Low-alloy super-strength steel and heat treatment technique for the same

An ultra-high-strength, low-alloy technology, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problems that the tensile strength cannot reach 2000MPa and the performance cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

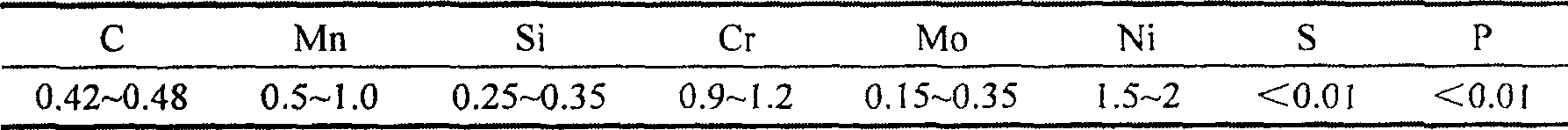

Embodiment 1

[0017] The material is purified and smelted in a vacuum induction furnace. The material composition is C 0.35, Mn 2.0, Si 0.4, Cr 2.0, Mo 0.4, Al 2.0, S 0.005, P 0.008, and Fe balance. After the ingot is forged, heat treatment is carried out, adopting the process of quenching + low temperature tempering, and then stabilizing aging treatment. The quenching temperature is 850°C, the quenching medium is water, the tempering temperature is 150°C, the tempering time is 1.5h, and the aging temperature is 100°C. , aging time 5h. Tensile properties after heat treatment σ b =2018MPa, σ s =1780MPa, δ(%)=10.2, φ(%)=48.3, impact energy α k = 30J. While having high strength, the material does not break until it is bent to an angle of nearly 120 degrees (such as figure 1 , 2 shown), indicating that the material also has good plasticity. The ingot is forged into bars of various specifications. The forging process shows that the material has good forgeability and high forging quality ca...

Embodiment 2

[0019] The material is purified and smelted in a vacuum induction furnace. The material composition is C 0.40, Mn 1.5, Si 0.27, Cr 1.5, Mo 0.33, Al 1.8, S 0.003, P 0.0021, and Fe balance. The heat treatment of the forged sample adopts the process of quenching + low temperature tempering, and then stabilizing aging treatment. The quenching temperature is 880°C, the quenching medium is water, the tempering temperature is 200°C, the tempering time is 2h, and the aging temperature is 120°C. The aging time is 5h. Tensile properties after heat treatment σ b =2120.3MPa, σ s =1856MPa, δ(%)=10.8, φ(%)=47.4, impact energy α k =22J. . The ingot is forged into bars of various specifications. The forging process shows that the material has good forgeability and high forging quality can be obtained, which guarantees the performance of the forged material. The forged material is annealed at 600°C, and the hardness after annealing is HRC36-37, which can ensure good machinability.

Embodiment 3

[0021] The material is purified and smelted in a vacuum induction furnace. The material composition is C 0.45, Mn 1.2, Si 0.3, Cr 0.79, Mo 0.25, Al 1.5, S 0.0031, P 0.0022, and Fe balance. Heat treatment of the forged sample, using quenching + low temperature tempering, and then stabilization aging treatment process, quenching temperature 900°C, quenching medium is oil, tempering temperature 250°C, tempering time 1.5h, aging temperature 150°C , aging time 5h. Tensile properties after heat treatment σ b =2017MPa, σ s =1774MPa, δ(%)=9.8, φ(%)=42.4, impact energy α k =24J. . The ingot is forged into bars of various specifications. The forging process shows that the material has good forgeability and high forging quality can be obtained, which guarantees the performance of the forged material. The forged material is annealed at 600°C, and the hardness after annealing is HRC36-37, which can ensure good machinability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com