Manufacturing method of high-strength, high-toughness and abrasion-resistant disc harrow

The invention relates to a technology of a disc harrow blade and a manufacturing method, which can be applied in the fields of columbine harrow, hand tools, application, etc., can solve the problems of low rigidity, delayed farming time, and large environmental pollution, and achieve high dimensional accuracy, good operability, and mechanical properties. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The disc rake sheet of the present embodiment adopts 6.5mm thick manganese-boron steel plate, and its chemical composition (wt%) is as follows:

[0050]

[0051] The production process is as follows:

[0052] (1) Plasma cutting, Ф675mm disc;

[0053] (2) punching machine, the center punches a 41mm square hole;

[0054] (3) Lathes, machining edge edges;

[0055] (4) punching machine, punching 11 gaps on the edge;

[0056] (5) heating furnace, the billet is heated to 900 ° C, and kept for 15 minutes;

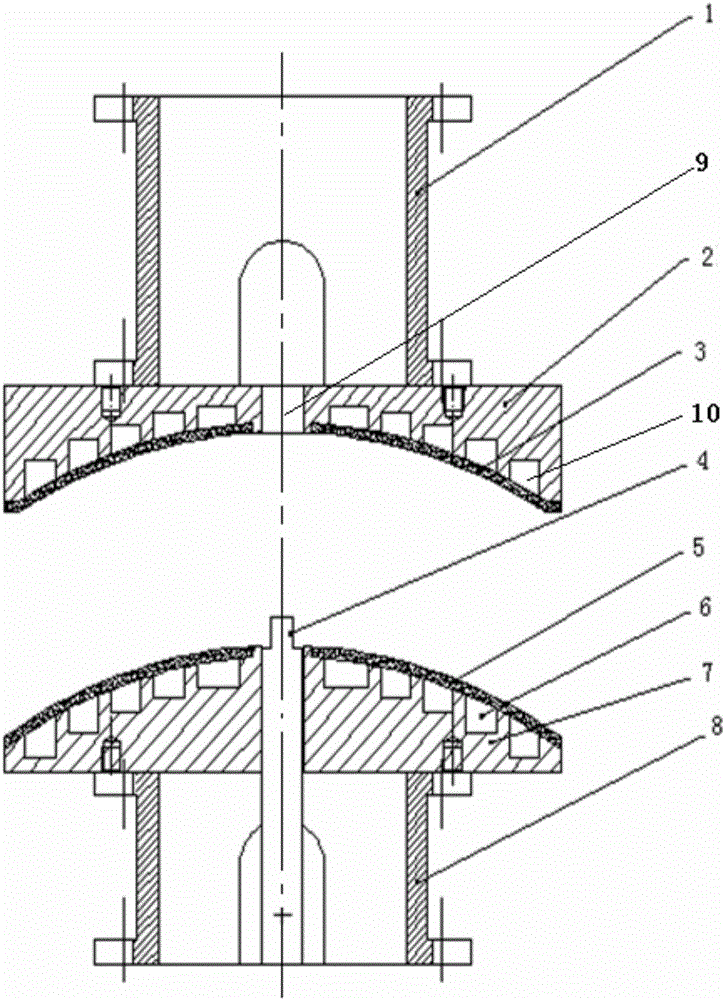

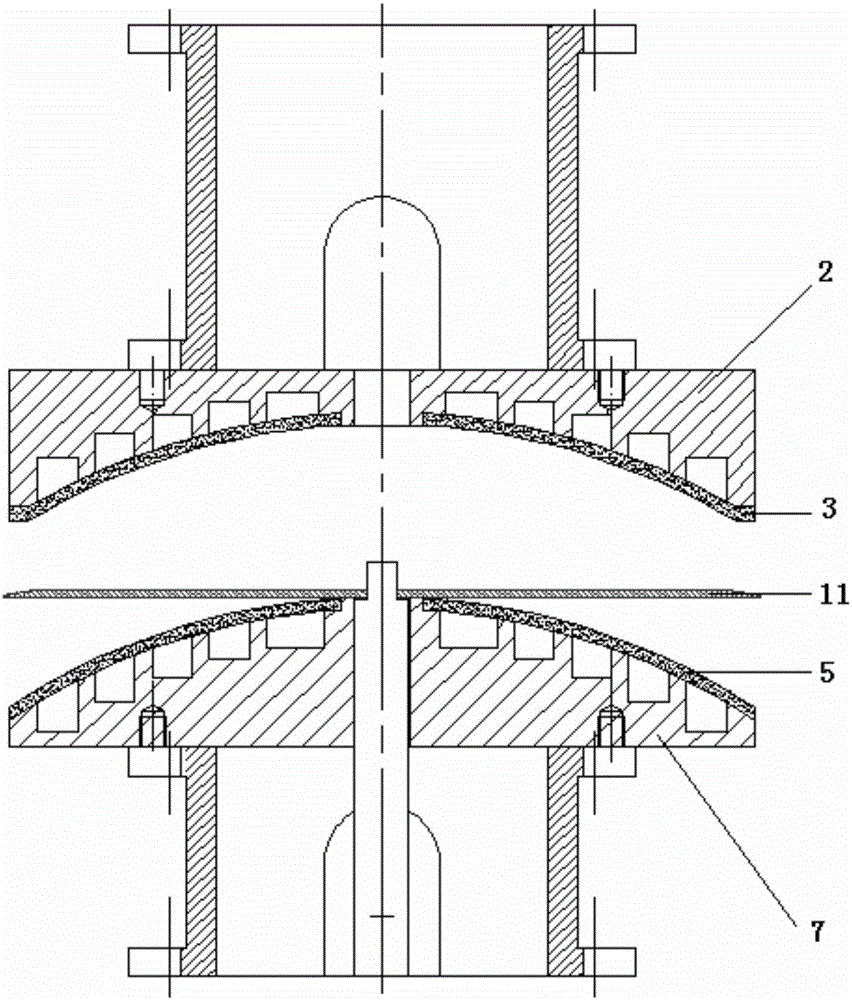

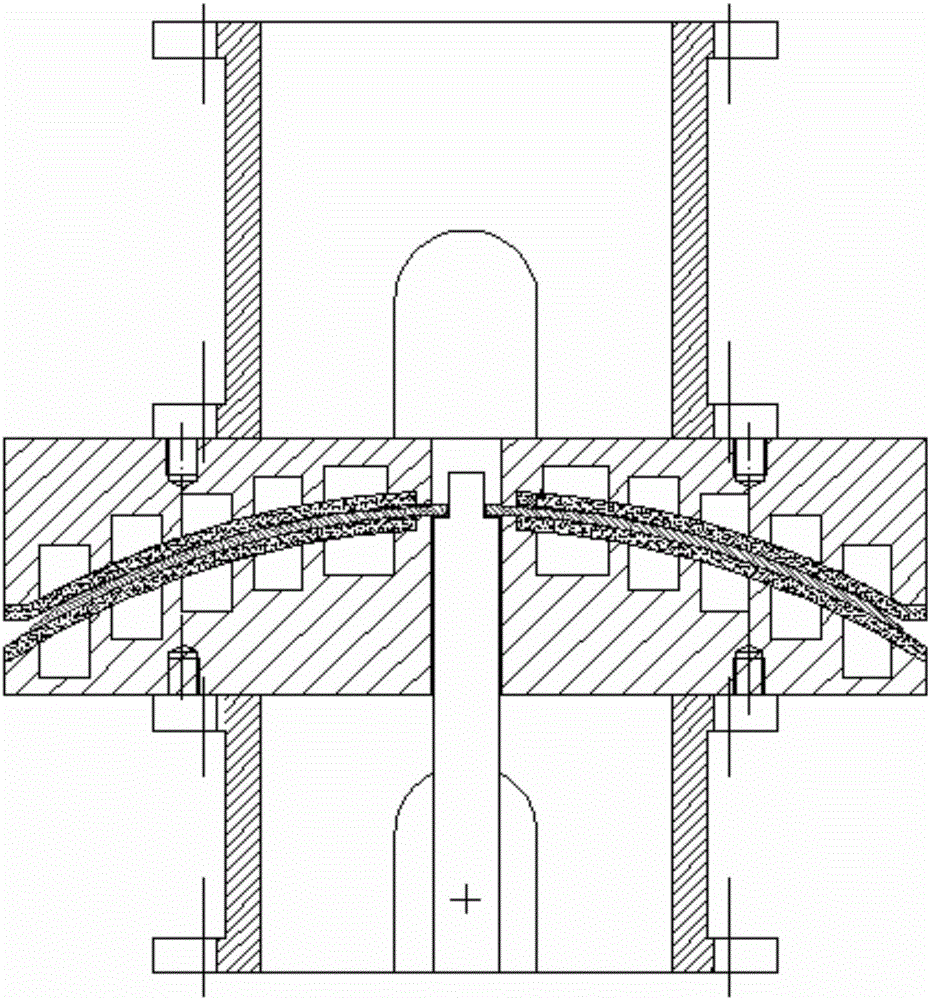

[0057] (6) Hot pressing, take out the billet from the heating furnace, put it into the mold, and immediately start the hydraulic press to press and form; the time from taking out the billet to the completion of pressing cannot exceed 25 seconds;

[0058] (7) After the pressing is completed, keep the pressure for 2 minutes, open the mold, lift the positioning rod, take out the workpiece, and complete a hot pressing production cycle.

Embodiment 2

[0063] The disc rake sheet of the present embodiment adopts 6.5mm thick manganese-boron steel plate, and its chemical composition (wt%) is as follows:

[0064]

[0065] The difference from Example 1 is that in the step (5) of the production process, the billet is heated at a temperature of 920° C. and kept for 15 minutes, and the rest of the process is the same.

[0066] The rake sheet performance that embodiment 2 produces is as follows:

[0067]

[0068] The results of the examples show that the disc harrow produced by the process of the present invention has a tensile strength of more than 1600MPa, a hardness of 48~52HRC, and an impact toughness (ak) of 20J / cm 2 Above, the performance is far superior to the 65Mn rakes widely used in China at present, and the dimensional accuracy of the rakes is high, and the circular runout is small. The production process is simplified, there is no quenching pollution, and the cost is low.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com