Spherical double suspension wide hook rapid pipe joint

A spherical and pipeline technology, applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing elements, etc., can solve problems such as concentrated leakage, and achieve ingenious and reasonable conception, convenient production and use, and improved sensitivity and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

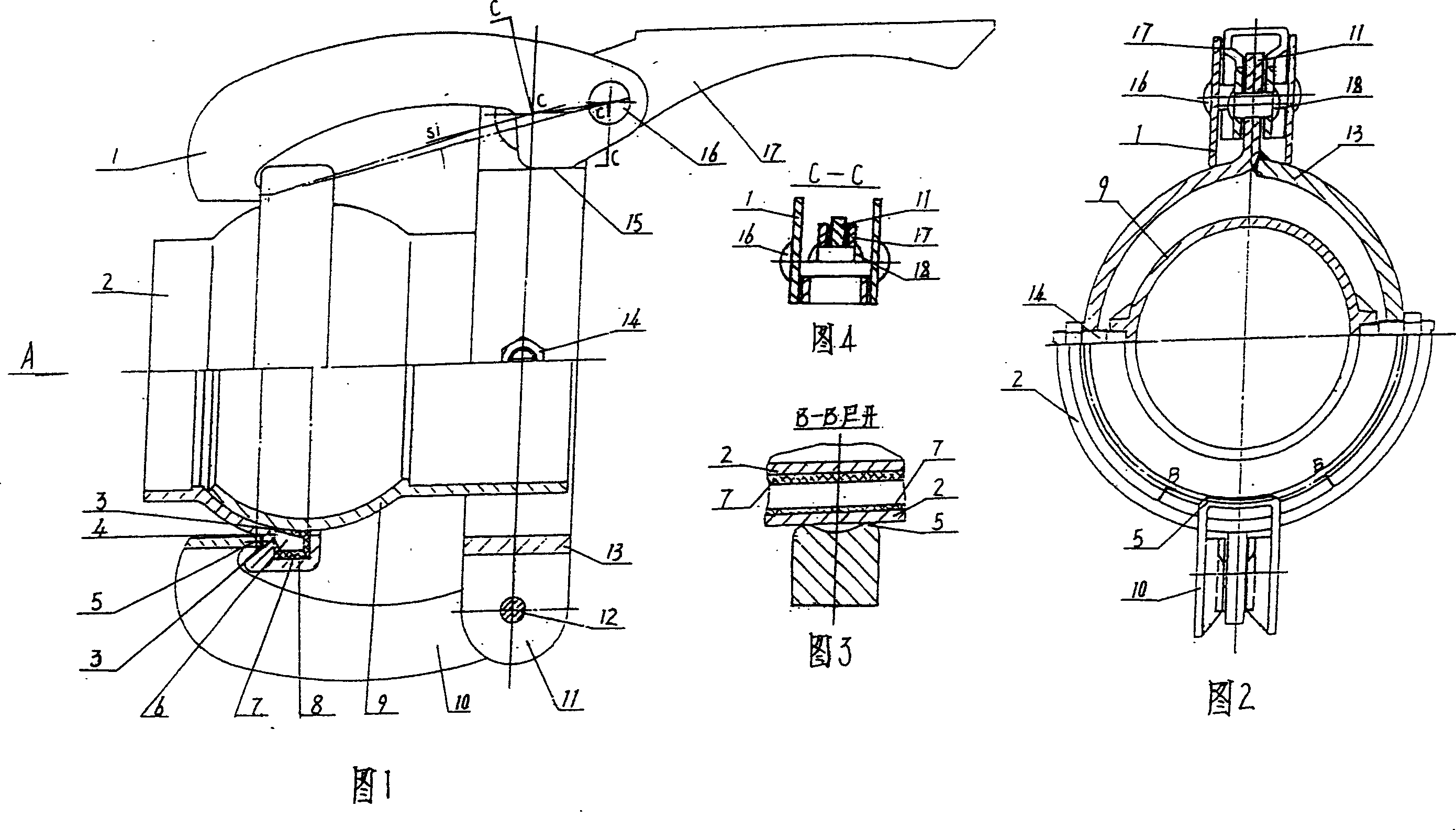

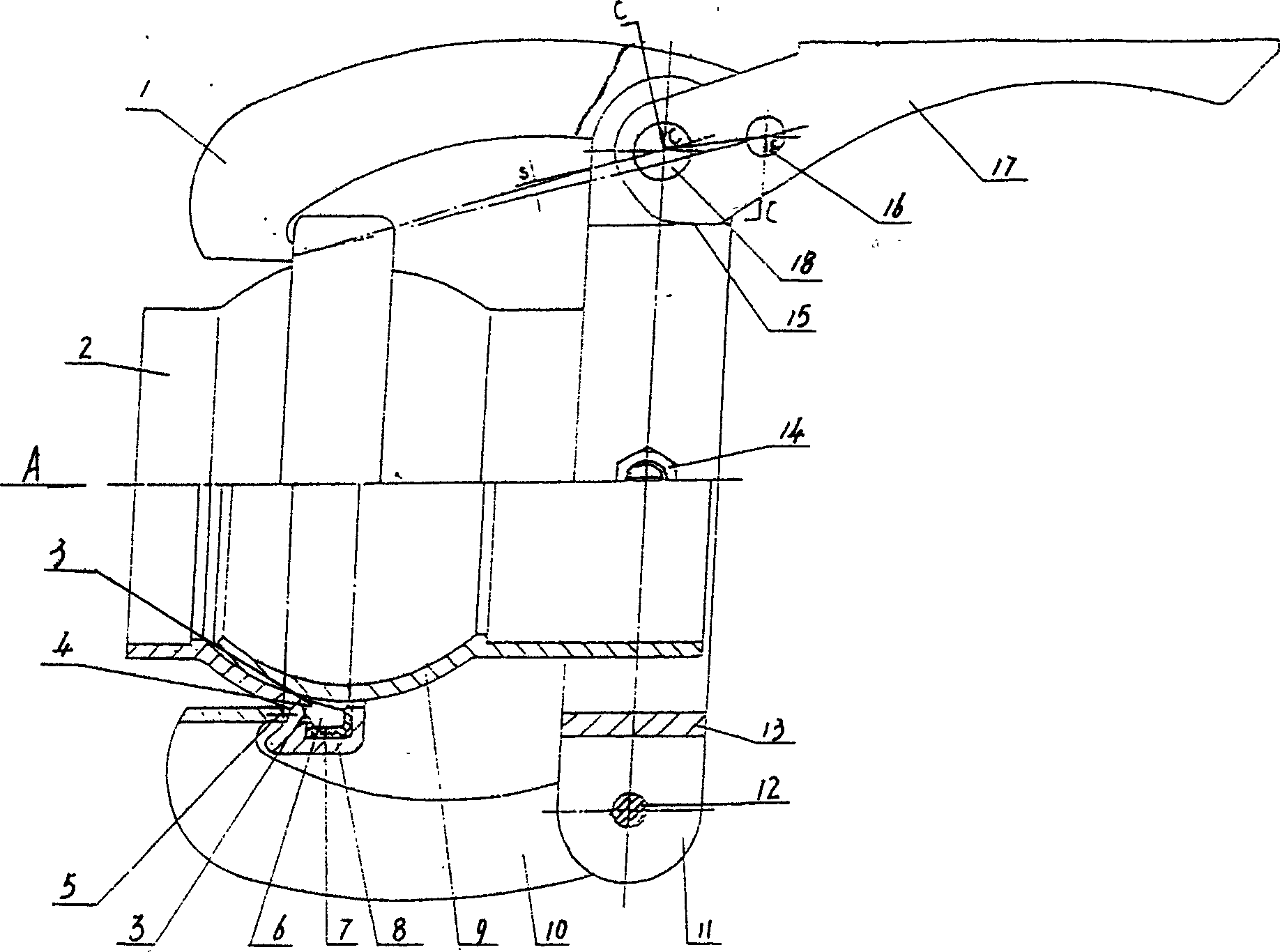

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

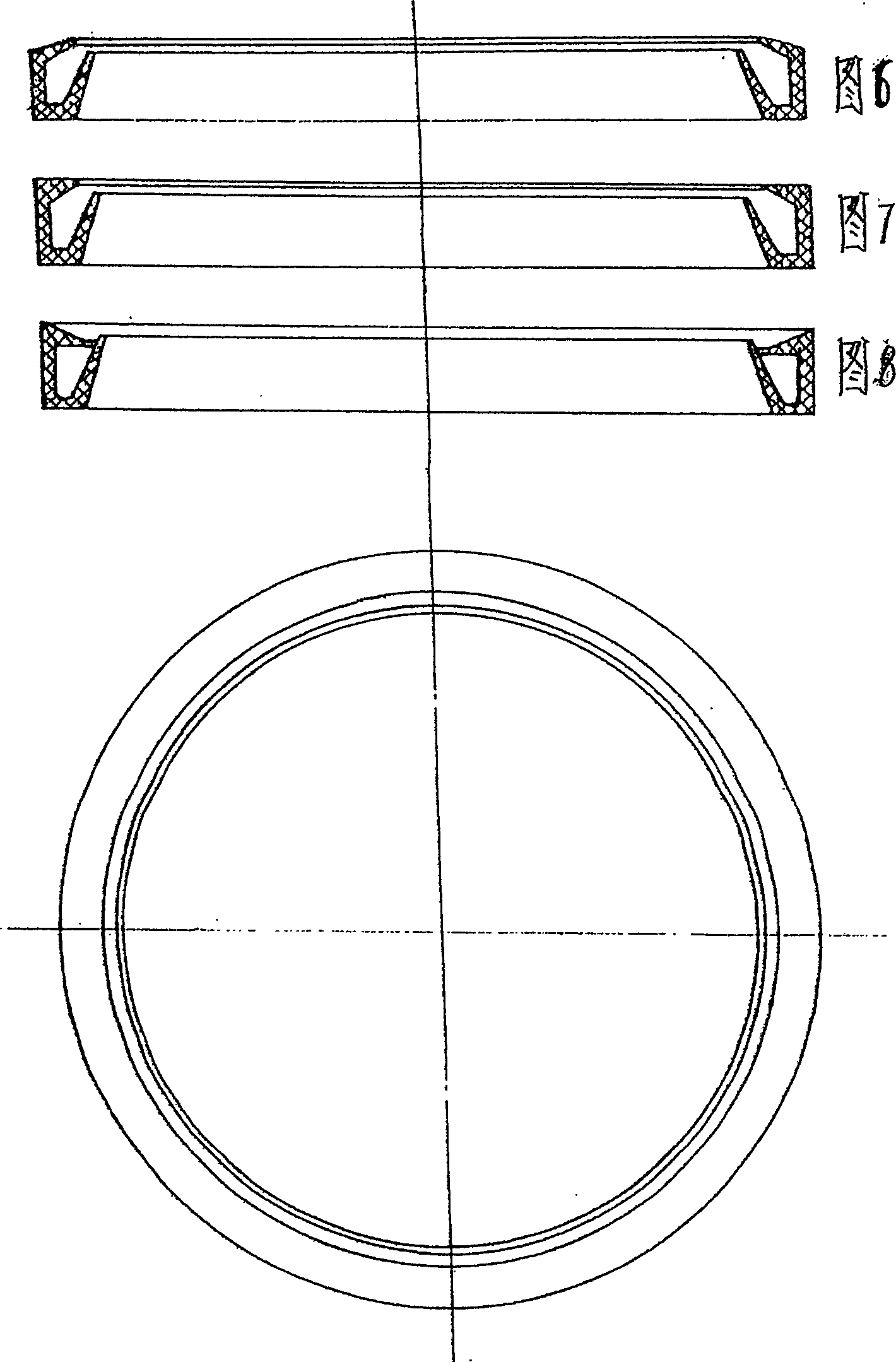

[0019] The meanings represented by the numbers in the accompanying drawings: 1 long hook 2 bowl tube 3 sealing tongue 4 annular opening 5 hook head 6 semi-closed shell cavity 7 ring body 8 sealing groove 9 ball tube 10 short hook 11 bracket 12 hook hinge shaft 13 Hanging ring 14 ring hinge shaft 15 limit pair 16 long hook hinge shaft 17 lock handle 18 handle hinge shaft s-lock distance

[0020] The first embodiment is shown in Figures 1-4, 6 and 9. It is a spherical double-hung wide-hook pipe quick connector used for the connection of a 76 mm sprinkler irrigation pipeline. Within 2-3 seconds, the full assembly or disassembly operation required for a joint connection is fully completed.

[0021] The joint structure of this example is basically consistent with the existing spherical double-hook pipe quick joint, that is, the two parts of the joint are respectively the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com