Bumper installation structure assembly of motorbike back suspension

A technology for installing structures and shock absorbers, which can be applied to axle suspension devices, bicycle accessories, transportation and packaging, etc. It can solve problems such as adverse effects on service life, eccentric wear of shock absorbers, and prone to abnormal noise, so as to ensure safe operation Sex, avoid axial movement, eliminate the effect of assembly clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

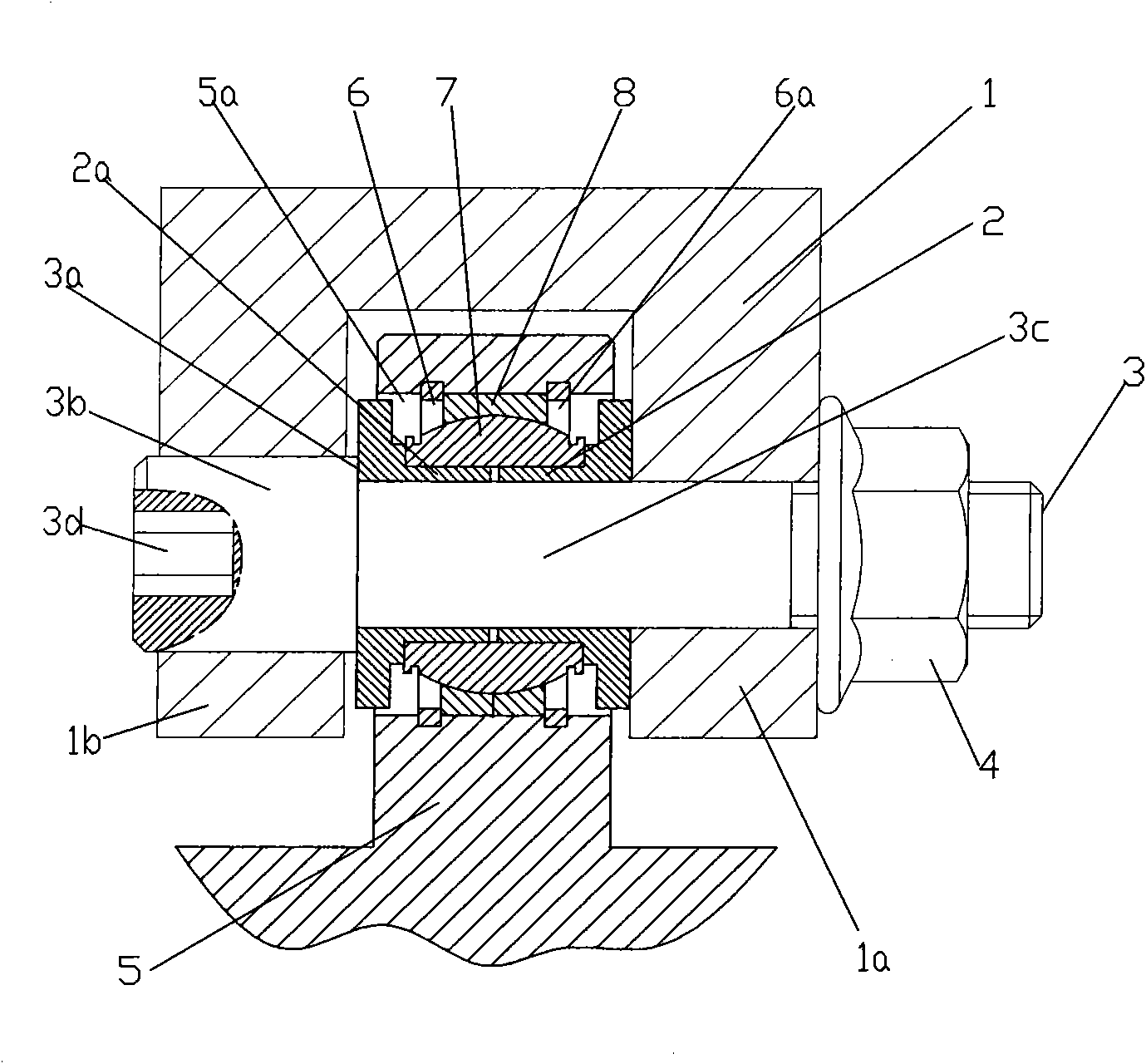

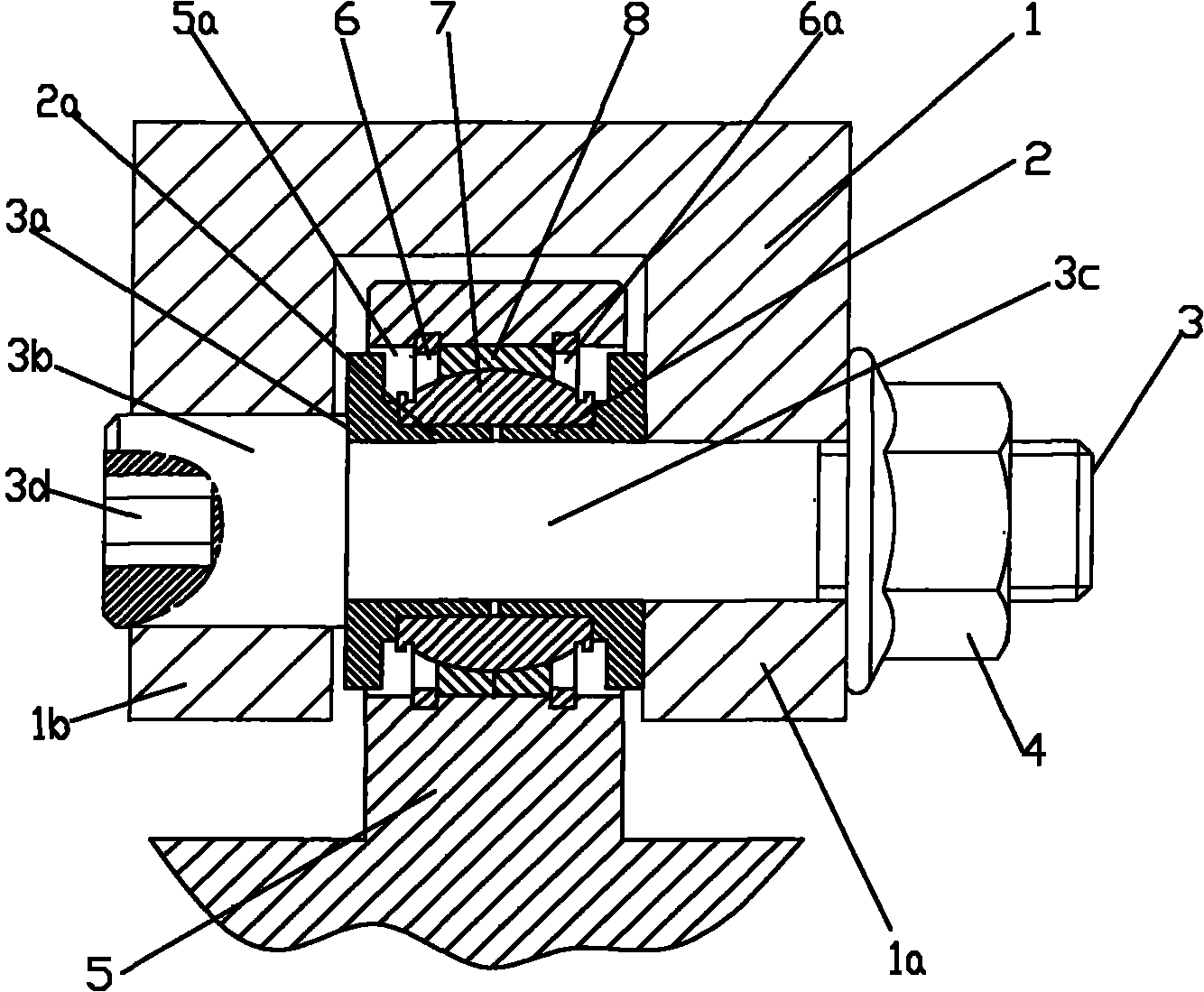

[0016] Accompanying drawing is the structure schematic diagram of the present invention, as shown in the figure: the motorcycle rear suspension shock absorber installation structure assembly of the present embodiment, comprises shock absorber upper joint 5, hinge pin shaft 3 and fixedly connected to vehicle frame U-shaped structure connecting frame 1, the upper joint 5 of the shock absorber is embedded in the two lugs of the U-shaped structure connecting frame 1 (the lugs 1a and 1b in the figure) and are hinged to the U-shaped structure connecting frame through the hinge pin 3 1. The hinge pin 3 passes through the hinge hole 5a of the upper joint 5 of the shock absorber through the shock-absorbing bush of the outer casing, and the hinge pin 3 is provided with a shoulder 3a close to an axial end surface of the shock-absorbing bush, The hinge pin shaft 3 passes through the other axial end surface of the shock absorbing bushing and the lug 1a on the corresponding side of the U-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com