Flexible water-cooling metal electrode for monocrystalline furnace

A metal electrode, single crystal furnace technology, applied in ohmic resistance electrodes, crystal growth, ohmic resistance heating parts and other directions, can solve the problem of difficulty in adjusting the position of the heater, reduce the difficulty, reduce manufacturing costs, reduce processing and The effect of assembly accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

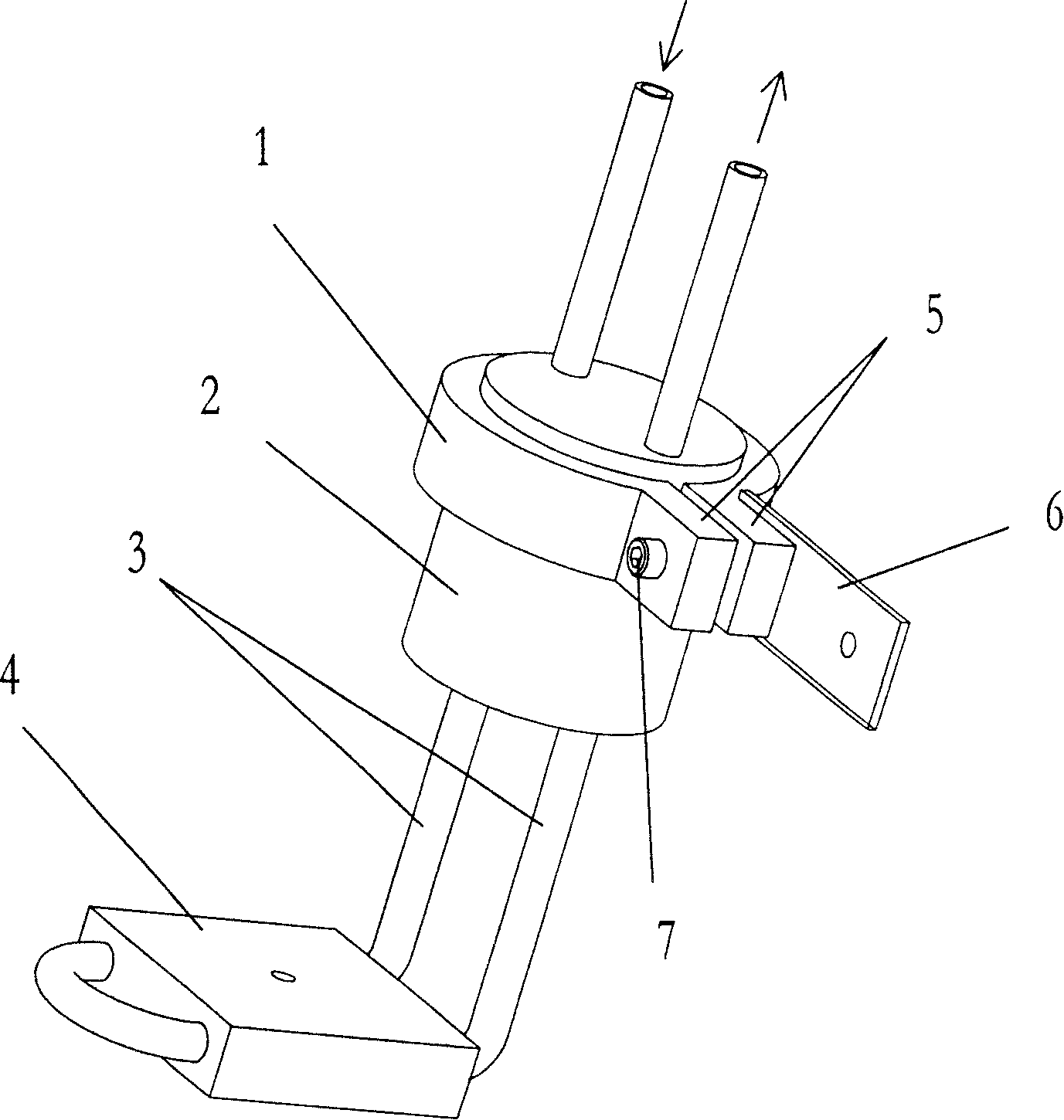

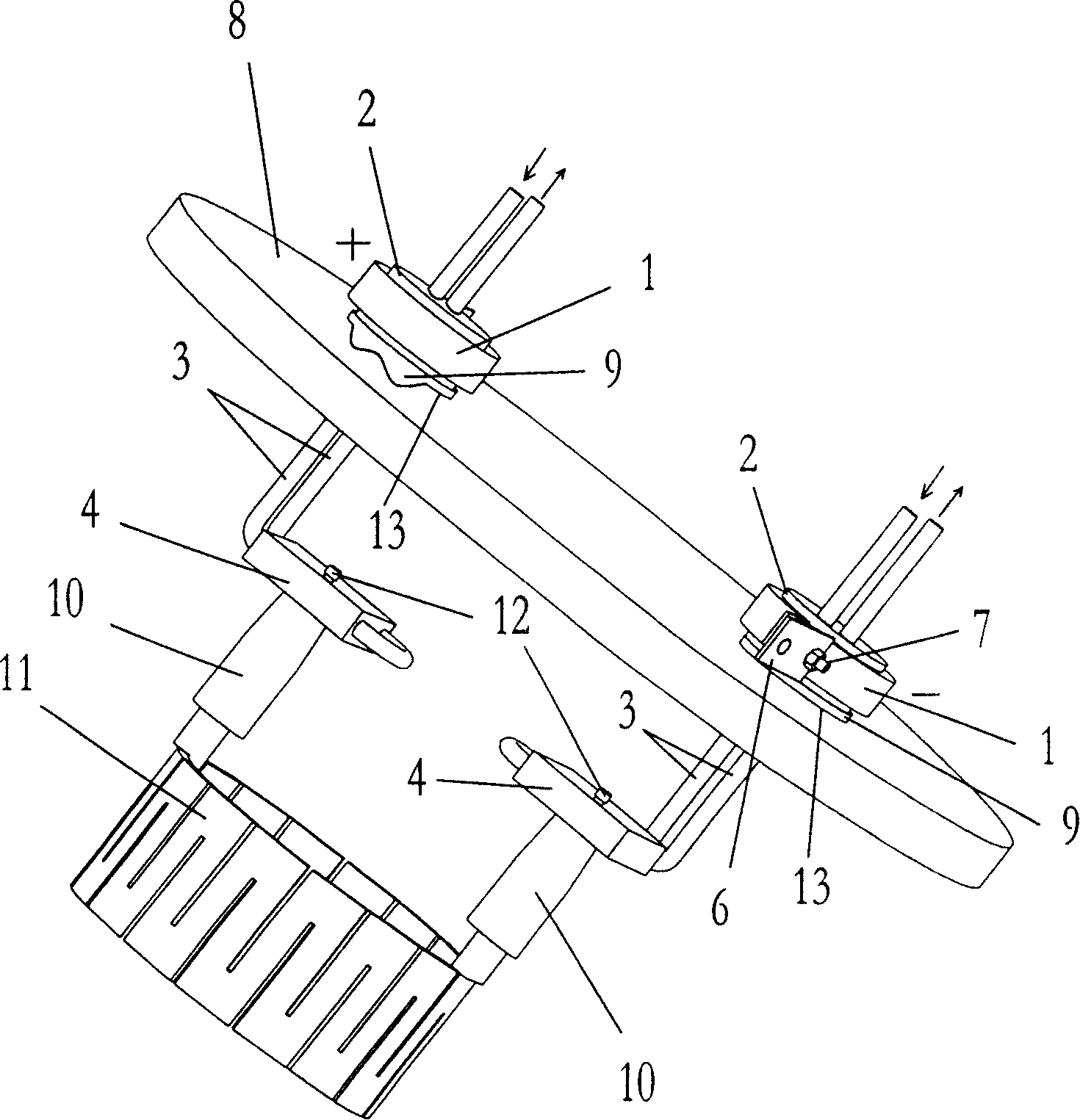

[0014] see figure 1 Shown: a flexible water-cooled metal electrode for a single crystal furnace, which includes a water-cooled copper tube electrode 3, a stainless steel electrode clamp 4, and a copper sealing sleeve 2. The water-cooled copper tube electrode 3 is a complete water-cooled For the copper tube, a complete water-cooled copper tube is used to pass through the stainless steel electrode clamp 4, and the stainless steel electrode clamp 4 and the water-cooled copper tube are well welded with alloy solder to ensure smooth transmission of current and heat. Then the water-cooled copper pipe passes through the copper sealing sleeve 2 and is well welded; the upper half of the copper sealing sleeve 2 is sleeved with a copper connection ferrule 1, and the copper connection ferrule is in the shape of an opening, and is bent at the opening of the copper connection ferrule. Two splints 5 are folded and protruded, and fastening bolts 7 for tightly connecting the copper ferrule 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com