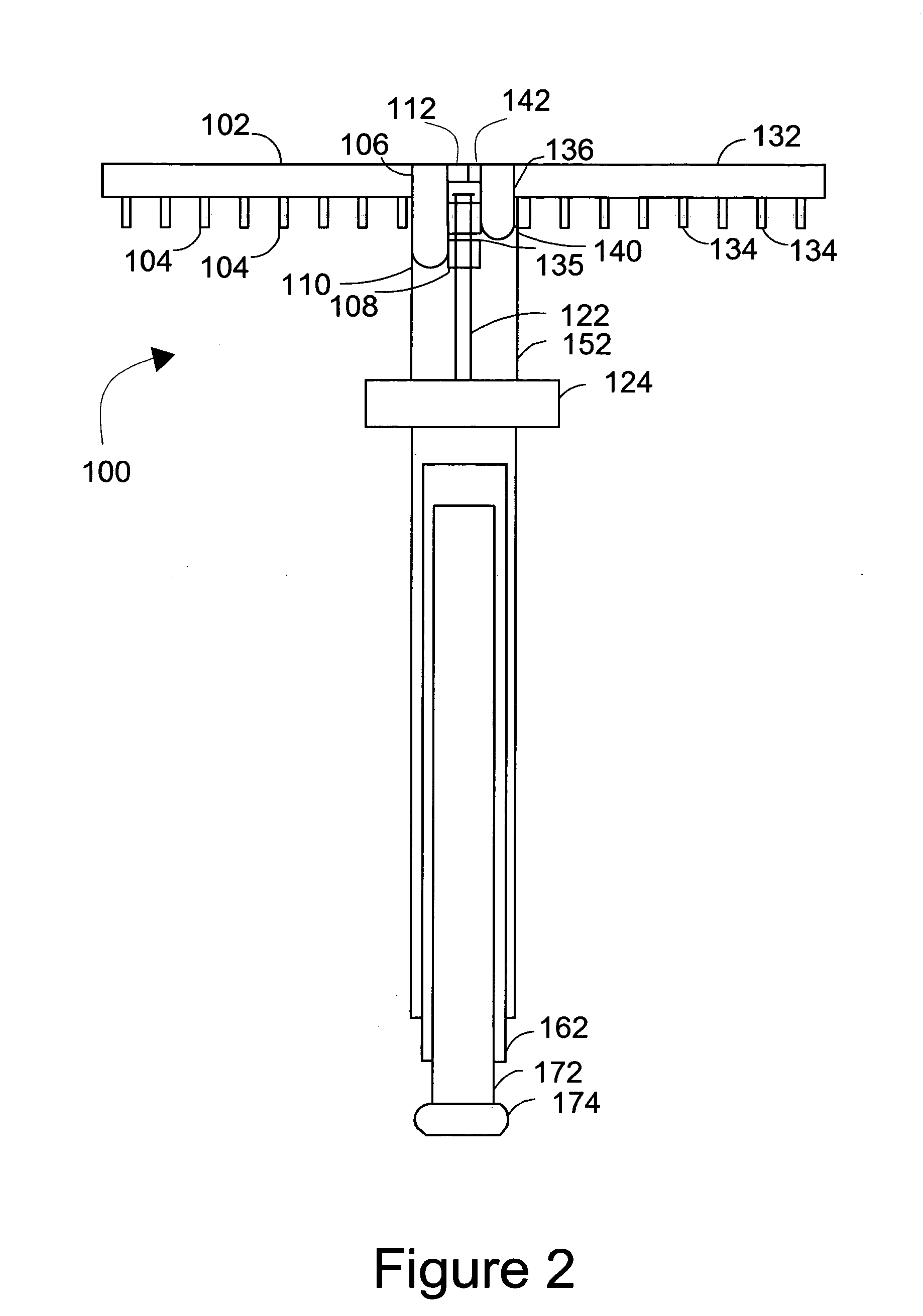

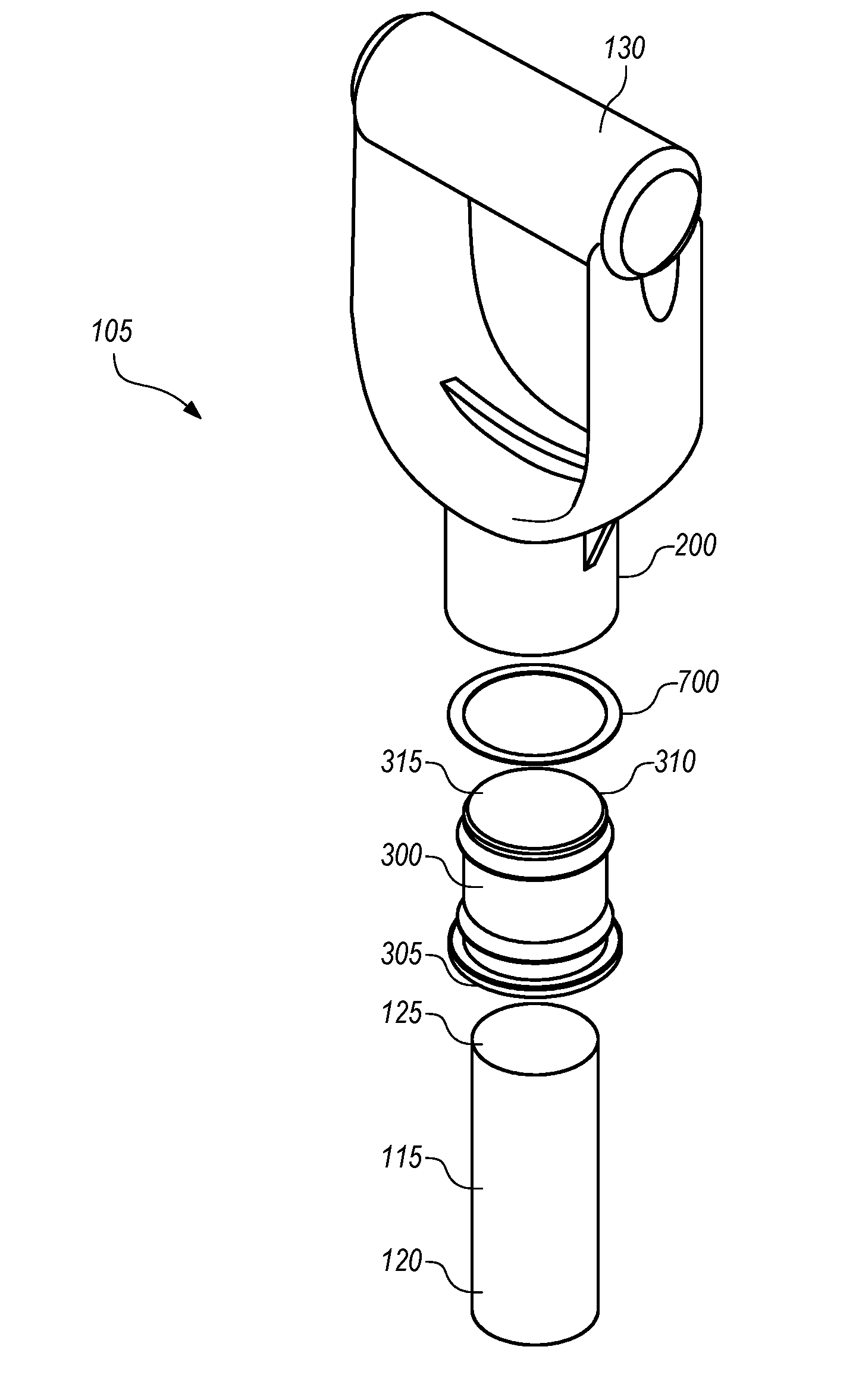

Lawn rake and cross head assembly

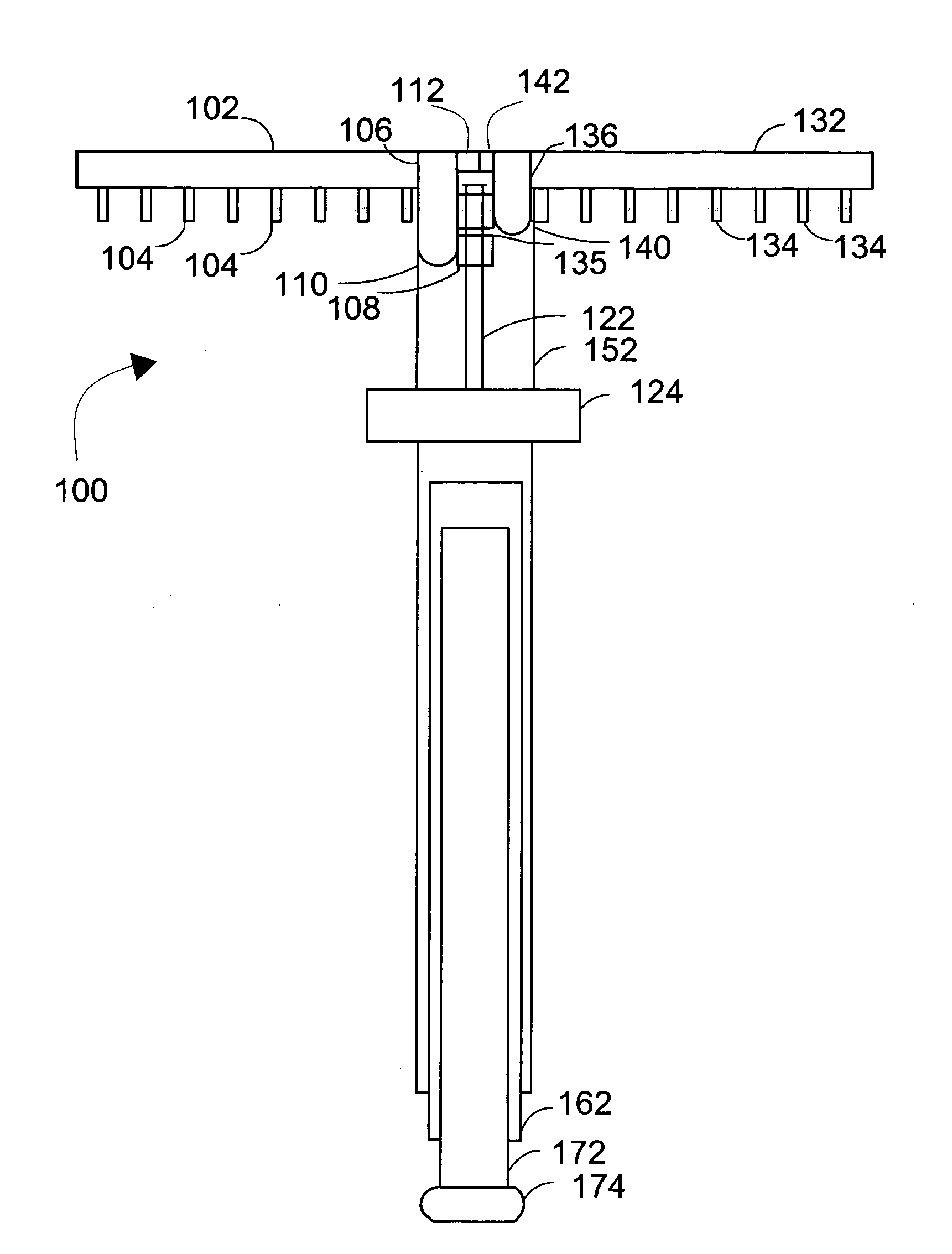

A lawn rake (100) has a cross head assembly (130) attached to a handle (120). A truncated tee (150) mounted on the cross arm (145) of the cross head assembly (130) receives the handle (120). A plurality of tines (170) is carried by the cross arm (145). The cross arm (145) is tubular and has a plurality of pairs (162) of apertures (164). The apertures (164) are larger than the cross section of the tines (170). The tines (170) are inserted through, and loosely positioned by, the apertures (164). The plurality of tines (170) forms an array (160) that is generally coplanar. The array (160) may form an obtuse angle with respect to the handle (120). Embodiments of the rake include arrays of tines (170) configured to form alternating rows of tines or a curvilinear arrangement of tines. A looped bend (178) formed in the end of each tine (170) distal to the ground engaging tip (176), snaps around the cross arm (145) to pivotally mount each tine (170). The tines (170) are replaceable, and are mountable on and removable from the cross arm (145) by application of finger force. The tines (170) are releasable. During raking action, an impact load directed upwardly on a tip (176) may cause release of the looped bend (178) from the cross arm (145), thereby preventing breakage of the tine (170). The lawn rake (100) can be used in a push mode. The lawn rake (100) may be distributed as a kit of parts. Components of lawn rake (100) are preferably made from a thermoplastic material. In particular the thermoplastic material may be polyvinylchloride.

Owner:MILBURY THOMAS G

Methods of adjusting stiffness and flexibility in devices, apparatus and equipment

A resilient rod that provides adjustable directional resistance is disclosed. In one aspect of the invention, a resistance level may be determined based on a thickness of the rod and a position of an applied force with respect to a fulcrum point. In another aspect of the invention, at least one spine may be attached to the beam to increase a diameter of the beam along one axis. The resistance level may be determined based on the thickness of the rod, the position of the applied force and an orientation of the at least one spine with regard to the direction of the applied force. In other aspects of the invention, the resilient rods may be incorporated into a golf club that provides for adjustable resistance levels.

Owner:ALLIANCE DESIGN & DEVMENT GROUP

Folding tools with locking hinges

Owner:ANDERSON BRENT L

Shovel and knife tool

This is a combination shovel and knife device for for campers and survival training. It will be lightweight yet durable and can be folded for easy storage.

Owner:SCHLENNER EVA LEE ANN

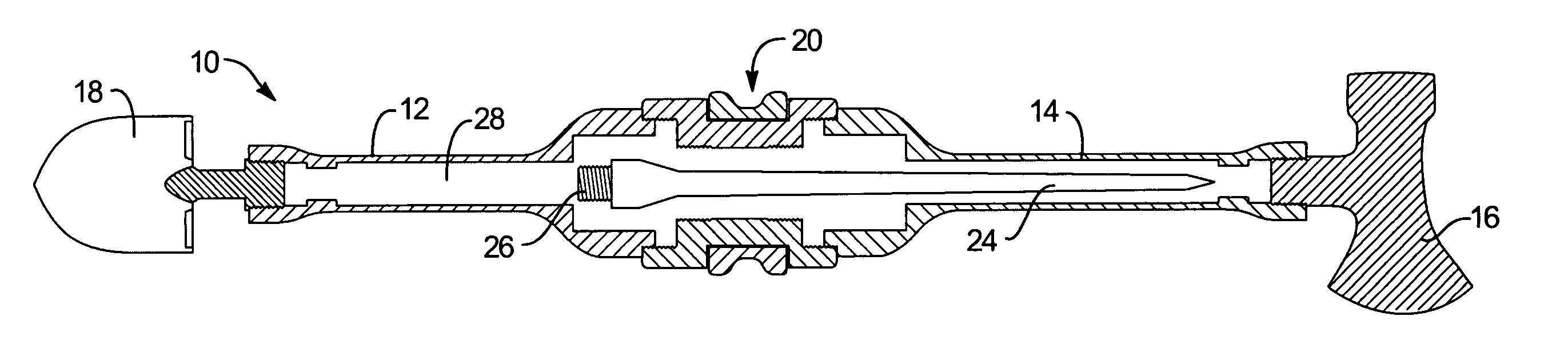

Multi-purpose tool

InactiveUS7219382B2Inexpensive and efficient and easyEasy to transportSpadesShovelsEngineeringPulley

A tool that can be assembled into multiple configurations for various uses. The tool includes at least two shafts that connect together, as well as multiple, interchangeable accessories that can be coupled to the shafts. Examples of some accessories include a stake, a digging tool, a cutting tool, a swivelling seat, and a swivelling pulley.

Owner:JOHNSON SHANE A

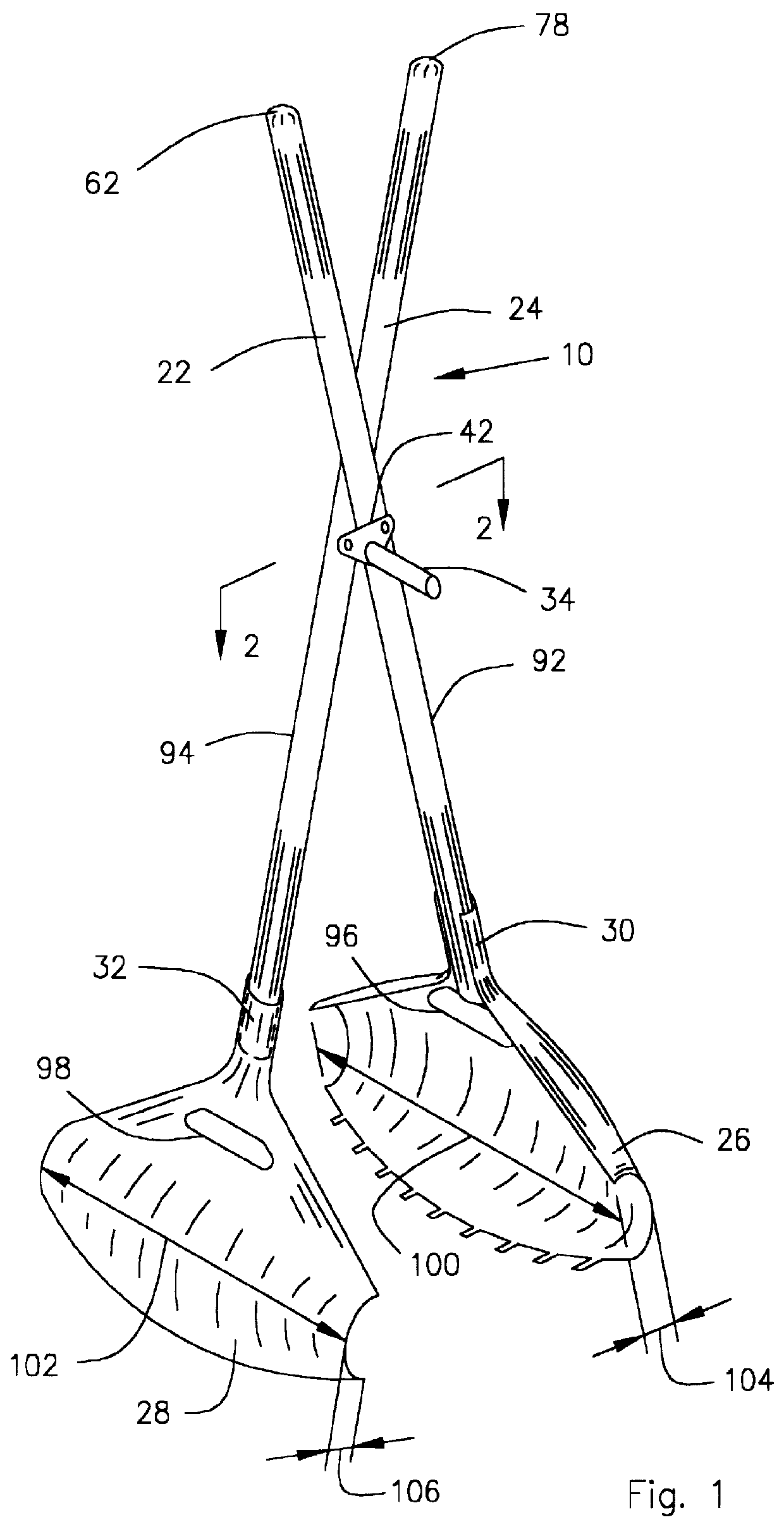

Device for gathering and lifting leaves

A device for gathering and lifting leaves that utilizes a specially designed pair of leaf scoops that are pivotally secured to each other in opposing orientation via their handles. Each of the leaf scoops is provided with a separate pivotal axis that extends through the handle of the leaf scoop. The leaf scoops are offset from each other so that the handles can be operated like the handles of a pair of scissors in order to open and close the heads of the leaf scoops relative to each other, thereby capturing leaves between the scoop heads so the leaves can be transported and so the leaves can be released when the leaves have been transported to the desired location. The device is provided with a central handle that attaches midway between the pivotal axes so that the user can grasp the central handle when lifting the device and the leaves.

Owner:JONES GEORGE WILLIAM

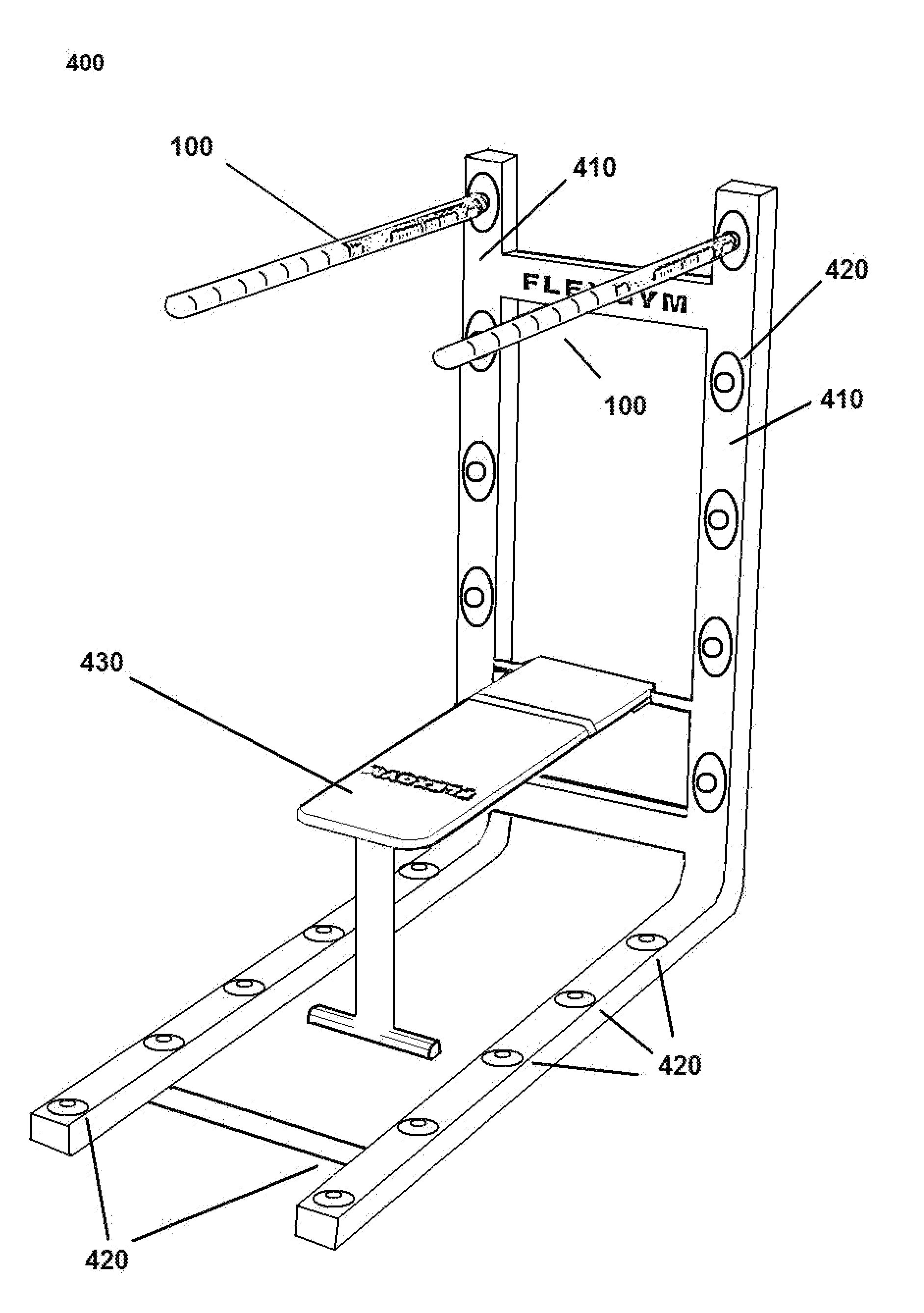

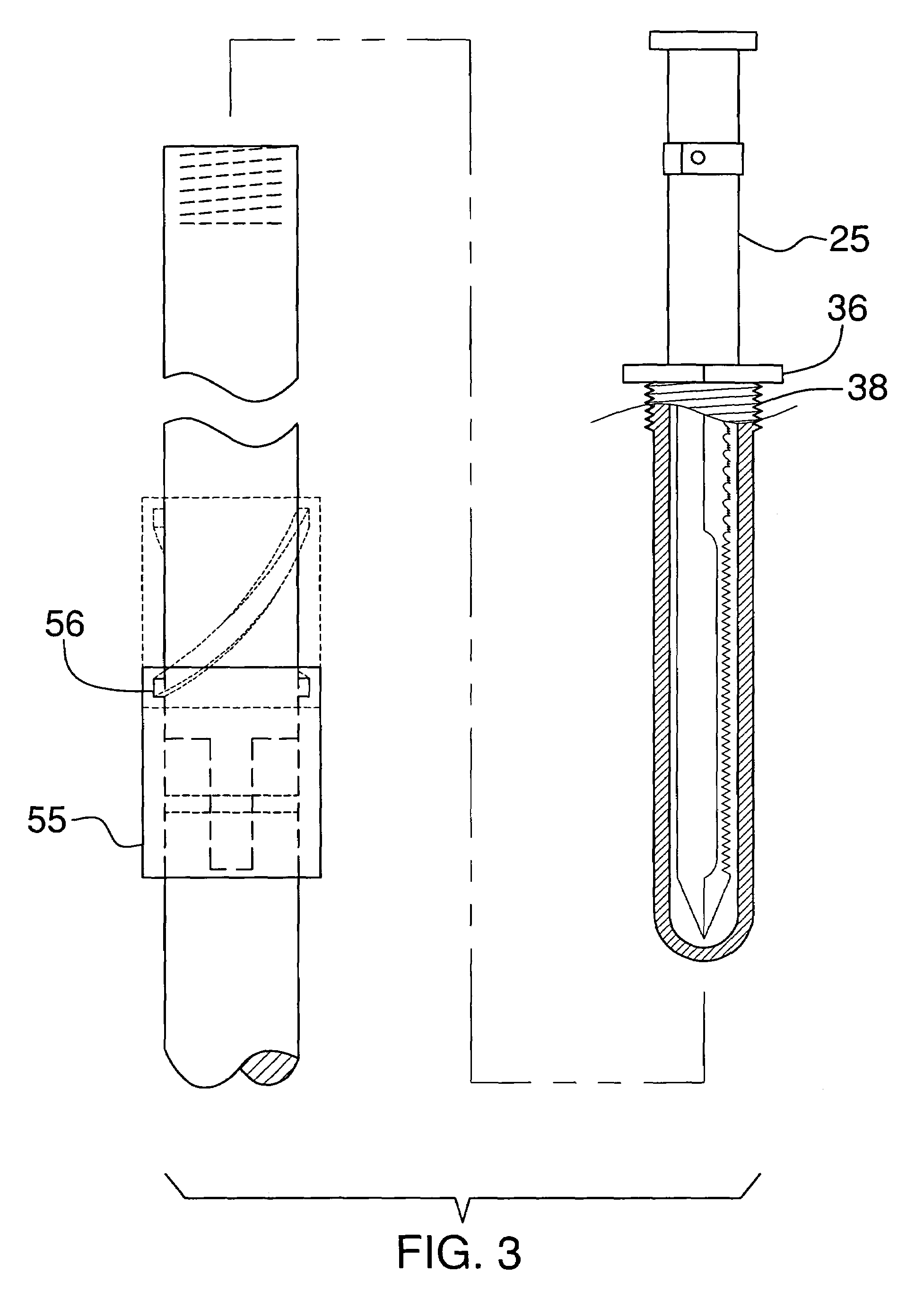

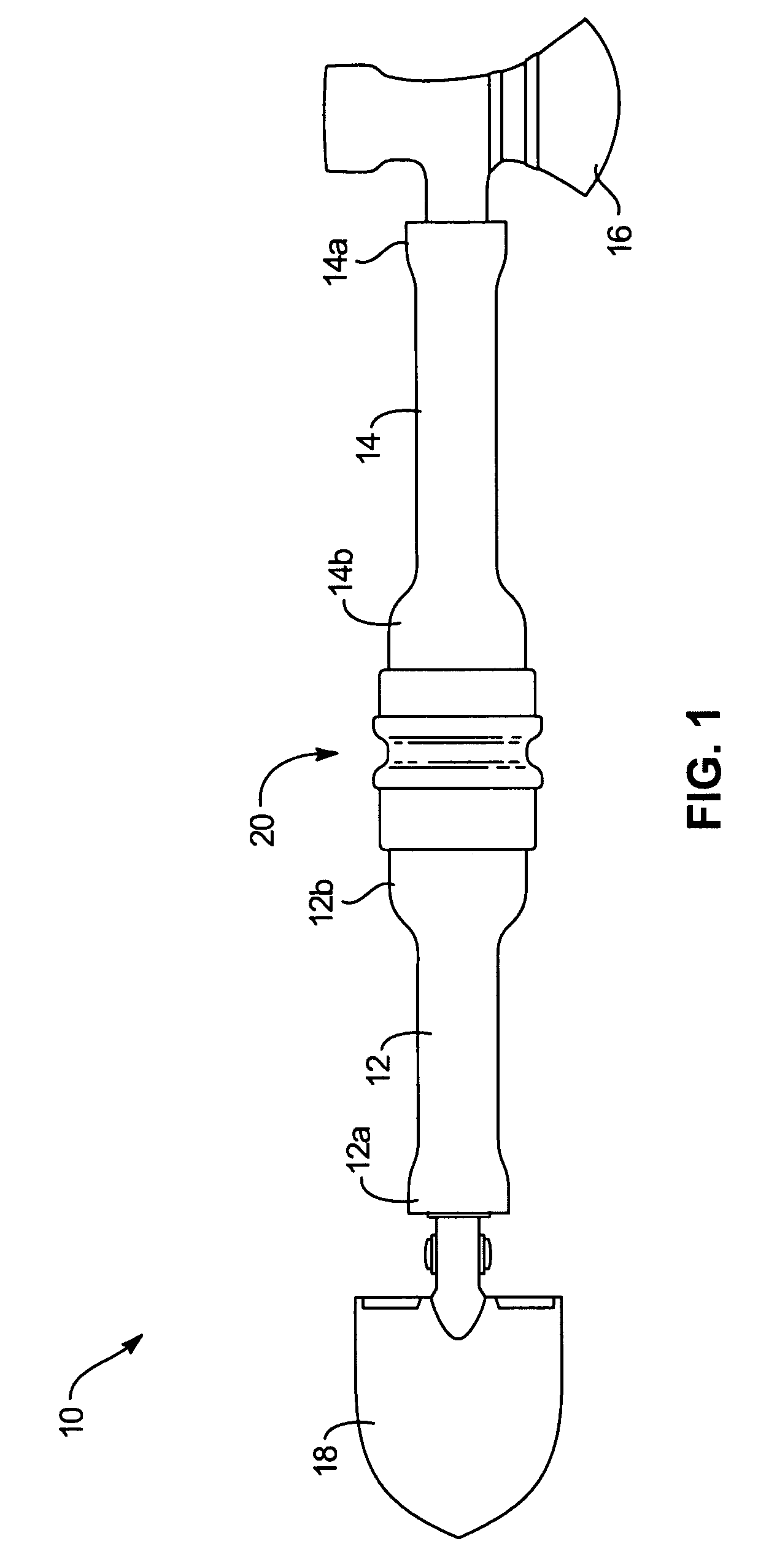

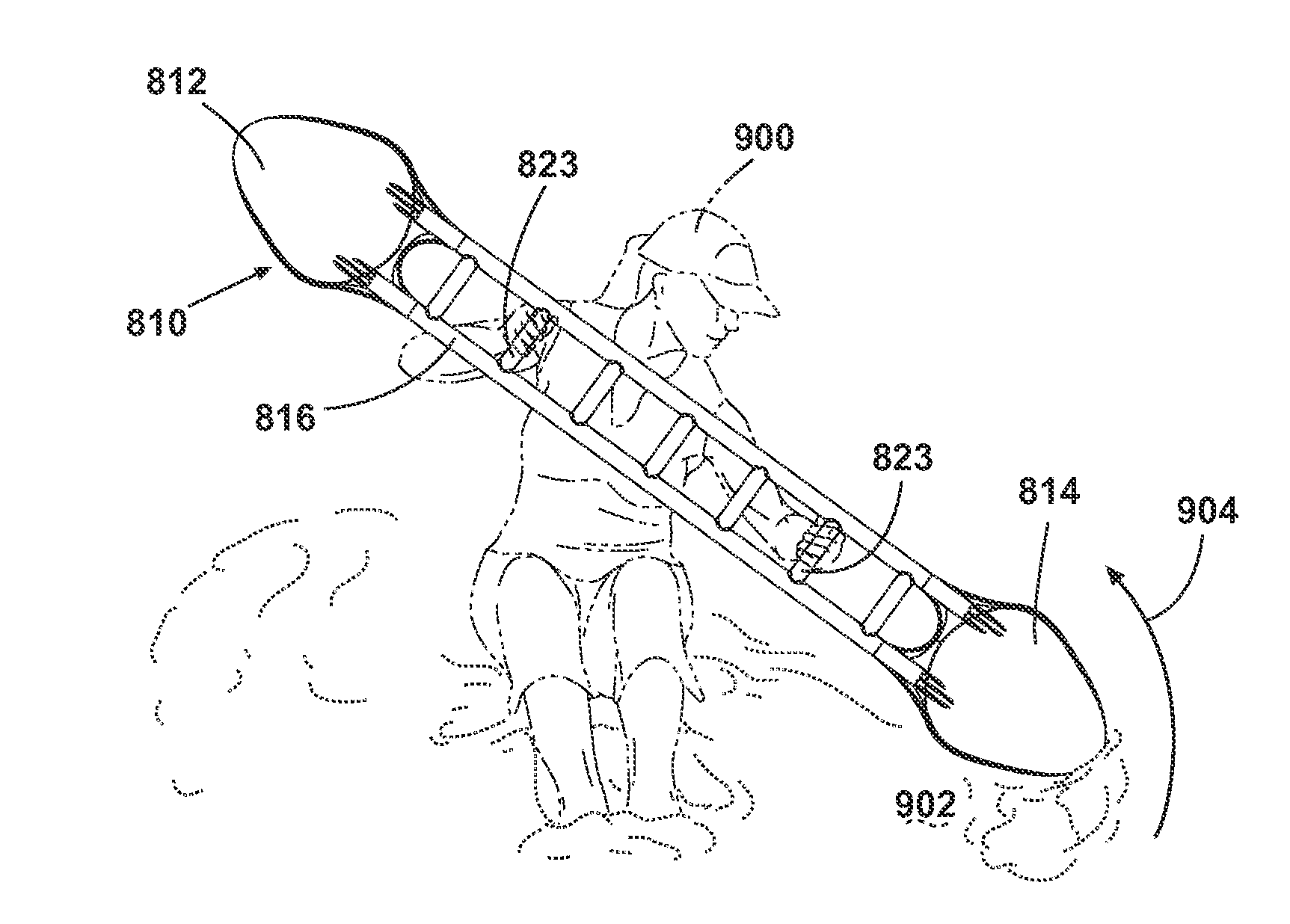

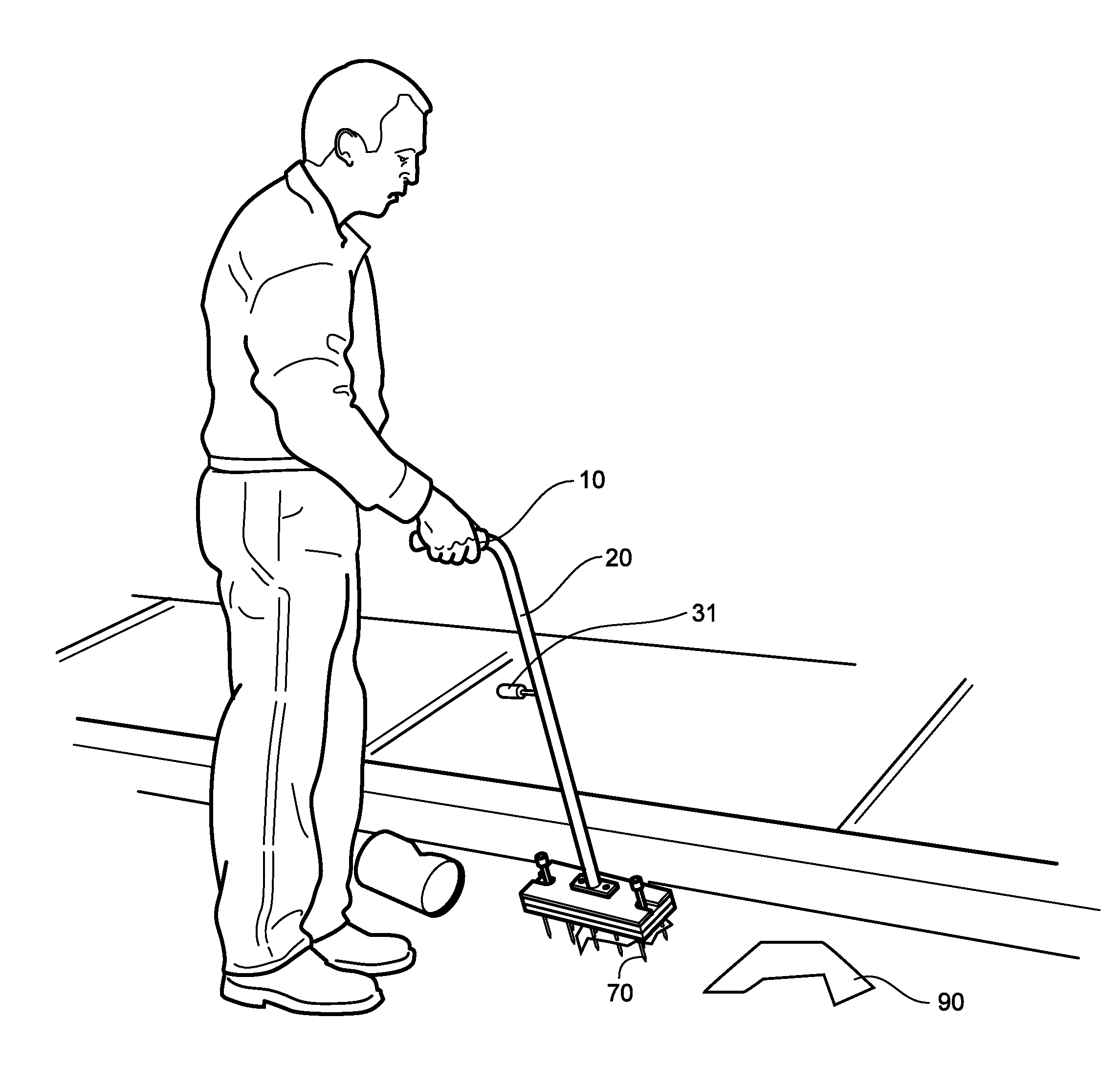

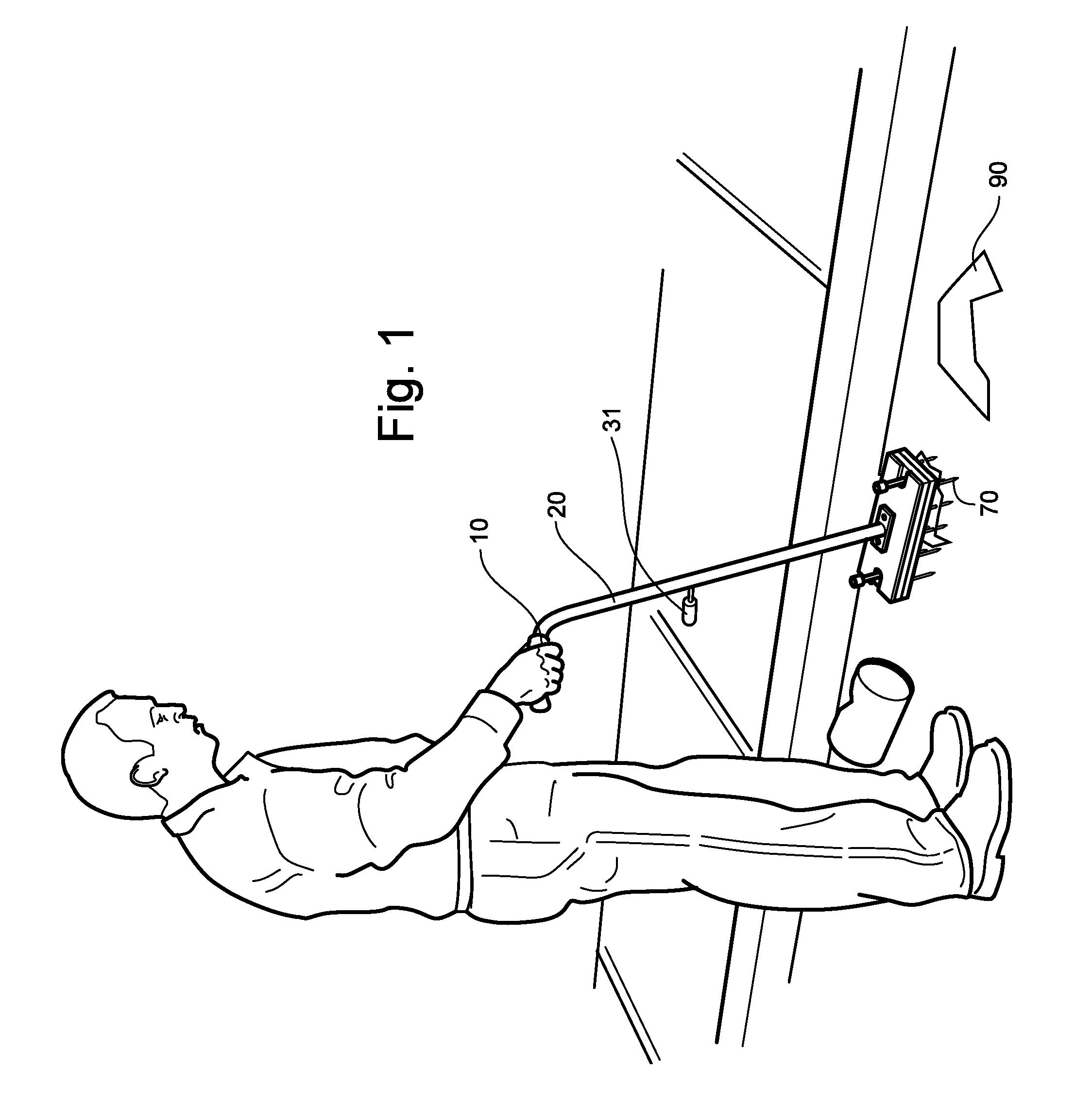

Exercise device and methods of use

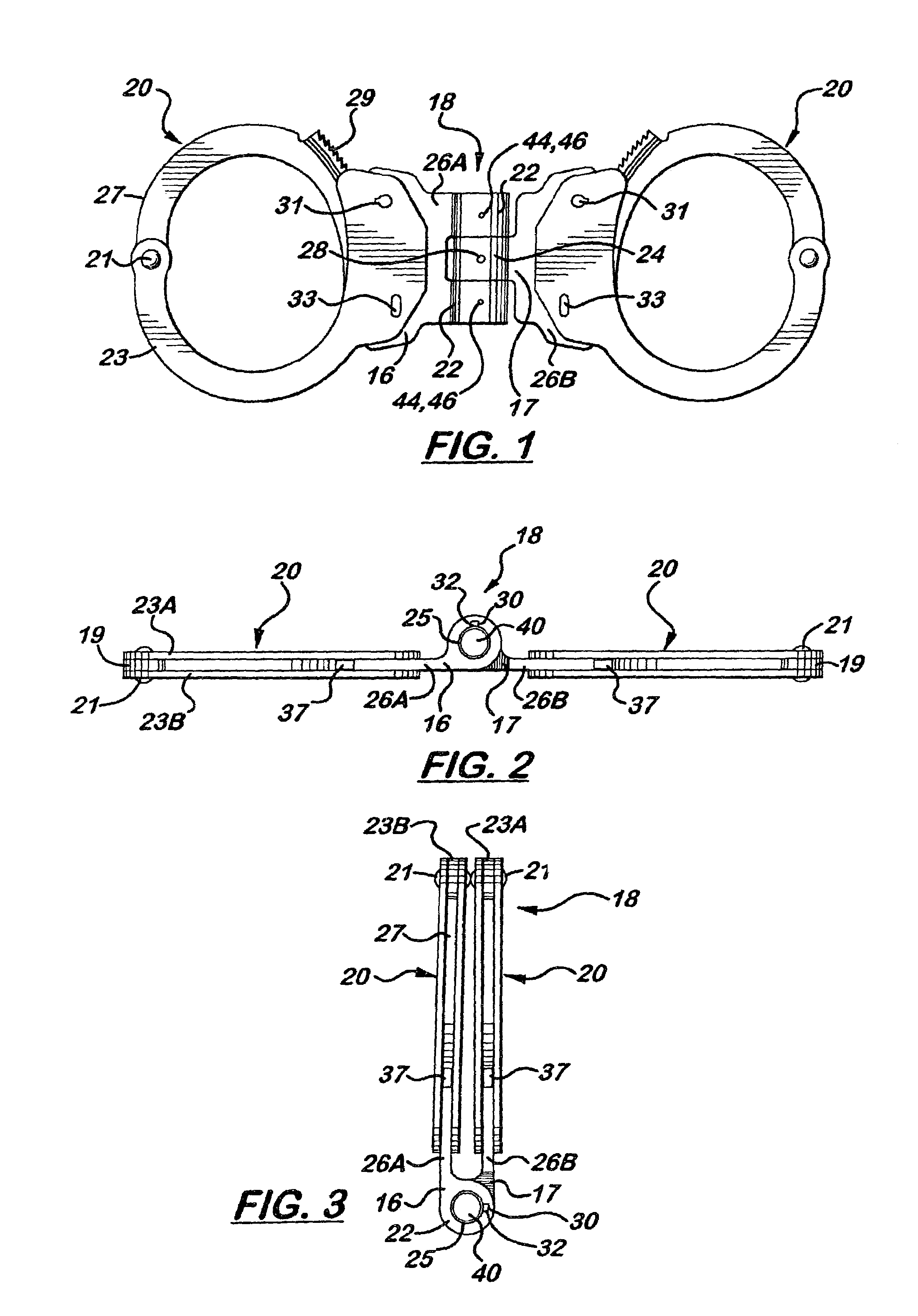

ActiveUS8337372B1Sufficient structural rigiditySolve the lack of rigiditySpadesDumb-bellsEngineeringStructural rigidity

The invention relates to an exercise device for use by a user on a selected surface material comprising a grasping member having a first end and a second end, a first tool head mounted to the first end of the grasping member and a second tool head mounted to the second end of the grasping member. Each of the first tool head and the second tool head has sufficient structural rigidity to be interacted with the surface material without significant deformation whereby a user can perform exercises upon the selected surface material by physically interacting the first tool head and second tool head with the surface material.

Owner:BEACHFIT

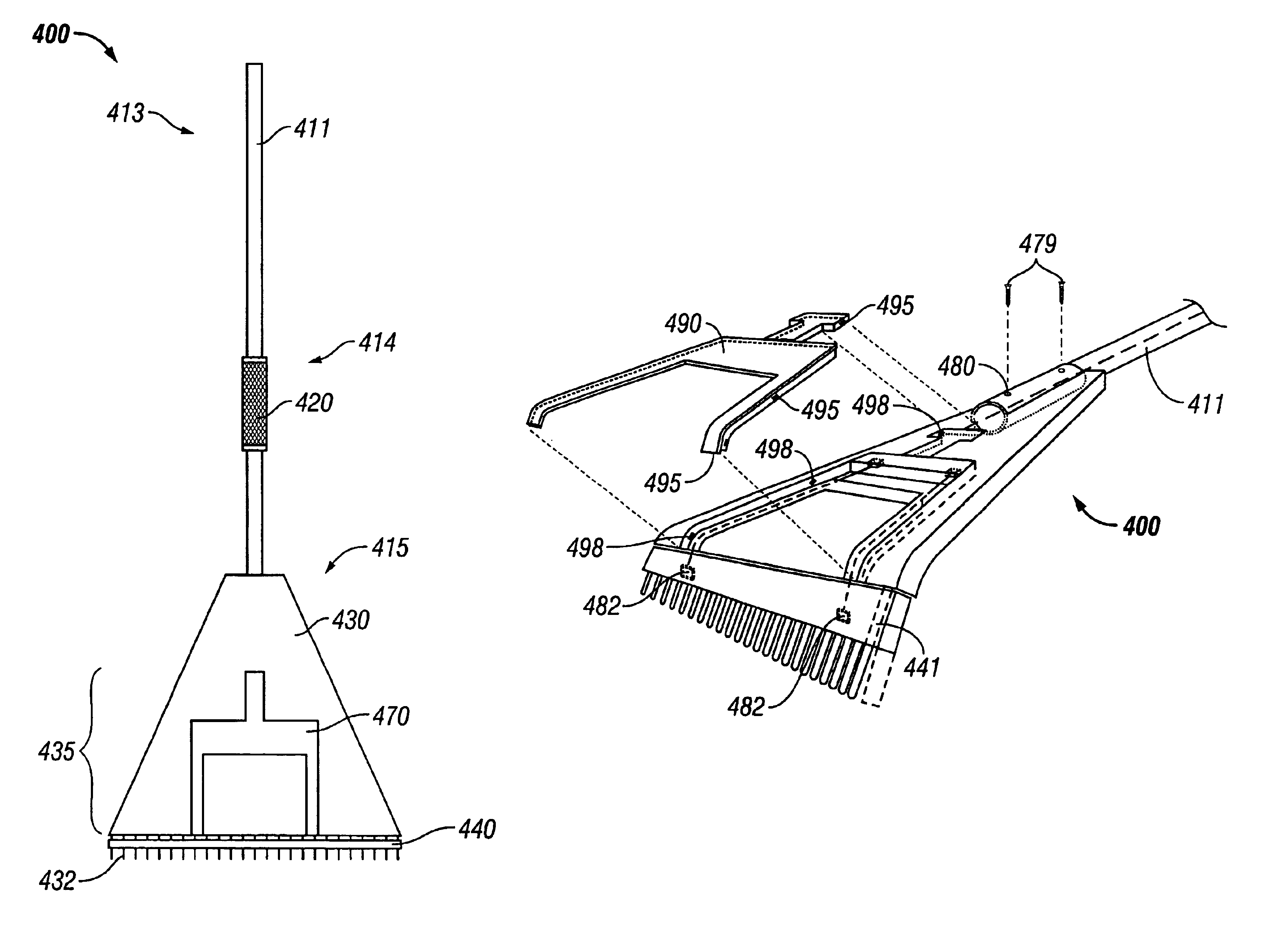

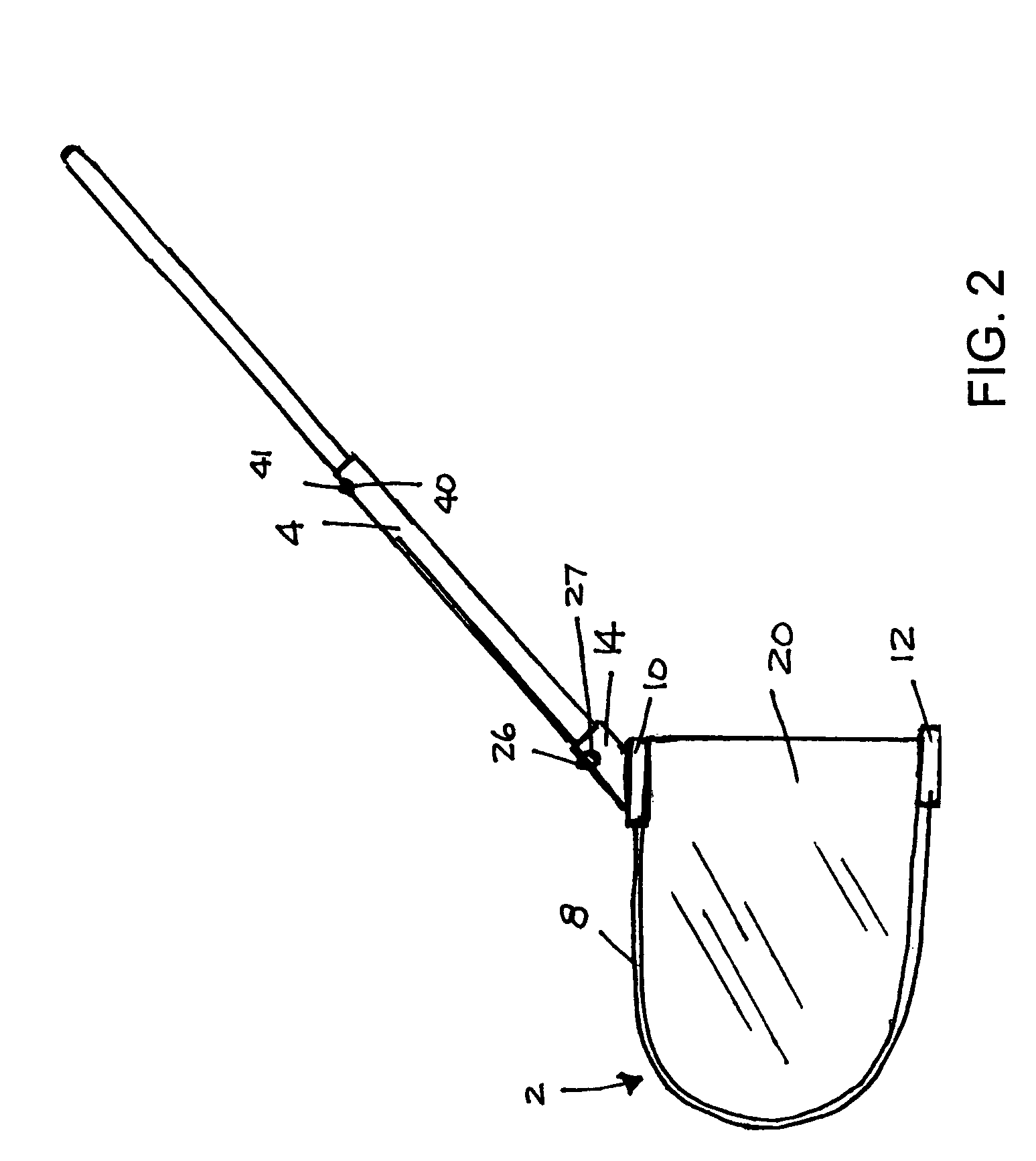

Self-cleaning rake

A rake having a self-cleaning mechanism and method of its manufacture. The rake comprises a handle, a body, a plurality of tines extending from the body, a push-rod extending along the handle to the body, a push rod actuator for extending and retrieving the push-rod, an actuator bar slidingly attached to the body and connected to the push-rod, at least one extender connected to the actuator bar, and a cleaning bar attached to the extender(s). The cleaning bar has a plurality of cleaning channels, one for each tine and is extended and retrieved along the tines when the push-rod actuator is actuated. Each of the cleaning channels has a shape and a size that generally corresponds to a shape and a size of a respective one of the tines. Upon actuation, cleaning bar moves along the tines such that the cleaning channels remove debris from the tines.

Owner:FALLING LEAF INNOVATIONS

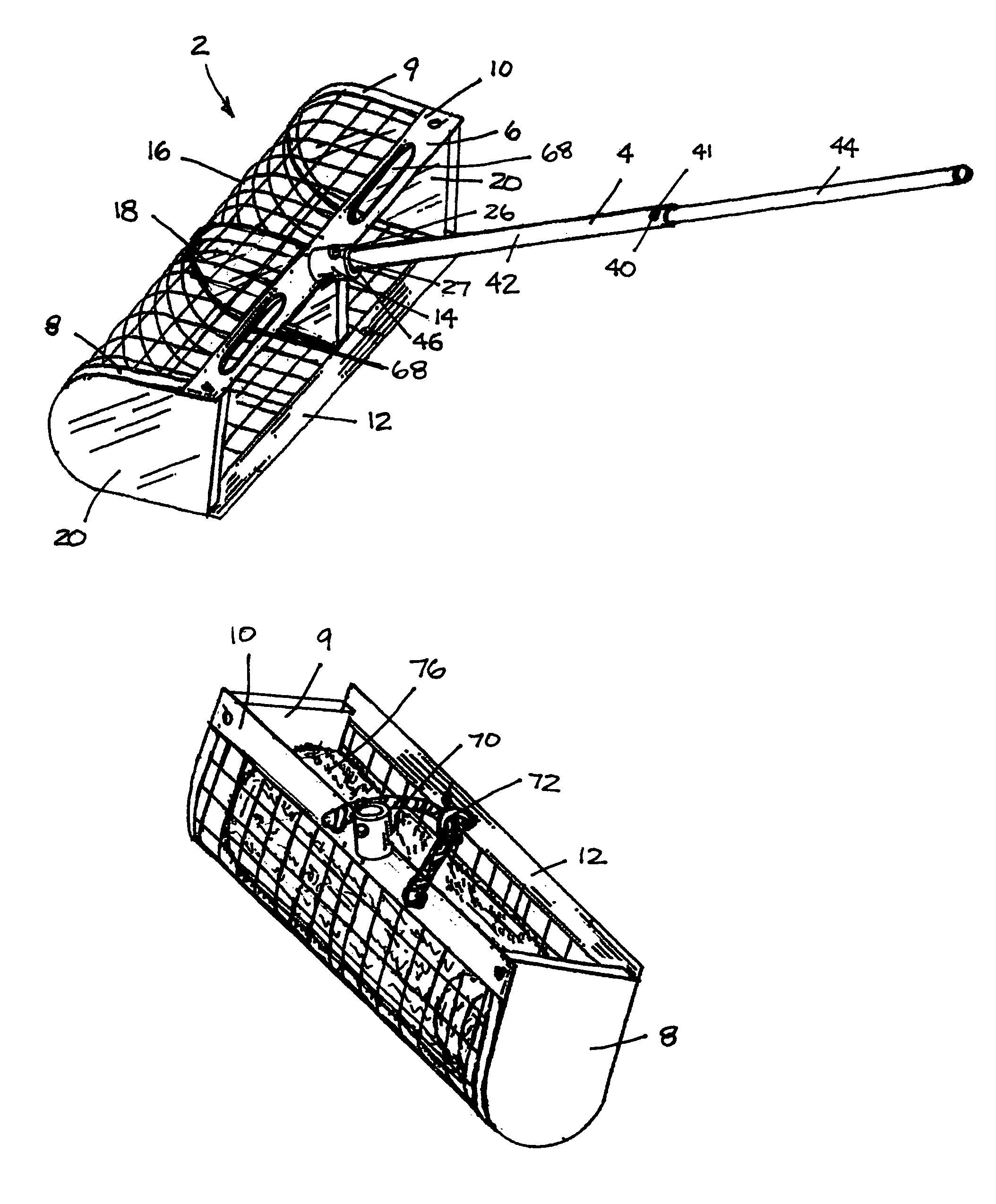

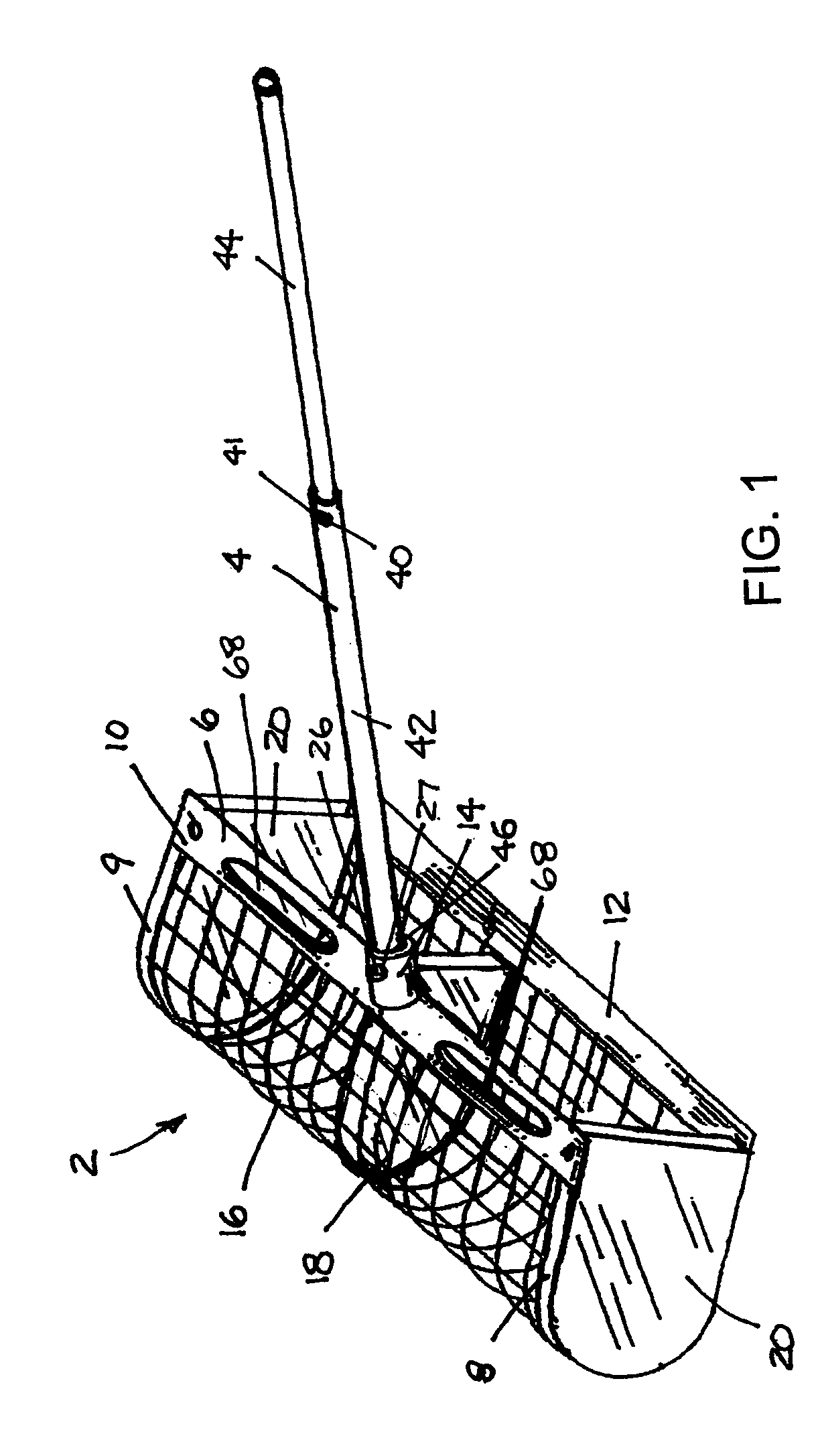

Multi-purpose rake

InactiveUS7111741B2Easy to disassembleEasy to transportSievingHand-operated machines/dredgersMechanical engineeringWire mesh

The multi-purpose rake includes a rake head and a detachable pole for pulling the rake across a surface. The rake head has a frame with two arced end ribs, an upper and a lower crossbar extending between the end ribs. The upper crossbar has a sleeve or other attachment means extending therefrom for receiving and retaining one end of the pole. A wire mesh cage is formed into an arc to conform to the end ribs and is attached to the ribs and the upper and lower crossbar. In the preferred embodiment, the end ribs are formed from a continuous panel so that the ends of the rake head are fully closed. The detachable pole is preferably constructed in multiple sections that can be broken down for easy transport. Optional clips or other retainers may be disposed on the rake head for retaining the pole sections for easy transport and storage. An optional handhold can be provided for facilitating transport of the disassembled rake.

Owner:BRAMANTE JOSEPH

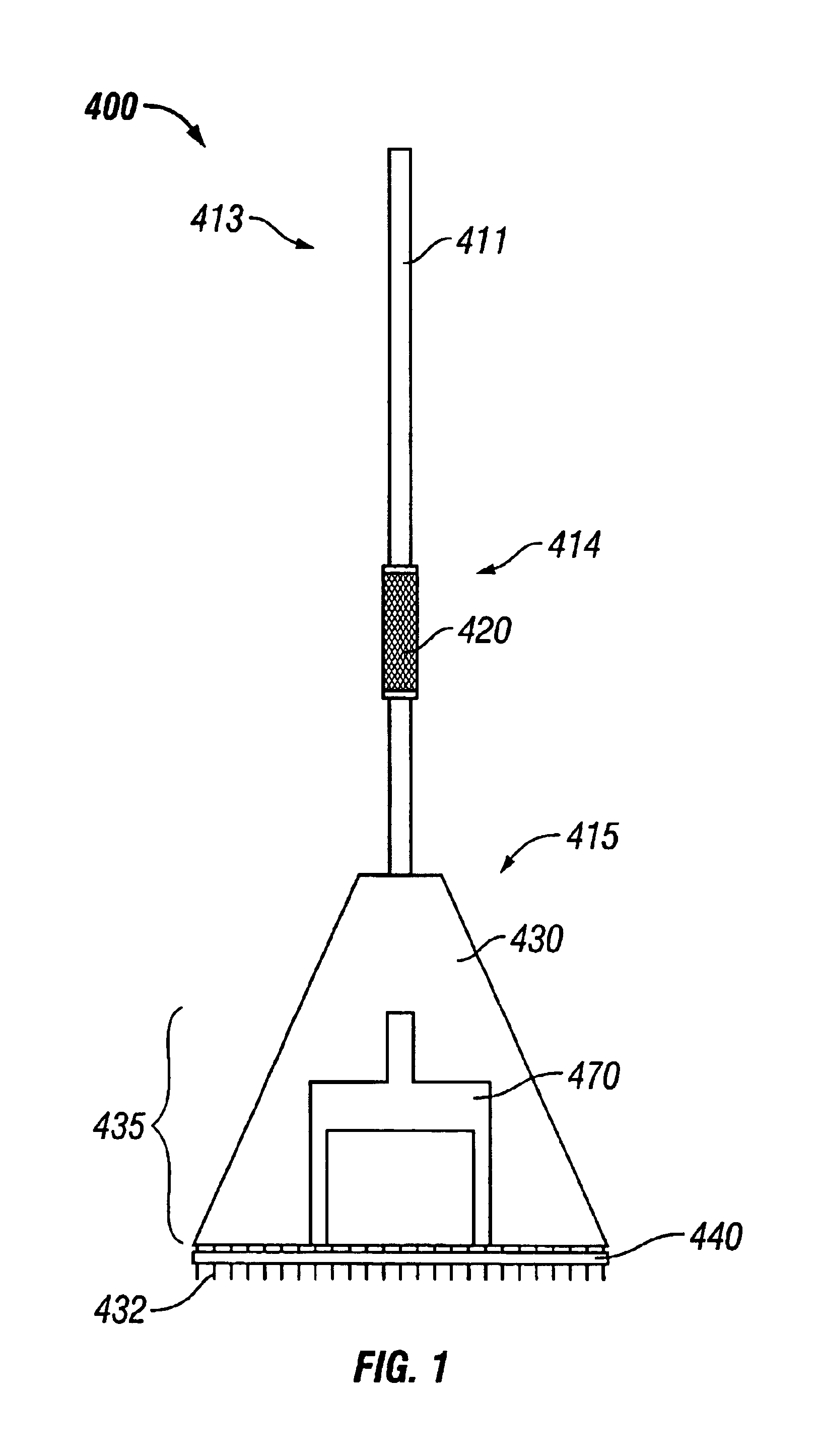

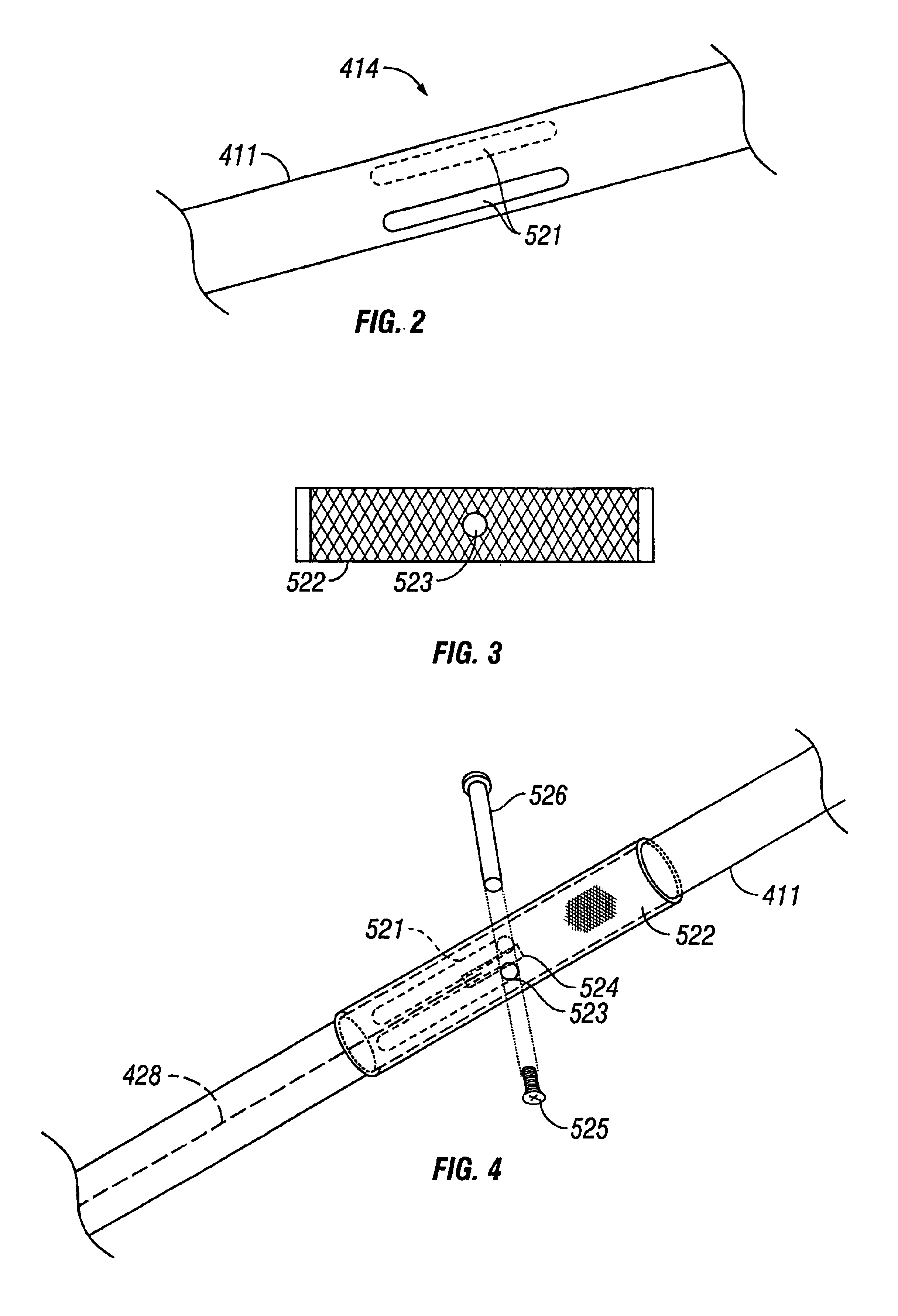

Hand tool stand

A hand tool (or an add-on accessory for the hand tool) with a handle includes one or more retractable arms that, when unfolded and extended maintains the tool in an upright position while the tool is at rest; and an attachment coupling the one or more retractable arms to the handle, the one or more arms rotatably engaged to attachment and the handle and when unfolded the one or more arm maintains the handle in an upright position off the ground to make the tool visible to an operator, wherein the one or more arms are retracted and secured into a closed position against the handle when the operator desires to resume work.

Owner:KIMBALL KIM S

Riding lawn mower leaf rake

A leaf rake for mounting to the chassis of a conventional lawn tractor. Frame kits for attaching the leaf rake to either the front or rear of the tractor for various manufacturers. The lawn tractor may be equipped with hydraulic systems for raising or lowering the leaf rake unit. A spring loaded locking hinge mechanism allows the unit to be raised. Designed leaf raking tines and a forward sweeping leaf rake collect the leaves and allow them to be piled up for disposal.

Owner:BECKETT JAMES

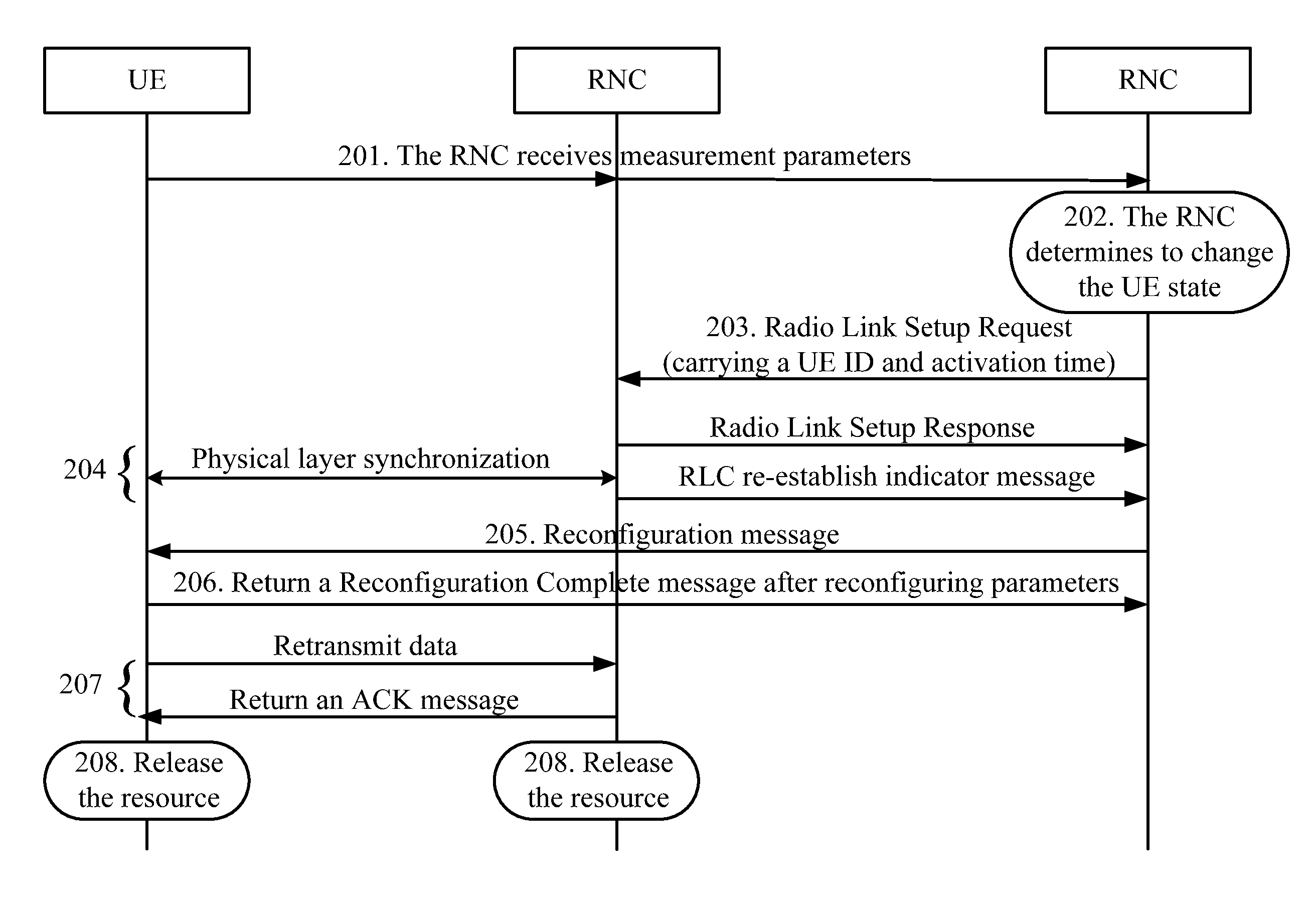

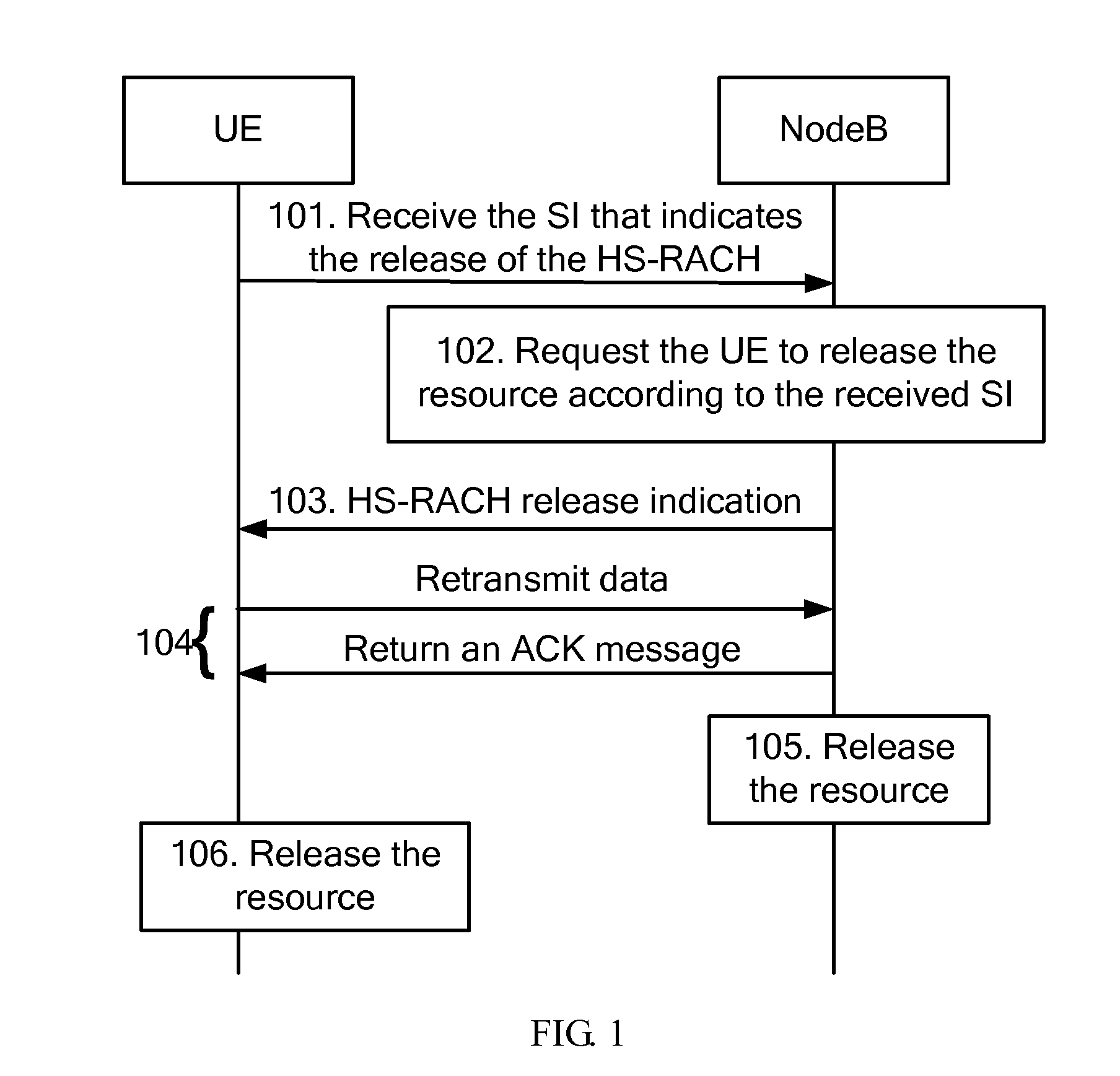

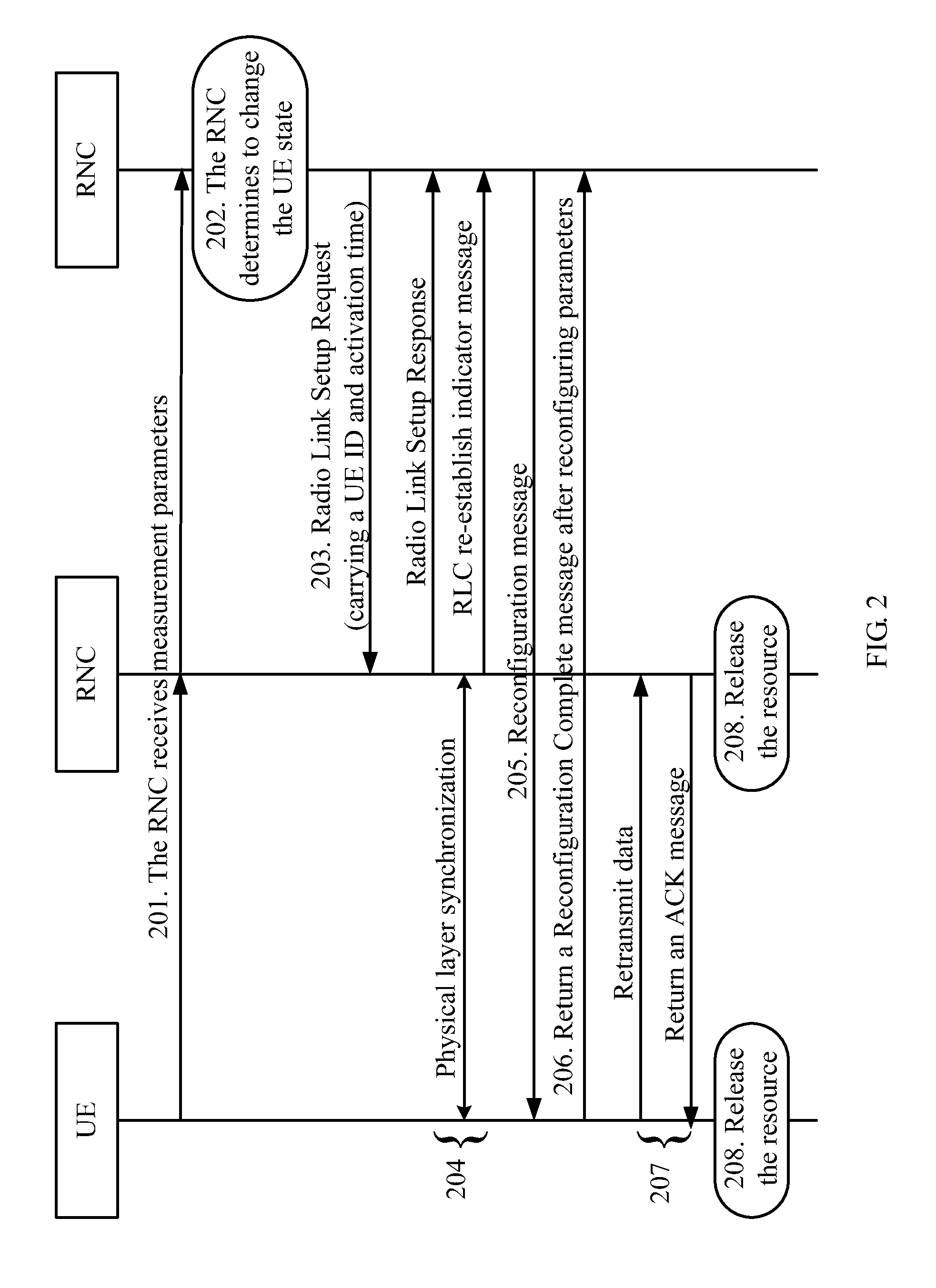

Resource Release Method, Communication Equipment, and Network System

InactiveUS20100265919A1Accelerated programSuitable for applicationSimultaneous amplitude and angle demodulationWhetstone containersNetworked systemRandom-access channel

A method for releasing resources includes obtaining trigger information; determining to release an allocated high-speed random access channel (HS-RACH) resource according to the obtained trigger information; and releasing the allocated HS-RACH resource at the local end.

Owner:HUAWEI TECH CO LTD

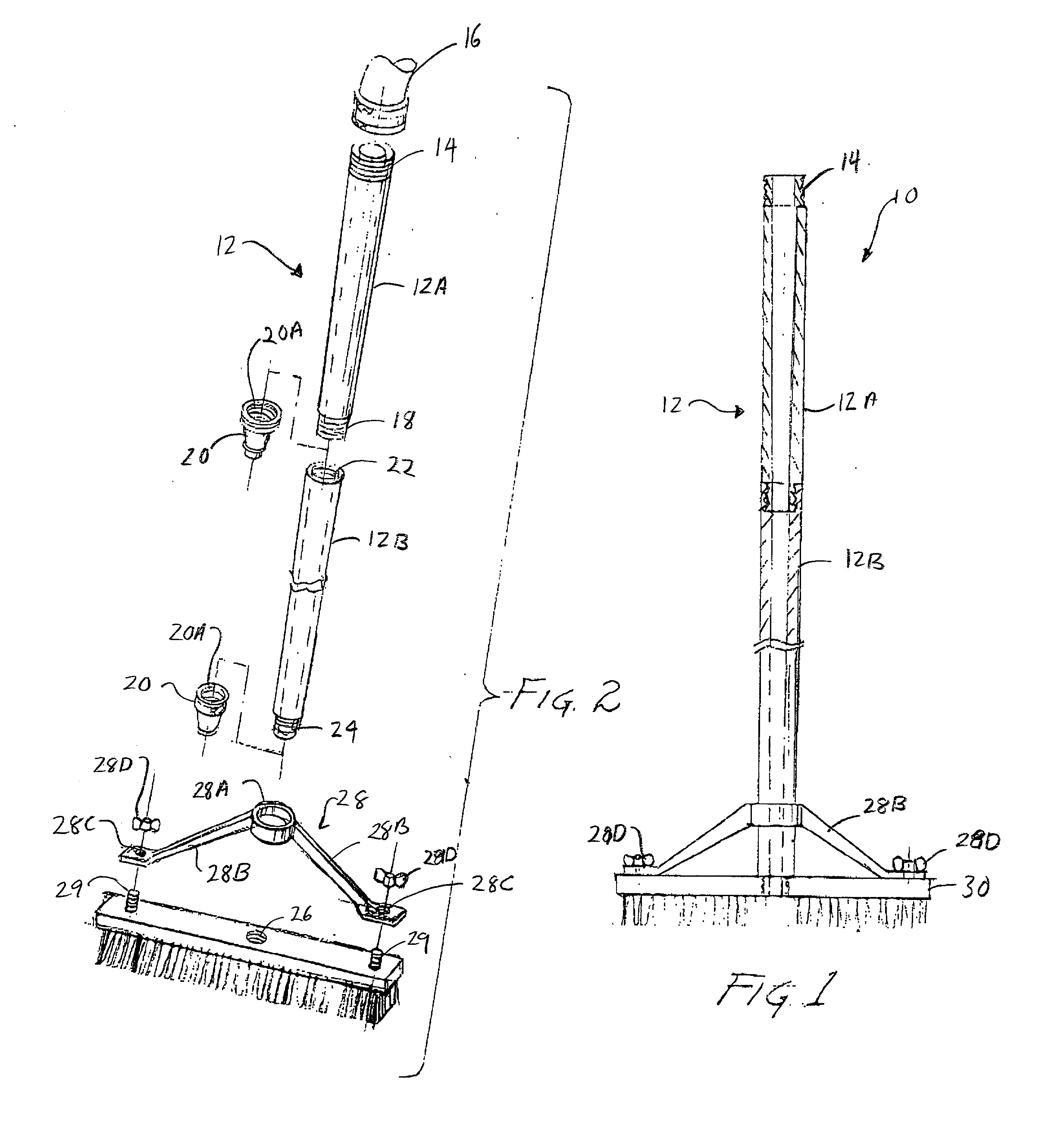

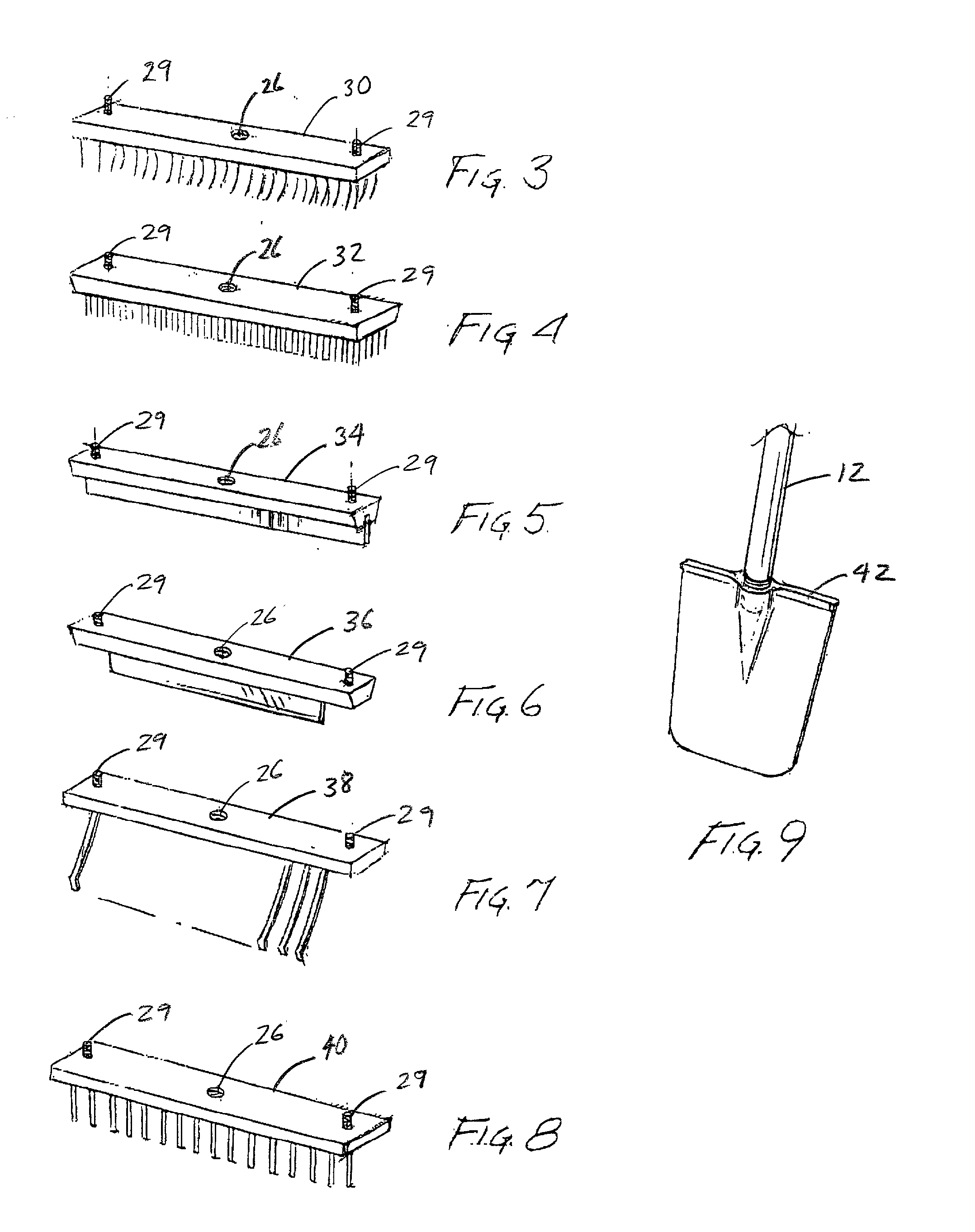

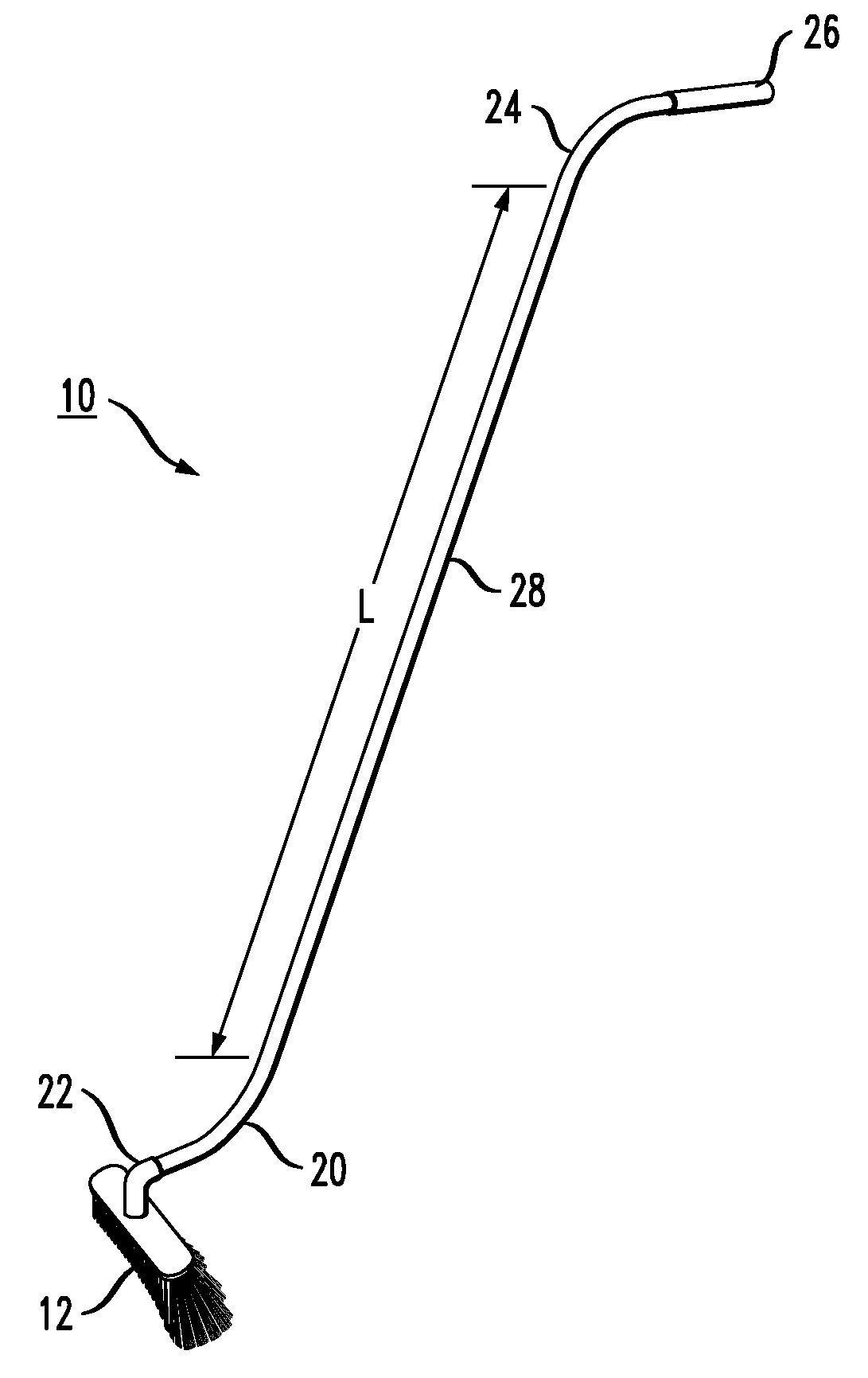

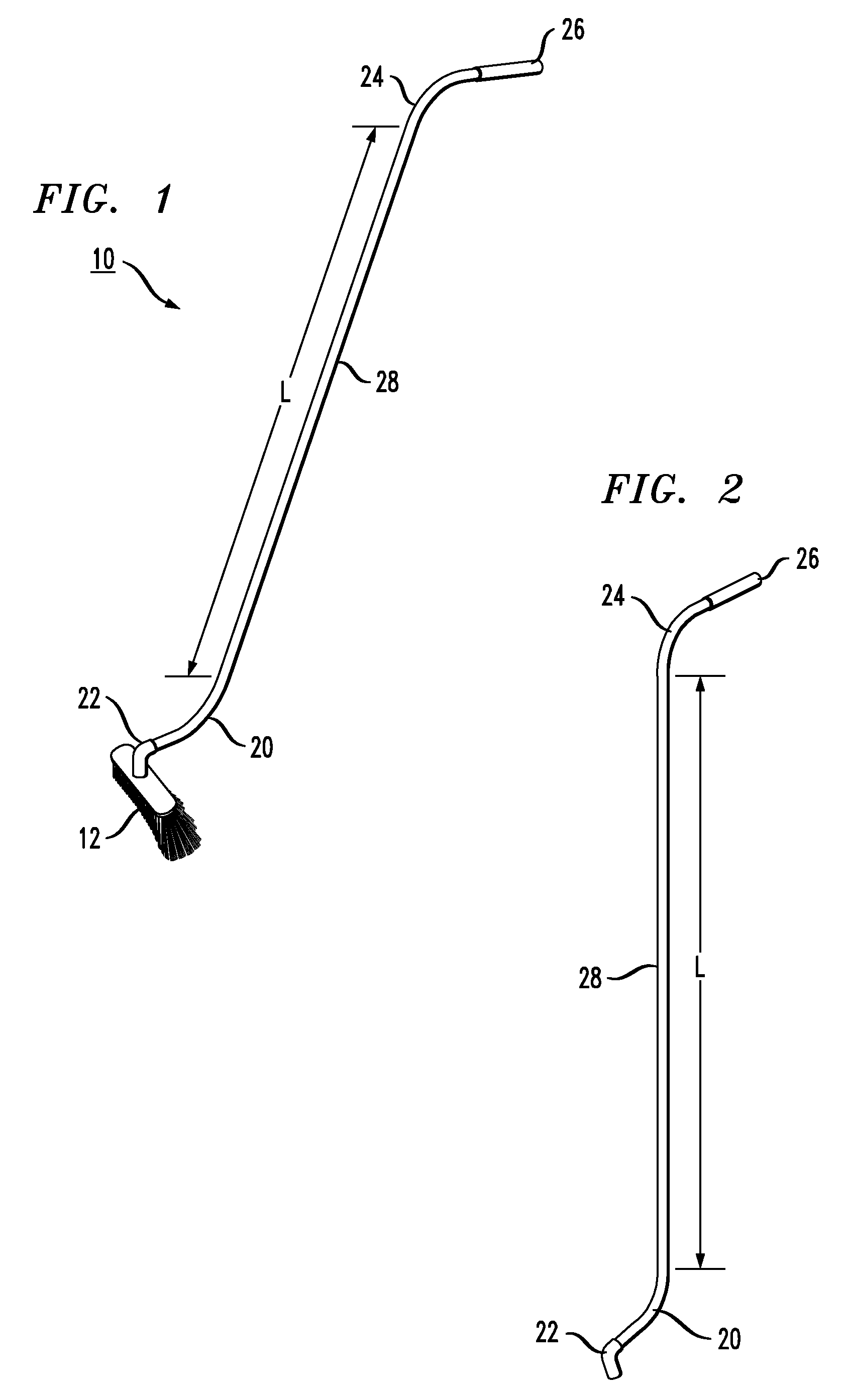

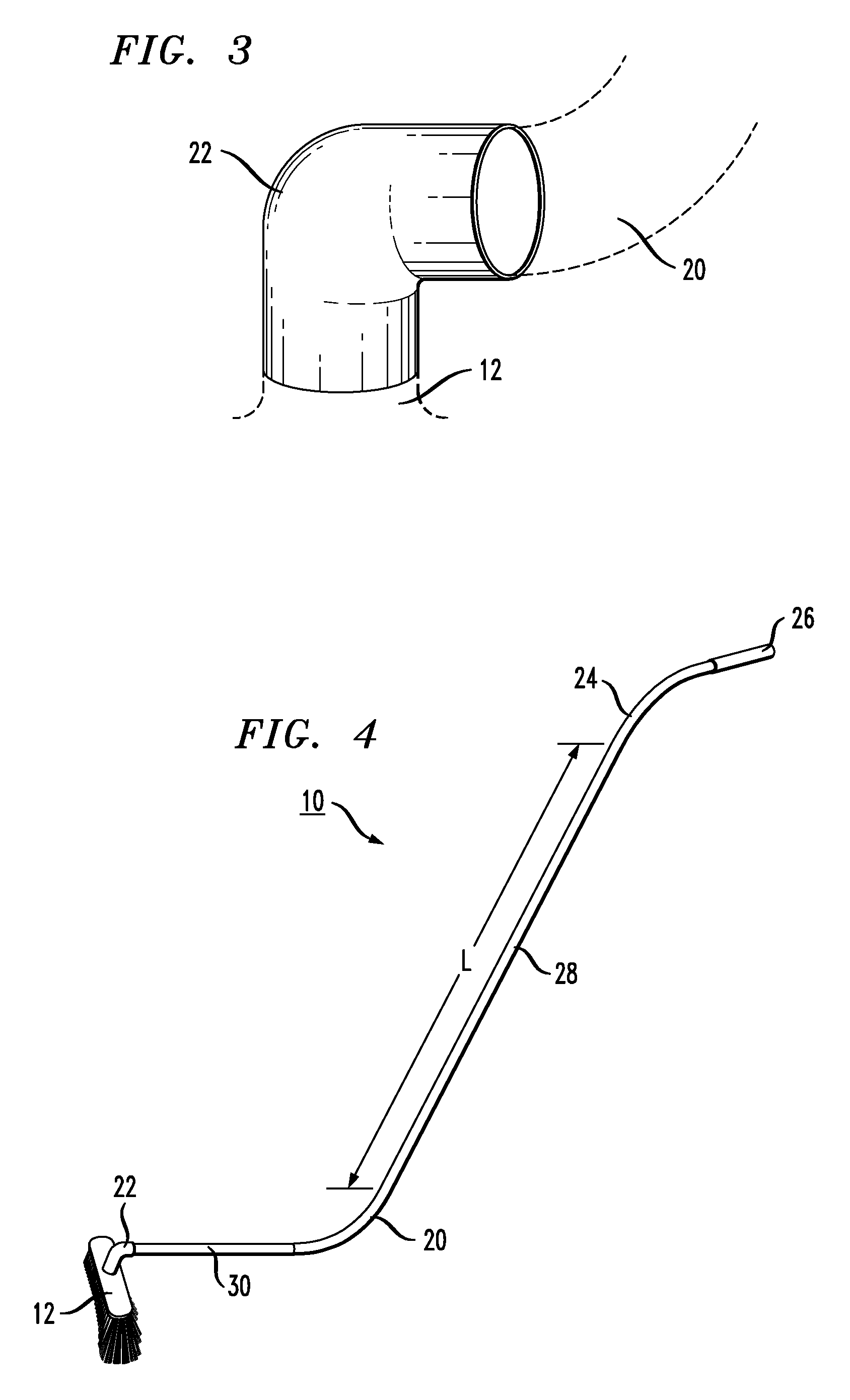

Ergonomically-configured handle for cleaning devices

InactiveUS8375499B1Reduce back strainReduce usageSpadesTravelling carriersBroomMechanical engineering

An ergonomically-configured handle for tools such as cleaning devices and, more particularly, to a handle for a broom or mop (for example) is formed with curved end terminations to reduce back strain and provide ease of use. A first curved end termination is attached to a tool head (such as a brush, rake head or the like) via an elbow joint. A straight section of handle is then attached to the first curved end termination, where a second curved end termination is then attached to the opposite end of the straight section. A handle grip may be disposed over the termination of the second curved end termination.

Owner:MARINO RICHARD LEE

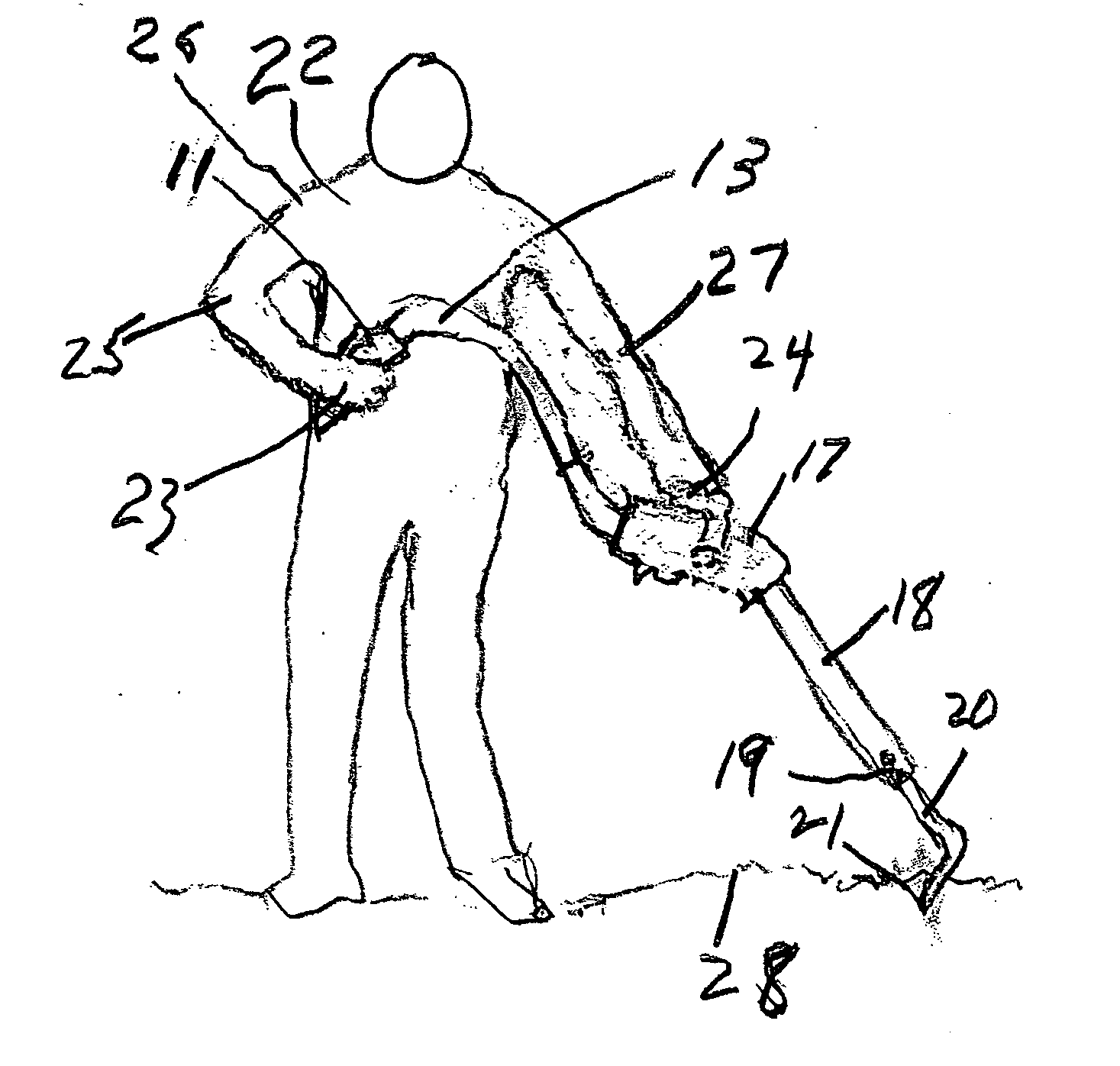

Utility tool handle

InactiveUS20050050689A1Reduce fatigueReduce injuriesWalking sticksTravelling carriersHand heldEngineering

This is a utility tool handle comprising an elongate handle which is especially designed with four straight segments and three curved segments with special hand holds so that a work-person or the like can exert maximum pulling power with a first hand while exerting maximum downward pressure with a second hand.

Owner:BIGGS BLYTH S

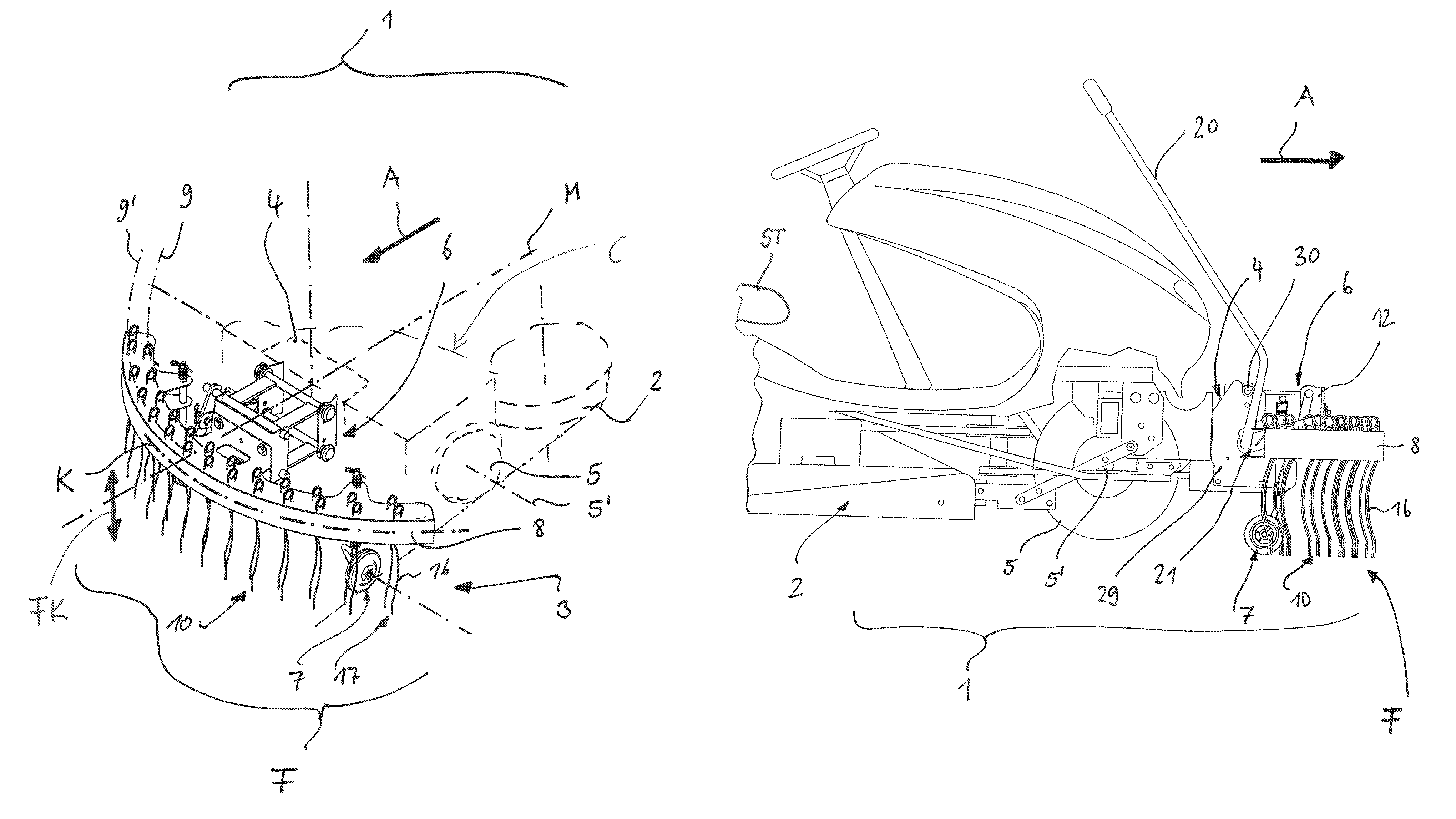

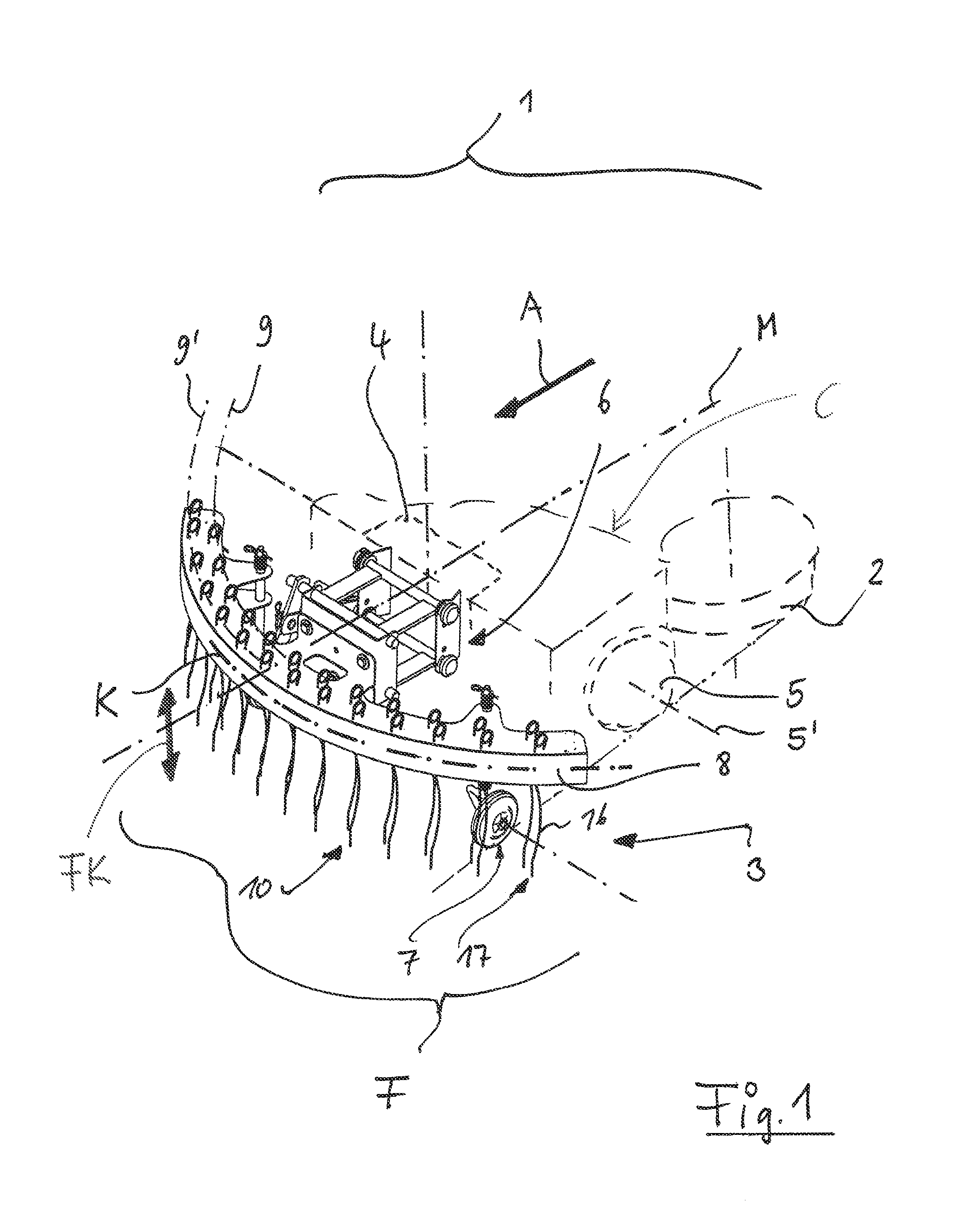

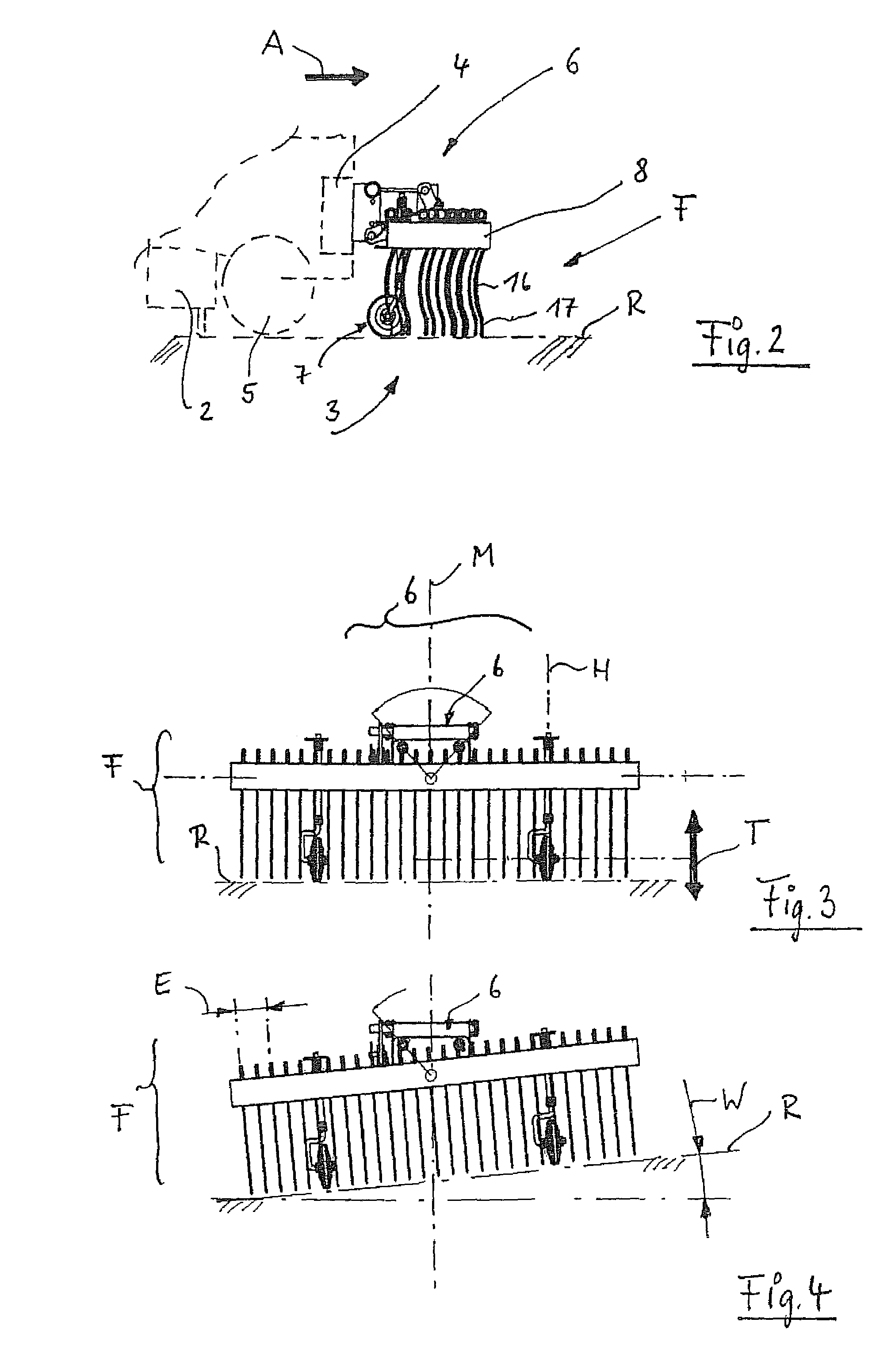

Device for landscape care with spring tine rake

A landscape care device has a first care tool embodied as a mowing device, a sweeping broom, or the like, and at least one second care tool in the form of a spring tine rake arranged in front of the first care tool and acting simultaneously or with time shift relative to the first care tool. A carriage with a front axle is provided, wherein only the spring tine rake is effective in front of the front axle of the carriage. The spring tine rake has spring tines and the spring line rake is designed such that the spring tines are effective by a substantially straight push movement exerted on the spring tine rake.

Owner:TIELBURGER DIRK

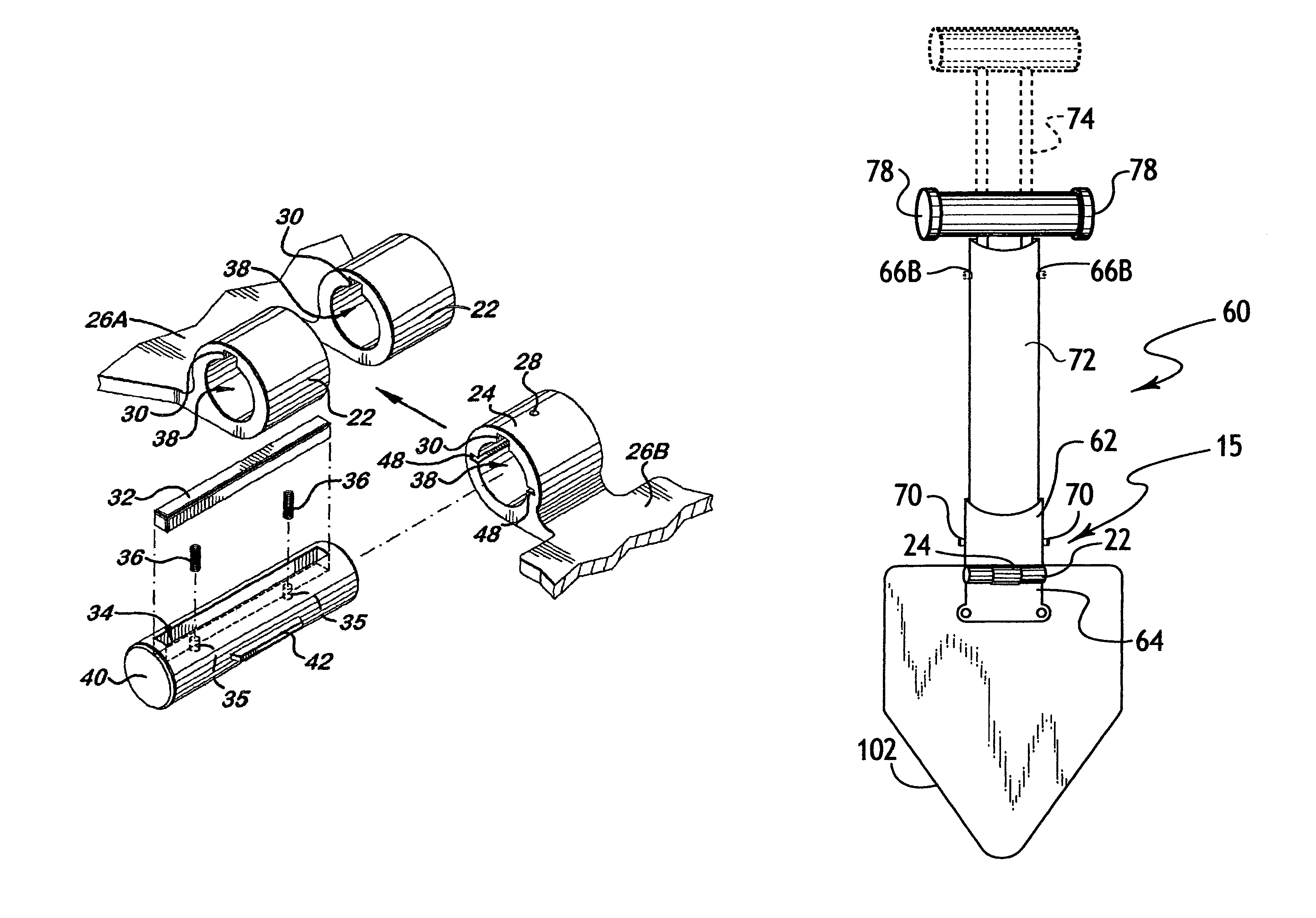

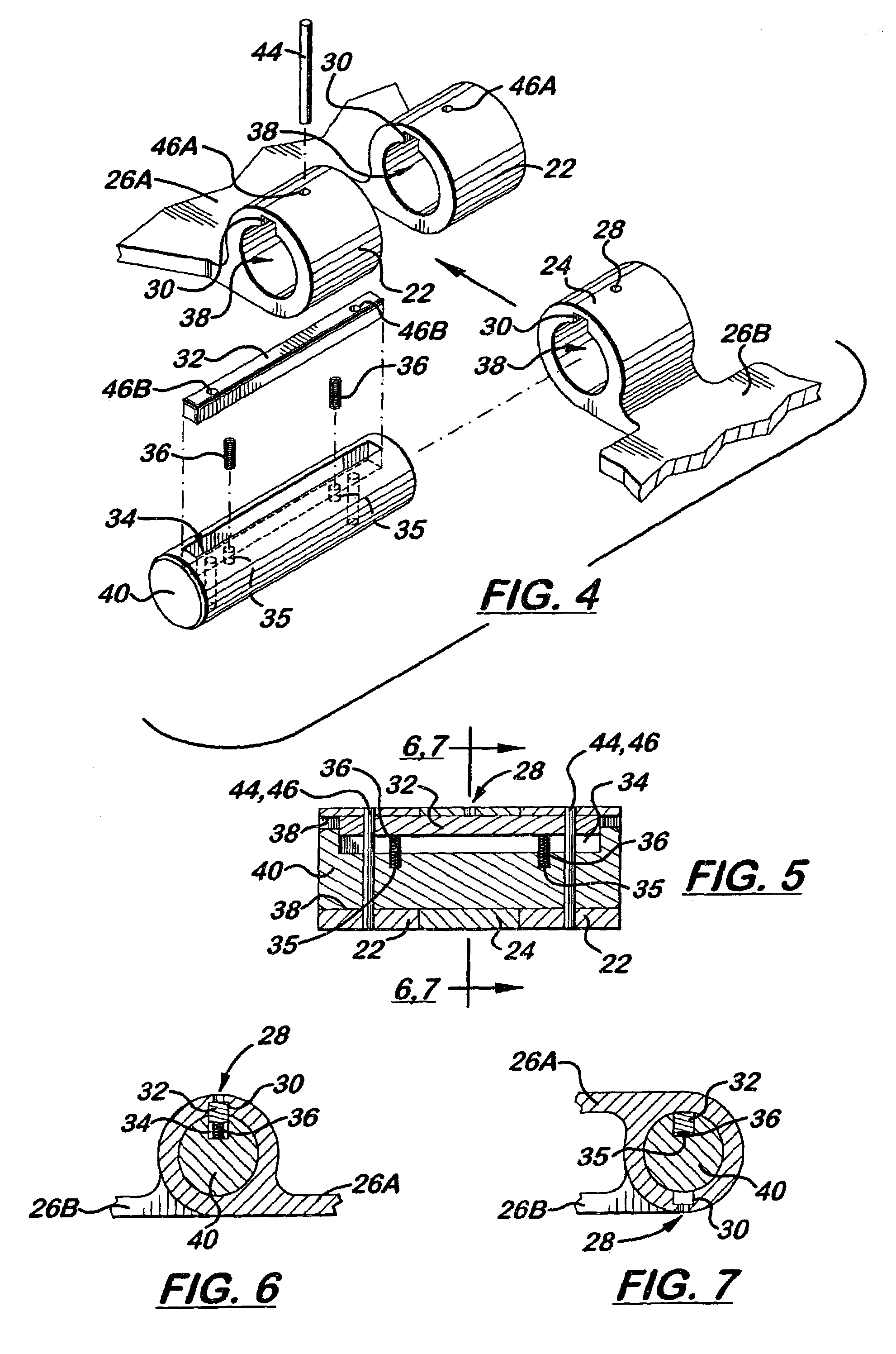

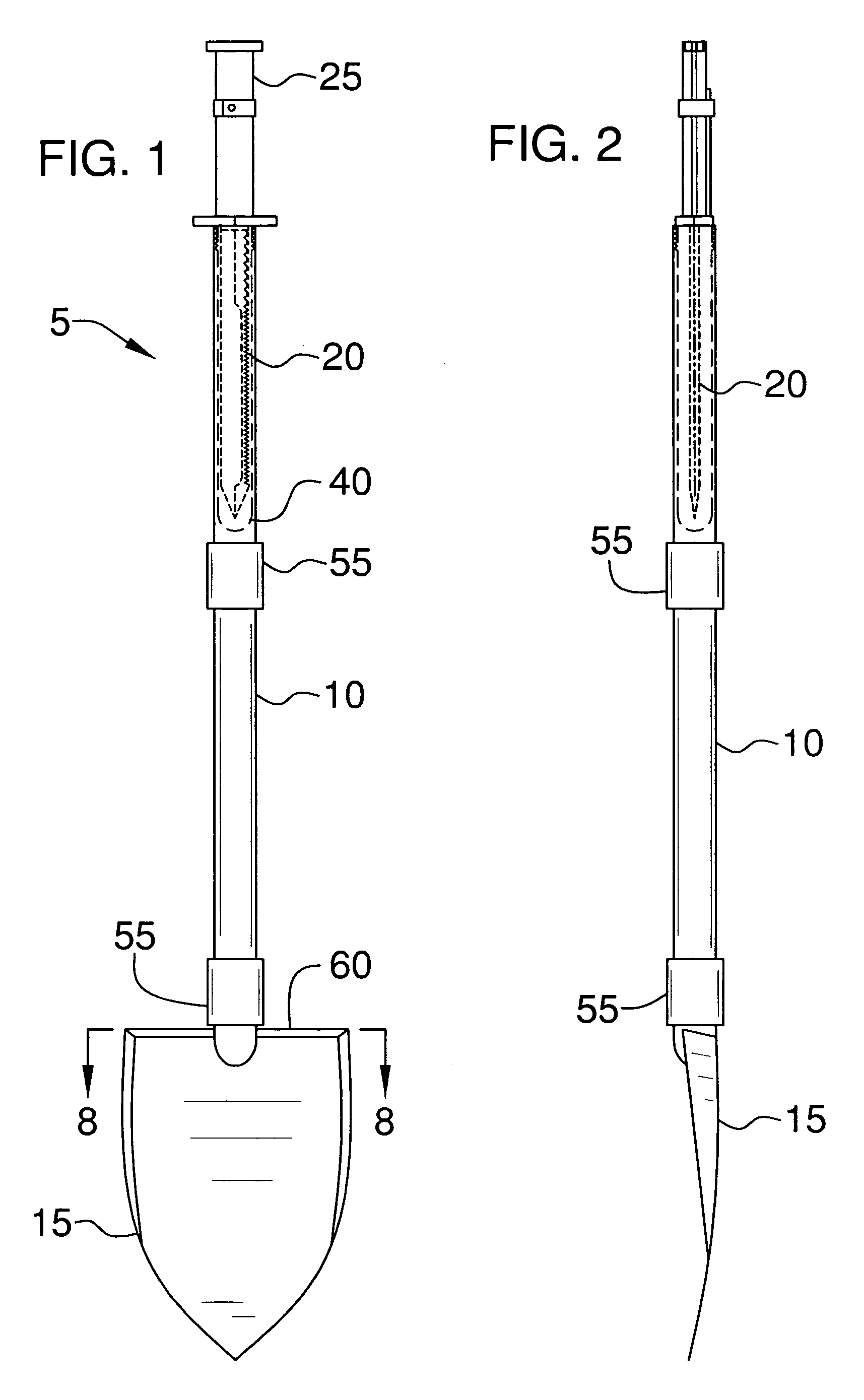

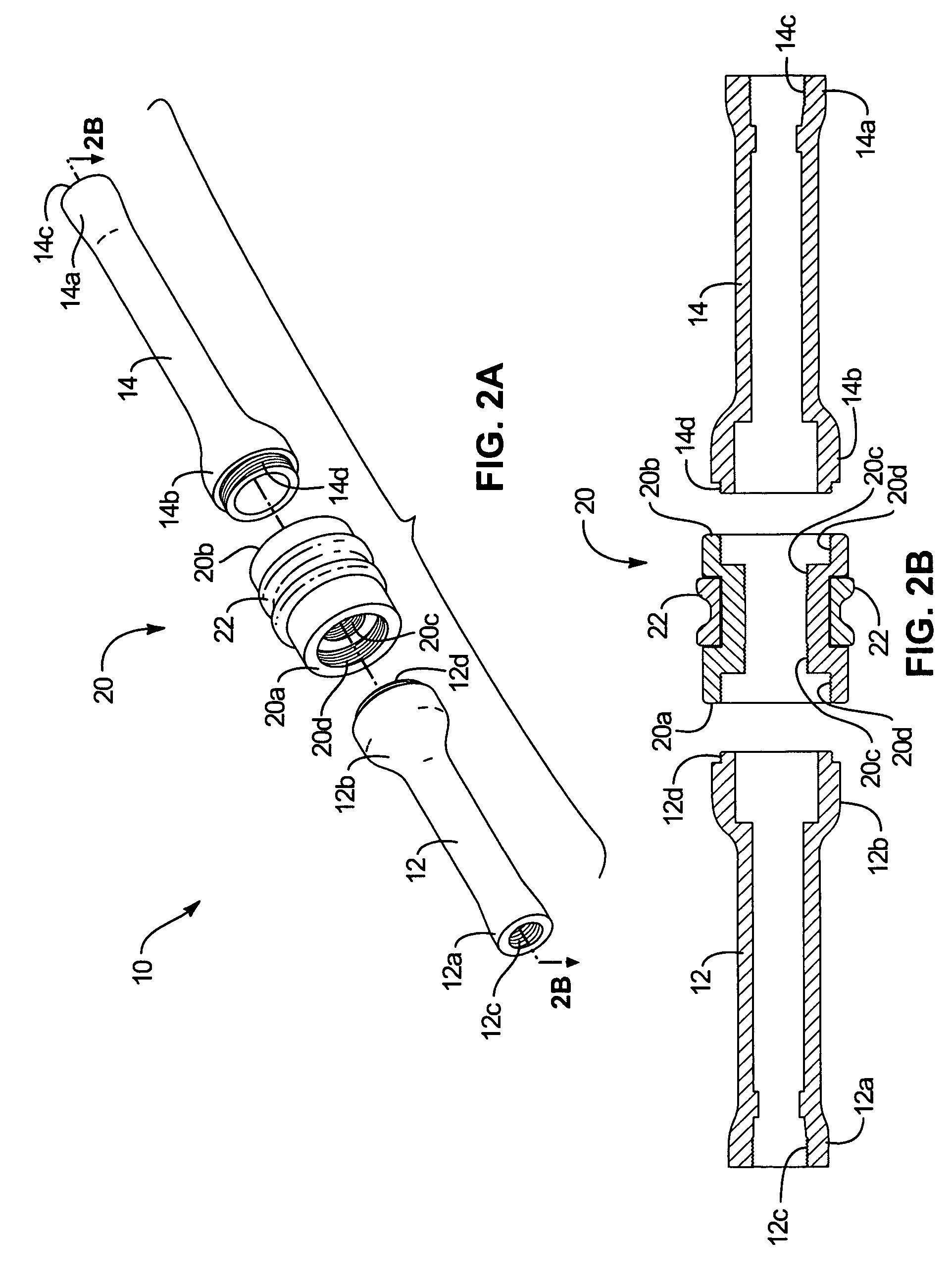

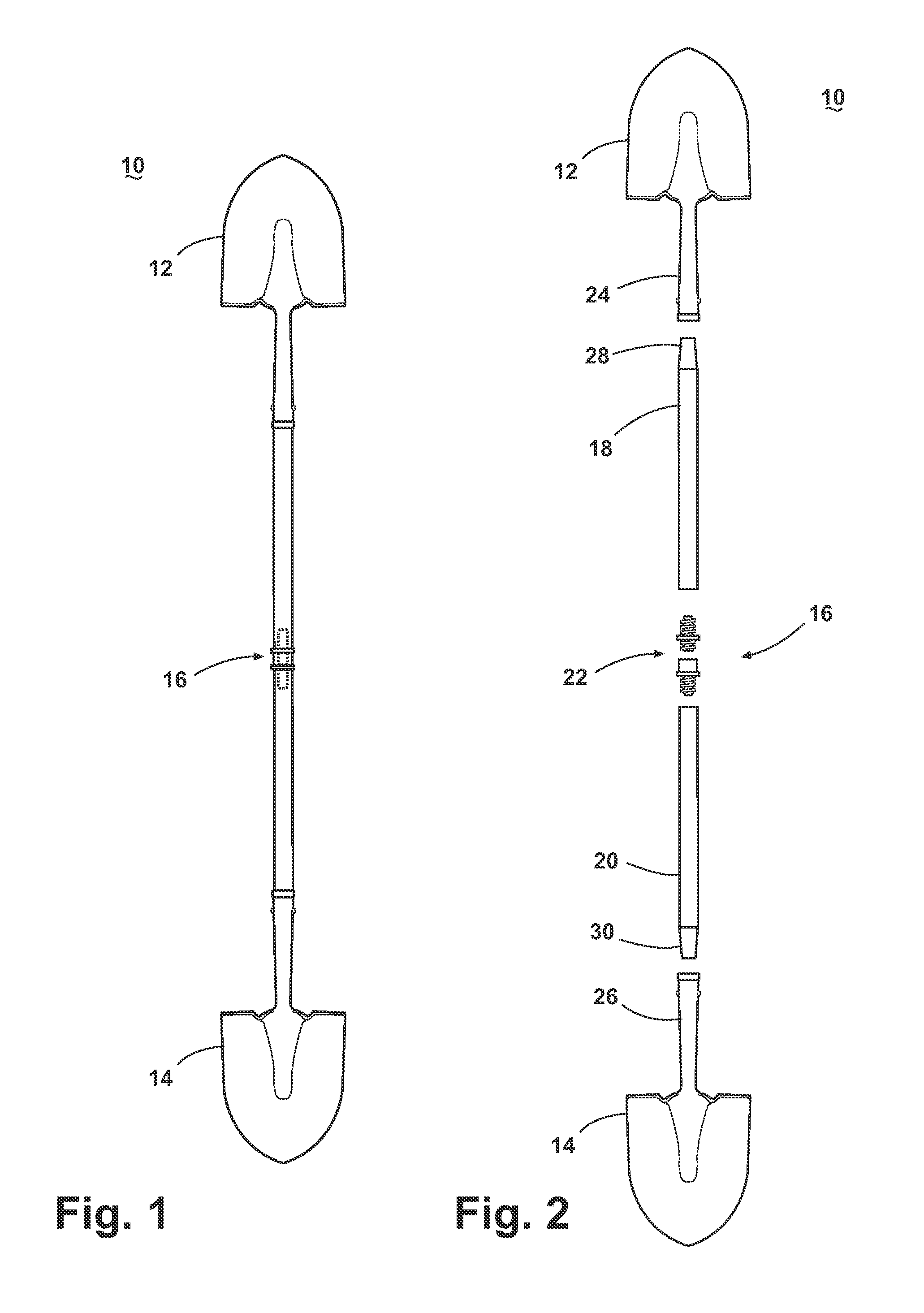

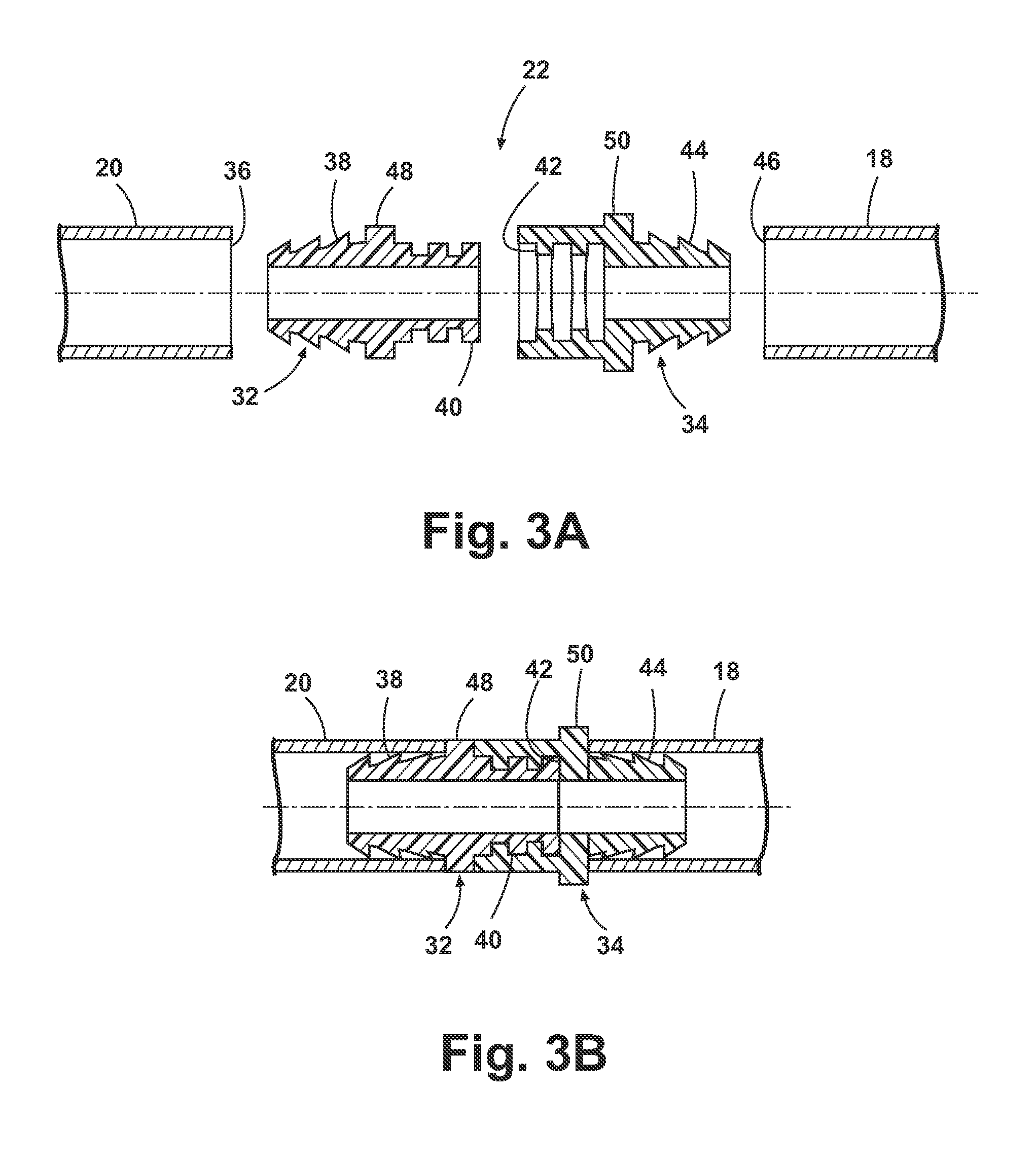

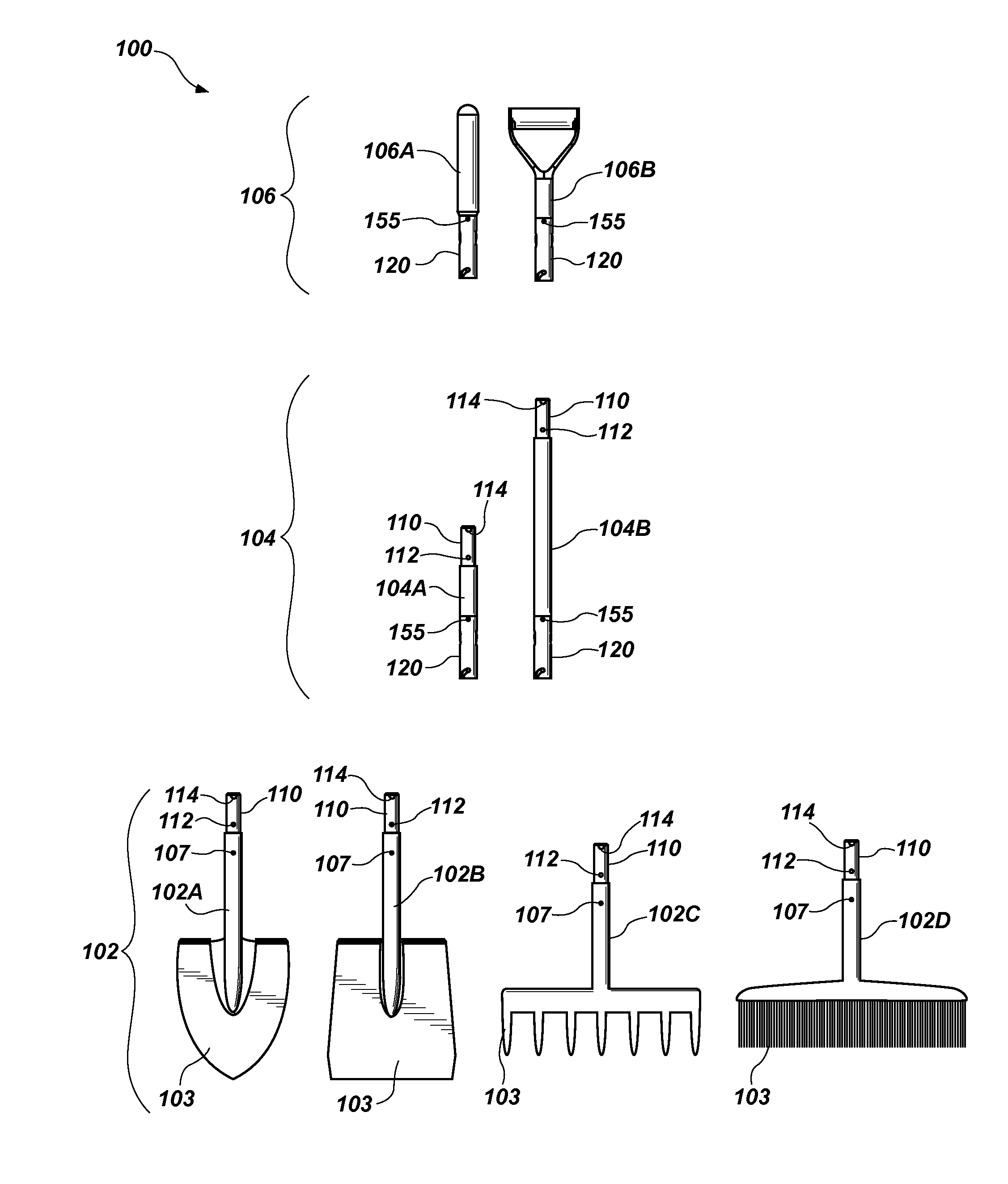

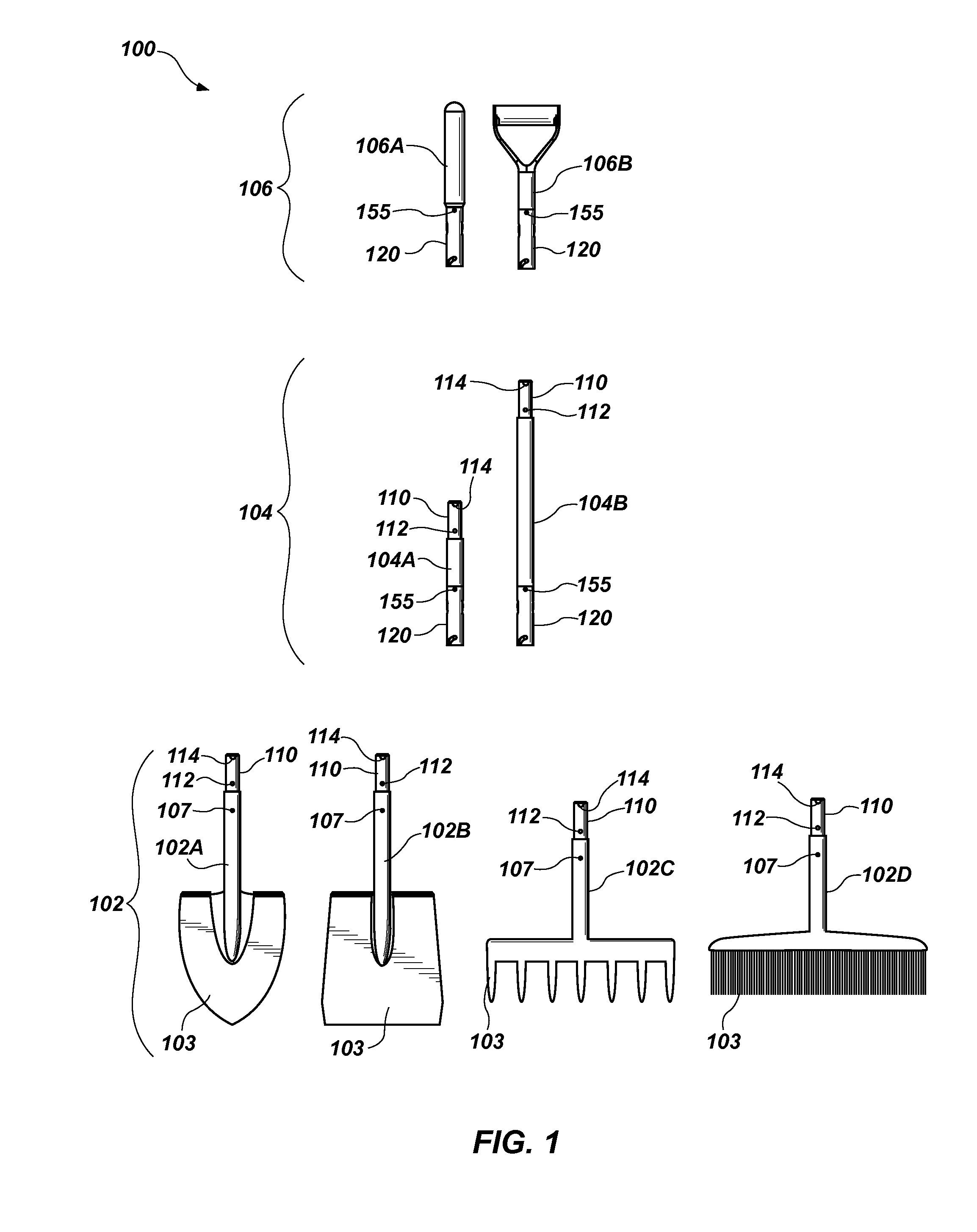

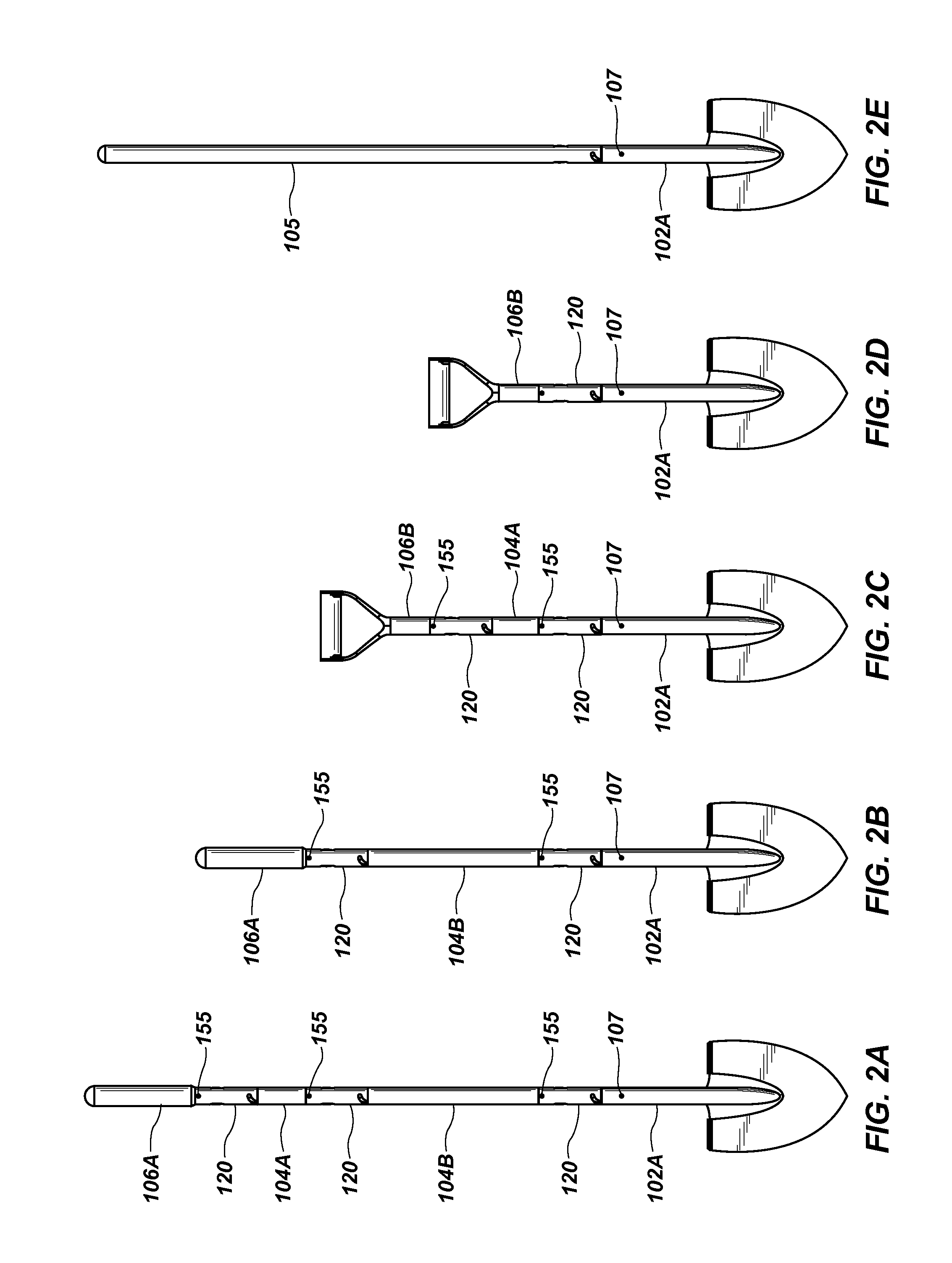

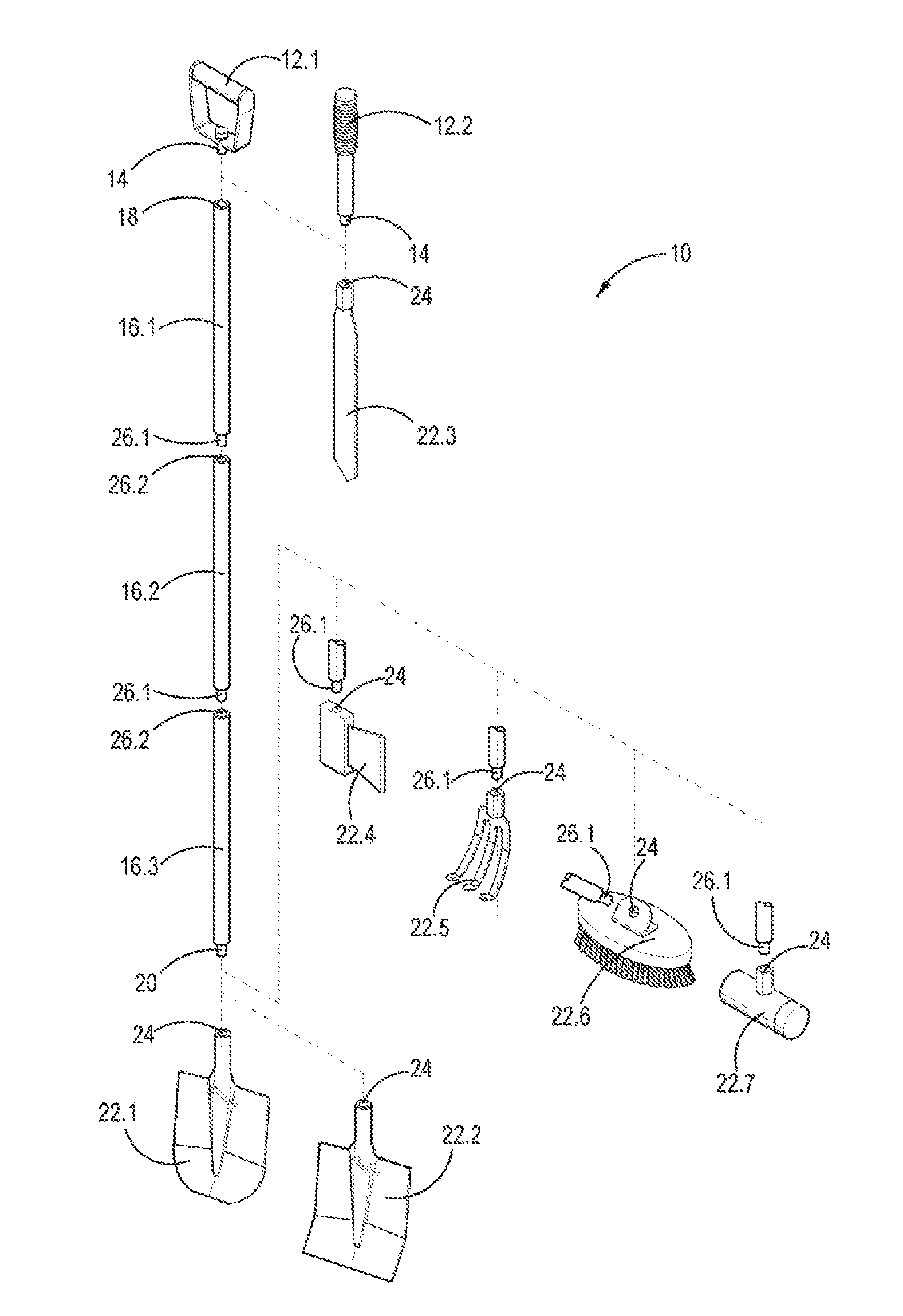

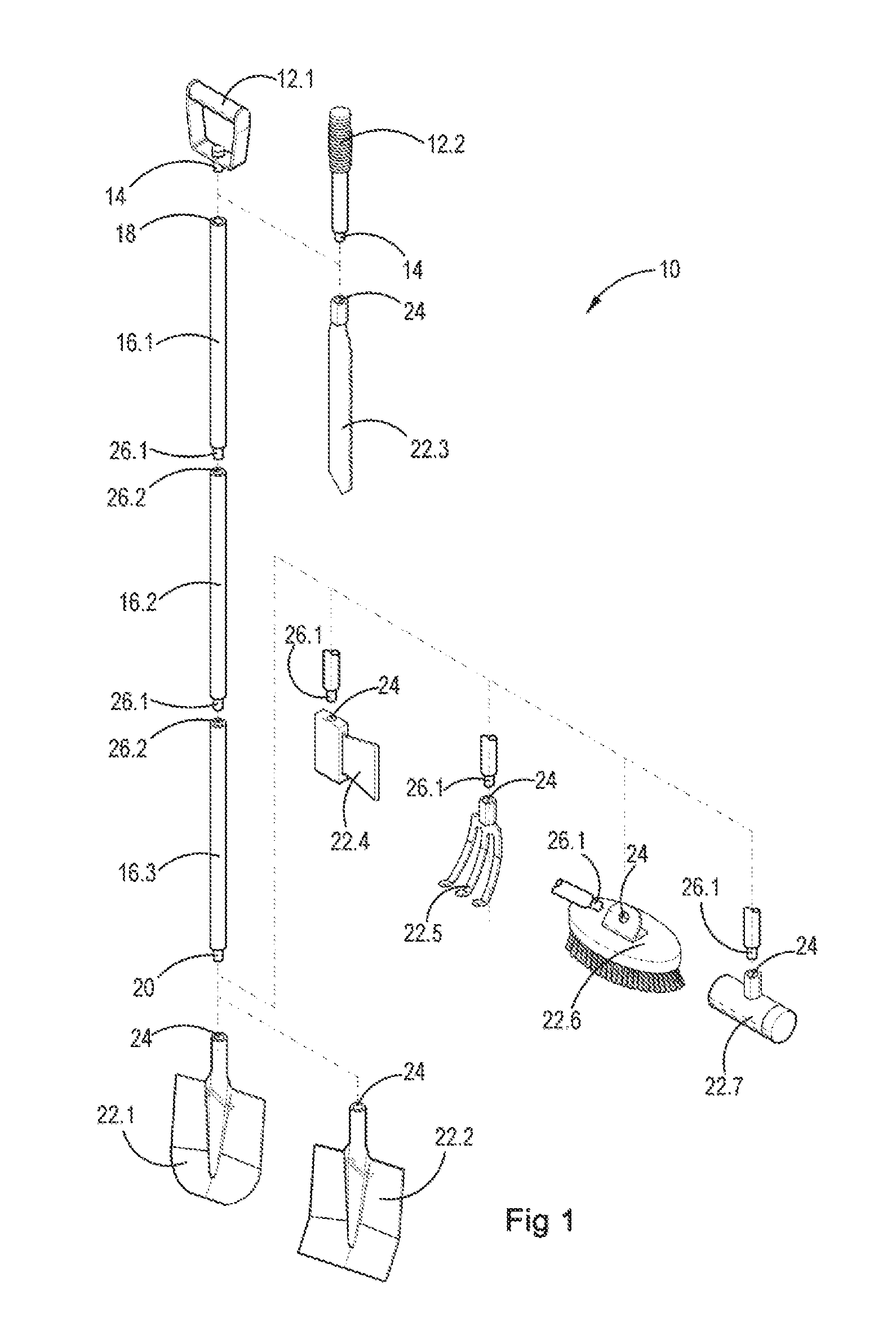

Outdoor tool system with interchangeable modular heads

A multipurpose tool system that can be assembled into multiple configurations by a user. The tool system may comprise a plurality of components, including tool heads, shaft segments, and handle ends. The components of the tool system can be combined in various configurations to provide different functions, at different lengths. Connectors may be utilized to connect the various components of the system using a twist lock mechanism. The connectors may include a tubular sleeve member having a biased locking shaft that interacts with a locking groove.

Owner:REDHED TOOLS

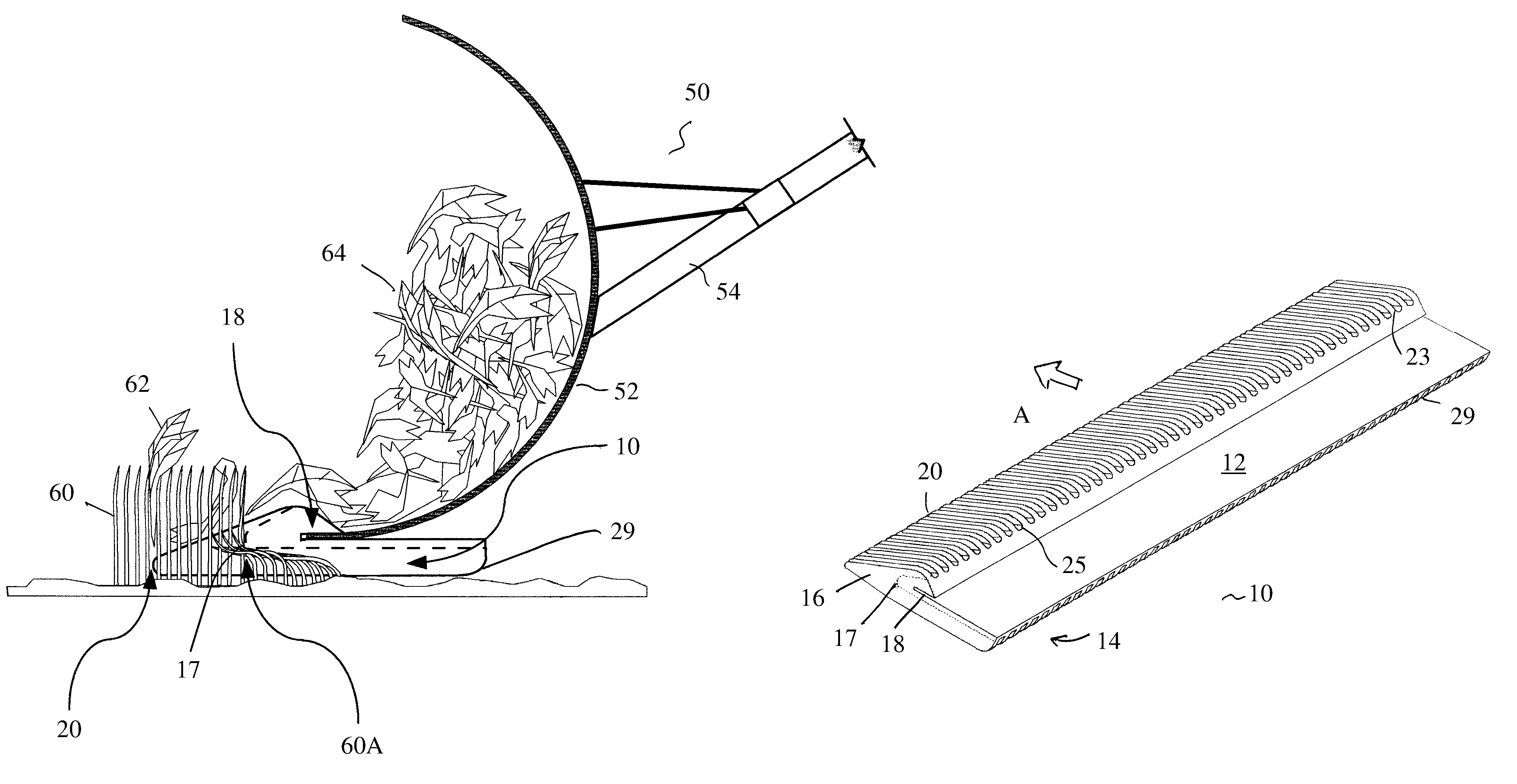

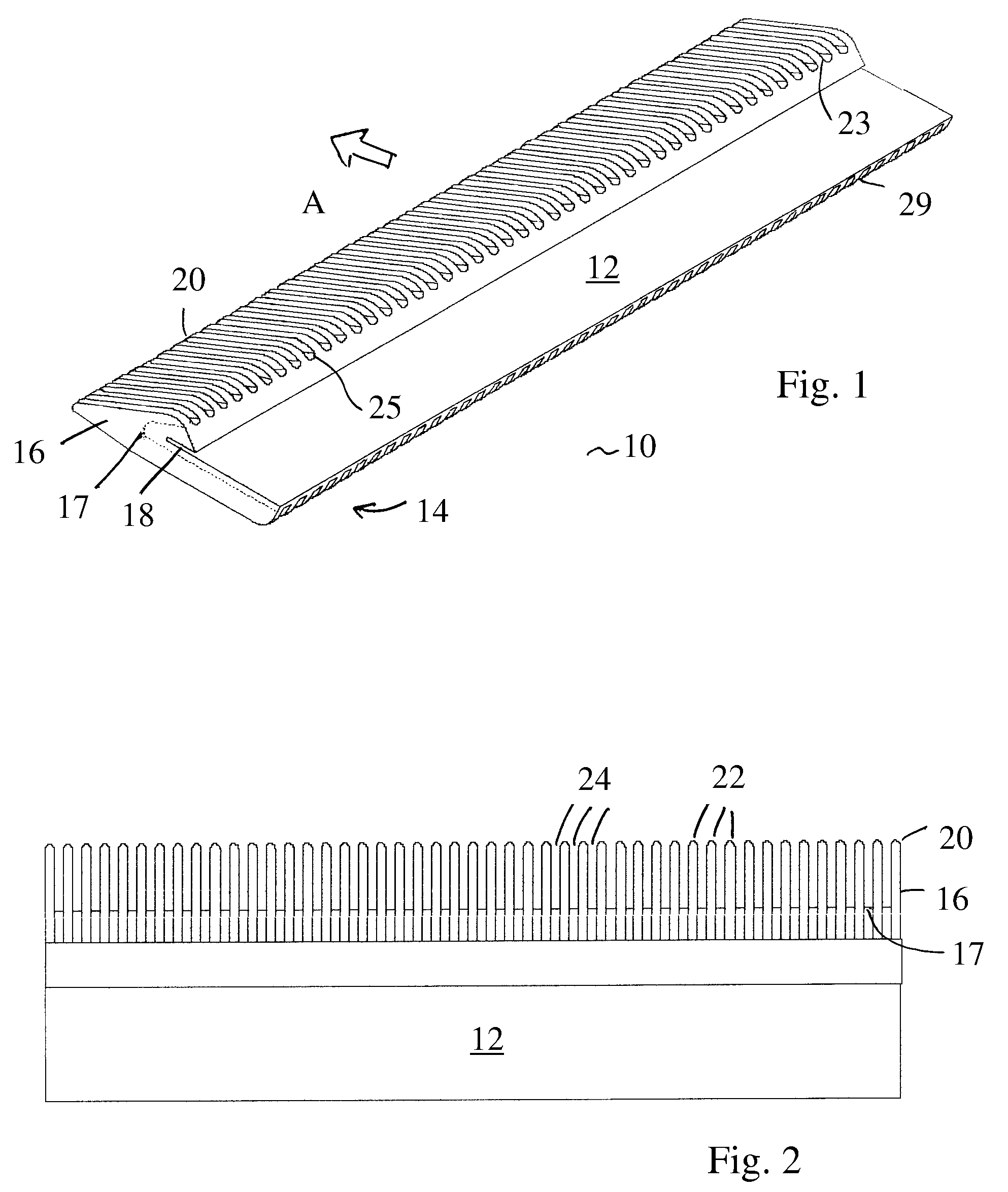

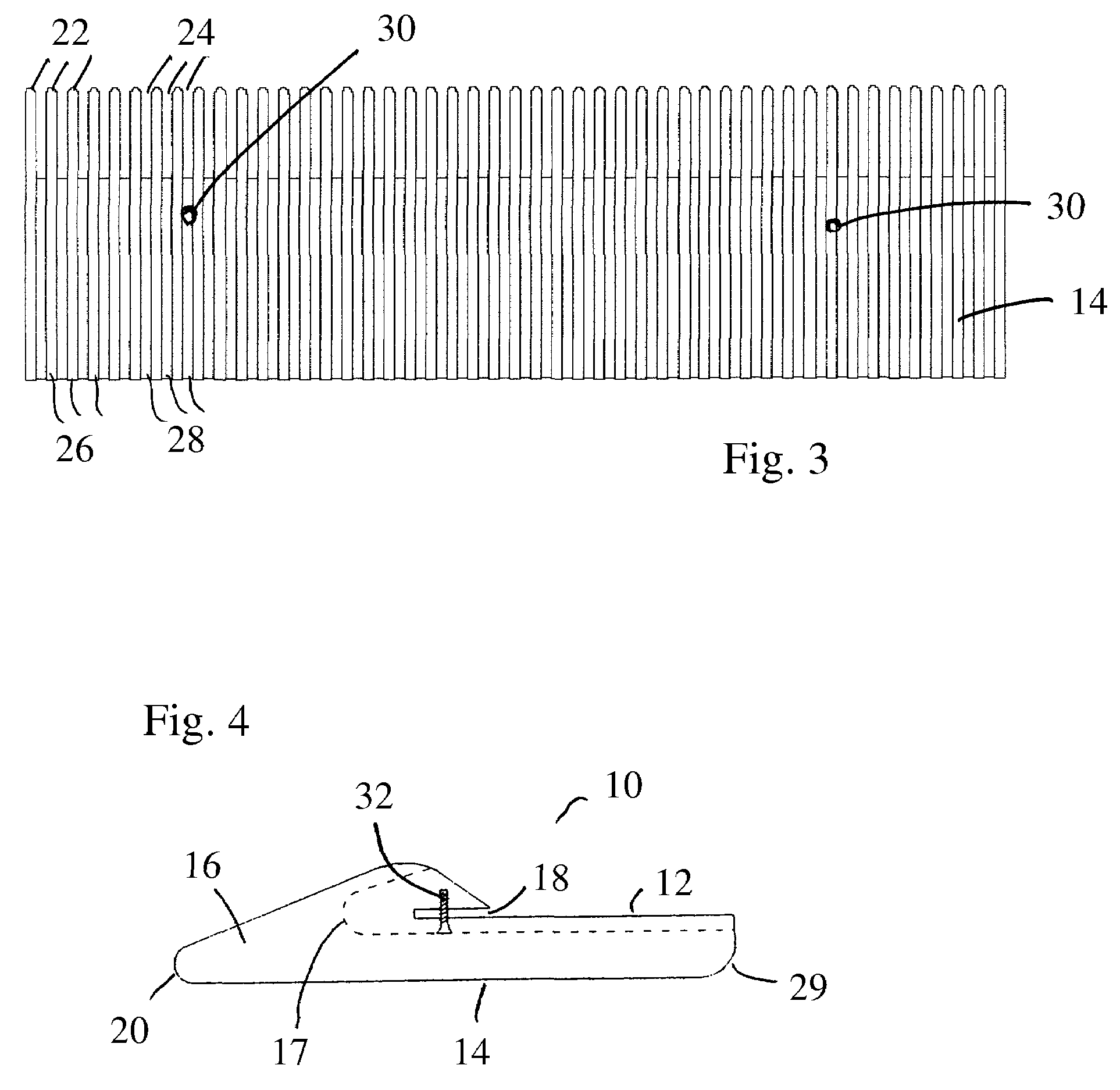

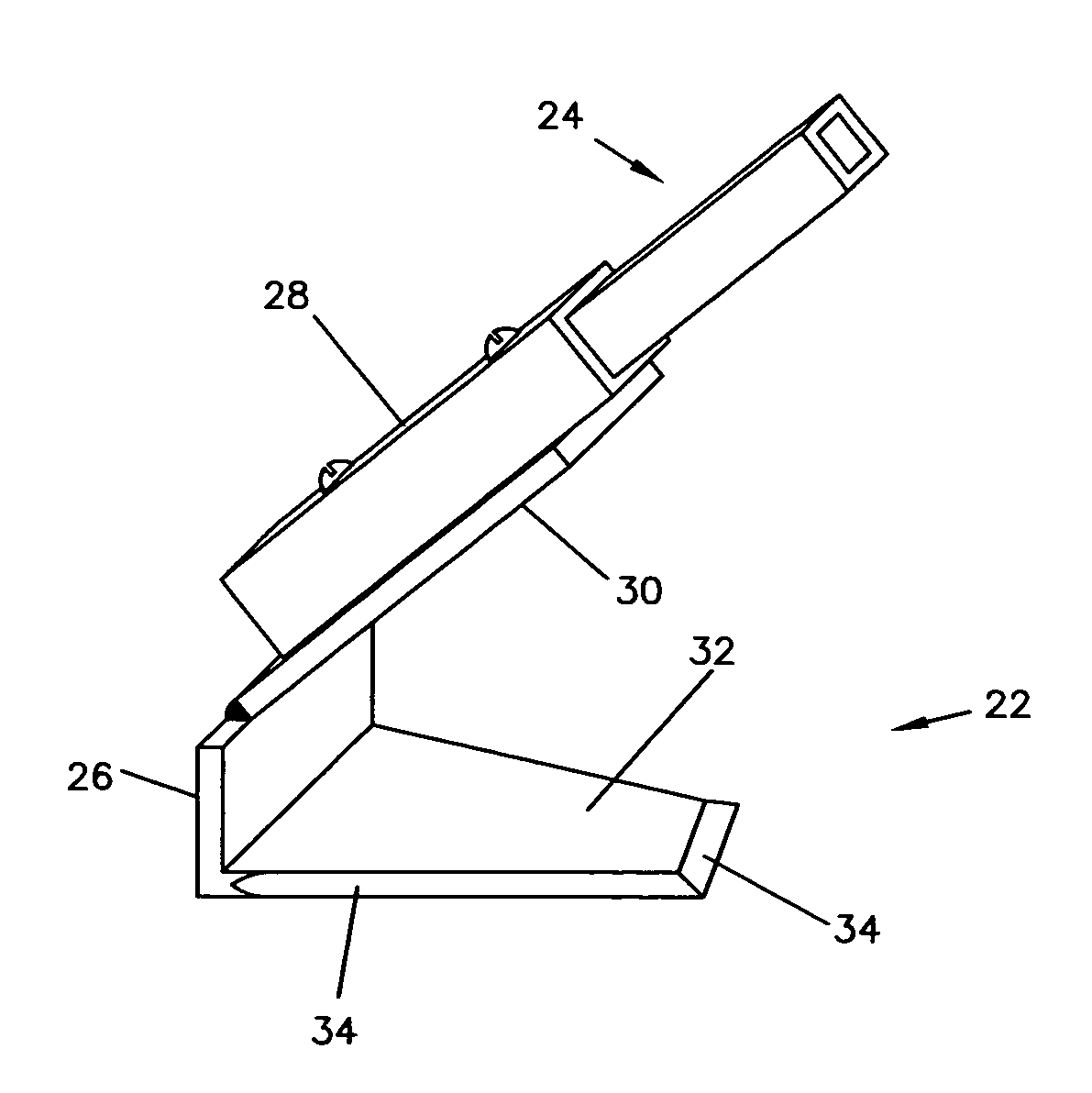

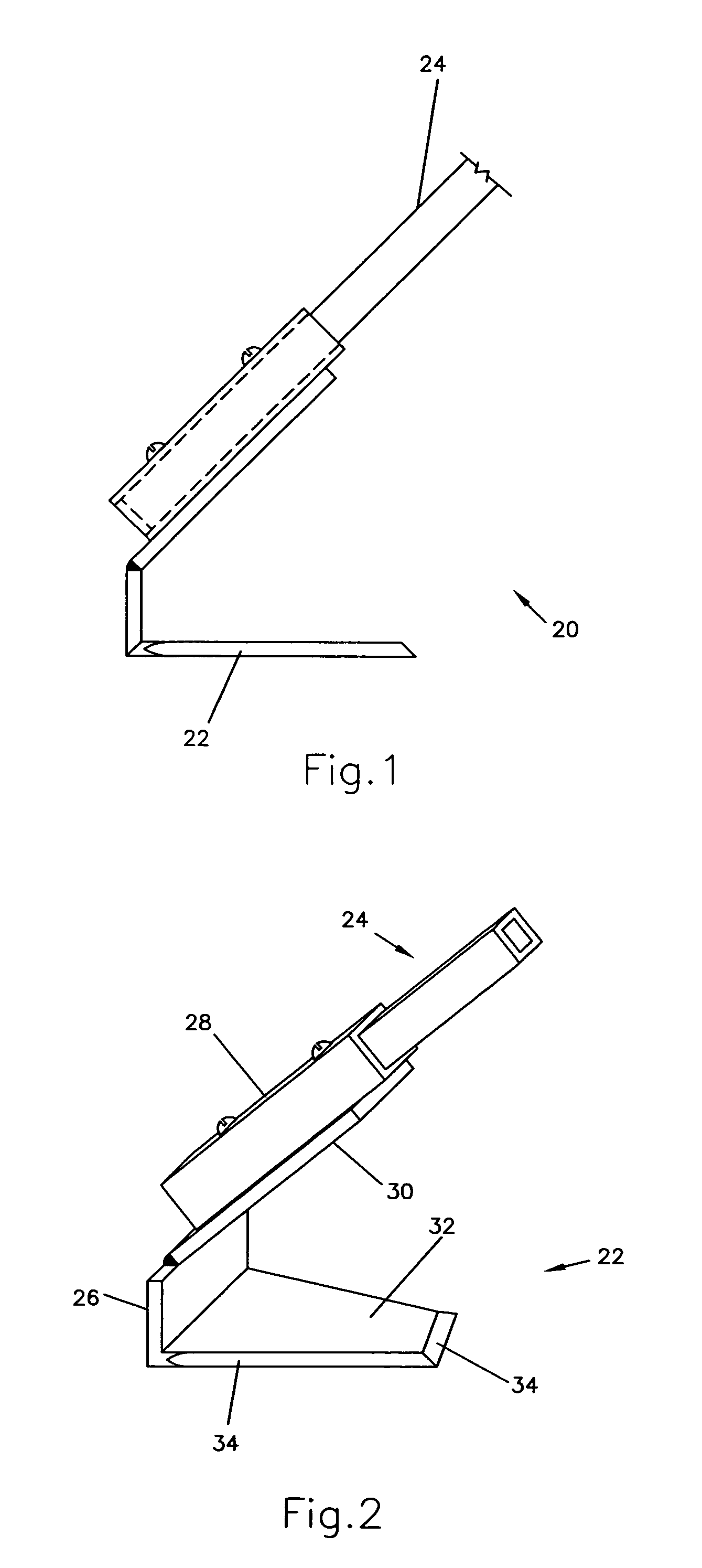

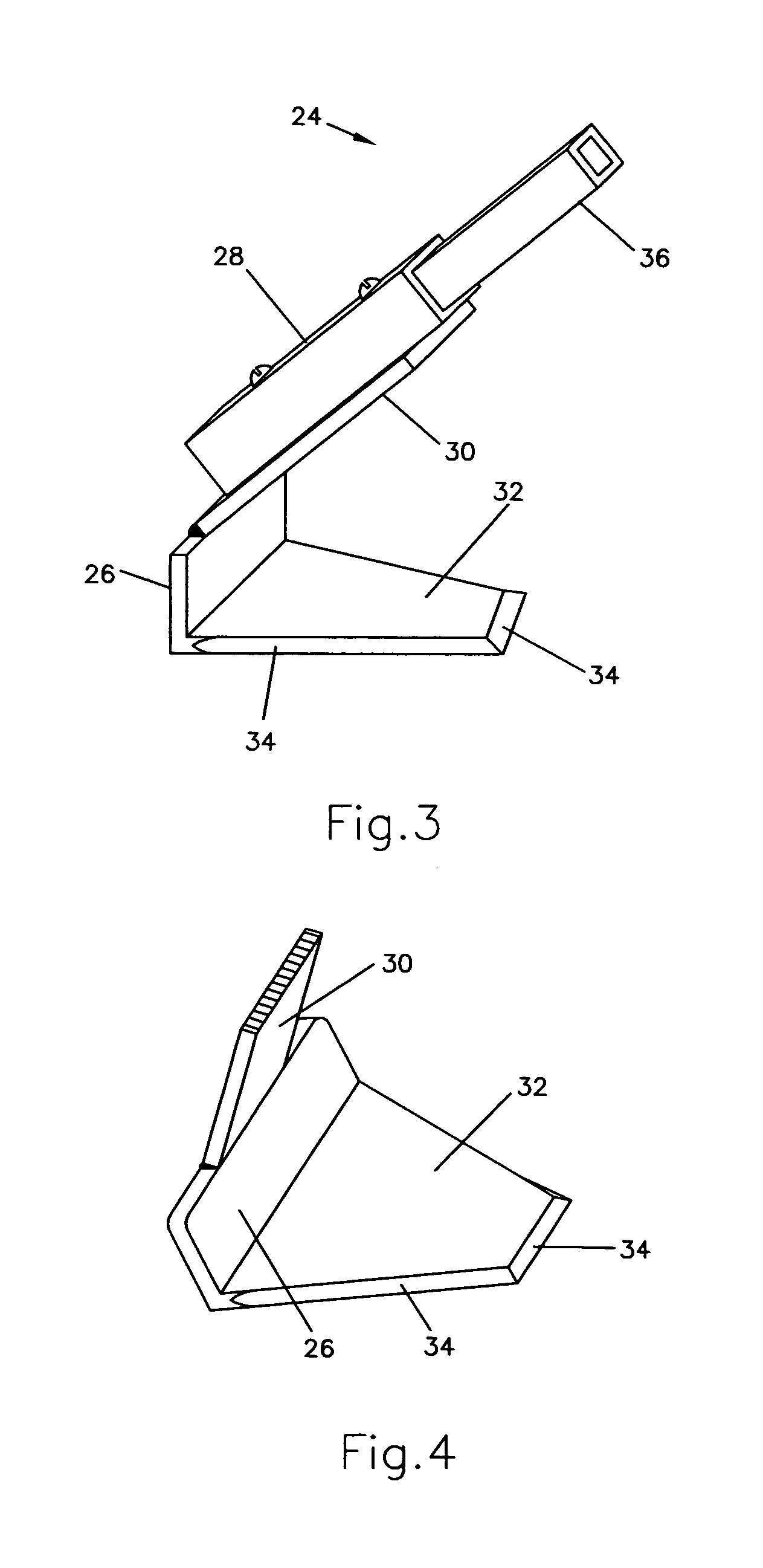

Lawn maintenance device having wedge-shaped front section

An exemplary lawn maintenance device for the collection of leaves or other debris on a grassed surface, comprises a substantially flat, planar device having a top surface, a lower surface, and a wedge-shaped front section affixed thereto, wherein the top surface of the device is substantially flat and planar, and has a transverse groove or slot therein for receiving the blade of a push shovel. Additionally, the wedge-shaped front section has a series of vertical tines forming a comb-like structure at the leading edge of the device, wherein the comb-like structure consists of a series of extending tine portions, separated by open areas cut within the leading surface of the device. The lower surface comprises a series of ridges and grooves. This configuration allows the device to be fitted to the blade of a push shovel, and the combination can be pushed across the surface of a lawn in order to collect leaves and other debris from the lawn.

Owner:MARCHESE VINCENZO

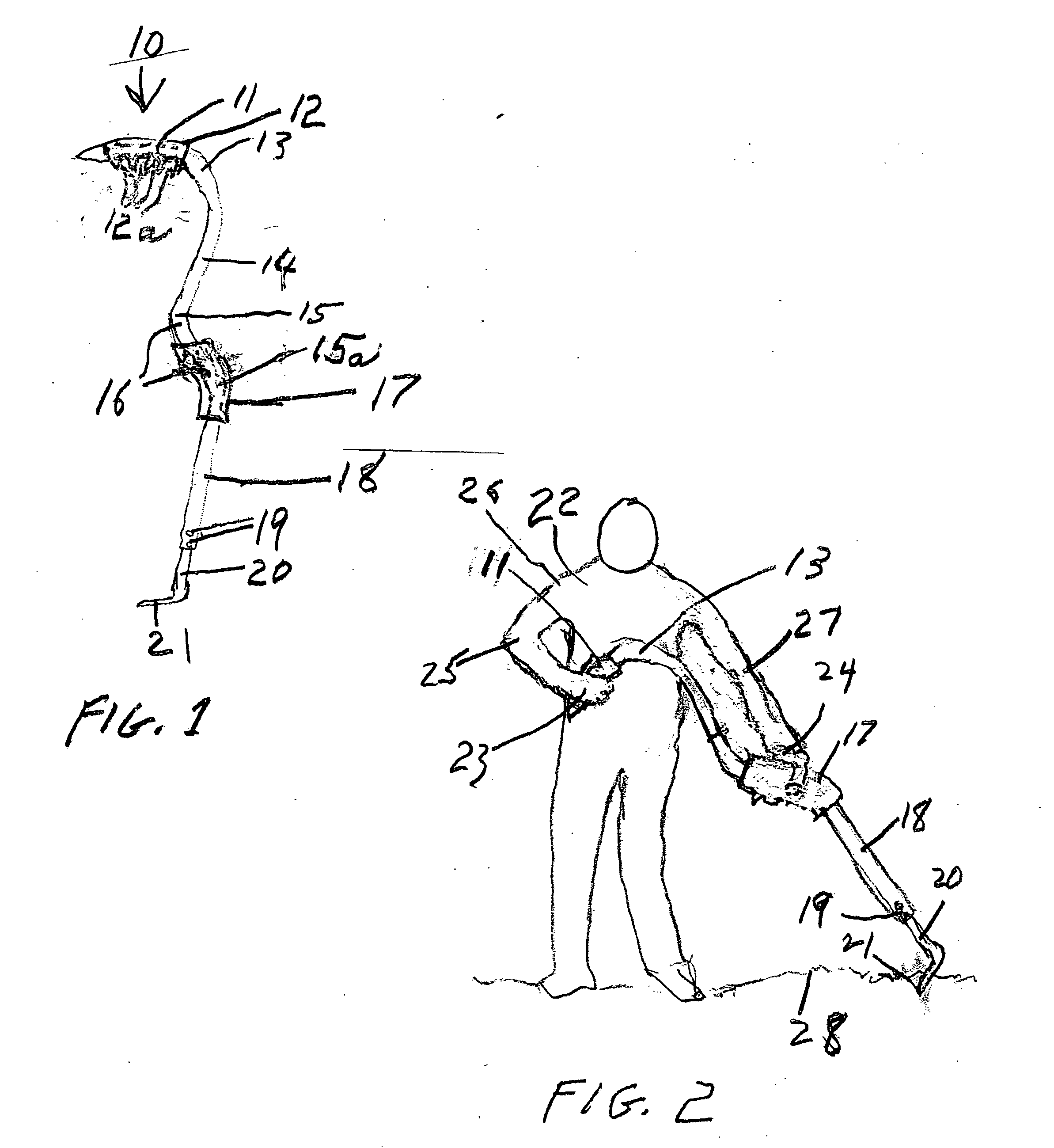

Ergonomic garden implement

This is a new rake incorporating the principles of spreading and compressing the rake tines by foot actuated lineal movement of a tine space adjustment member with the principles of an ergonomic mop handle which allows for quick conversion from a wide rake to a shovel-like member for easy conversion from raking to shoveling debris.

Owner:BIGGS BLYTH S

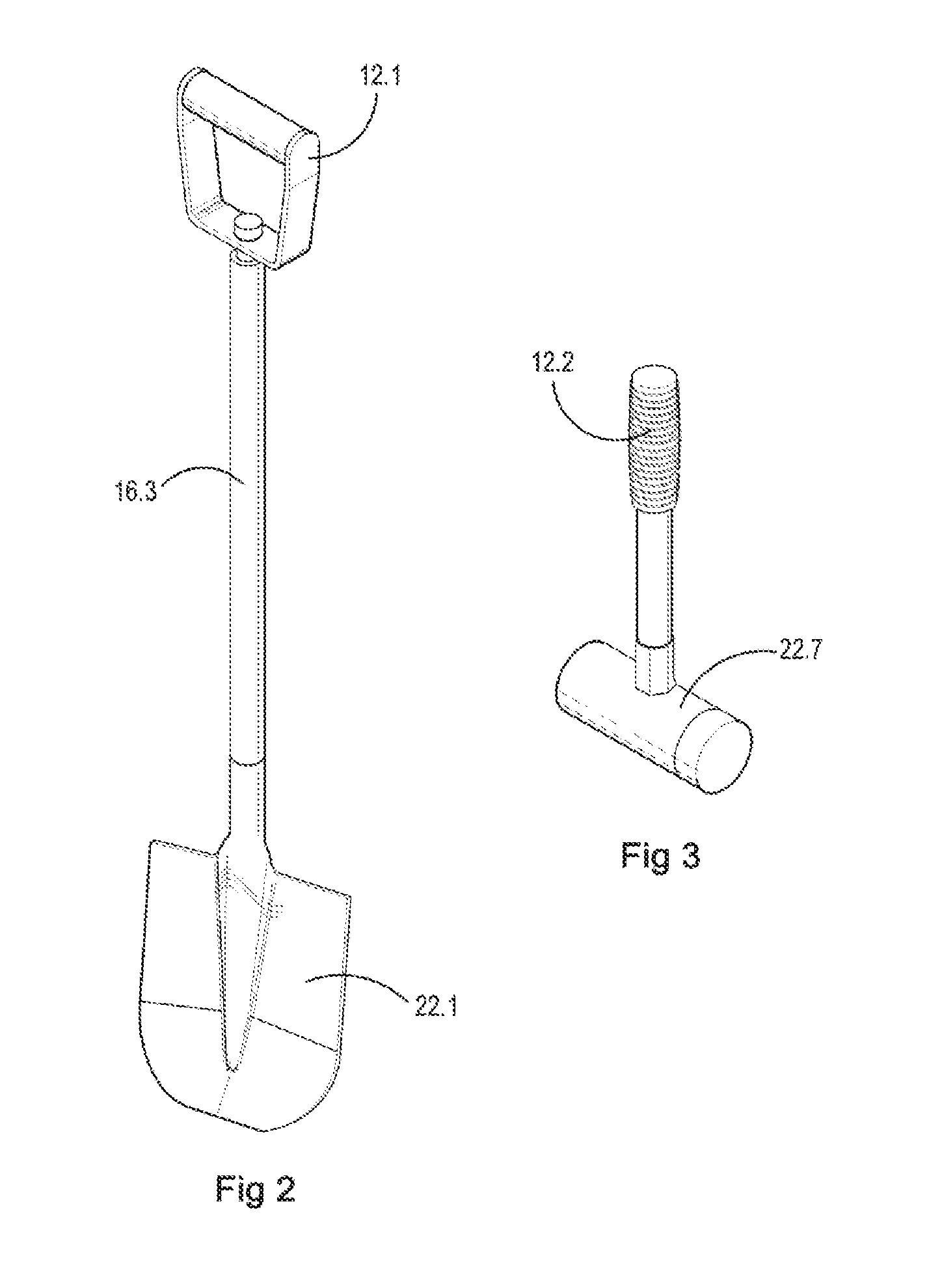

Working Toolkit

InactiveUS20170057074A1Easy to disassembleSpadesMetal sawing devicesEngineeringMechanical engineering

A working toolkit includes an extendible shaft, a tool handle and a tool head, each having connection formations so that the tool handle may be releasably attached to one end of the shaft, and the tool head may be releasably attached to an opposite end of the shaft to form a working tool, and thereafter disassembled for storage and transportation in a compact form. The tool handle may be directly releasably attached directly to the tool head. A variety of connection formations are provided, particularly adapted for a tubular shaft. The working toolkit may include several different tool handles and tool heads for selectively forming a variety of working tools.

Owner:DAVIGNON GINA MARINA +1

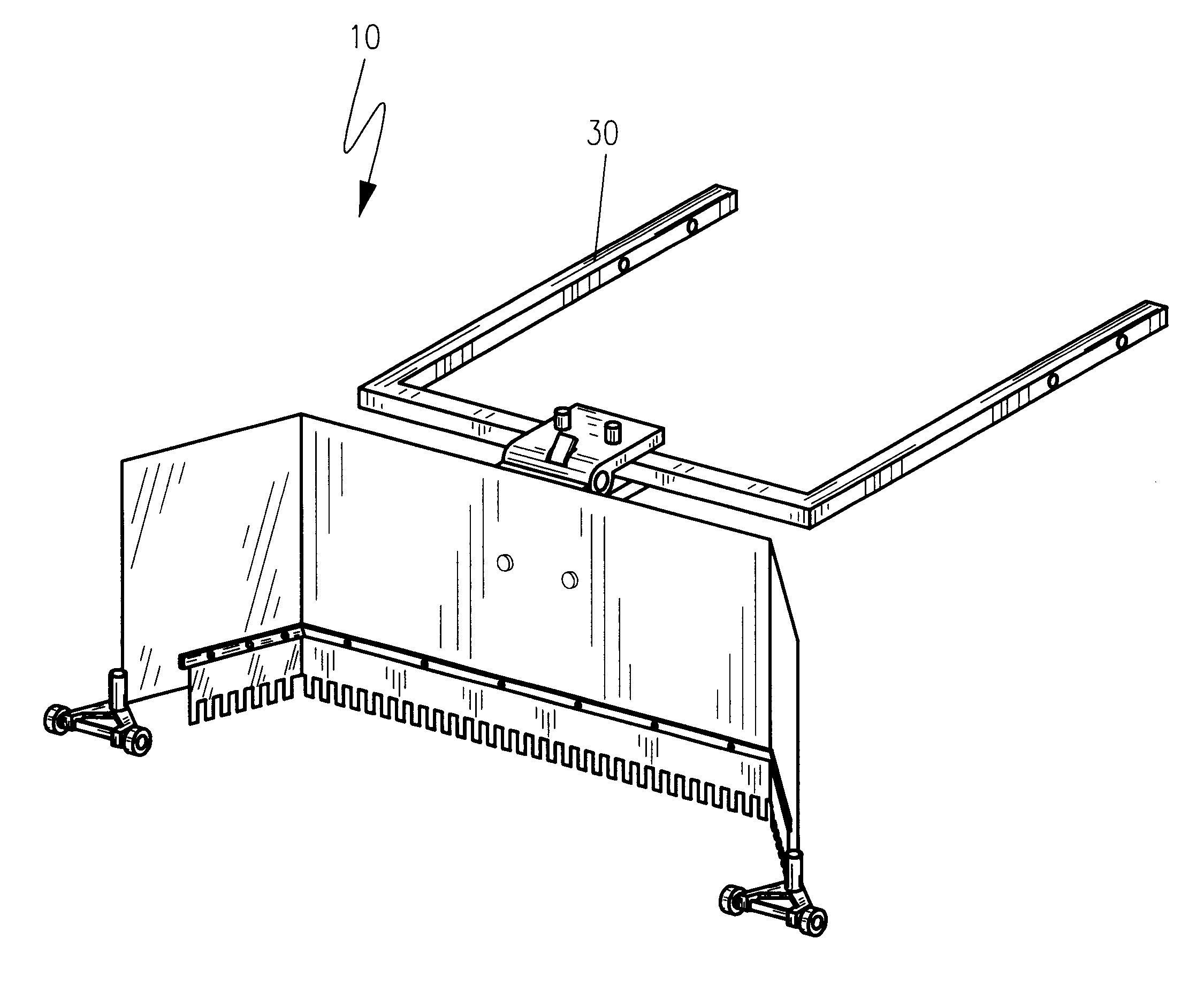

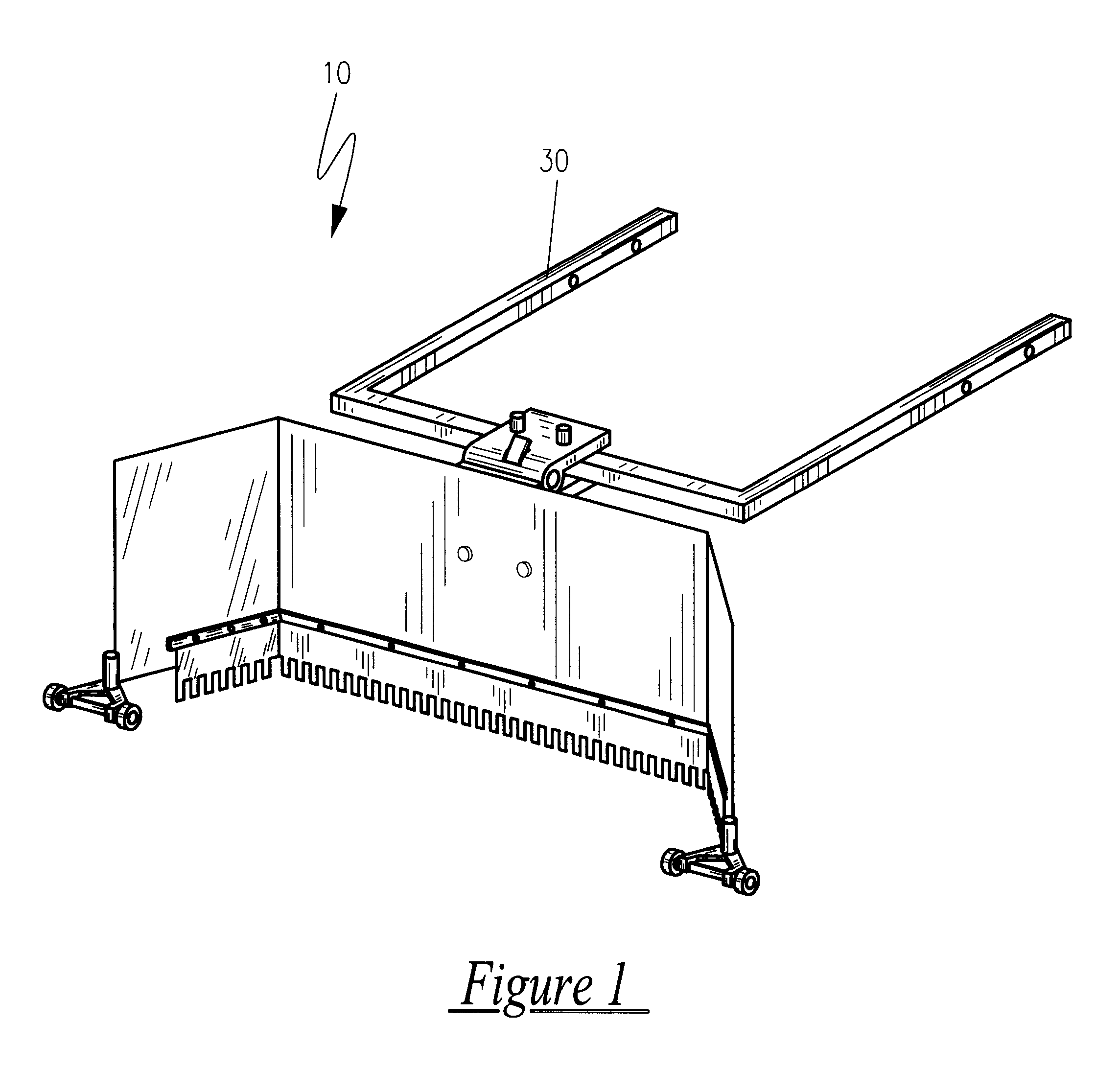

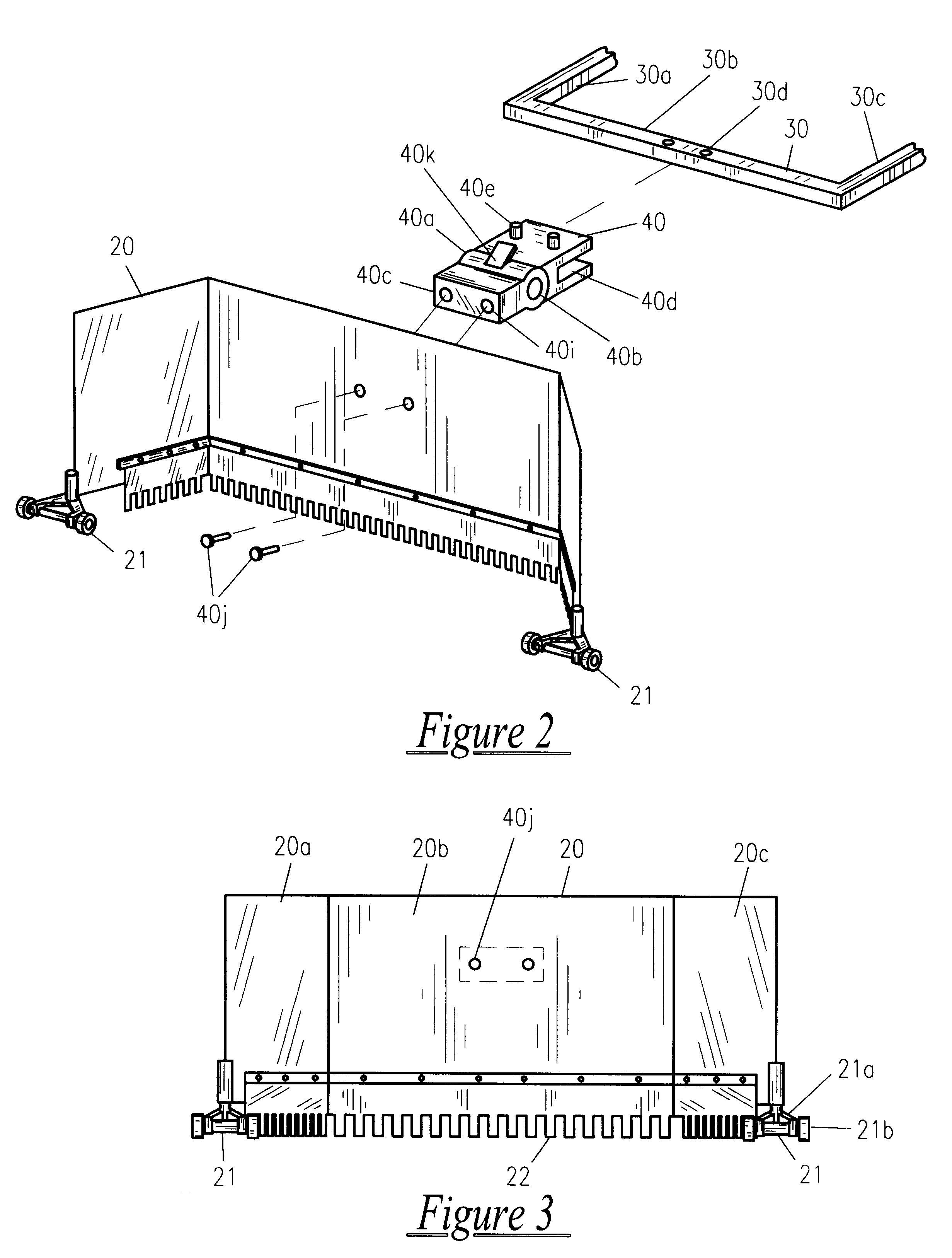

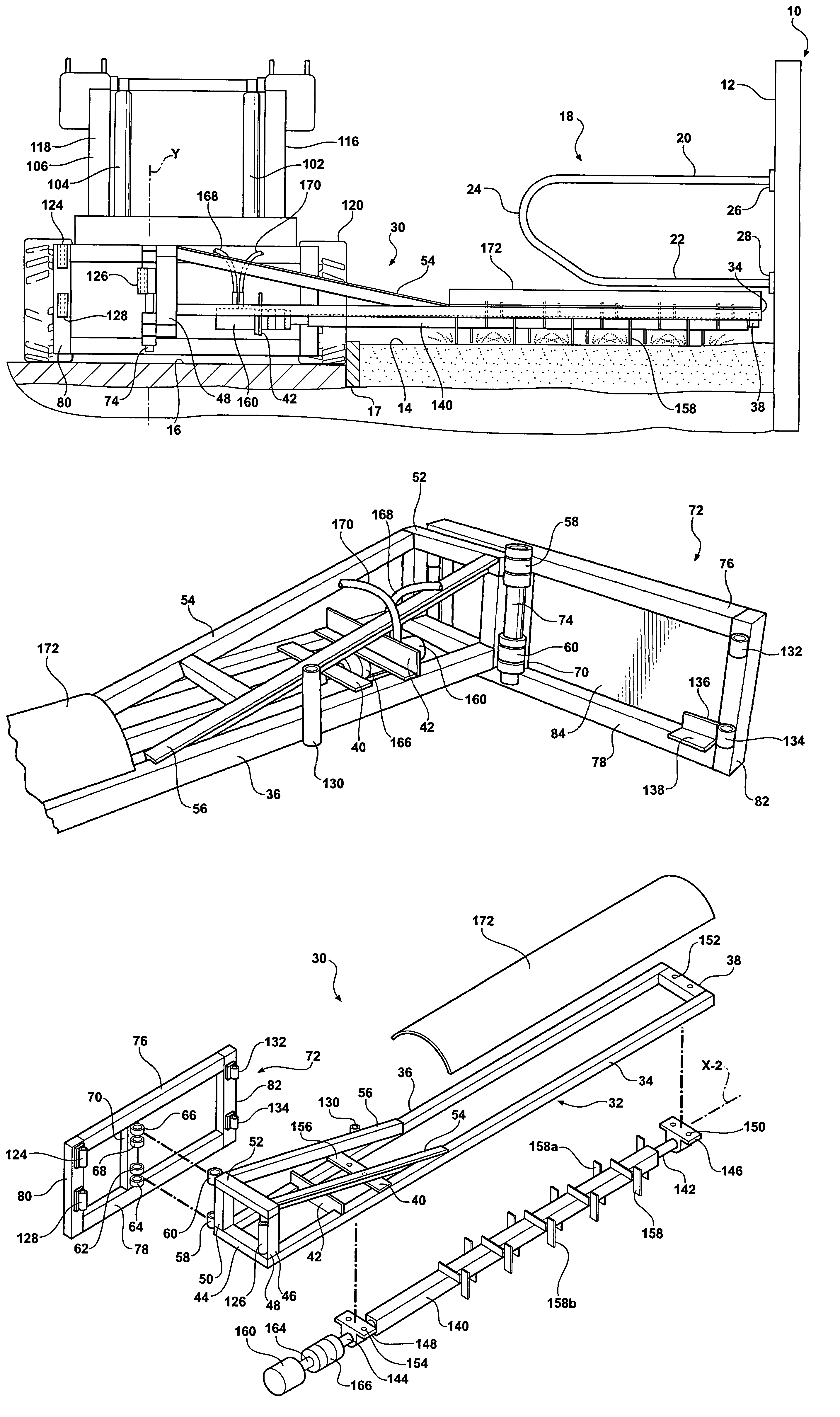

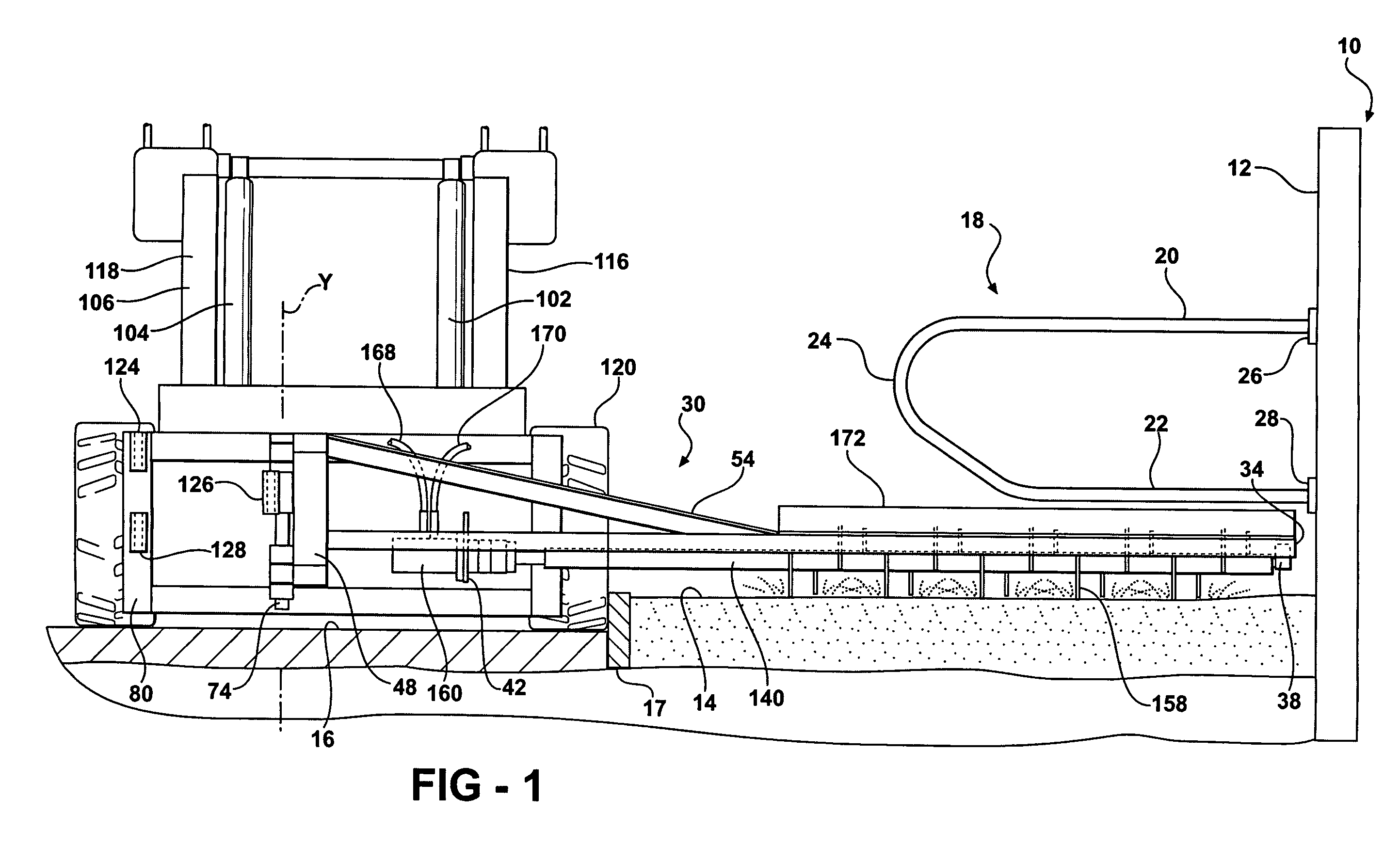

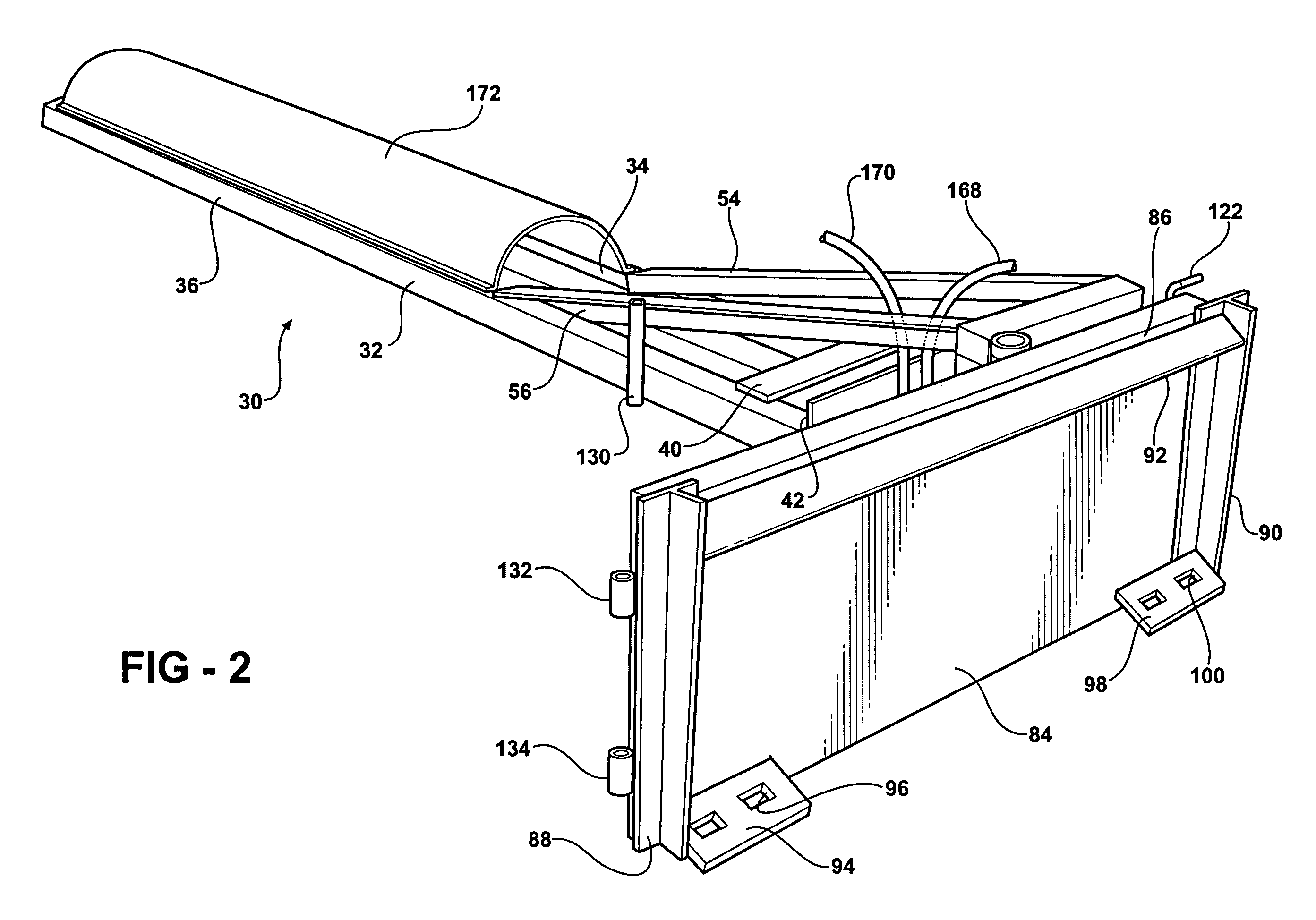

Animal stall soil agitator

The animal stall soil agitator includes a mounting plate assembly pivotally attached to a tractor loader boom for pivotal movement about a transverse horizontal loader boom axis. An elongated frame assembly has an inboard frame end attached to the mounting plate assembly and outboard frame end that extends laterally to one side of the tractor loader boom. An elongated bar is journaled on the elongated frame assembly. A plurality of flat soil agitator bars are fixed to the elongated bar. The flat soil agitator bars are oriented to minimize lateral movement of agitated soil. A reversible hydraulic motor is connected to a hydraulic system of the tractor and rotates the elongated bar in a selected direction. The elongated frame assembly is pivotable about a vertical axis relative to the mounting plate.

Owner:BRADE GENE M

Ergonomic planar grading hand tool

InactiveUS6988561B1Apply evenlyMinimal strainLiquid surface applicatorsHoesEngineeringVariable length

A hand tool having a flat, planar blade parallel to a surface and a variable length handle allows efficient and effective grading or leveling of a surface. The device allows for effective grading without undue stress on the body of the operator. The ergonomic design of the device, as well as the functional design, allow for effective and efficient grading of surfaces next to and surrounding sensitive structures.

Owner:CAMPBELL JUSTIN

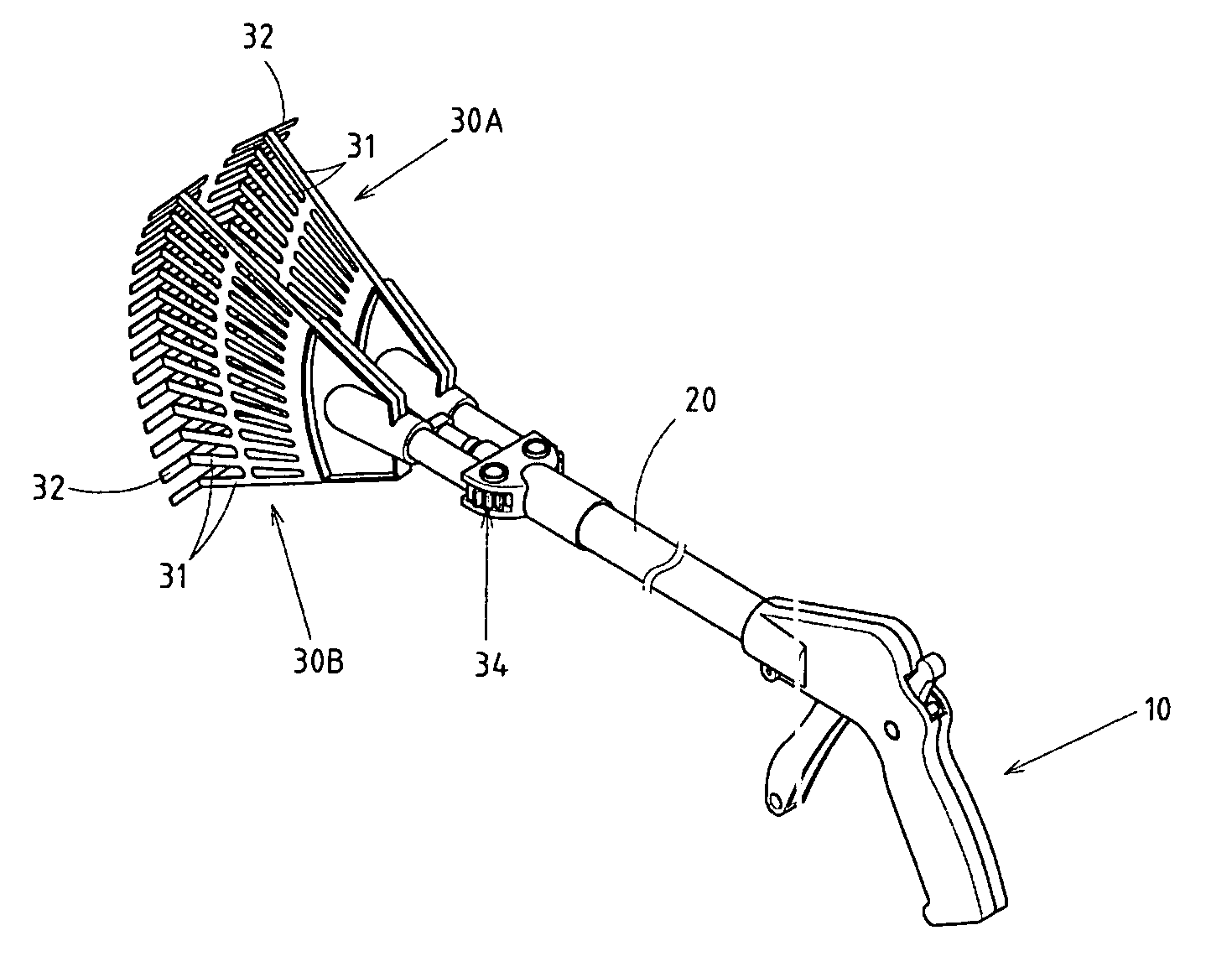

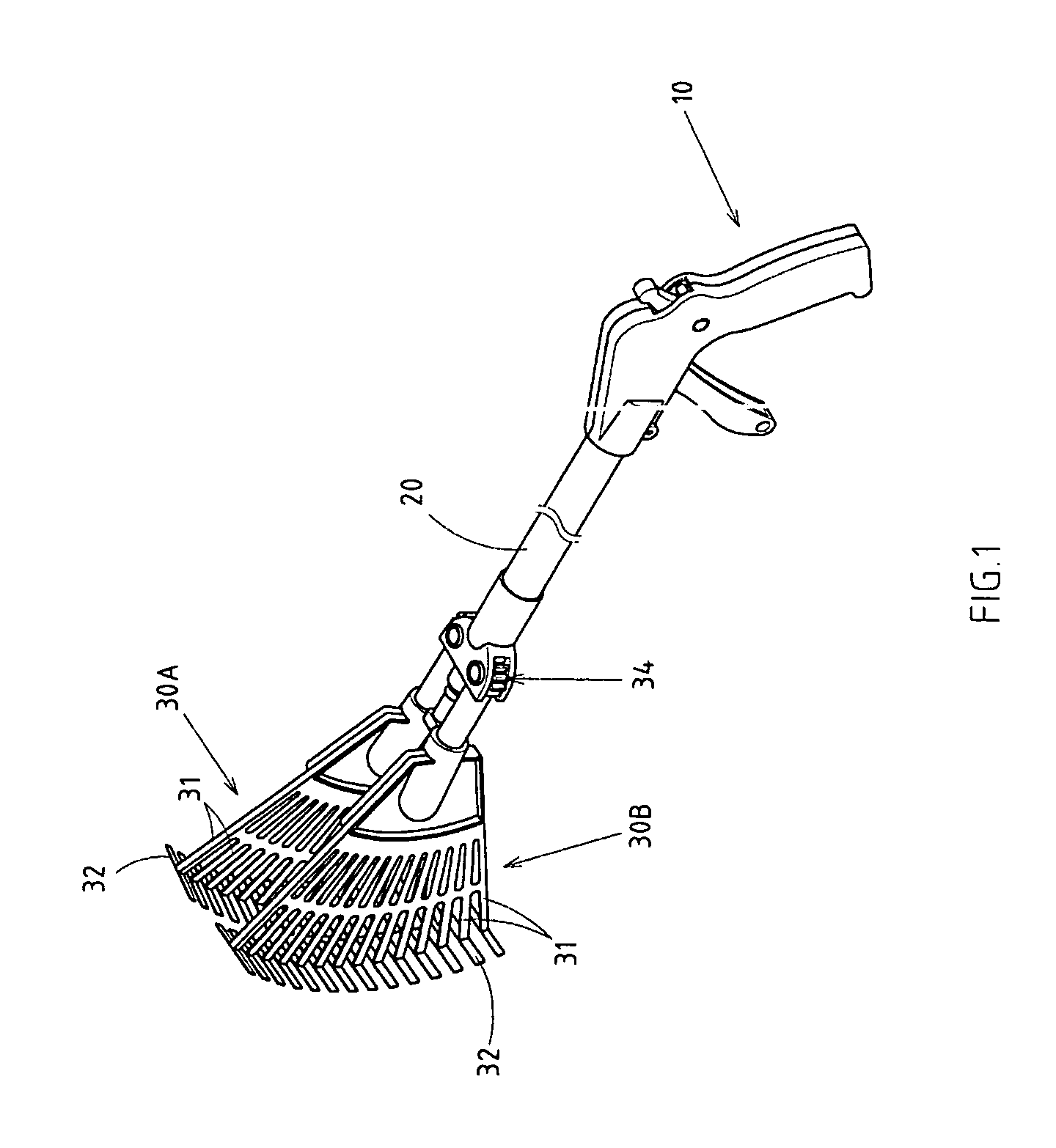

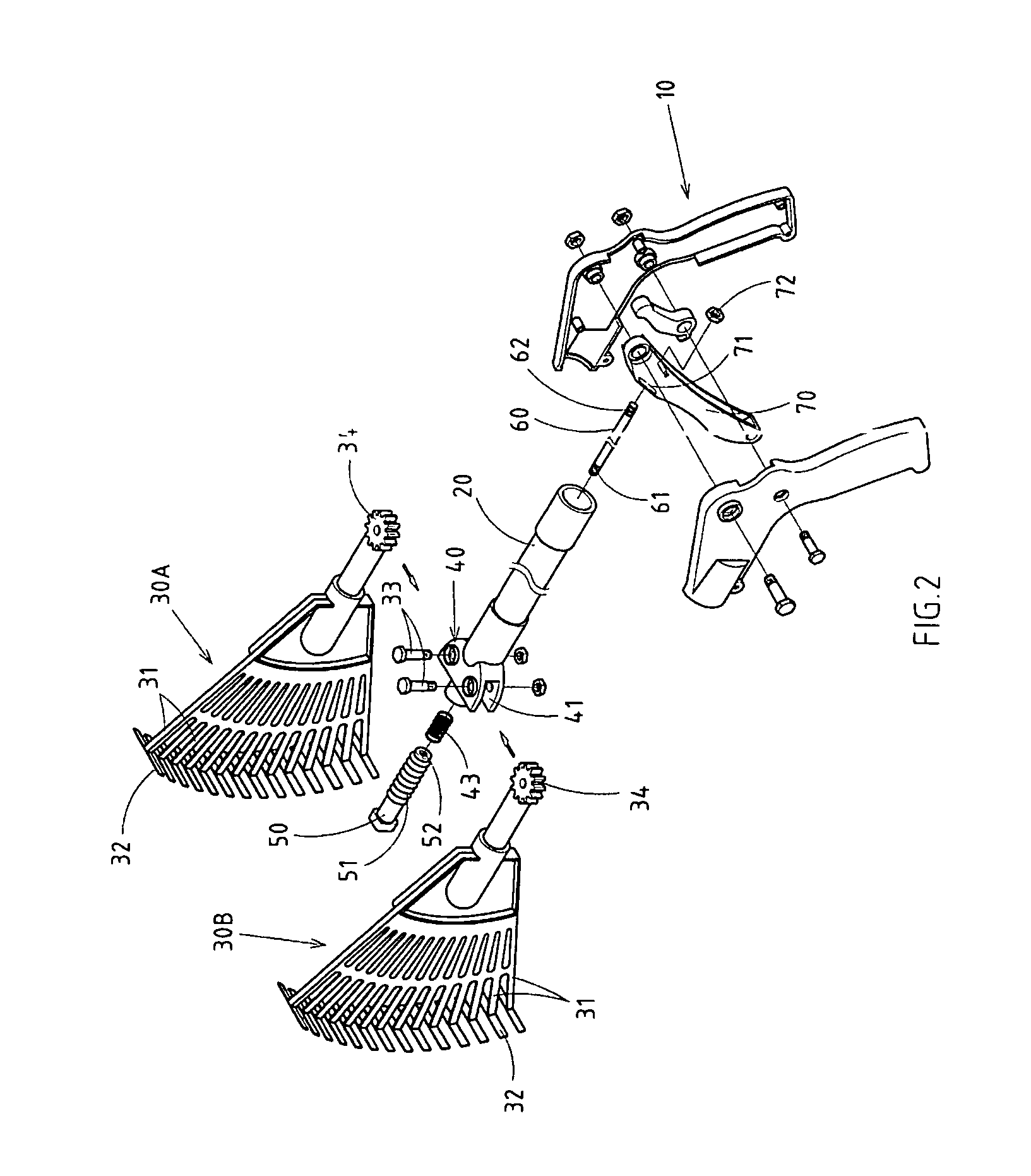

Collapsible rake

A novel rake minimally consists of: at least two tine frames, each tine frame having a plurality of tines coupled thereto; a tine frame coupling for coupling to proximal ends of each of the tine frames; pivot mechanisms coupled between the tine frames and the tine frame coupling; a rake handle coupled at a proximal end to the tine frame coupling, and adapted for being grasped at a distal end for raking activity; and a locking mechanism adapted to lock the tine frames into an operational raking configuration, and adapted to unlock the tine frames for transition to a non-raking stowage configuration. When the tine frames are unlocked, the tine frames are adapted to have their distal ends pivoted toward the distal end of the rake handle into the stowage configuration with the distal ends of the tine frames being at least in close proximity of the rake handle.

Owner:SANDERS JAMES

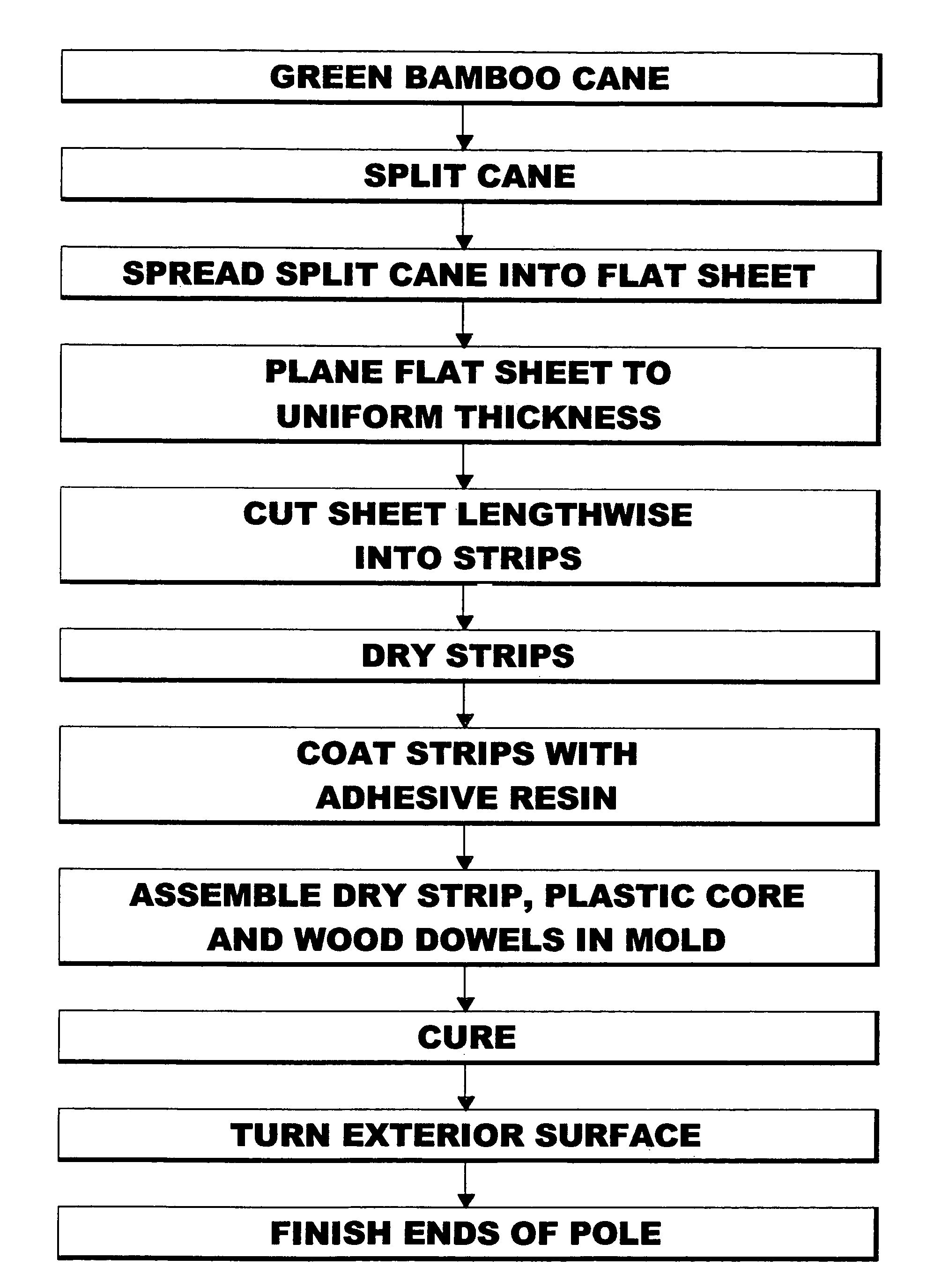

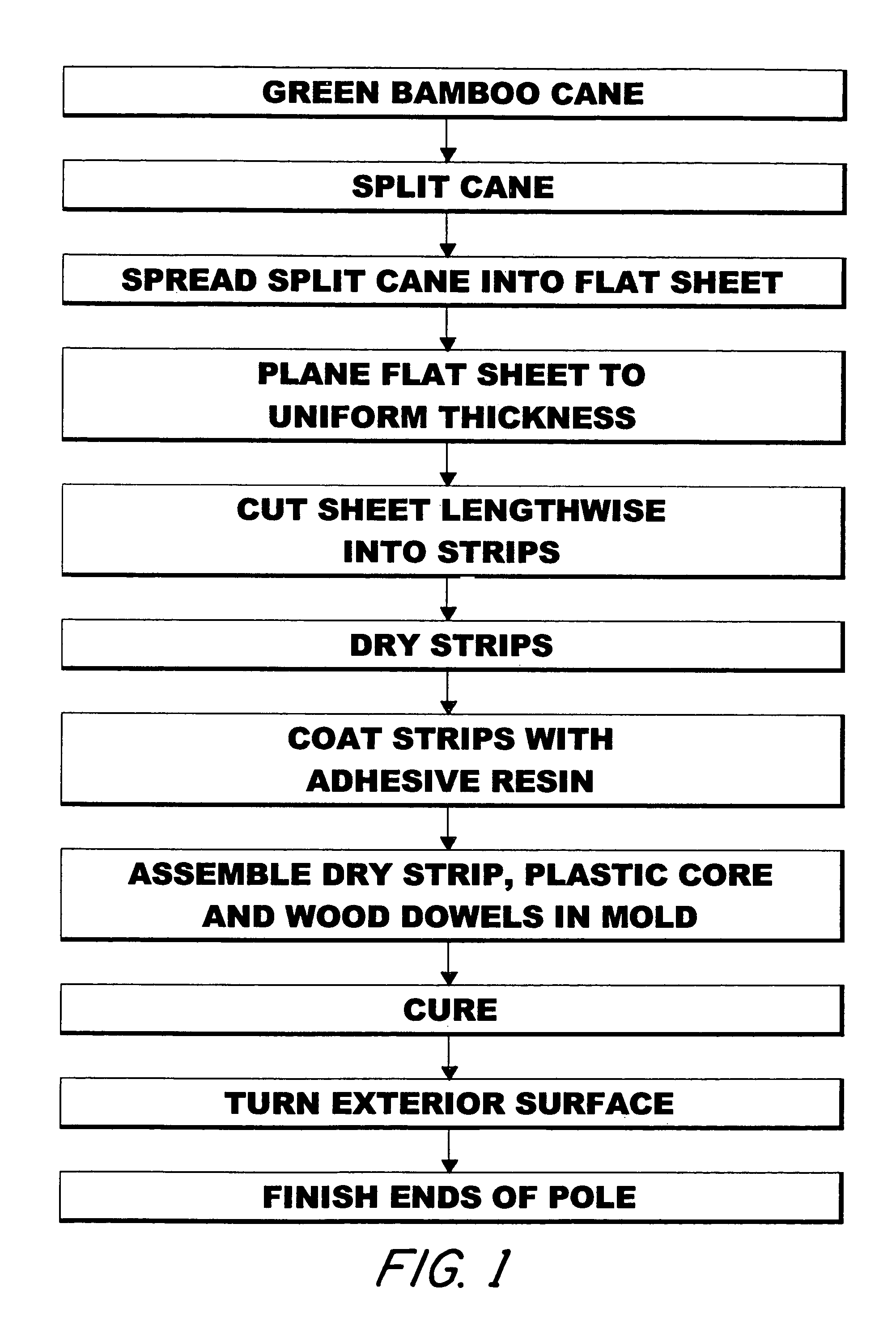

Elongate laminated wooden handles and method of manufacturing same

InactiveUS7785681B2Easy to manufactureLess laborWing handlesBrush bodiesAdhesiveBiomedical engineering

A method of manufacturing elongate wooden handles for floor mops and the like comprises (a) splitting a green bamboo cane lengthwise and then spreading it into the shape of a sheet, (b) planing both surfaces of the sheet to give it a substantially uniform thickness, (c) cutting the bamboo sheet into an elongate section of selected width, (d) drying that bamboo section, (e) providing an assembly comprising a pair of dowels, at least one elongate core member, said bamboo sections and an adhesive, with the bamboo section wrapped around the dowels and the core member and the adhesive disposed between the bamboo section and the dowels and core member, (f) heating that assembly under pressure so the adhesive will bond the dowels and core member to the surrounding bamboo section and thereby form an elongate pole, and (g) turning the elongate pole to a selected outer diameter.

Owner:LIAO DICK

Gardening rake with improved structure

Owner:HO CHENG GARDEN TOOLS

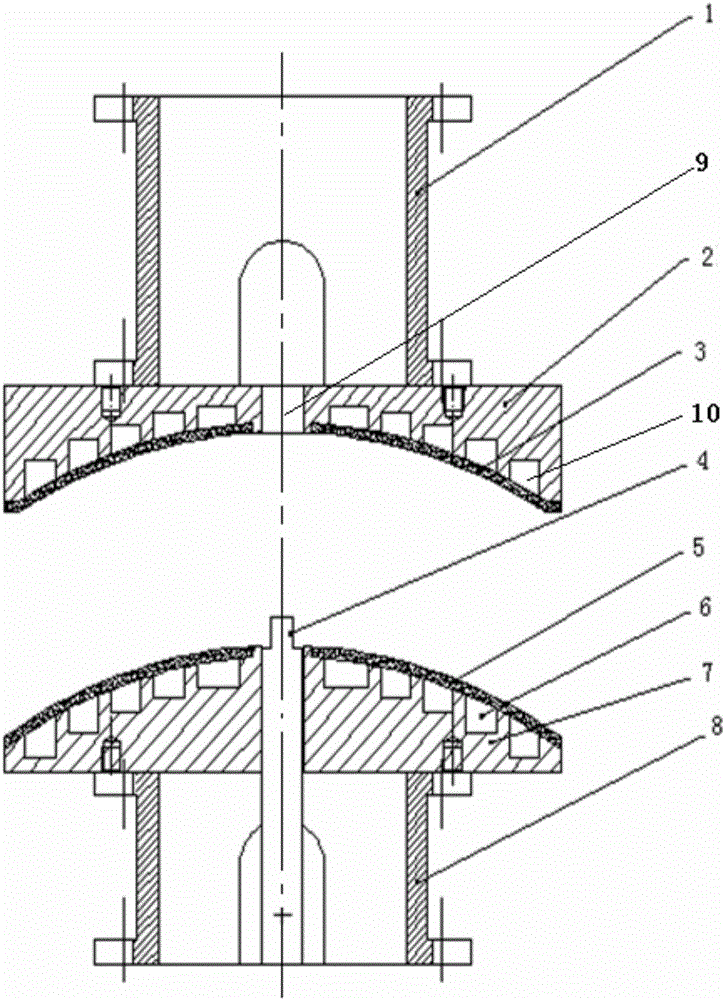

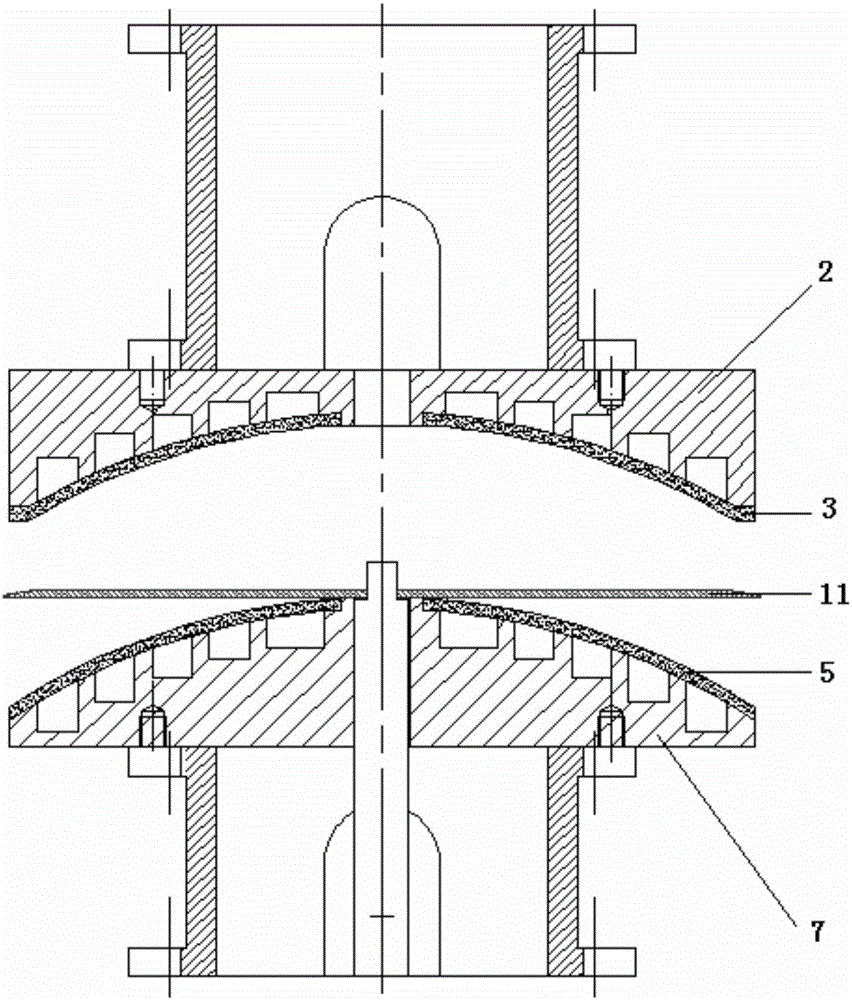

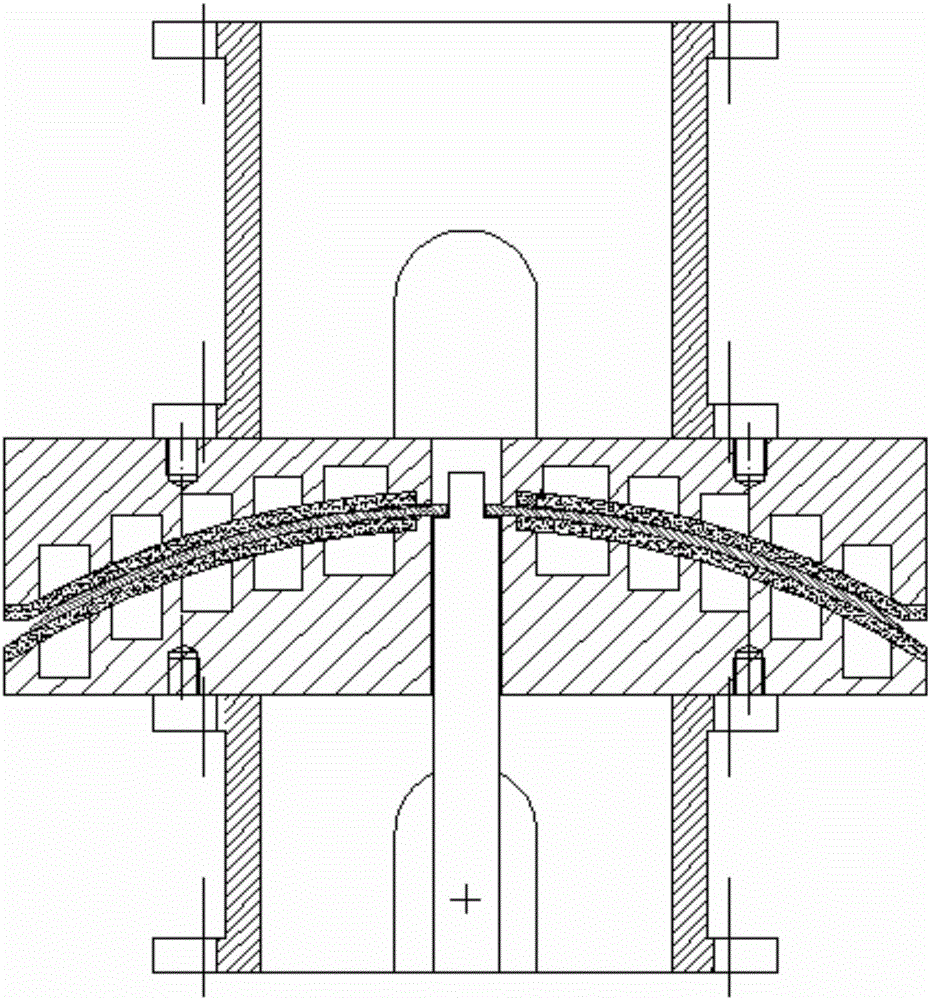

Manufacturing method of high-strength, high-toughness and abrasion-resistant disc harrow

ActiveCN105033098AHigh critical cooling rateHigh dimensional accuracyRakesForksHigh intensityHardness

The invention relates to the field of production and machining of agricultural implements, in particular to a manufacturing method of a high-strength, high-toughness and abrasion-resistant disc harrow. A high-strength steel plate serves as a raw material, and quenching and pressing of the harrow are finished at the same time through the stamping forming and quenching integrated process. After a machined disc harrow blank is heated to austenitizing temperature and subjected to heat preservation for a certain time, the blank is quickly transferred into a forming die, subjected to stamping forming and quickly cooled to temperature below Martensite start transformation temperature (Ms) of the material in the die, and forming and quenching are finished at the same time. The disc harrow produced through the manufacturing method is simplified in production process, free of quenching pollution and low in cost. The tensile strength is more than 1,600 MPa, the hardness is 48-52 HRC, the impact toughness (ak) is more than 20 J / cm<2>, and the performance is far superior to that of 65 Mn harrows massively used domestically at present. The harrow is high in dimensional precision and small in circle run-out.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

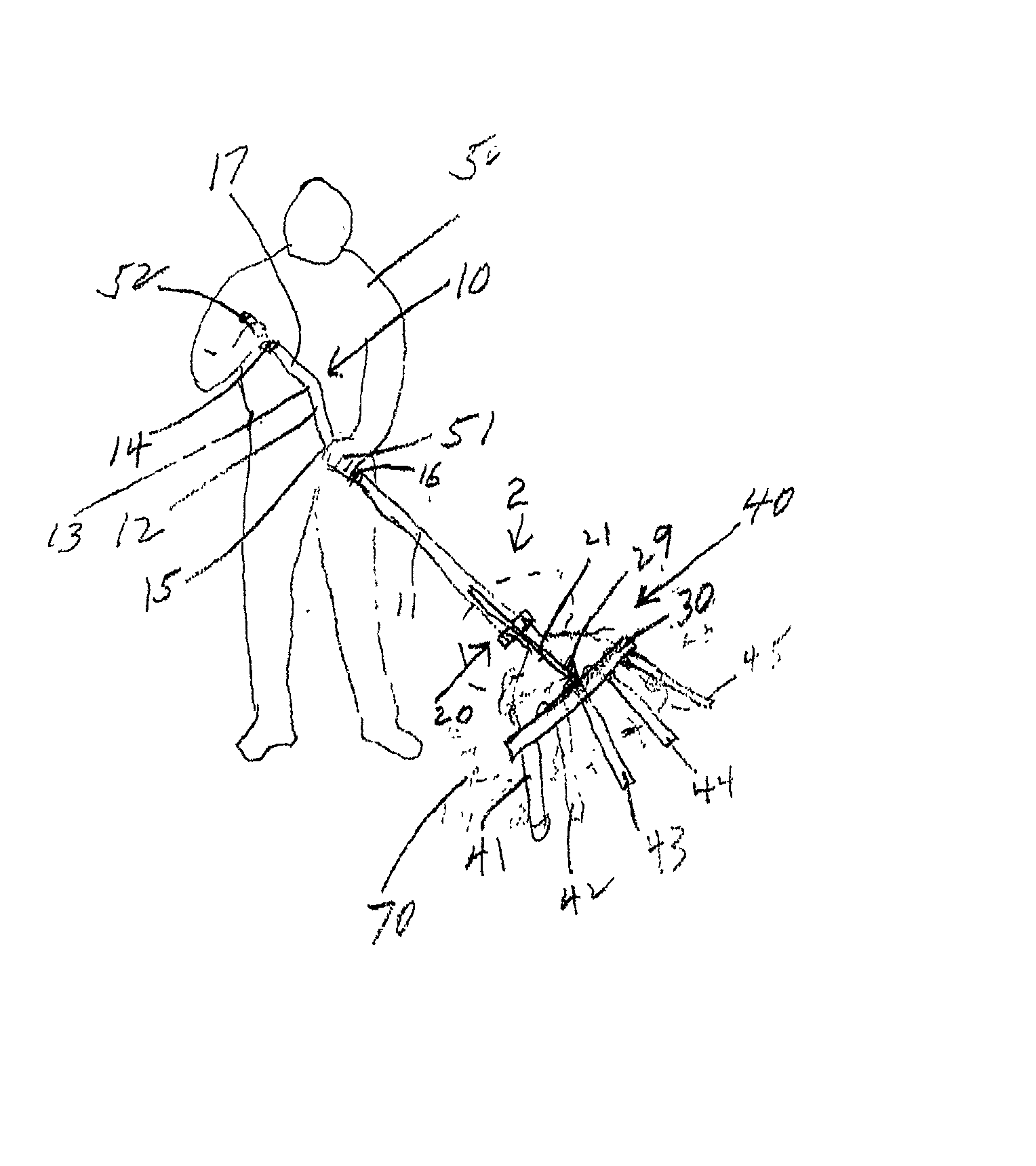

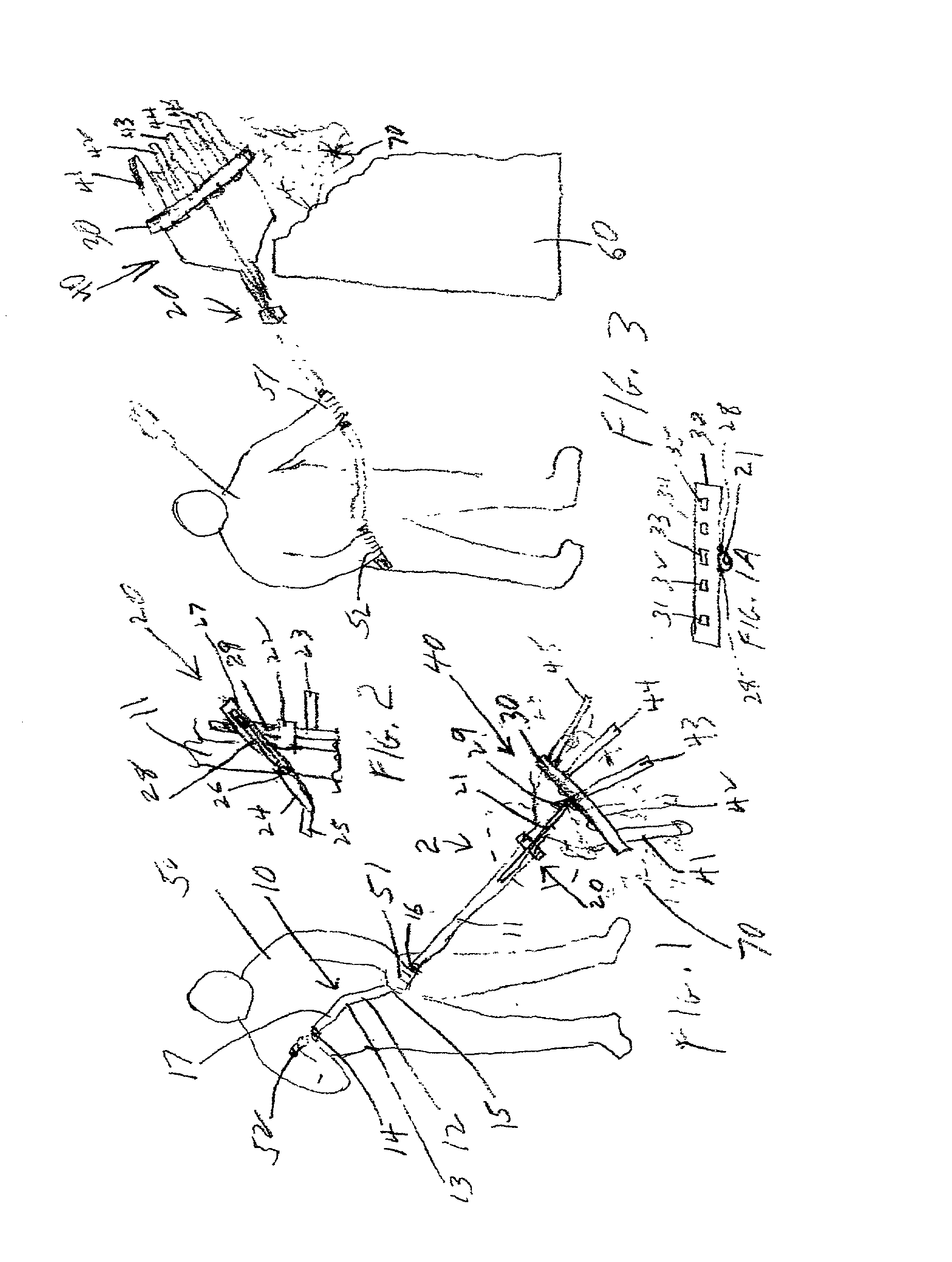

Apparatus for ergonomic application of rotational handle garden tool

ActiveUS20170014986A1Improve productivityIncrease powerSpadesHand-operated machines/dredgersPower applicationEngineering

An apparatus for an improved hand tool device wherein a rotatable apparatus may rotate the rotating handle apparatus in 15 degree increments to adjust to the user to help reduce the risk of injury and increase power application while gardening by adjusting and creating a favorable angle between the ground and the point of entry of the hand tool device into the ground.

Owner:CHOU HANK HUNG KUNG

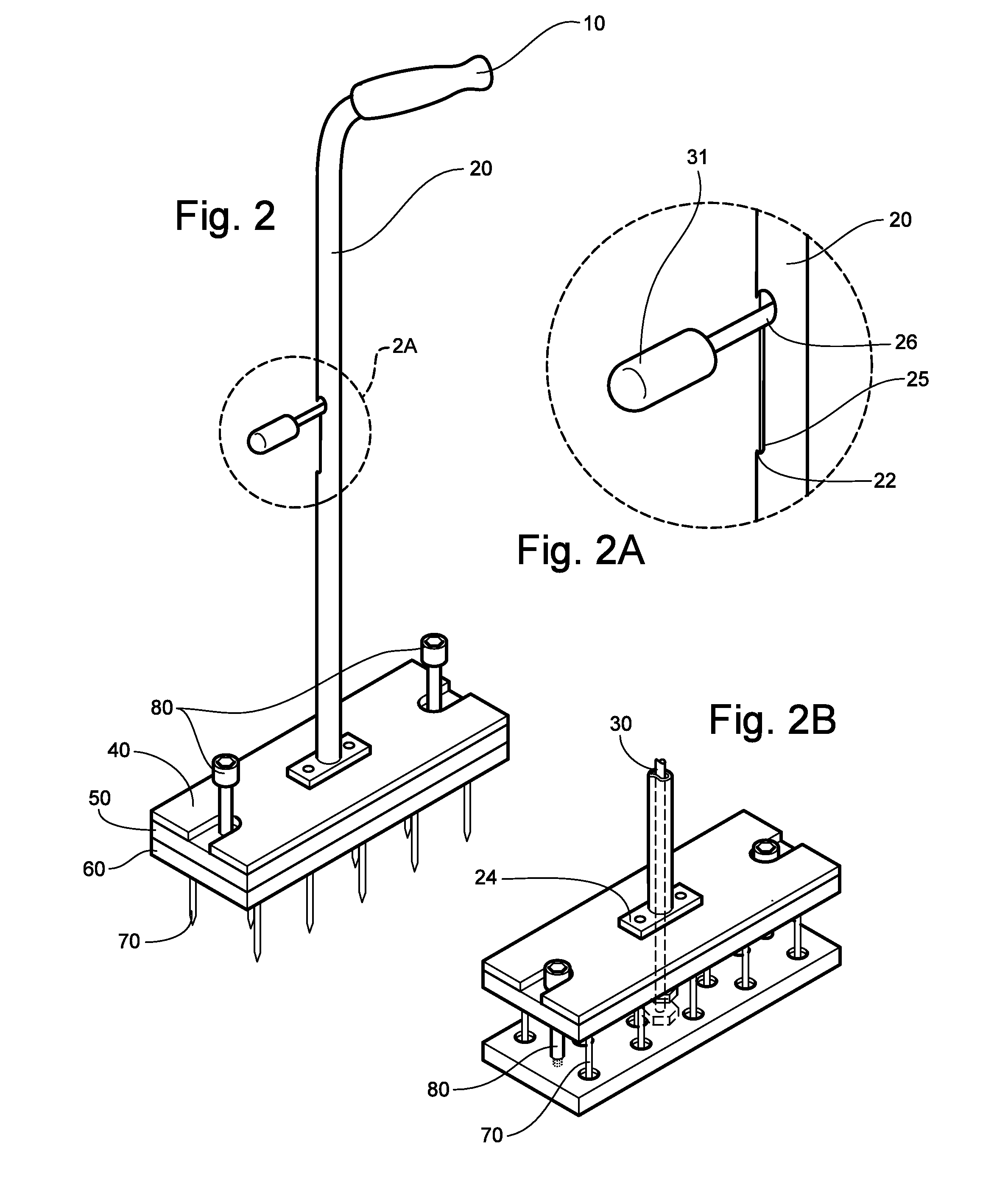

Debris collection device

The invention is a device for the safe and efficient collection of debris displaced across a collection field. Utilizing a plurality of spikes which pierce and penetrate articles of debris, the invention contemplates the accumulation of articles of debris on the spikes. When the device has become loaded with debris, the device self ejects the debris using a compression spring force trigger mechanism.

Owner:WILLIAMS RONNIE D

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com