Iron-base bulk amorphous alloy with high glass-forming ability

An amorphous alloy and glass technology, applied in the field of iron-based bulk amorphous alloys, can solve problems such as limiting the application range of alloys, and achieve the effects of high glass forming ability, large application potential and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

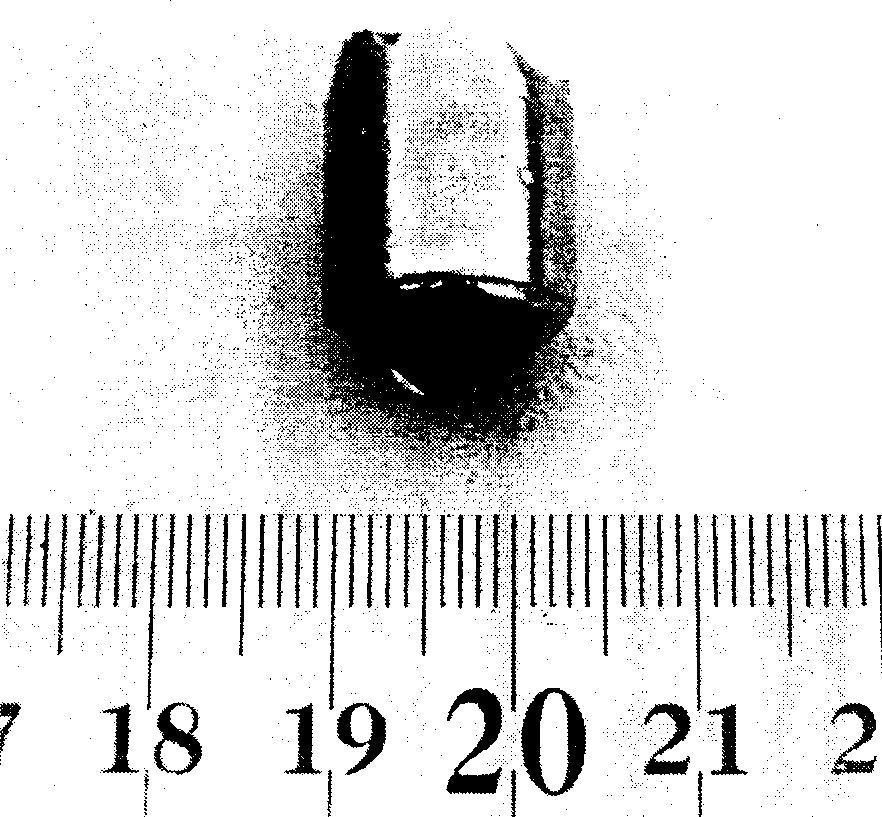

Image

Examples

specific Embodiment approach 1

[0012] Specific Embodiment 1: The iron-based bulk amorphous alloy of this embodiment is composed of Fe, Co, Cr, Mo, C, B, and Y, wherein the atomic percentage of each element is: Fe 36-41%, Co 5-10 %, Cr 15%, Mo 14%, C 15%, B 6%, Y 1-5%.

specific Embodiment approach 2

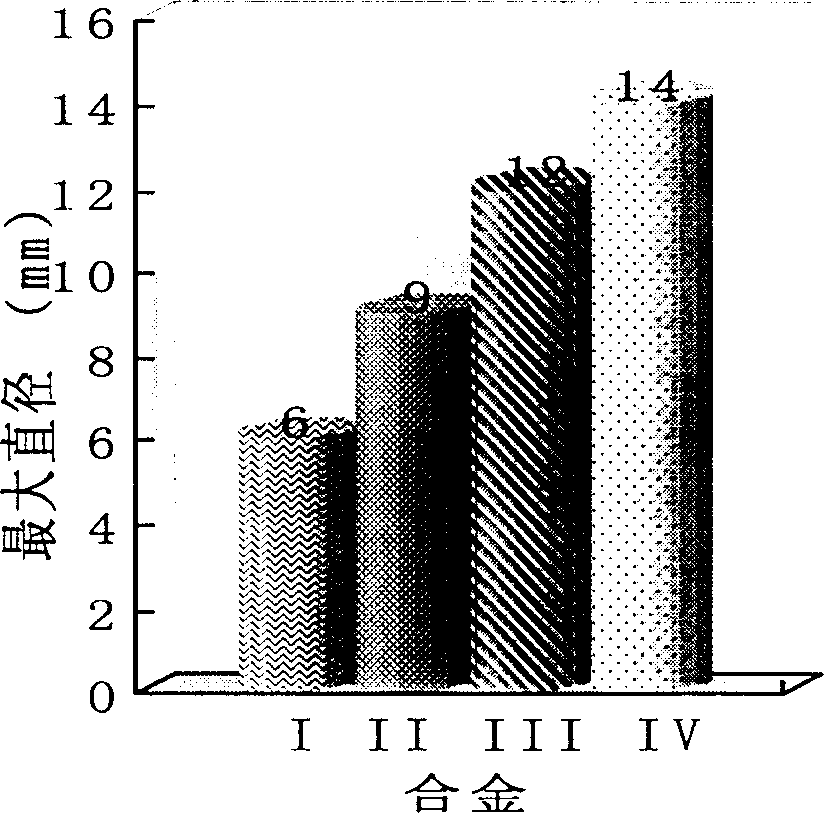

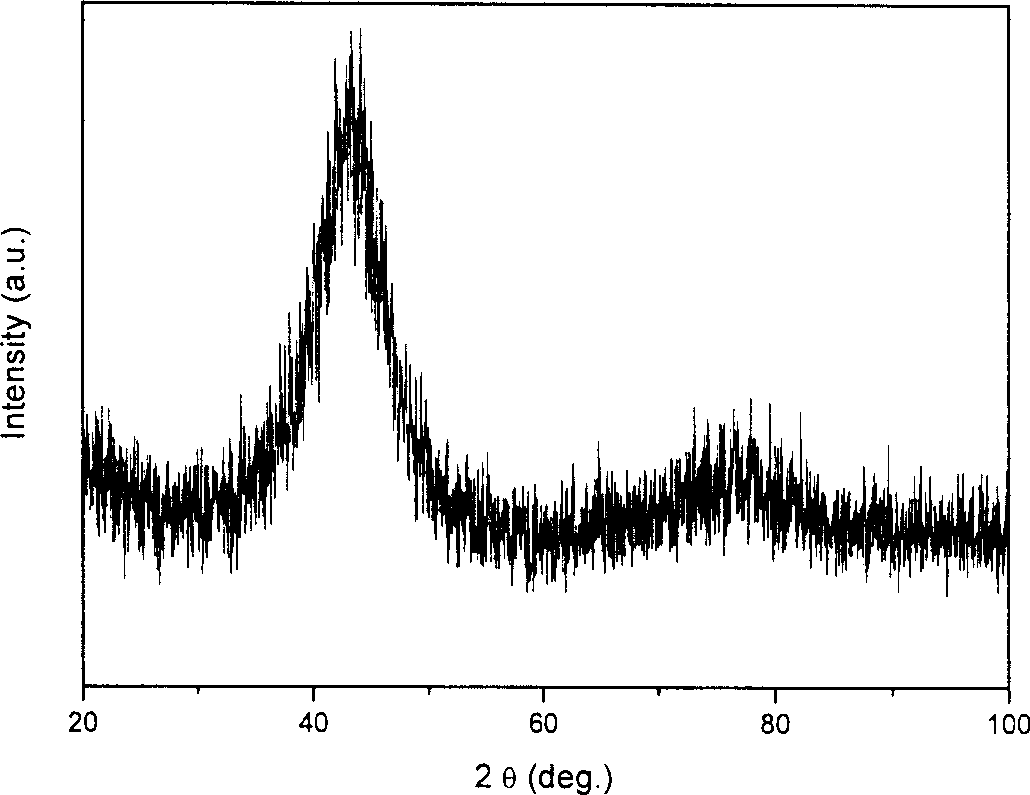

[0013] Specific implementation mode two: the iron-based bulk amorphous alloy Fe in this implementation mode 38 co 10 Cr 15 Mo 14 C 15 B 6 Y 2 Composed of Fe, Co, Cr, Mo, C, B, Y, the atomic percentage of each element is: Fe 38%, Co 10%, Cr 15%, Mo 14%, C 15%, B 6%, Y2% . Fe in this embodiment 38 co 10 Cr 15 Mo 14 C 15 B 6 Y 2 Amorphous alloys have high glass-forming ability, and can obtain bulk amorphous alloys with a critical size not less than Φ8mm under arc melting ordinary copper mold casting conditions.

specific Embodiment approach 3

[0014] Specific implementation mode three: In this implementation mode, the iron-based bulk amorphous alloy Fe 45 co 3 Cr 15 Mo 14 C 15 B 6 Y 2 Composed of Fe, Co, Cr, Mo, C, B, Y, the atomic percentage of each element is: Fe 45%, Co 3%, Cr 15%, Mo 14%, C 15%, B 6%, Y 2 %. Fe in this embodiment 45 co 3 Cr 15 Mo 14 C 15 B 6 Y 2 Amorphous alloys have high glass-forming ability, and bulk amorphous alloys with a critical size of not less than Φ9mm can be obtained under arc-melting ordinary copper mold casting conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical dimension | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com