Amorphous/amorphous nano structured alloy

A nanostructure and alloy technology, which is applied in the field of manufacturing or forming amorphous/amorphous nanostructured alloy materials and powders, can solve the problem that amorphous nanostructured materials are not widely used in industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] More than 20 kinds of alloys were prepared by adopting the composition of the amorphous nanostructure alloy material of the present invention, and the composition of some furnace numbers is shown in Table 1.

[0011] the element

furnace number

Mo

Cr

Ni

P

B

Si

C

Fe

Remark

1

14

3

6

7

2

2

0.2

Remain

The furnace number in the table is not

with actual test furnace

same number

2

9

3

6

4

1

2

0.1

Remain

3

5

9

3

8

3

2

0.3

Remain

4

3

6

3

6

1

3

0.5

Remain

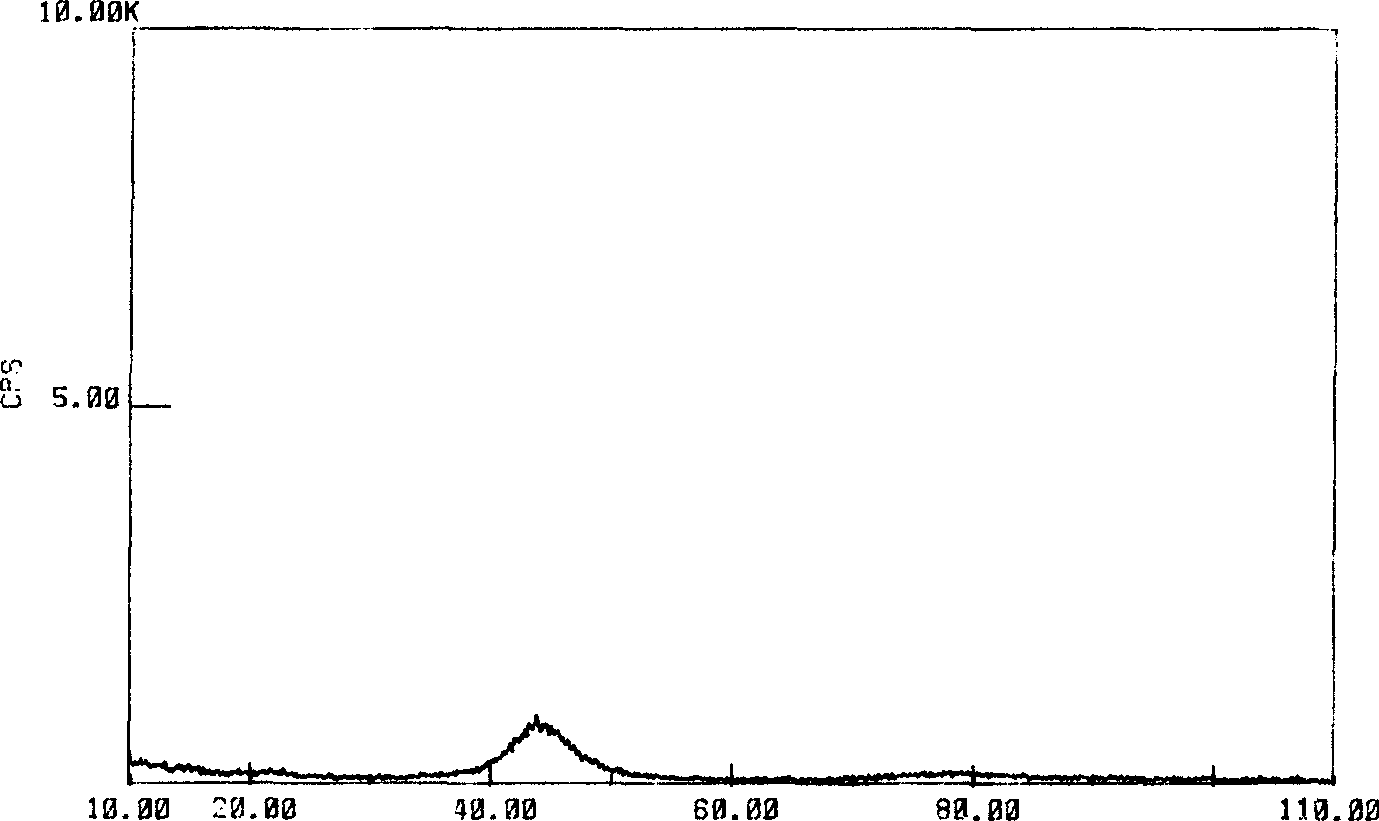

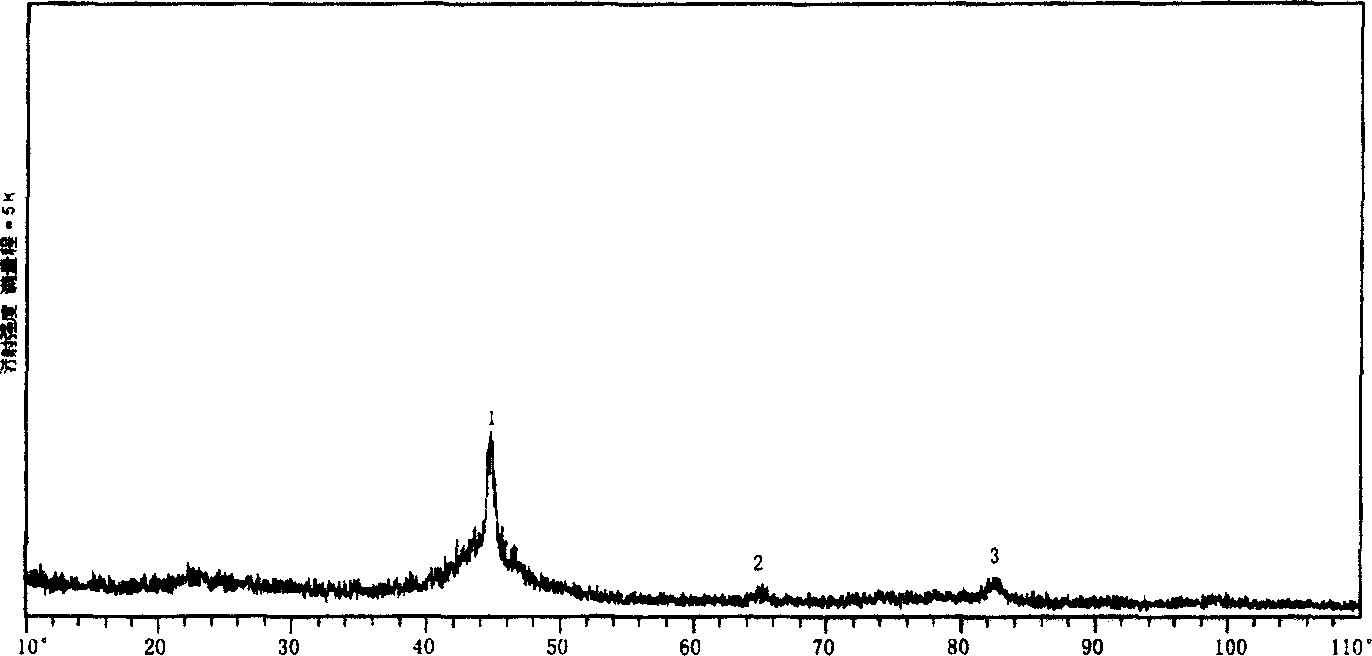

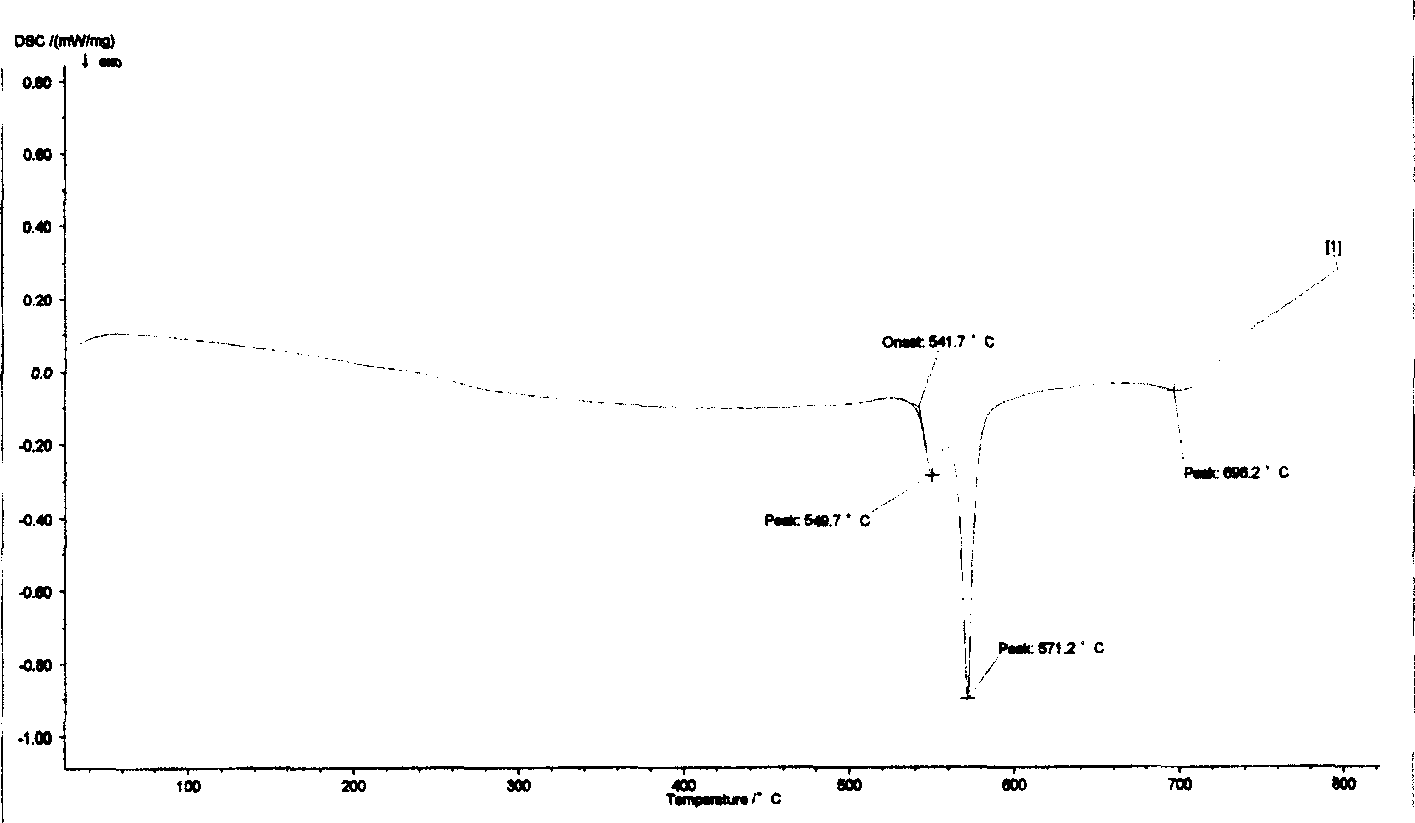

[0012] Melt the above alloy in a high-frequency induction furnace, then cool the alloy solution to make powder, and obtain amorphous alloy powder. The X-ray diffraction curve of a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com